High impact polystyrene (HIPS)

Colors:

- White

Description:

HIPS is a high-impact polystyrene with excellent processability and balanced mechanical properties, designed for general-purpose injection moulding. With a moderate flexural modulus and good impact resistance, it is ideal for producing rigid parts that require ease of moulding and dimensional consistency. The material’s stable flow behavior and good surface finish make it particularly suited for aesthetic or thin-walled parts in appliances and electronic housings, where visual quality and cost-efficiency are key.

Processes:

Special properties

- Impact resistance

| Property | Value, metric |

|---|---|

| Density | 1.04 g/cm³ |

| Elongation at Break | 70% |

| Hardness | 96 (R-Scale) |

| Ultimate Tensile Strength | 23.5 MPa |

-

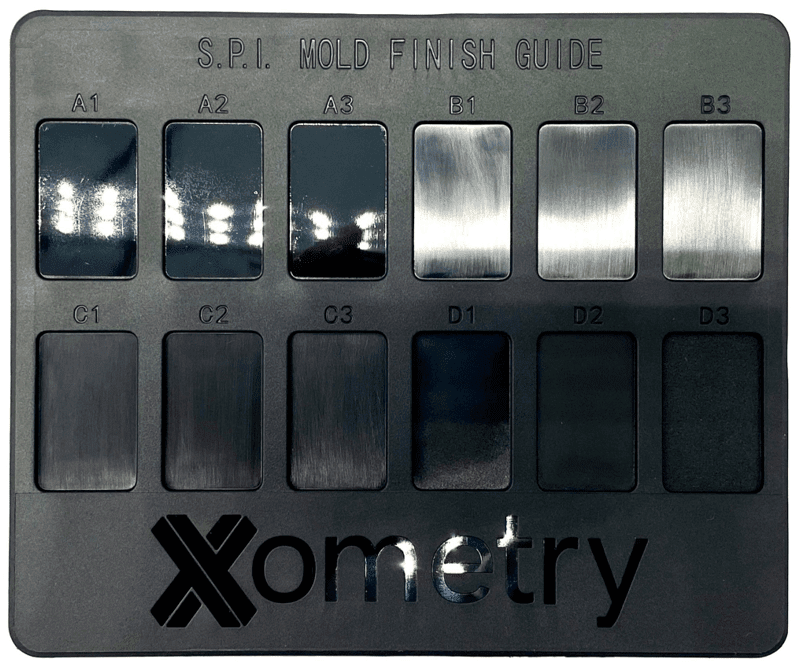

Injection moulding SPI surface finishesInjection Moulding SPI Finishes

SPI

SPI finishes are a set of standard mould finishes with different polished textures for enhanced properties.

Notes:A1, A2, A3, B1, B2, B3, C1, C2, C3, D1, D2, D3

Final result:

- Heavily polished, to semi-gloss to fine and coarse matte depending on the selection

-

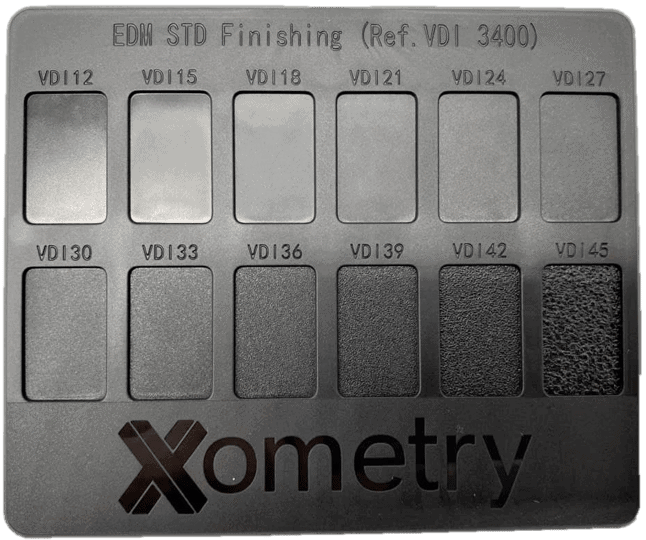

Injection moulding VDI surface finishesInjection moulding VDI surface finishes

VDI

VDI is an international standard for mould texturing of matte surfaces. It is mainly processed by Electrical Discharge Machining (EDM) when mould machining.

Notes:VDI12, VDI15, VDI18,VDI21, VDI 24, VDI27, VDI30, VDI33, VDI36, VDI39, VDI42, VDI45

Final result:

- Fine-to-coarse grain depending on the selection

-

Custom

Mouldmaker’s choice of finish. Typically SPI B-2, depending on geometry and drafts. Interior, non-cosmetic faces, are typically as-machined.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account