Hi, we are CoreSpin, a team of 14 students from Maastricht University representing 16 countries and diverse backgrounds in biology, chemistry, engineering, and computer science. United by curiosity and a shared drive to bridge the gap between the lab and the real world, we are exploring how biology can reshape engineering.

Our project brings biological thinking to a field it rarely touches: thermal engineering. We are developing a thermally conductive nanolayer that coats heat exchange surfaces to combat biofouling and the buildup of dust and sediment.

Engineering From a Different Perspective: Synthetic Biology

Synthetic biology is quietly reshaping modern life — from the food we eat to the medicines we take. It involves redesigning natural organisms to enhance their functions or create entirely new ones. At the crossroads of biology, engineering, chemistry, physics, and computer science, this field brings together disciplines to design and build biological systems with purpose.

Drawing inspiration from nature, synthetic biology provides innovative routes toward a more sustainable and circular economy. By merging principles from multiple disciplines, it lets us rethink how we design materials and systems — even in areas traditionally untouched by biology.

One such area is thermal engineering, where biological ideas can offer innovative solutions to long-standing industrial challenges.

Inspired by nature — specifically by the remarkable properties of spider silk — we are engineering proteins capable of binding directly to copper and fine-tuning their sequences to achieve optimal mechanical strength, thermal conductivity, and nanoscale structure.

The Backbone of Modern Life: Heat Exchangers

To understand where such innovation could make a difference, we turned our attention to one of the most overlooked yet essential technologies of modern life — heat exchangers. They cool car engines, keep refrigerators running, regulate building temperatures, and form the backbone of cooling systems in data centres. In fact, more than 90% of the heat used in industrial processes passes through a heat exchanger at least once before completion. These devices are therefore not only vital to the smooth operation of countless systems but also play a key role in improving overall energy efficiency.

During our visit to the energy centre of our local hospital, we spoke with technicians and managers who introduced us to a major challenge in this field — heat exchanger fouling. This meeting made the problem tangible and helped us define our project’s real-world relevance.

The Problem: Bacteria, Dust, and Sediment on The Surfaces of Heat Exchangers

Liquid-to-air heat exchangers transfer heat from a liquid to the surrounding air. However, because they operate in open environments filled with dust, debris, and bacteria, they are highly susceptible to biofouling, corrosion, and sedimentation. For instance, bacteria can adhere to conductive surfaces and form a slimy layer known as a biofilm. While this may seem minor, biofouling on copper surfaces has been shown to drastically reduce thermal conductivity. A biofilm as thin as a single strand of hair can decrease heat transfer by up to 98%. In addition, these bacteria contribute to natural corrosion, which over time degrades the material’s surface and lowers thermal efficiency by more than 20%. The accumulation of dust and sediment can cause a further 30% drop in heat conduction.

Collectively, these issues disrupt normal heat exchanger operation and significantly reduce efficiency. To compensate, systems must work harder, consuming more energy and producing greater greenhouse gas emissions.

Current cleaning methods offer only short-term relief and often rely on harsh chemicals that pose health risks and consume valuable resources. Maintenance also causes downtime and increases operational costs. As a result, companies frequently choose to decommission old components instead of maintaining them, further depleting resources and generating unnecessary waste.

The Solution: Merging Nature and Technology Towards a Brighter Future

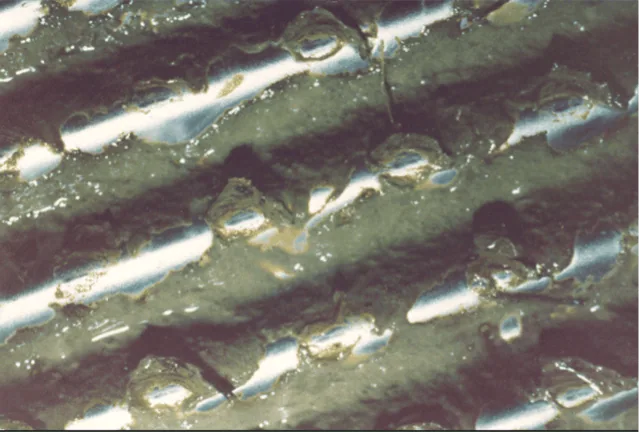

To overcome the limitations of existing cleaning and maintenance methods, we explored biological materials capable of providing both thermal efficiency and self-cleaning properties. Spider silk emerged as a natural model for such multifunctional performance.

Spiders produce various types of silk, each forming a different part of their web. Among them, dragline silk — also known as major ampullate silk — has drawn particular attention. As the weight-bearing element of the web, it contains unique proteins that give it exceptional properties: it is as strong as steel, three times tougher than Kevlar, and five times more elastic than nylon. Spider silk is also remarkably thermally conductive — roughly on par with copper.

Coupling of a Protein onto Copper Surfaces

While spider silk exhibits remarkable strength and thermal conductivity, its natural proteins — spidroins — do not inherently bind to metals, a key requirement for our design. To translate the silk’s properties into a functional coating, we needed a way to anchor these proteins directly onto copper surfaces, which were chosen for their excellent thermal conductivity and stable crystalline structure.

To achieve this, we introduced an additional cysteine residue into the protein sequence. The thiol group of this residue forms a covalent copper–sulphur bond, creating a direct molecular connection between the protein layer and the metal surface. This bond is essential for phonon coupling — the transfer of heat energy from the copper into the spidroin fibrils. Without this linkage, microscopic gaps would remain between the metal and the protein layer, trapping air and turning the coating into an insulating barrier rather than a conductive one.

In addition to ensuring efficient heat transfer, this covalent attachment also helps establish the nanoscale surface structure responsible for the coating’s antibacterial properties.

Self-Cleaning Effect: How Surface Topography Kills Bacteria And Repels Dust

With the protein successfully bound to the copper surface, the next step was to explore how its structure could be engineered to deliver additional functionality. By designing the coating’s nanoscale topography, we aimed to replicate natural surfaces that not only maintain thermal performance but also resist bacterial growth and contamination.

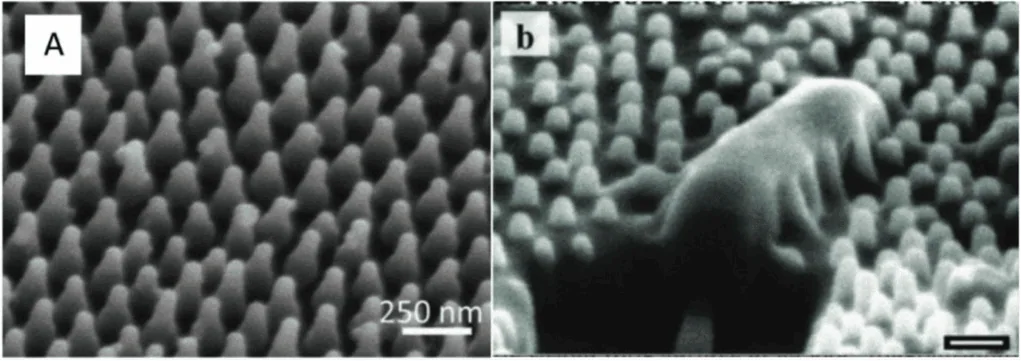

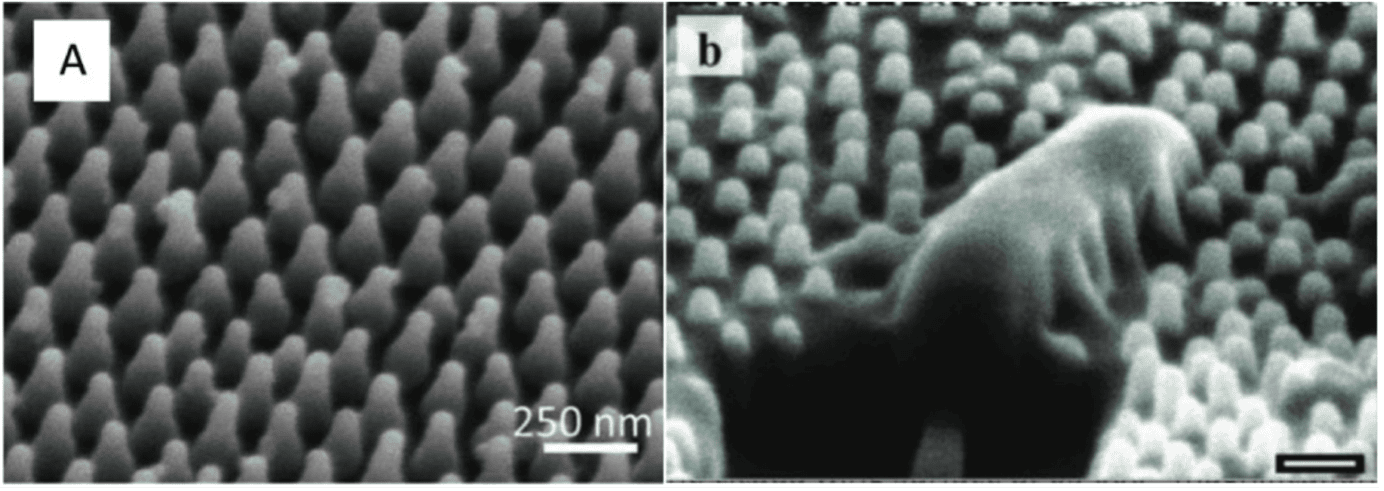

Once again, we turned to nature for inspiration — this time to the wings of dragonflies and cicadas. These insects feature nanostructured surfaces that naturally prevent bacterial attachment through a size-exclusion principle: when the surface features are smaller than bacterial cells, the available area for adhesion is drastically reduced.

Their wings are covered with a highly ordered array of nanopillars standing perpendicular to the surface. When bacteria attempt to attach, these pillars stretch and rupture the cell membrane, leading to cell lysis. This purely physical mechanism enables our nanolayer to remain antibacterial without relying on chemicals or antibiotics.

It is also hypothesized that the same principle applies to dust and sediment. The ordered nanopillar structure limits the ability of these contaminants to settle, giving the surface a self-cleaning effect.

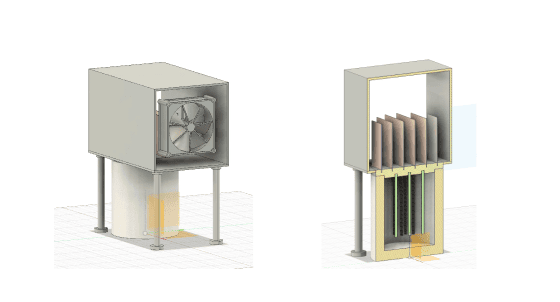

The Prototype: Real-World Testbed

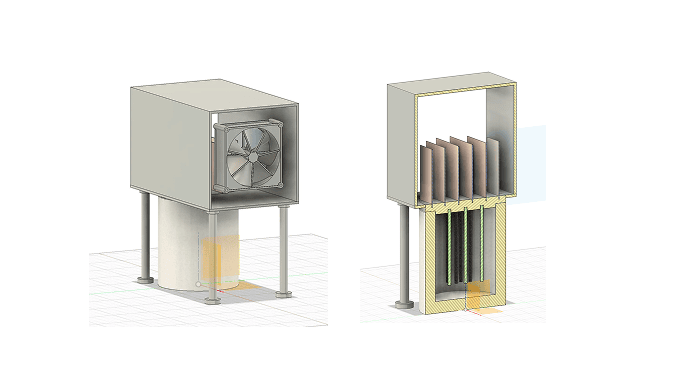

Building on the insights from natural nanostructures, we proceeded to implement our bioengineered coating in an experimental setup. This prototype was developed to quantitatively assess the coating’s thermal conductivity, fouling resistance, and antibacterial performance under controlled heat-exchange conditions representative of real-world applications.

The experimental setup evaluates the thermal transfer efficiency of copper heat-exchanger sheets under three coating conditions:

- Untreated pure copper

- Copper with biofilm growth

- Copper coated with modified spider silk proteins

The aim is to simulate realistic fouling conditions in air-liquid heat exchangers and measure the effect of surface coatings on thermal performance.

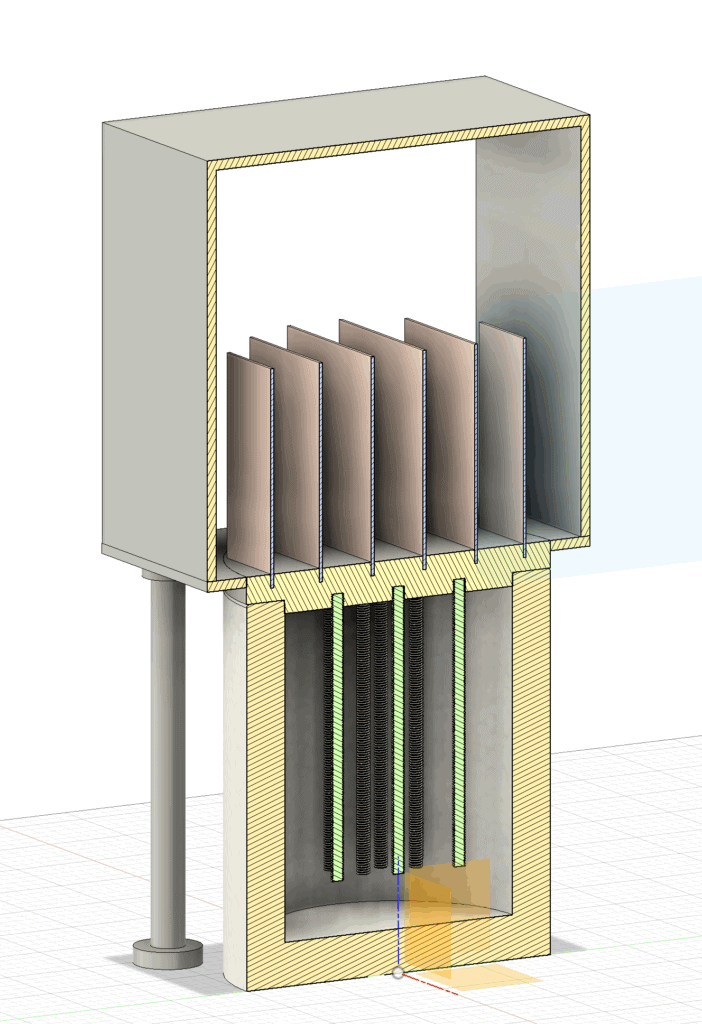

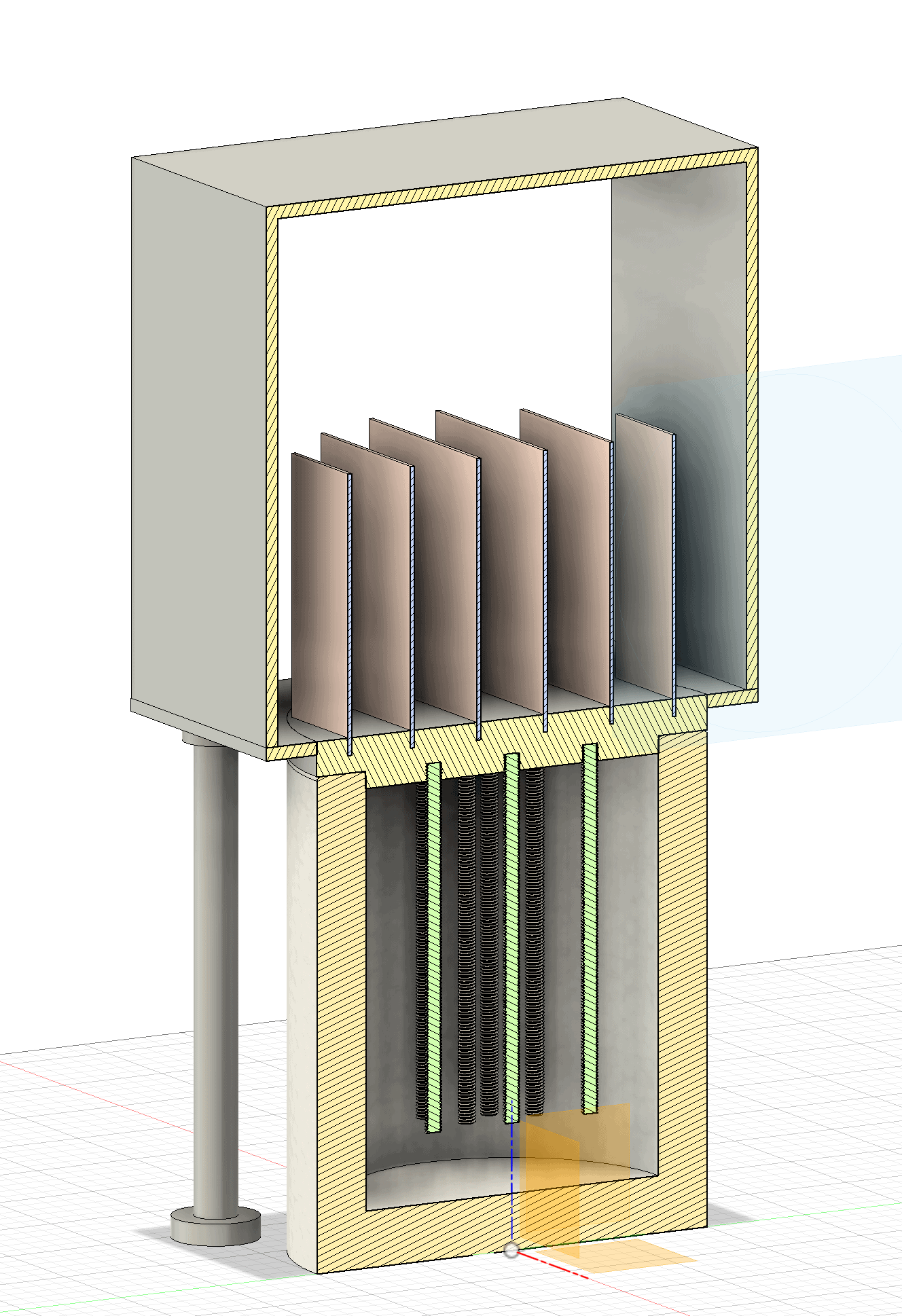

The experimental setup will be divided into 3 different parts: the calorimetry system, the specialized heat exchanger lid, and airflow and environmental control.

Calorimetry System

A calorimetry cup is one of the most basic thermodynamic equipment used experimentally, consisting of a cup made of thermally insulating material, and will serve as the primary heat reservoir in the following experiment. The experiment will begin with filling this cup with 100 °C water, but the measurements will range from 80°C to 40°C, ensuring a consistent initial thermal gradient.

A temperature probe (±0.1 °C accuracy) will be submerged in the water to continuously monitor and record its temperature. Additionally, the cup will be sealed with a specialized lid, minimizing evaporative losses and acting as a heat exchanger between the water and the ambient air.

Heat Exchanger Assembly

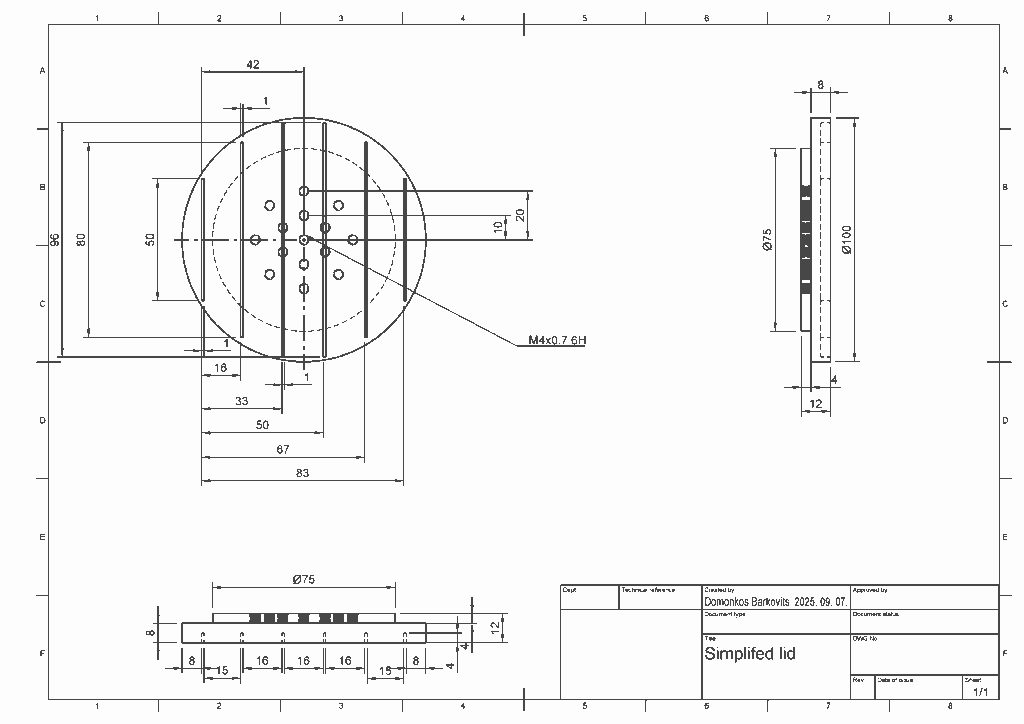

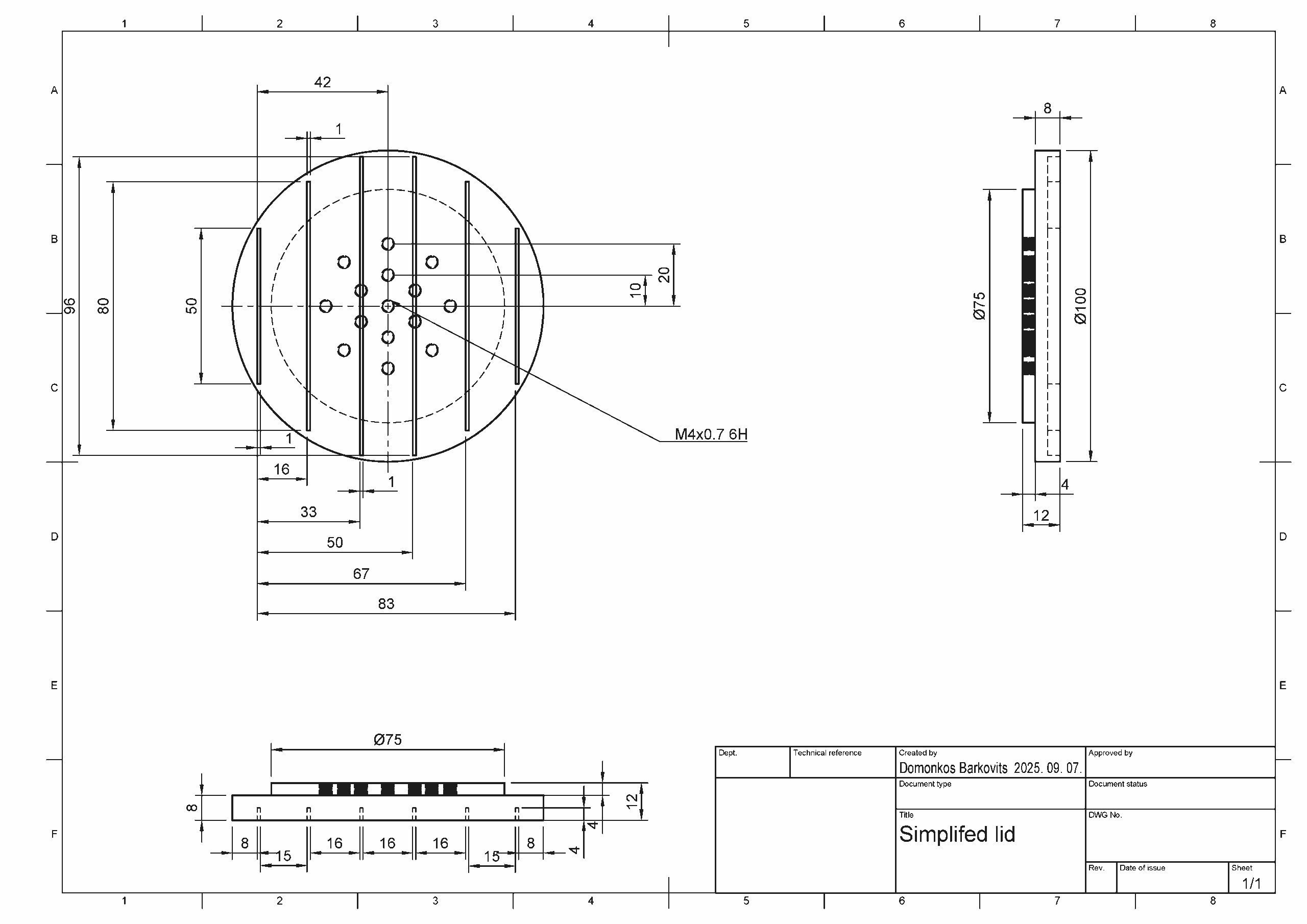

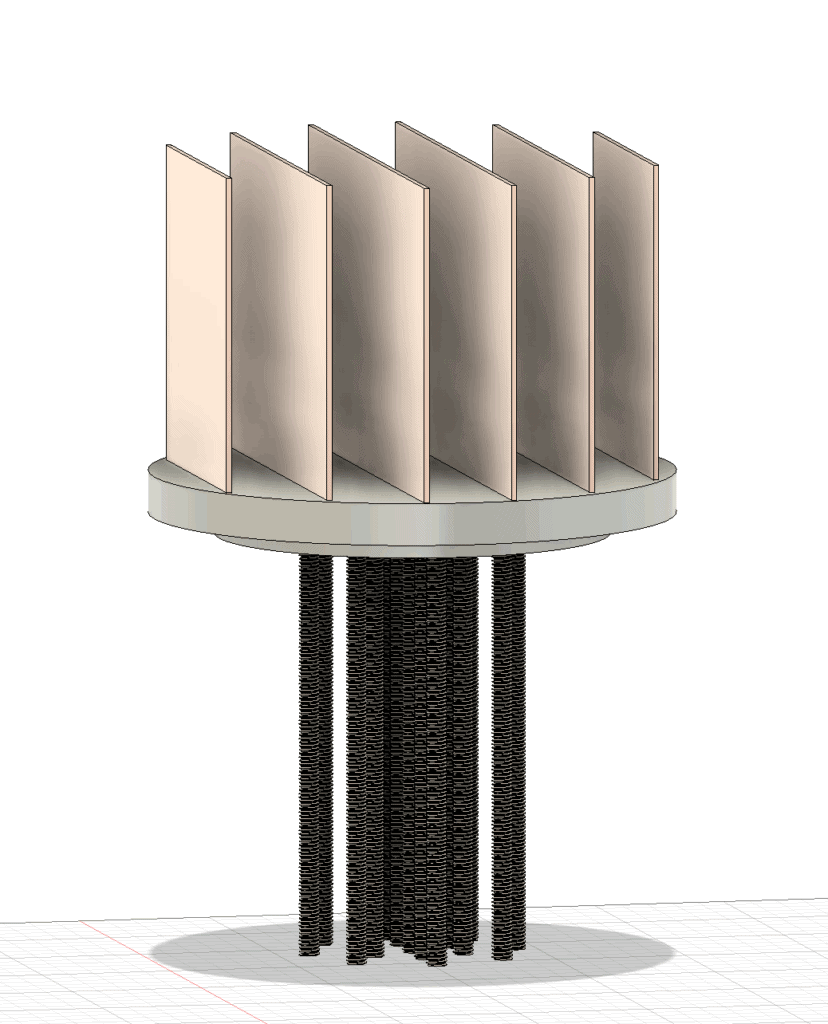

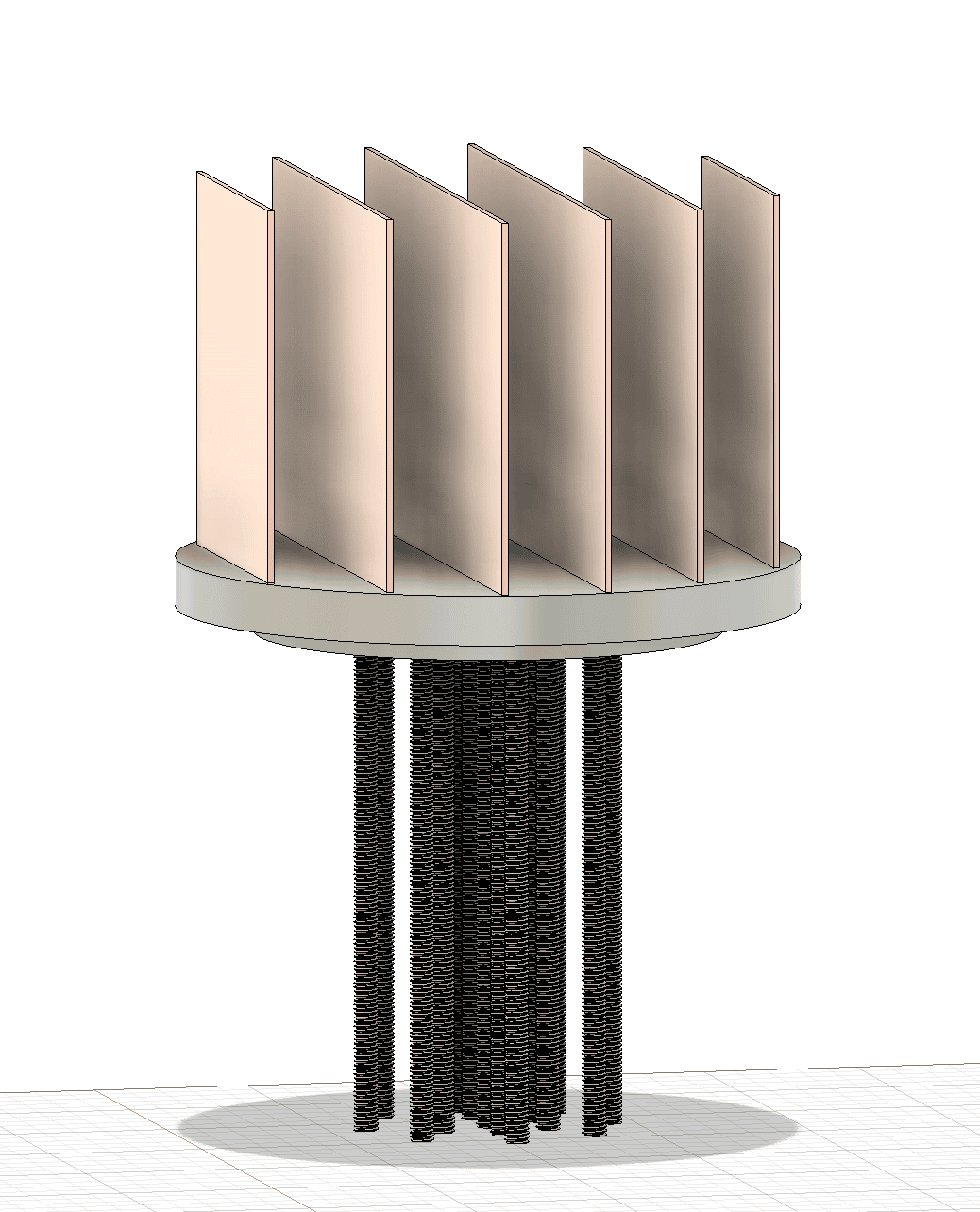

We designed the lid assembly as a modular thermal transfer interface, optimized for experimental protein testing under realistic heat exchange conditions. It consists of three precision-engineered components:

- 15x 84mm M4 threaded aluminium rods, responsible for transferring the thermal energy from the water medium to the lid surface. Aluminium was selected for its high thermal conductivity-to-price ratio ensuring fast experiments with low costs.

- A custom-machined aluminium lid, featuring 15 threaded ports for the aluminium rods and 6 milled “rails” on the top surface. This will ensure a proper heat exchange between the rods and the sheets.

- Six 1mm copper heat exchange plates, positioned in the milled rails to facilitate heat transfer from the rods through the lid to the surrounding air. Currently copper’s crystalline structure allows for the correct binding to exchange the heat conducted with the ambient air. These are mounted atop of the lid in the pre-milled rail.

All the contact interfaces between the rods, lid, and copper sheets will be bonded using thermal paste and high-temperature adhesive to minimise interfacial thermal resistance and enhance conduction efficiency.

Design Philosophy and Constraints

The lid was engineered with manufacturability and modularity in mind. Additionally, given the project’s limited funding, we prioritized the use of commercially available, mass-produced materials that could be sourced from local hardware stores. Consequently, only the lid required custom CNC machining, simplifying replication and scalability with limited funding.

The key considerations included:

- Compatibility with the standard calorimetry cup, ensuring proper thermal seal. A dual-diameter interface with a 100mm outer and 75mm recessed base was designed. This will provide a tight fit, minimizing heat losses.

- A bottom-mounted rod array to maintain consistent heat transfer from the fluid media upward to the conductive lid

- Adjustable, replaceable copper plate configuration, allowing different number of parallel plate placement.

Experimental considerations

In the experimental setup, the copper plates will function as the test surface for the evaluation of our anti-fouling, and heat transporting proteins.

Depending on the experiment these plates will be:

- Left untreated as a baseline control sample,

- Intentionally fouled with biofilm and sediments to simulate real-world contamination

- Coated with engineered proteins enabling comparative assessment of thermal performance and fouling resistance in practice.

This modular and thermodynamically optimized design allows our team to quantitatively assess how biological coating influences heat transfer performance, the first step toward sustainable and efficient bio-inspired materials for heat exchangers.

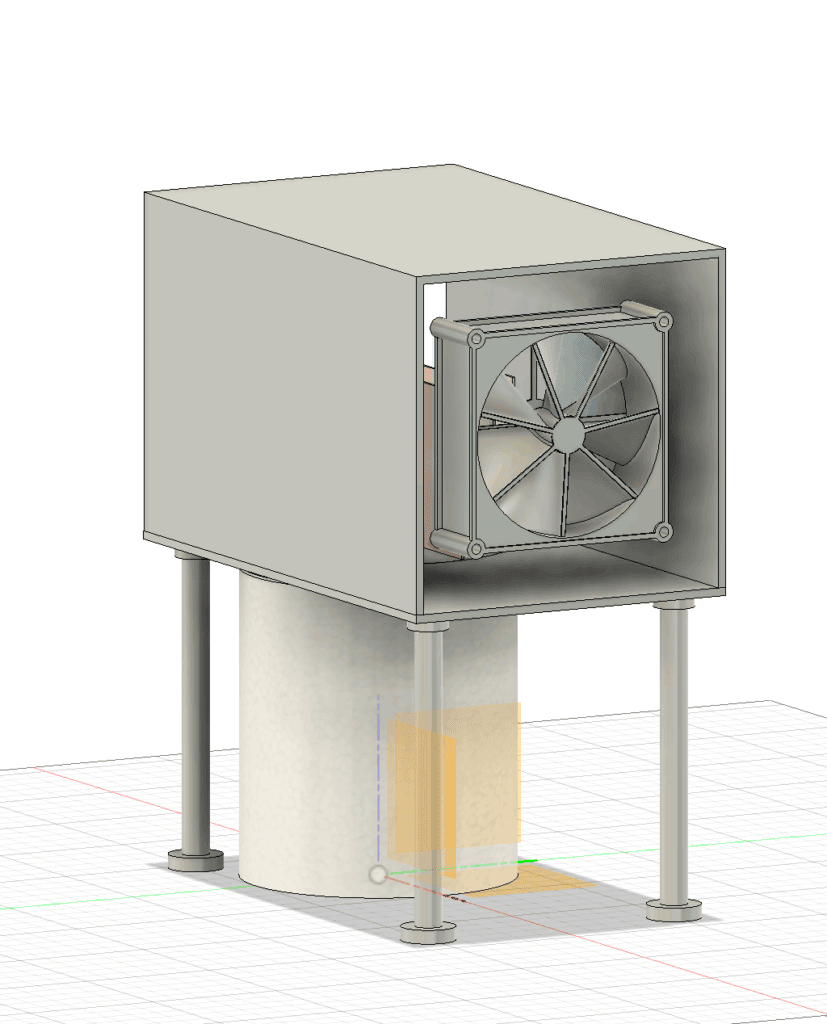

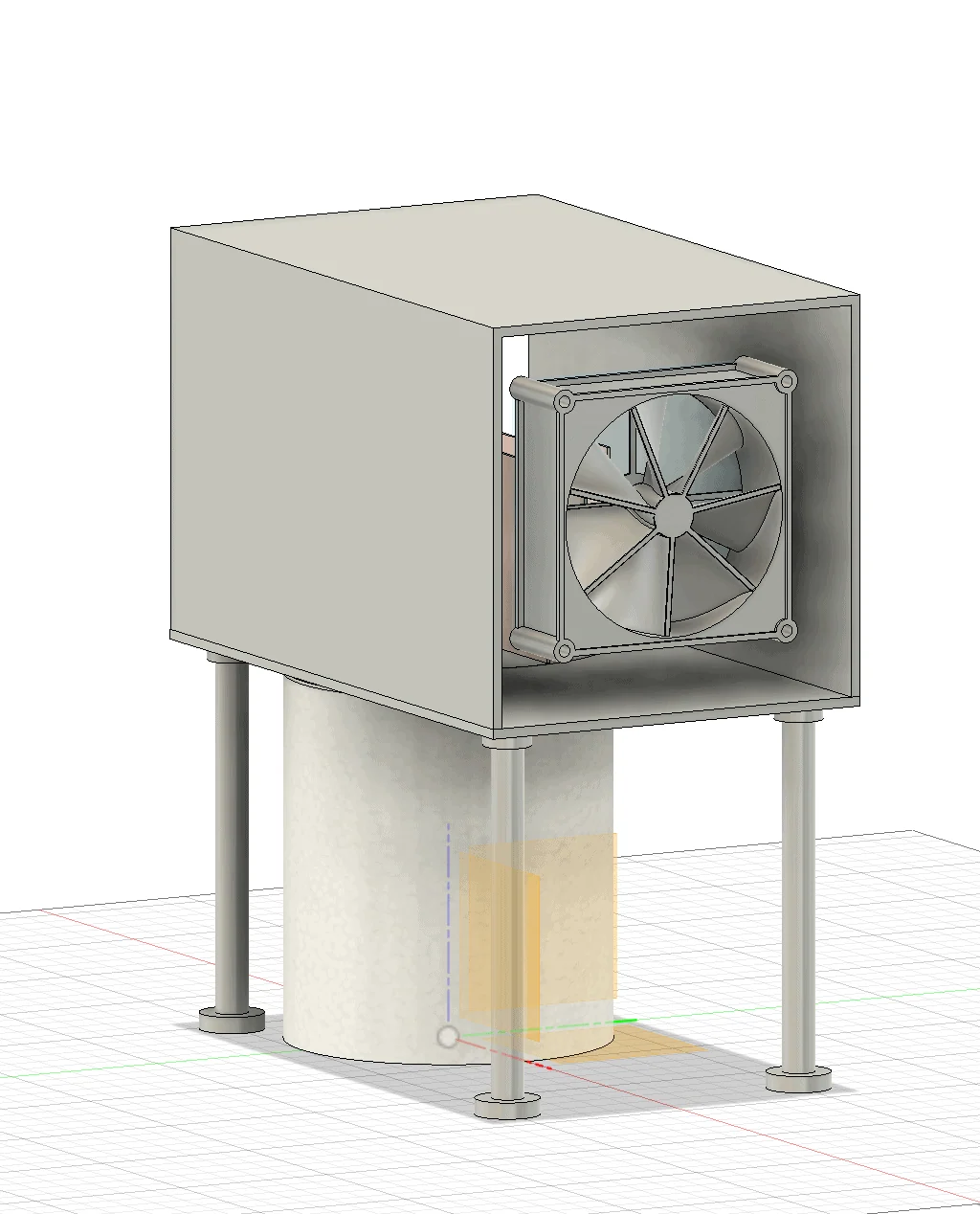

Airflow and Environmental Control

The entire heat-exchanging assembly will be placed in a closed plastic chamber to further reduce the risk of non-anticipated errors. This whole assembly will sit inside a fume hood to negate the change of humidity and to have a constant temperature in the intake of the airflow. Here, a DC axial fan will be placed to increase the flow of air through the copper sheets, simulating real-world forced convection.

Two monitoring sensors will be positioned between the fans and the conducting copper plates to ensure that the same conditions are taking place for the three sub-experiments, including a temperature sensor to monitor the inlet air temperature and a pressure sensor to validate a consistent volumetric flow rate.

This configuration will allow the quantification of air-side heat uptake while ensuring stable boundary conditions across replicates.

From Prototype to Practice

So far, we have successfully expressed our engineered proteins and achieved their coupling to copper surfaces. The next stage of our work will focus on evaluating the antimicrobial properties of the nanostructure and assessing its scalability.

Using our modular prototype system, we will then test the thermal conductivity of coated copper plates and expose them to controlled airflow, humidity, and fouling environments to simulate real operational stresses. This will allow us to quantify improvements in heat transfer efficiency, biofouling resistance, and durability compared to untreated or fouled copper surfaces.

Ultimately, we plan to apply our protein coating to full-scale heat exchangers to assess its impact on thermal performance in a real-world system and to validate its application in HVAC units and data centers. By bringing a completely new technology to a field that has never considered a biological solution to counter its flaws, CoreSpin aims to power the future with efficiency.

What’s the most exciting engineering–biology crossover you’ve worked on or seen? Share your story with us in the comments!

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)