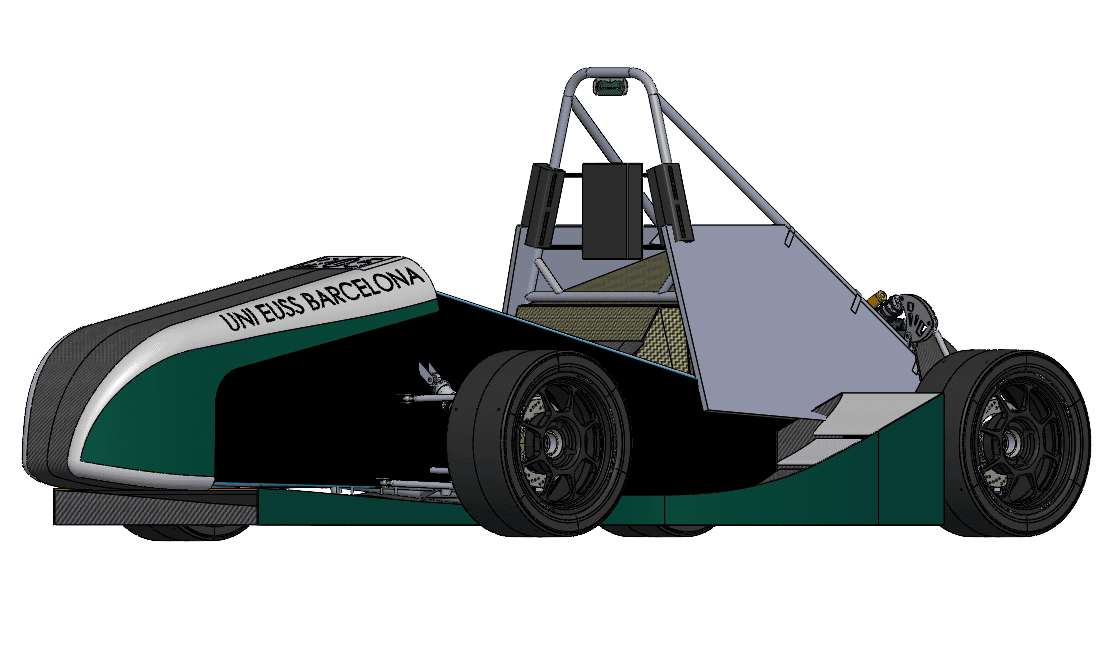

My passion for motorsport has always driven me to seek hands-on experience in the field. Formula Student provided the perfect opportunity to gain real-world experience in designing and manufacturing before stepping into the industry. It offers invaluable practical knowledge that employers across various industries look for in candidates.

Oxford Brookes Racing (OBR): A Legacy of Excellence

Established in 1999, Oxford Brookes Racing (OBR) has become one of Europe’s top Formula Student teams. OBR specialises in designing, testing, and building high-performance electric vehicles. We compete in the IMechE Formula Student competition in both the UK and Europe, boasting a total of 11 total wins since 2003.

Beyond the competitive aspect, being a part of OBR is an incredible learning experience. Members gain practical skills in electrical circuit design, aerodynamic simulation, and manufacturing processes. The fast-paced nature of the team closely mirrors the intensity of professional motorsport, making it one of the best environments for students aspiring to work in the industry. Additionally, it offers a unique networking opportunity, helping members establish valuable connections that last a lifetime.

Advancing Brake Performance

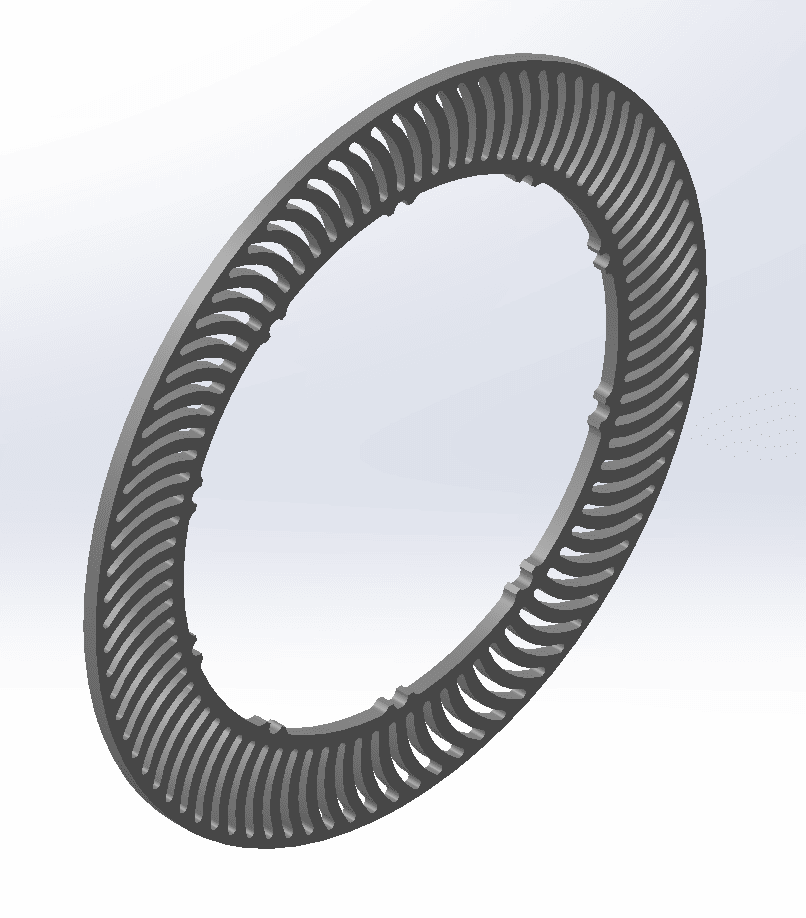

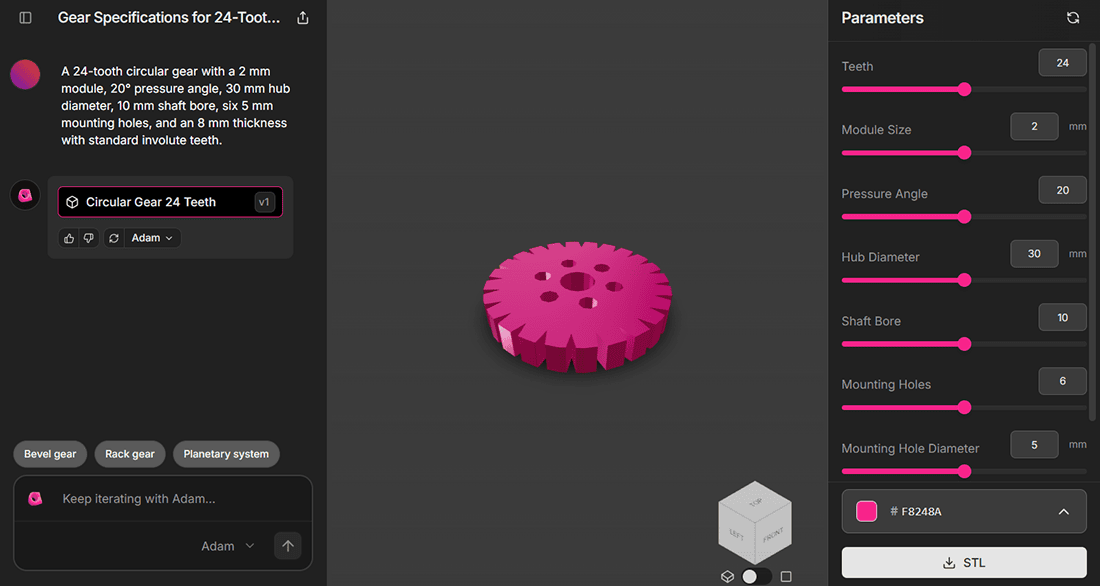

Brakes have always been one of the most critical parts of our high-performance vehicle. For 2025, our goal was clear: make them lighter and more efficient without sacrificing reliability. After countless hours of brainstorming and testing, we developed a new brake disc design that cuts nearly 20% of the weight while keeping performance rock solid.

It wasn’t easy. We spent weeks running simulations, tweaking the volume-to-surface area ratio, and experimenting with different cut-out types—slotted, drilled, you name it. Each iteration brought us closer to the perfect balance between weight reduction and cooling efficiency. Finally, we landed on a concept that not only shaved off mass but also improved heat dissipation, all while staying within our design standards.

Using SolidWorks, we rapidly prototyped and refined the design, making adjustments with every test. Now, as we move into manufacturing, the real test begins. Driver feedback will be crucial in evaluating braking sensitivity, and during official Formula Student brake tests, we’ll see how well our new system holds up under pressure. To take things a step further, we’re even considering using infrared sensors to monitor brake temperatures in real-time, feeding us valuable data for even more fine-tuning.

Overcoming Challenges: Campus Move and Manufacturing

With OBR transitioning to new campus facilities, access to traditional workshop resources has been limited. This presented a challenge in manufacturing the updated brake discs. Given their nearly two-dimensional nature, water jet cutting was chosen as the ideal method, allowing for precise and complex cuts that would have been difficult to achieve with CNC machining.

By leveraging Xometry’s waterjet cutting services, our team has been able to stay on track with deadlines while maintaining high-quality standards in component production.

Next Steps: Manufacturing, Car Build, and Competition

As OBR progresses toward the final stages of development, the next focus is on manufacturing and assembling the car. This is an exciting phase where all the hard work from various team members comes together. Once the car is built, rigorous testing will begin to validate every design and optimise performance before the competition. The ultimate goal remains clear: to win Formula Student UK and secure a Top 10 finish in FSCz.

Advice for Teams Facing Similar Challenges

For teams going through a campus move with limited in-house manufacturing, simplicity is key. It is important not to overcomplicate things and instead focus on refining existing designs to make them better. By utilising the resources we have effectively, we can avoid unnecessary delays and ensure a smoother transition. The more complex things get, the longer they take to execute, so we always aim to keep processes streamlined for long-term benefits.

Through innovation, adaptability, and teamwork, we at OBR continue to push the boundaries of student motorsport, setting new benchmarks in the Formula Student community.

Learn more about Oxford Brookes Racing: https://obr.brookes.ac.uk/obr-home

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)