We sat down with Mecagent’s CEO Owein Dourneau to discuss their journey, what they’ve done so far and what they’re looking to achieve.

Offloading Repetitive Tasks

What inspired you to start Mecagent?

We started in February 2025 after realising that generative AI wasn’t being widely adopted in the mechanical engineering space. My cofounders, as mechanical engineers, saw how AI was revolutionising software development with tools like Cursor and felt this space is missing out.

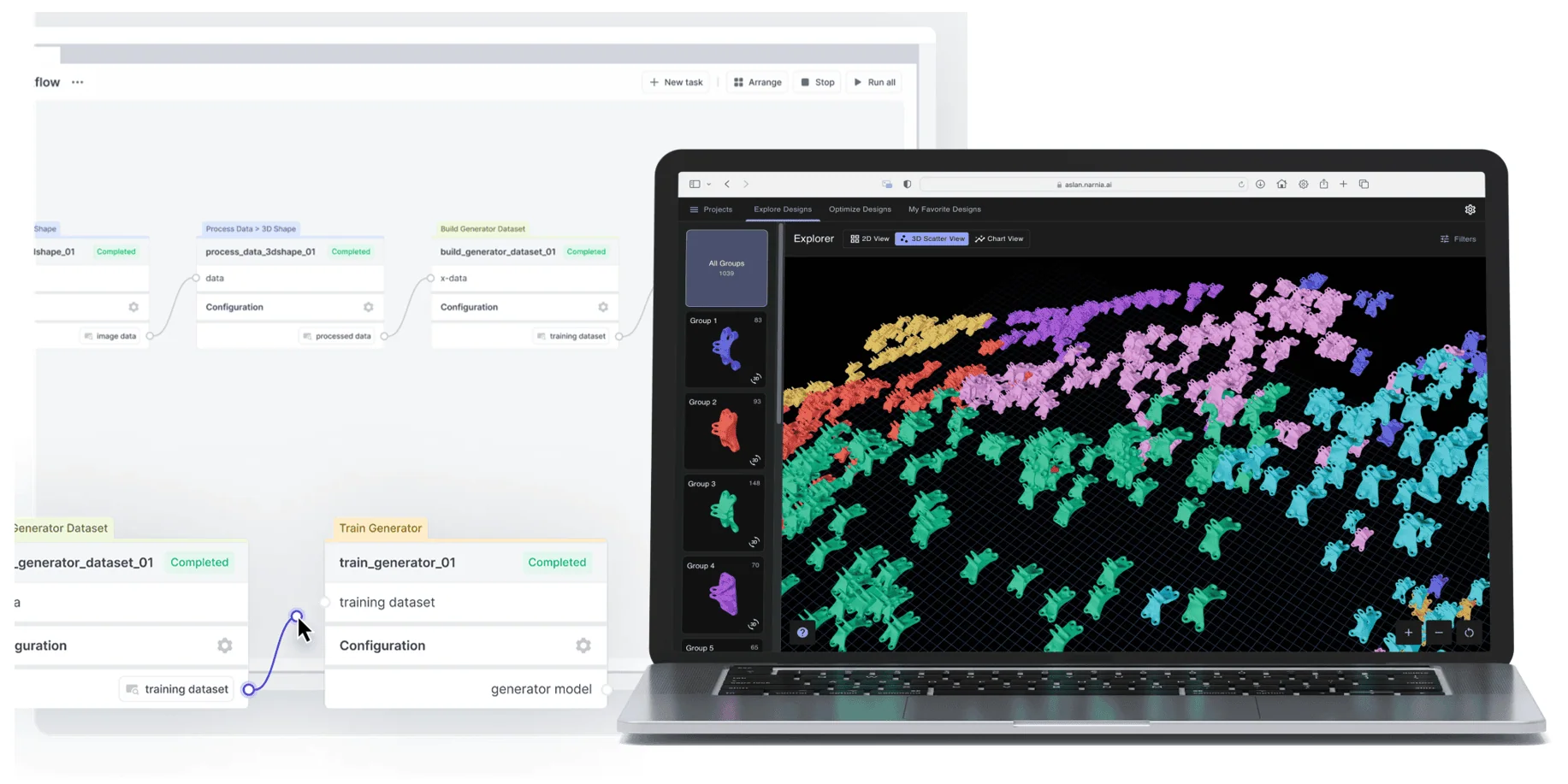

Initially, we explored flashier ideas like AI-generated parts, but the technology isn’t ready for reliable use. While training those models, we realised mechanical engineers needed something more practical and trustworthy.

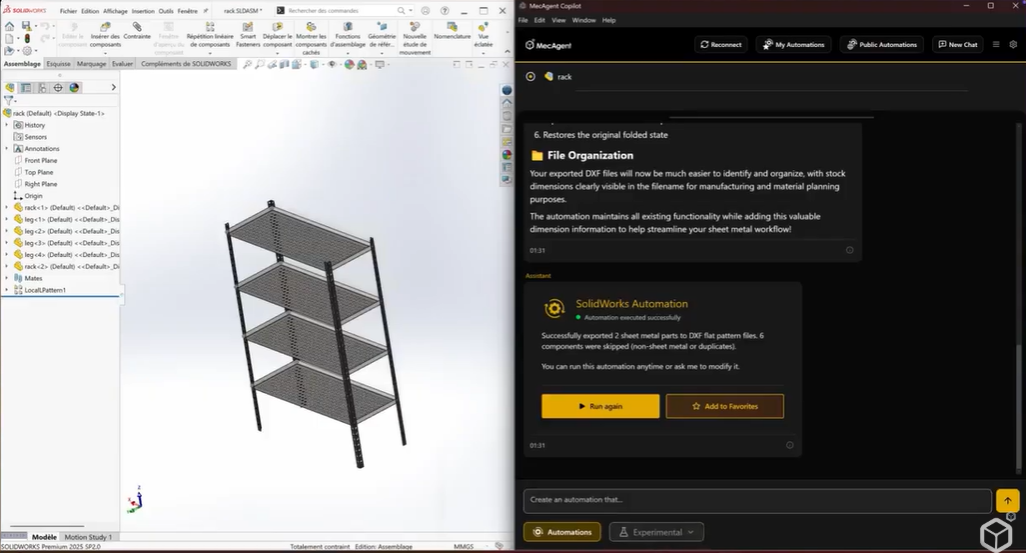

We talked to engineers and identified real pain points. Ultimately, we decided to build an AI copilot that integrates directly with CAD software, essentially creating a chat interface within the CAD environment to help engineers complete tasks more efficiently.

What specific challenges are you addressing?

How do you move faster in the design phase? How do you offload repetitive tasks that don’t require human expertise? These are the fundamental questions.

Mechanical engineers spend enormous amounts of time on simple modifications like changing fillet radii, adjusting hole sizes, and similar tasks. These are just a few clicks each, but when repeated hundreds of times, they consume significant resources. Our goal is to let engineers focus on actual engineering.

What was your approach to getting engineers to use your product?

In the beginning, we tried to tackle too many things at once. We’ve since focused primarily on CAD automation through macros.

Most engineers don’t utilise macros because they require knowledge of VBA, C#, or whatever programming language their CAD software uses. But macros are incredibly powerful – they let you automate modifications, exports, and other repetitive but time-consuming tasks by making use of the same commands available in the UI.

Macro creation became our core feature and entry point to a longer journey of building AI that truly helps mechanical engineers.

How does macro creation work?

At its core, you’re creating a script that calls functions within your CAD software. You first think through what functions you need and how you’d perform the task manually. Then you use the chat interface to automate it. The tool guides you through the process, making macro creation accessible even without programming expertise.

Experimental Features

What other features does Mecagent offer?

Beyond macro automation, we have several experimental features.

Online Part Search. We’re partnering with online CAD part libraries. The automation can interact with technical sheets to help find standard components, e.g. bearings, that are selected based on your existing model features.

Knowledge Specialist. We’ve integrated extensive engineering documentation and general knowledge PDFs. If you ask how to calculate pressure loss in piping, it returns an answer with sources so you can verify accuracy. We’re careful about intellectual property, focusing on common knowledge sources that don’t raise licensing concerns.

Users will be able to upload their own documentation and standards for internal use only.

Instant Pricing. This is an early prototype we’re developing with third-party providers.

Is part generation still in the works?

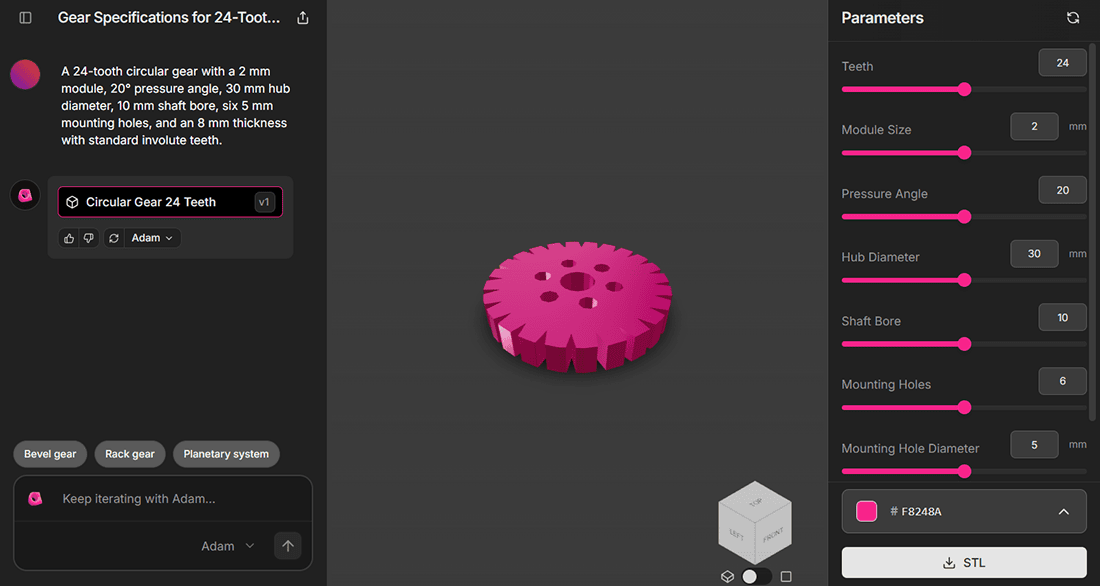

We’re testing autonomous part creation, but we’re not there yet. Currently, it can only create simple parts, so it’s not useful for real engineering work. You have to start somewhere, though.

Are these generated parts parametric?

Yes, which is exactly why we’re limited to simple parts right now. Parametric models require all the basic operations in the CAD kernel – from sketching to feature generation. You need to maintain parametric properties during the part generation process. Some people are even talking about creating entirely new CAD systems to enable this type of functionality, but that’s a very long journey.

AI can generate impressive STL meshes suitable for 3D printing, but they’re useless for mechanical engineers unless they’re detail-perfect, which doesn’t happen yet.

I like to compare it to PNG versus SVG files. A PNG is fixed – it is what it is. But an SVG uses vectors and mathematical equations, so you can edit it. That’s what engineers need.

Which CAD platforms does Mecagent integrate with?

Currently, we only support SolidWorks. We are also looking to add Inventor, Catia V5 and Creo in the near future.

The Benefits Right Now

What makes engineers willing to pay for Mecagent?

As you mentioned, you’ve used macros and understand their value, but haven’t created them yourself. That’s typical. Currently, it’s easiest for us to reach people who already work with macros. They immediately see the value because we make automation much easier and faster. The rest of the mechanical engineers have to learn that macro even exists.

Part search gets significant use, but it’s more of a nice-to-have. If we’re talking about one killer feature, it’s macro automation.

We’re still in beta, so there are errors and issues. The engineering community is quite skeptical about AI, and a single hiccup can mean they write us off. But engineers who work with macros are more motivated to explore potential use cases. Once they see a task that took 12 hours now taking 3 minutes, they’re sold.

Any surprising user stories?

One customer changed their brand name and had 70,000 drawings that needed updating. It’s such a simple change, but it took them 2 months manually. They wanted to automate it but didn’t know how. They tried ChatGPT, but it hallucinated instructions because these requirements are very specific to CAD software. With Mecagent, the script ran for a few hours and completed the entire job.

We’ve had several instances where people automated exporting files in different formats, saving 8-12 hours per week on that alone.

Some clients have created custom dashboards with Mecagent that check assemblies for compliance – verifying sheet thicknesses and other properties automatically.

One of our users needed to change hole sizes on a convex surface, with dimensions relative to the radius of the inside and outside surfaces. Doing this manually across a large quantity of parts would have taken weeks. After a few iterations with Mecagent, he had an automated script to handle the entire task. Now he uses our tool daily.

Mecagent is in beta. When is the full launch expected?

Our immediate goal is securing partner status with CAD software companies. We’re in discussions with them to ensure we’re using their software correctly.

Such partnerships will give legitimacy for all parties involved. Software providers will do their due diligence to make sure we’re using their assets properly. And users can rest assured that adding a layer of Mecagent will not mess anything up. Also, we’re working through bugs but that will remain an ongoing process for likely some time.

Our website currently offers a freemium version that anyone can try. We’re using user feedback to iterate quickly.

All in all, the public release will come once we have official partnerships and have nailed our core value proposition. Right now, that appears to be macro automation. So hopefully soon.

Moving from GPT-2 to GPT-4

What are engineers’ biggest fears about your product and AI in general?

The main concern is company IP protection. Many companies avoid ChatGPT for this reason. We’re following GDPR to ensure secure data flows. We don’t use or retrieve any of our customers’ CAD models, all data is processed on the fly. We only store the chat history and automation scripts on AWS. Without proper IP protection, we couldn’t serve large companies.

The second fear is job replacement. I’m a software developer, and many experts in my field acknowledge that AI already produces most of the code. You just need a human expert managing the process, but manpower needs have diminished significantly.

In mechanical engineering, we’re very far from that scenario. We’re focused on giving engineers more time to apply their core skills instead of wasting hours on repetitive tasks. It’s hard to imagine a future where bridges and critical structures are built by AI without human involvement. Software bugs are fixable, structural failures in physical infrastructure come with serious consequences.

Where on the scale of “total hype” to “you can’t miss this” is AI in engineering currently?

Generative design using AI has been a part of CAD packages for a while now. So leaving that aside, the hype around AI is massive, both inside and especially outside the industry.

I think mechanical engineering is at the level of GPT-2, while many of us are acting like we’re at GPT-4. That’s partially marketing noise. We’ve shown generated scooters and F1 cars, and sometimes that backfires when people try the product expecting those capabilities.

Even as an AI maximalist, I have to admit we’re quite far from that point. But GPT-2 was still useful for many people despite its limitations. AI in mechanical engineering is at a similar stage.

Over the long run, there’s enormous opportunity.

What would accelerate progress in this space?

I love open source. It lets everyone make the best use of available data. If there were comprehensive model databases accessible to everyone, we could learn much faster as an industry.

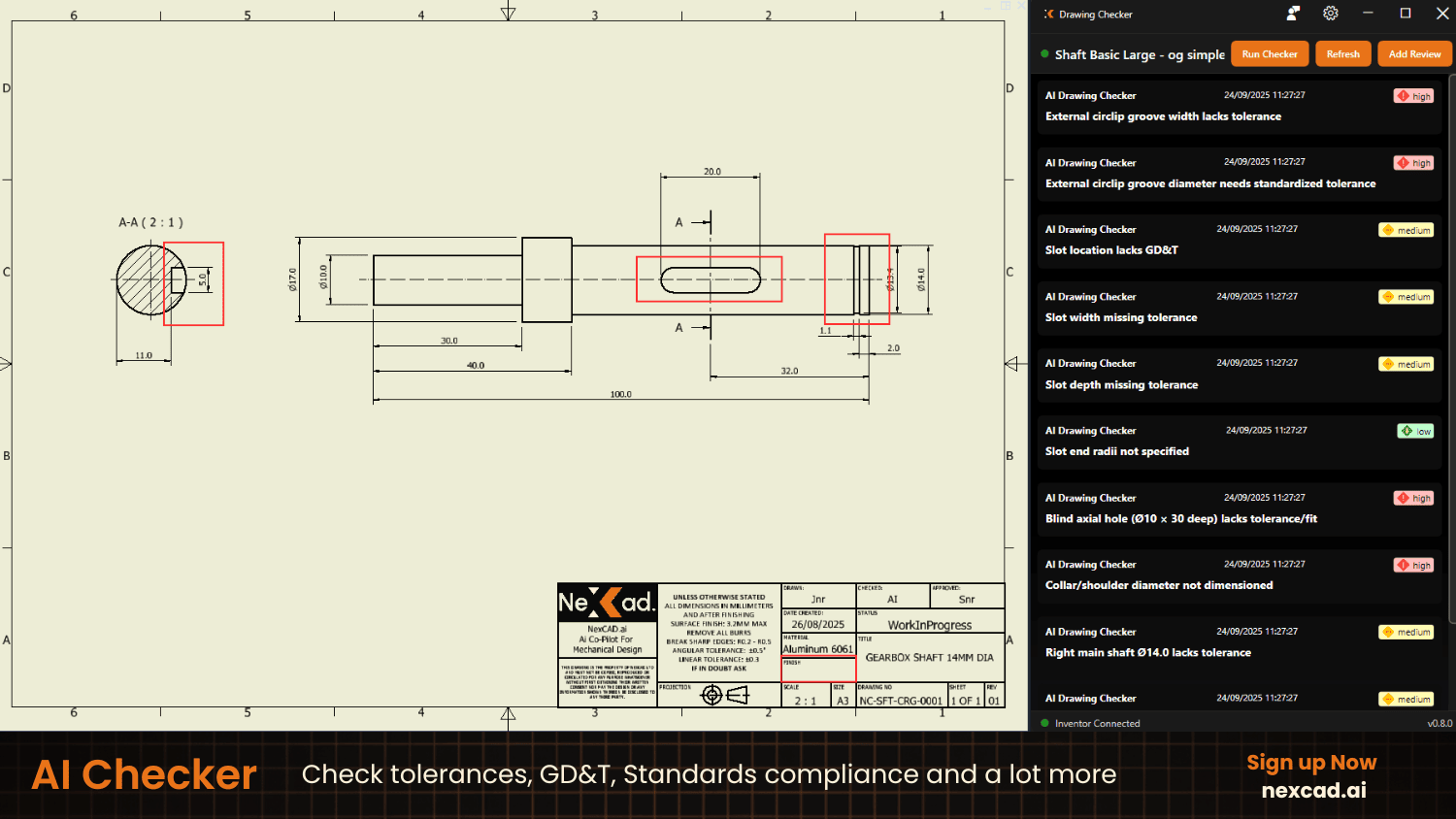

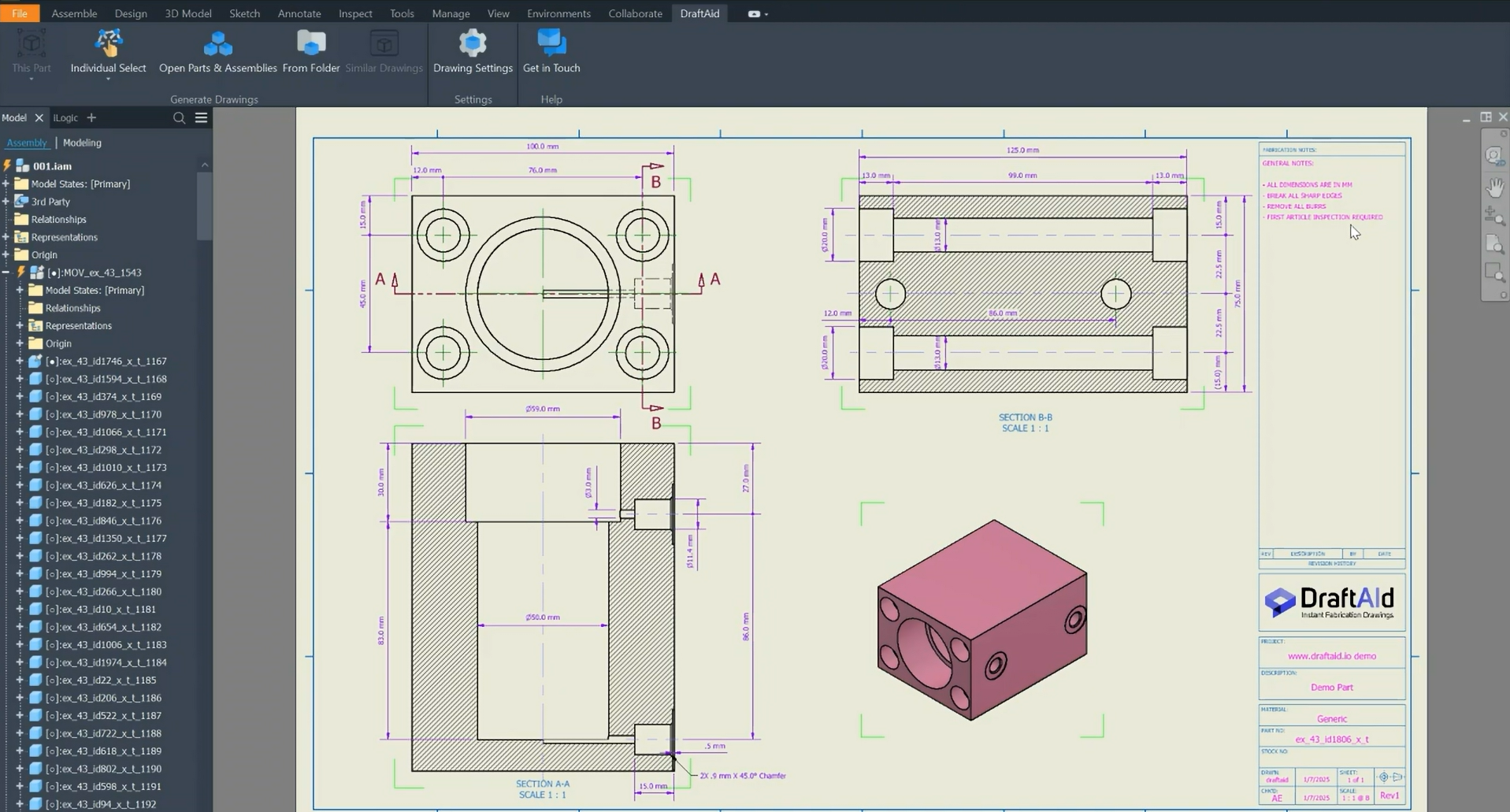

Any other AI tools you’d recommend for engineers?

Draftaid is solving a tangible problem by automating drawing creation.

And there’s a stealth startup using AI for FEA simulations. They’re doing impressive work, dramatically reducing simulation time while providing near-deterministic results.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)