Will a 6mm dowel fit in this hole?

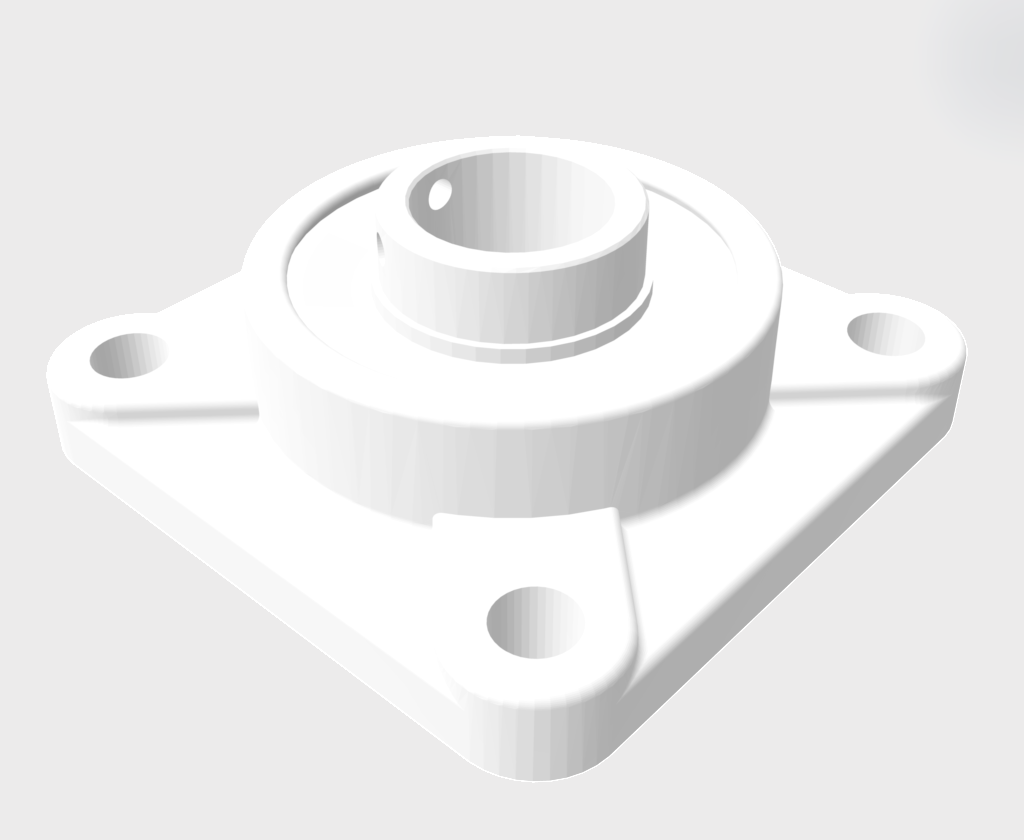

hello, I’m designing a part with an FDM 3D printed hole to hold a 6mm wooden dowel, but I’m unsure about the actual fit due to print tolerances and material shrinkage. The hole is modeled at 6mm in CAD, but I know FDM printers often produce slightly smaller or irregular holes depending on factors like layer adhesion and filament type. For those who have tested similar setups, should I oversize the hole slightly to ensure a proper fit? If so, what diameter would you recommend to achieve either a snug slip fit or a light press fit without excessive post-processing?

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account