Ejector pin placement near snap-fit

M

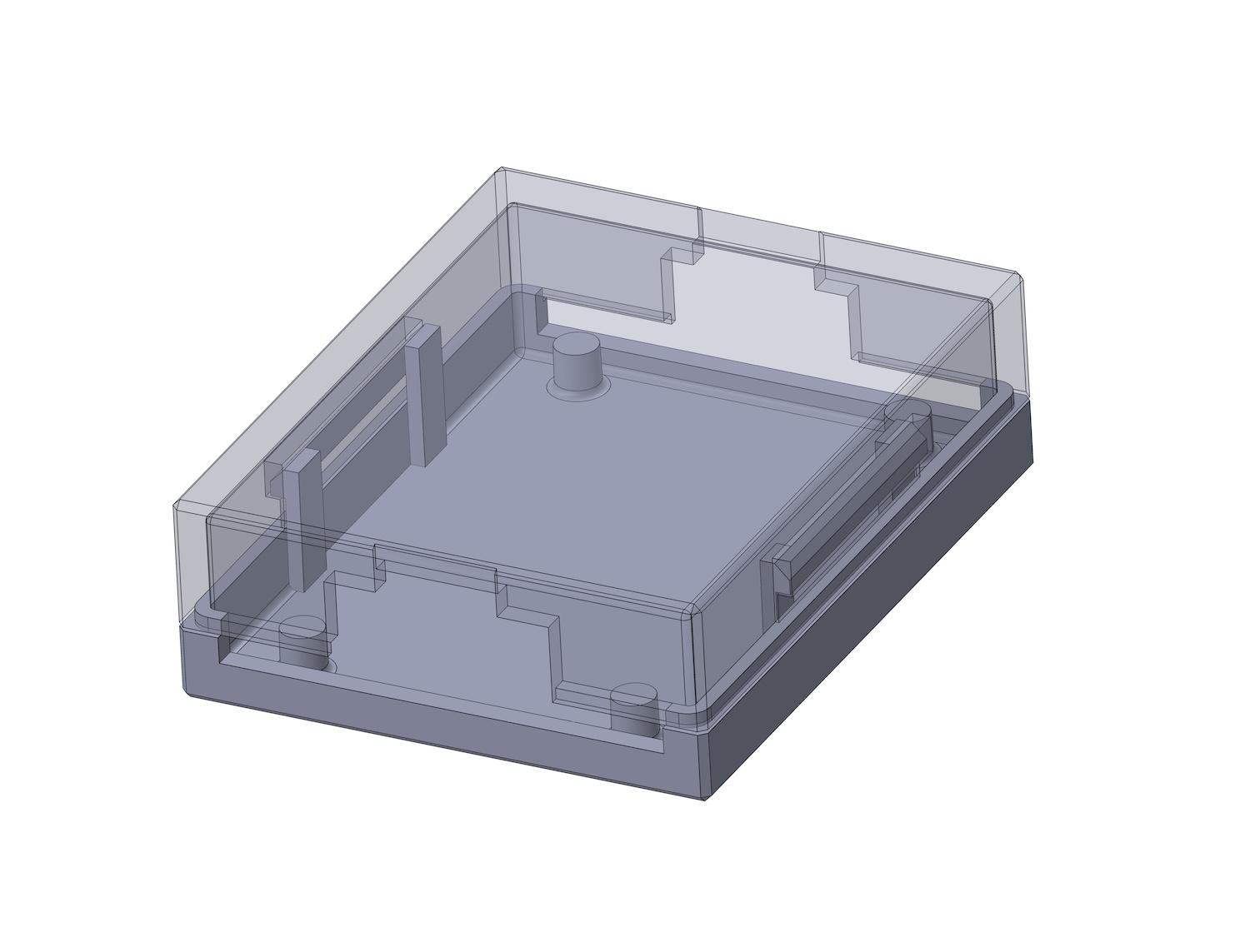

I’m working on a small injection-molded housing for an automotive sensor, using PA6 GF30. There are two snap-fit arms inside (cantilever type), about 2 mm-thick walls. I’m not sure where to place the ejector pins without risking marks or deformation near those arms. Anyone here dealt with ejector placement on flexible features like this? Especially with glass-filled nylons that don’t forgive much?

Suggested Topics

Topic

Replies

Views

Activity

Thermal expansion modelling for a braced rectangular steel tank

hi, for a welded steel coolant reservoir for a test stand - 4 m × 2 m × 1.5 m with internal bracing I need to account for thermal expansion. Fluid runs at 80–90... read more

0

64

Dec 22

Designing holes for M3 threaded inserts in an ABS enclosure

Hi! In my design for a small ABS enclosure for an onboard sensor module I want to switch from molded bosses to heat-set M3 inserts for the lid screws. Before I finalize CAD, what... read more

1

102

Dec 23

Airtight joint between two aluminum frame enclosures?

Hi, I have two 400 mm cubical enclosures from 20×20 mm aluminum profiles with glass on all sides except one. I need to connect them into a single temperature-controlled unit and keep the joint... read more

2

154

Dec 29

SLA wall thickness issue for microfluidic channels

Hi, I created a 3D design for a small microfluidic part using SLA (Clear Resin) with internal channels ~0.4 mm wide and wall thickness around 0.5 mm. The function relies on optical inspection through... read more

1

1.1k

Jul 29

Embossed vs. engraved text for outdoor molded parts

Hi there, I need to add a part number and recycling symbol on the surface of molded parts in PP GF20 for outdoor use. I initially planned to use engraved text for aesthetic reasons,... read more

2

1.5k

Jul 30

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account