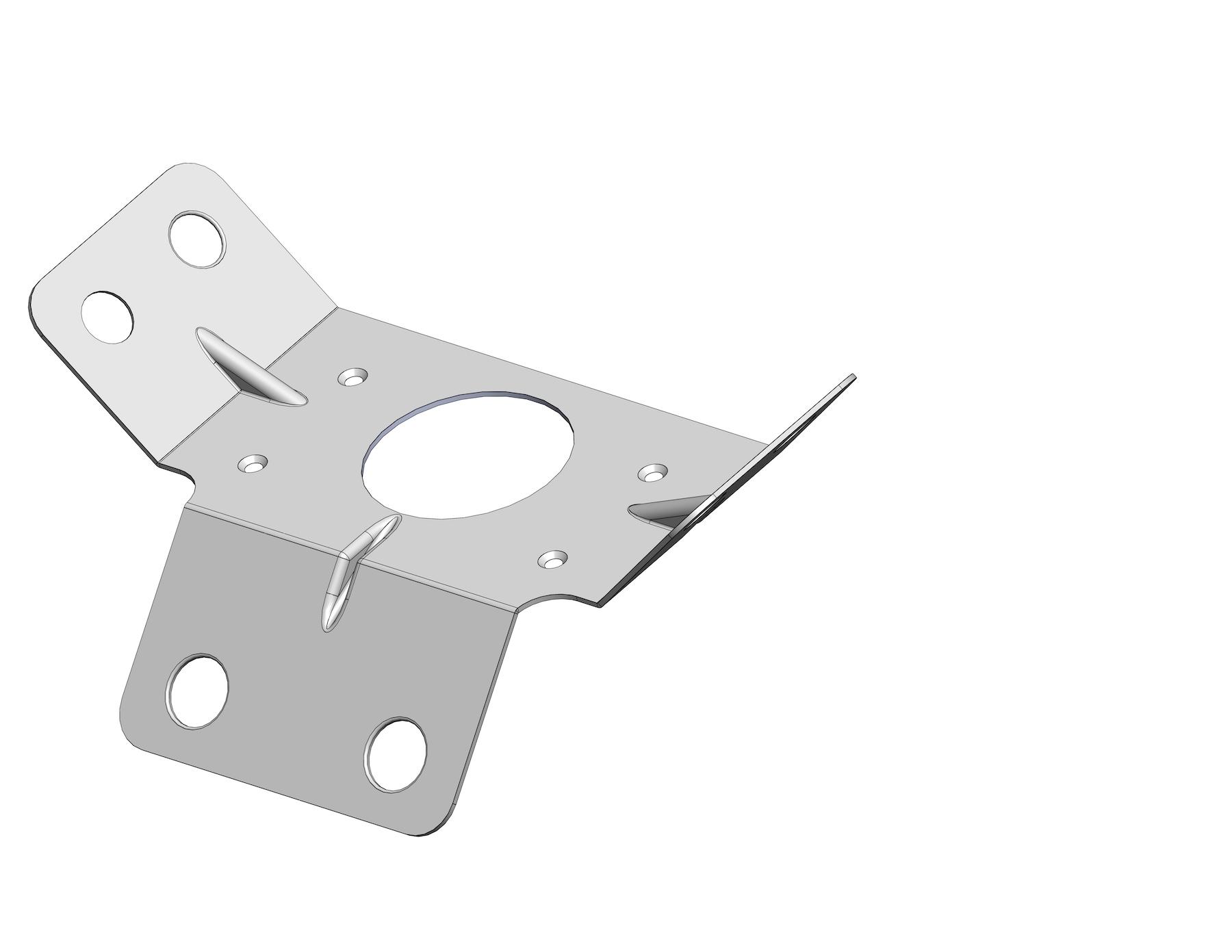

Hello, I’m working on a sheet metal enclosure (as in the image) that requires flush mounting for M6 countersunk screws. I need to add a countersink on a few holes, but the part is already flat-cut and formed. Has anyone successfully added a countersink post-process in this kind of setup without warping the part? Looking for the most practical approach, either manual or otherwise.

Suggested Topics

Topic

Replies

Views

Activity

Ejector pin placement near snap-fit

I’m working on a small injection-molded housing for an automotive sensor, using PA6 GF30. There are two snap-fit arms inside (cantilever type), about 2 mm-thick walls. I’m not sure where to place the ejector... read more

0

601

Printed bracket cracking – how to reinforce?

Hi, I'm prototyping a small bracket for holding a plastic cover in place—roughly 60 × 30 × 10 mm, with two hooks and two screw holes (M3) on the top side. I printed it in PLA with 20% infill... read more

0

358

Will a 6mm dowel fit in this hole?

hello, I'm designing a part with an FDM 3D printed hole to hold a 6mm wooden dowel, but I’m unsure about the actual fit due to print tolerances and material shrinkage. The hole is... read more

0

428

0.4mm text in PLA

Hey all, my part needs to have perforated text on a thin PLA sheet, and the text is 0.4 mm thick. Do you think that’s wide enough to print cleanly without running into issues... read more

0

457

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account