Turkey’s First Developer of Robotic Rehabilitation Systems: BAMA

Founded in Ankara in 2010, BAMA Technology is the first and only local manufacturer of robotic rehabilitation systems in Turkey. With its R&D center located in ODTÜ Teknokent and its production facility in OSTİM, the company runs both product development and manufacturing in parallel. BAMA, certified to ISO 13485:2016 standards, successfully positions its CE-marked products in both domestic and international markets.

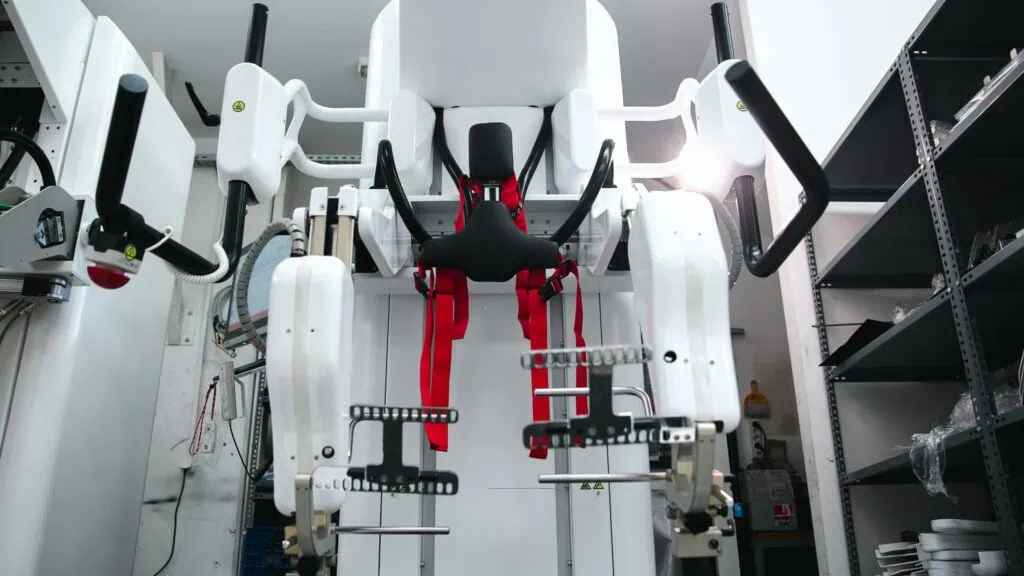

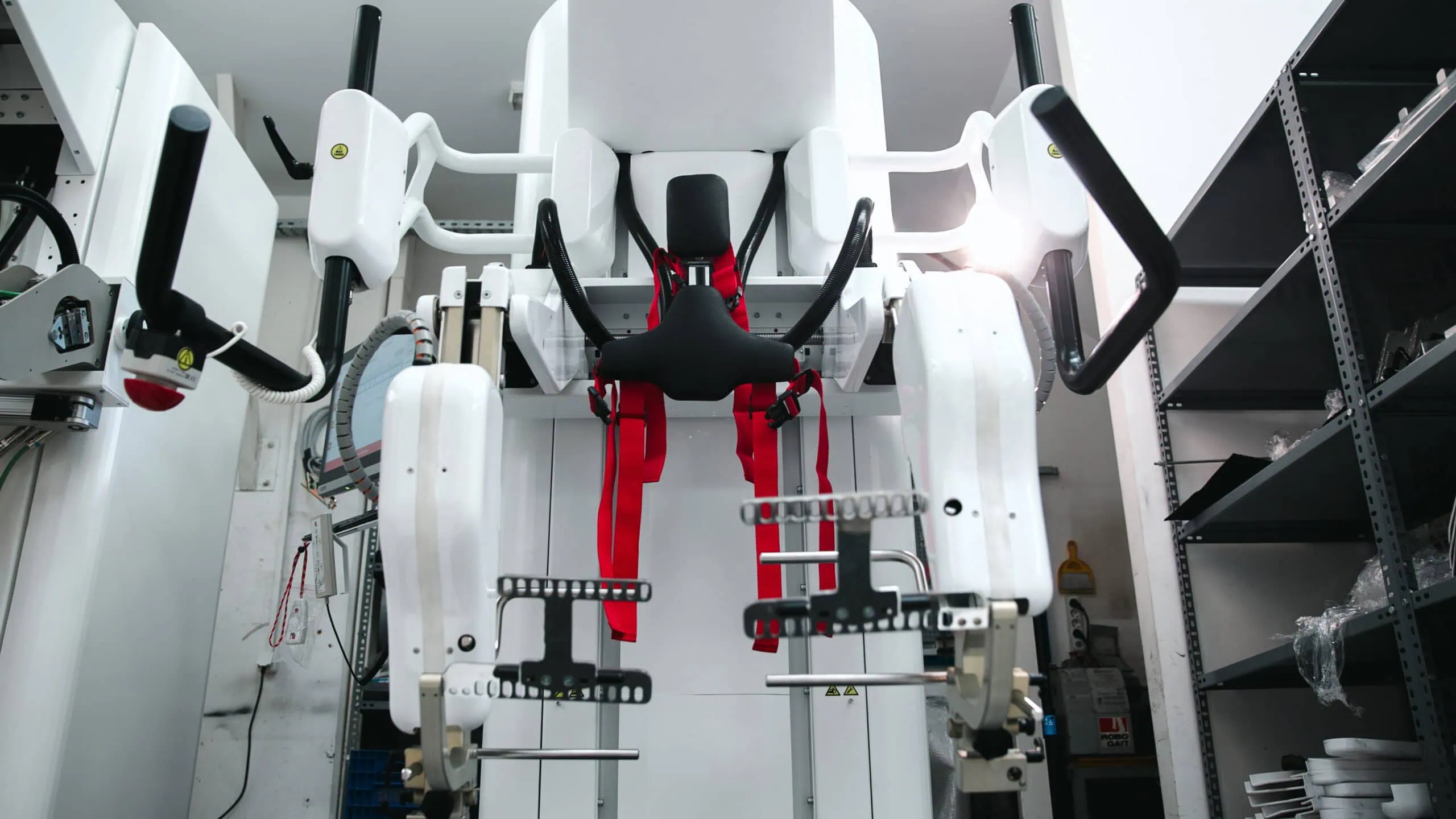

RoboGait – High-Tech Gait Rehabilitation in Clinical Settings

RoboGait is a robotic rehabilitation system that helps patients regain walking ability after conditions such as stroke, brain injury, spinal cord injury, or other neurological disorders. The system electromagnetically replicates the natural gait pattern and uses real-time data analytics to personalise therapy. It comes in both adult and pediatric versions and features a modular structure adaptable to patient needs.

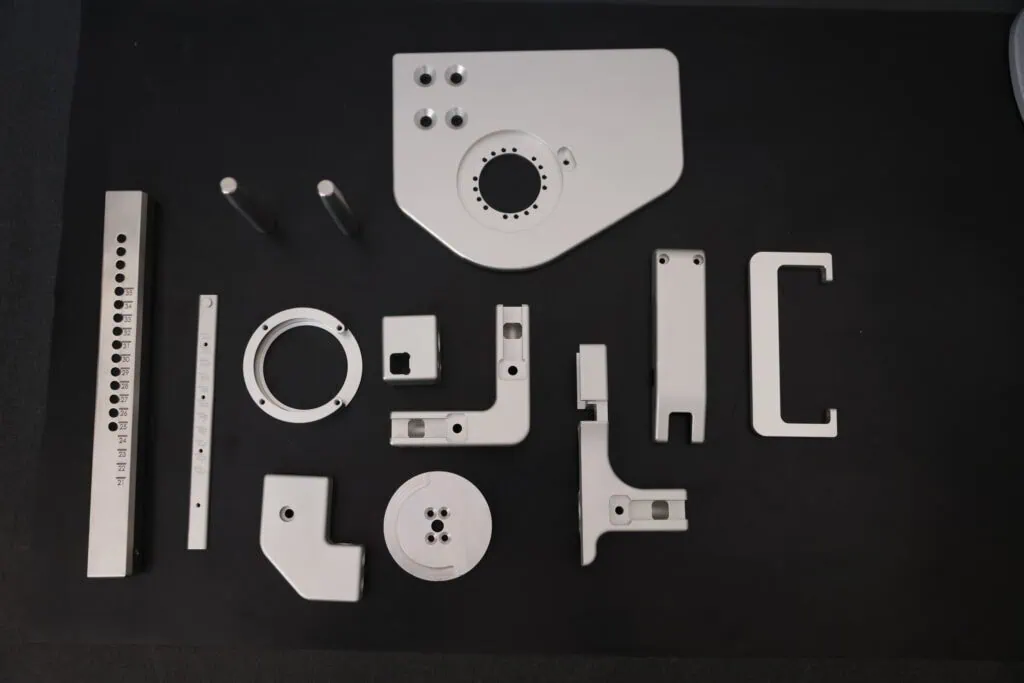

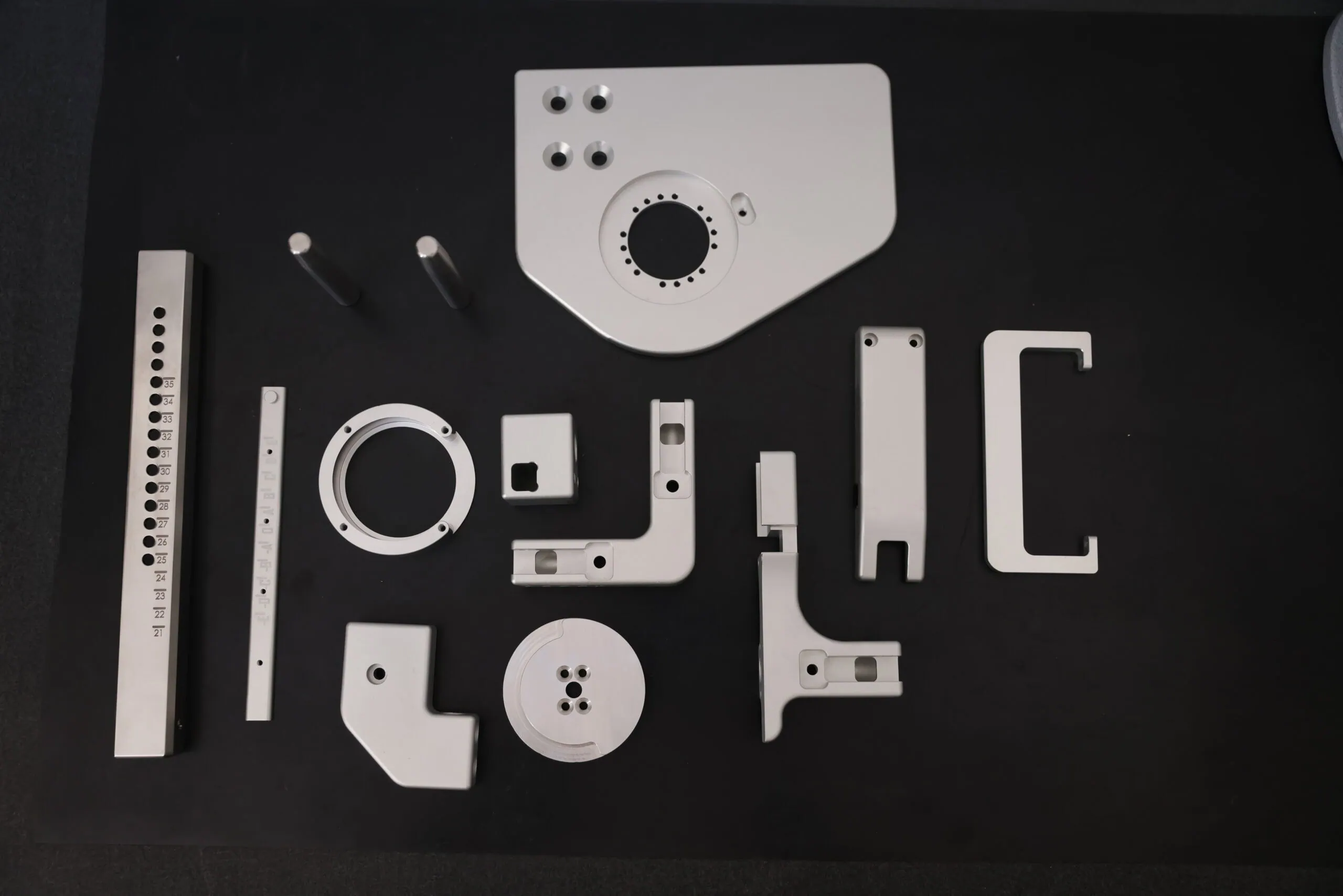

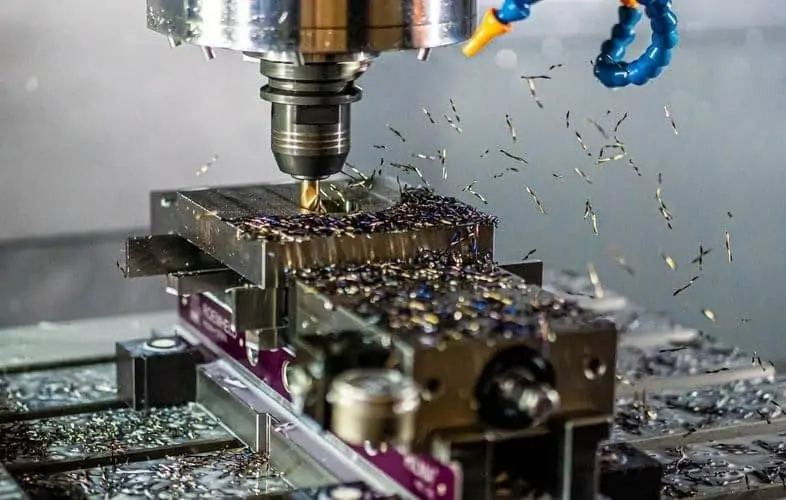

A large portion of the precision CNC-machined parts used in this sophisticated system are manufactured through Xometry. Especially in moving and high-precision components, Xometry’s global manufacturing network ensures the required surface quality, rigidity, and accuracy are consistently achieved.

FreeGait – A Lightweight, Adjustable Exoskeleton for Mobility

FreeGait is an active, motor-driven exoskeleton system designed to support the mobilisation of individuals who have partially or completely lost the ability to walk. With adjustable femur and tibia lengths, hip width, and patient-specific connectors, the system accommodates a wide range of body profiles.

This medical device delivers both lightness and durability to support ergonomic performance—made possible by the high-performance components produced with Xometry.

A Trusted Manufacturing Partnership Spanning Over 4 Years

The collaboration between BAMA and Xometry Türkiye began over four years ago. Today, around 90% of all machined components in the RoboGait device are sourced through Xometry. This partnership goes beyond cost efficiency—it is reinforced by consistent quality, clear communication, and reliable engineering support.

Close coordination with Xometry’s Istanbul office ensures fast turnarounds for revisions and tolerance checks on critical parts.

Global Quality, Local Speed: A Partnership That Makes a Difference

In medical devices like RoboGait and FreeGait, surface quality is critical not just for aesthetics but for performance. For parts in direct contact with patients or involved in movement, homogeneity, corrosion resistance, and durability are essential.

BAMA, which previously struggled to achieve this level of quality with local suppliers, gained access to an expansive range of surface finishes and production processes through Xometry’s network in Turkey, Europe, and Asia.

Components used in RoboGait underwent various finishes including bead blasting + anodising, hard anodising, white alodine coating, electro-galvanising, electropolishing, powder coating, and custom RAL coatings. These finishes were applied to metals like Aluminum 6061, 5054, 7075, Stainless Steel 303 and 304, and Steel 42CrMo4 and S235JR—as well as plastics like POM, Nylon, and ABS.

Process Versatility: End-to-End Sourcing on a Single Platform

Parts manufactured via Xometry include chain lock blocks, positioning shafts, brake interfaces, mounting blocks, pelvic module components, hip motor housings, and bearing assemblies.

These parts were produced using CNC milling and turning, as well as sheet metal fabrication processes like laser cutting, press braking, and welding.

In addition, Xometry’s MJF and FDM 3D printing services have been used over the years for prototyping and design verification phases.

Reliable Planning & On-Time Delivery

In medical device production, timing is not just a matter of scheduling—it directly affects quality, safety, and reliability.

With Xometry Türkiye, BAMA can plan manufacturing with precise lead times and react quickly in urgent needs. The team emphasises that deliveries are always made on time and at the expected quality, helping them maintain seamless production.

Looking Ahead: New-Generation Rehabilitation Systems

BAMA Teknoloji continues to develop next-generation rehabilitation systems, and components of these new devices will also be produced through Xometry. Especially during the prototyping phase, Xometry’s fast turnaround times and engineering support significantly reduce the time required to move from design to production.

For more, visit the BAMA website: https://www.bamateknoloji.com/tr

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)