Hi, we’re Cellsius – a student engineering team at ETH Zurich. With Project H2, we set ourselves an ambitious goal: achieve an emission-free flight over the Gotthard Pass, powered entirely by hydrogen.

At the heart of our mission is the H2-Sling—a fully modified ultralight aircraft that we developed and built from scratch. This project represents not only technical innovation, but also our generation’s drive to align sustainability with practical engineering.

Driven by Passion and Engineering Excellence

From the start, we wanted to demonstrate that emission-free flight is achievable using technologies available today. No futuristic concepts—just smart integration, good design, and plenty of testing. We chose the Sling High Wing platform for its balance of payload, simplicity, and modifiability. Then we rebuilt it around a completely new powertrain.

We handled the design and integration ourselves: from fuel cell layout and energy management to cooling systems, mechanical adaptation, and structural reinforcements. The result is an aircraft that’s already flown—and is now being prepared for a bold next step: crossing the Alps on hydrogen power alone.

Taking Off with Hydrogen

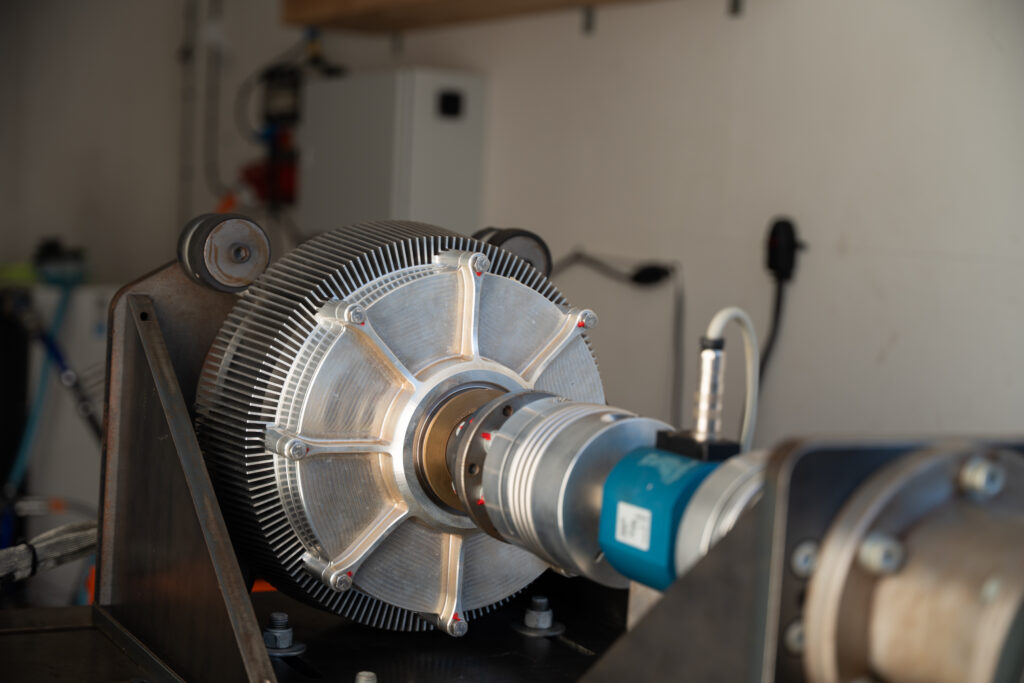

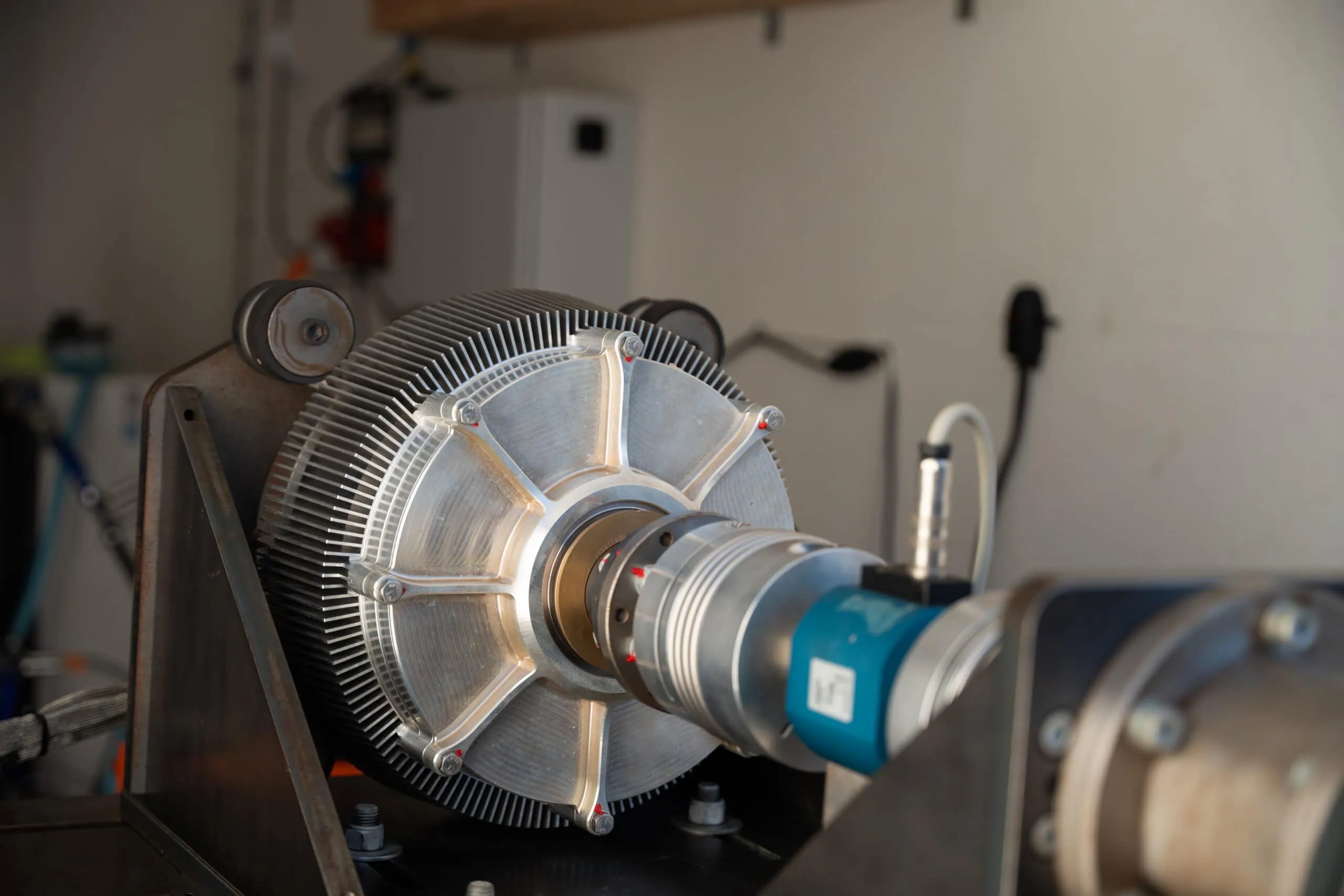

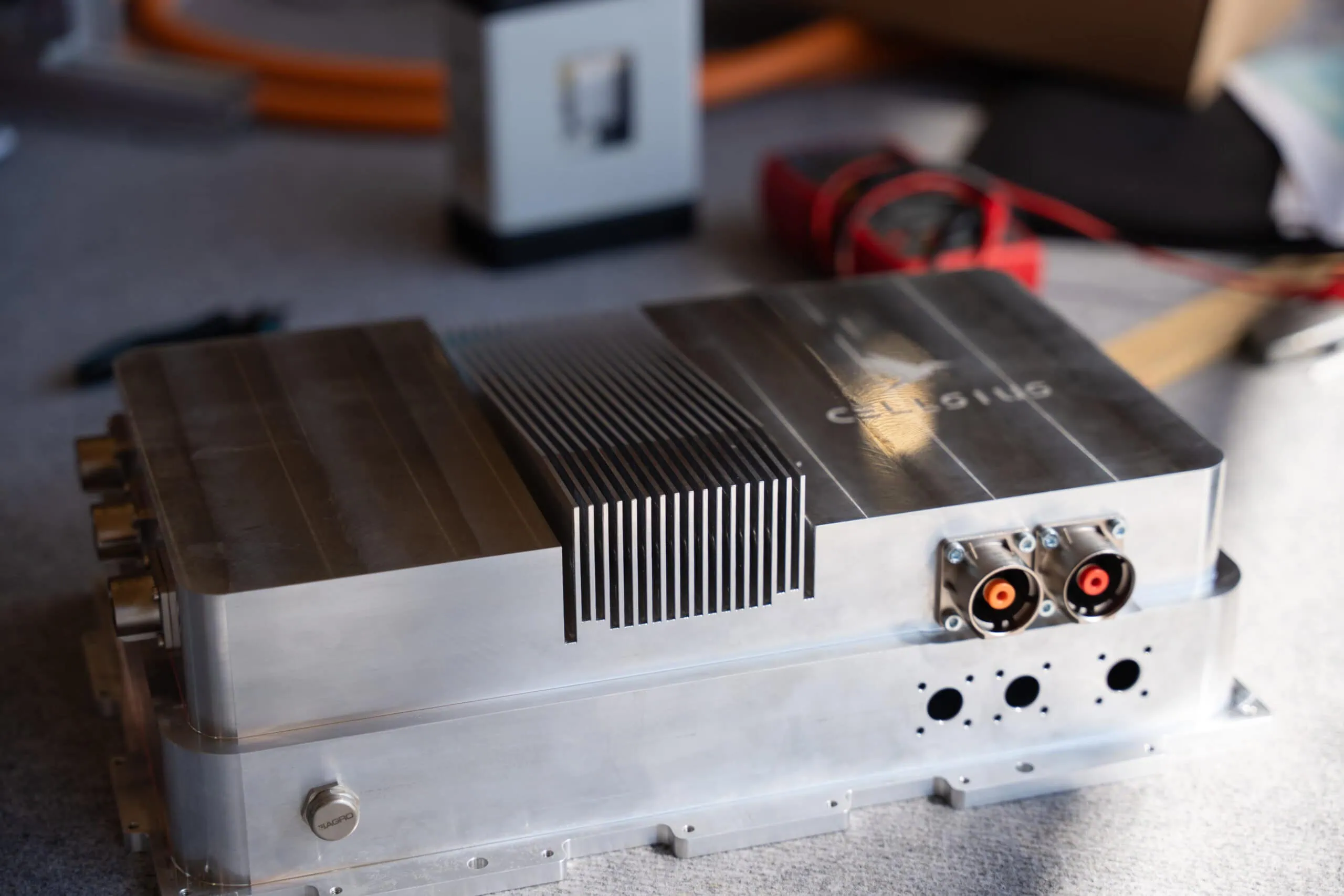

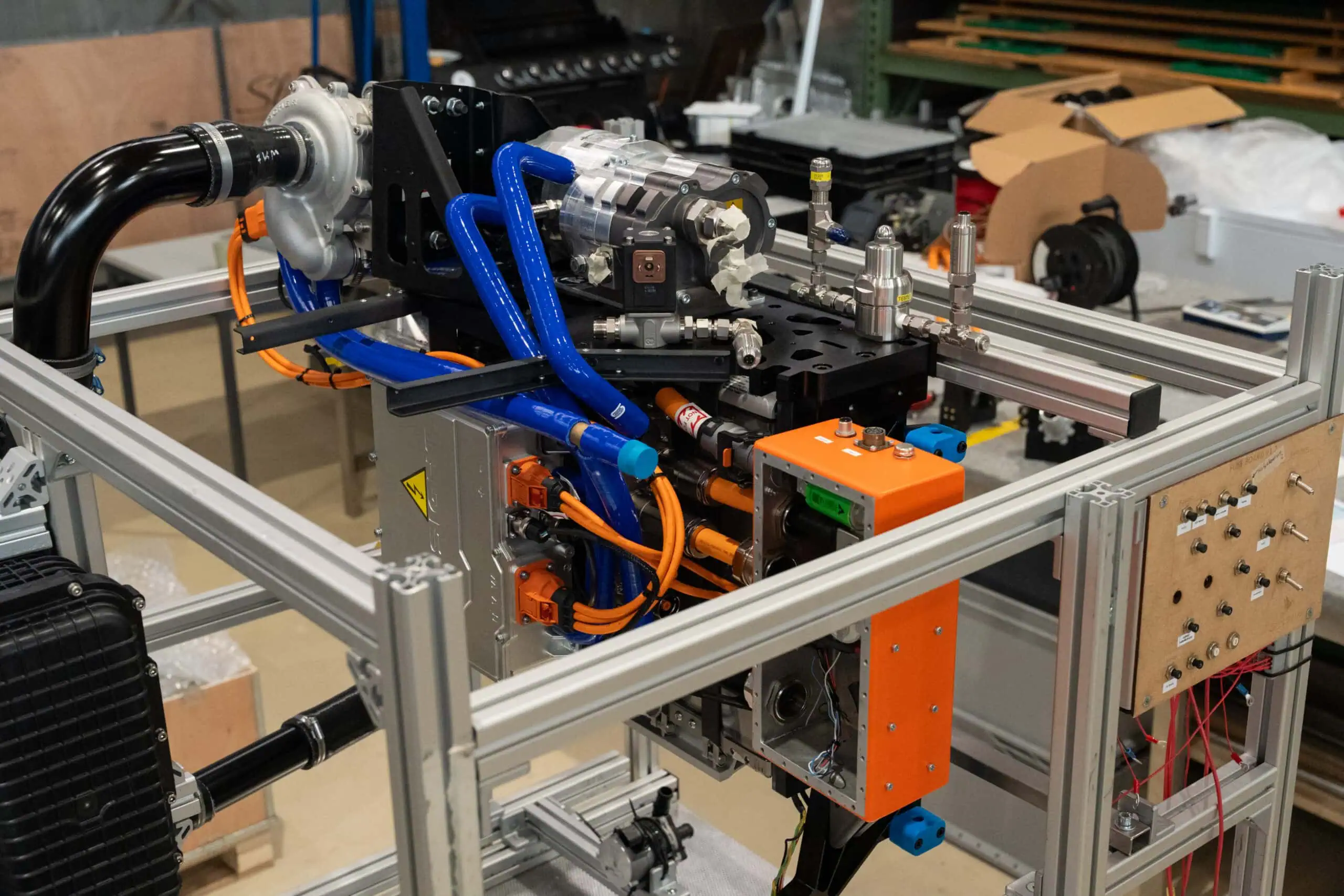

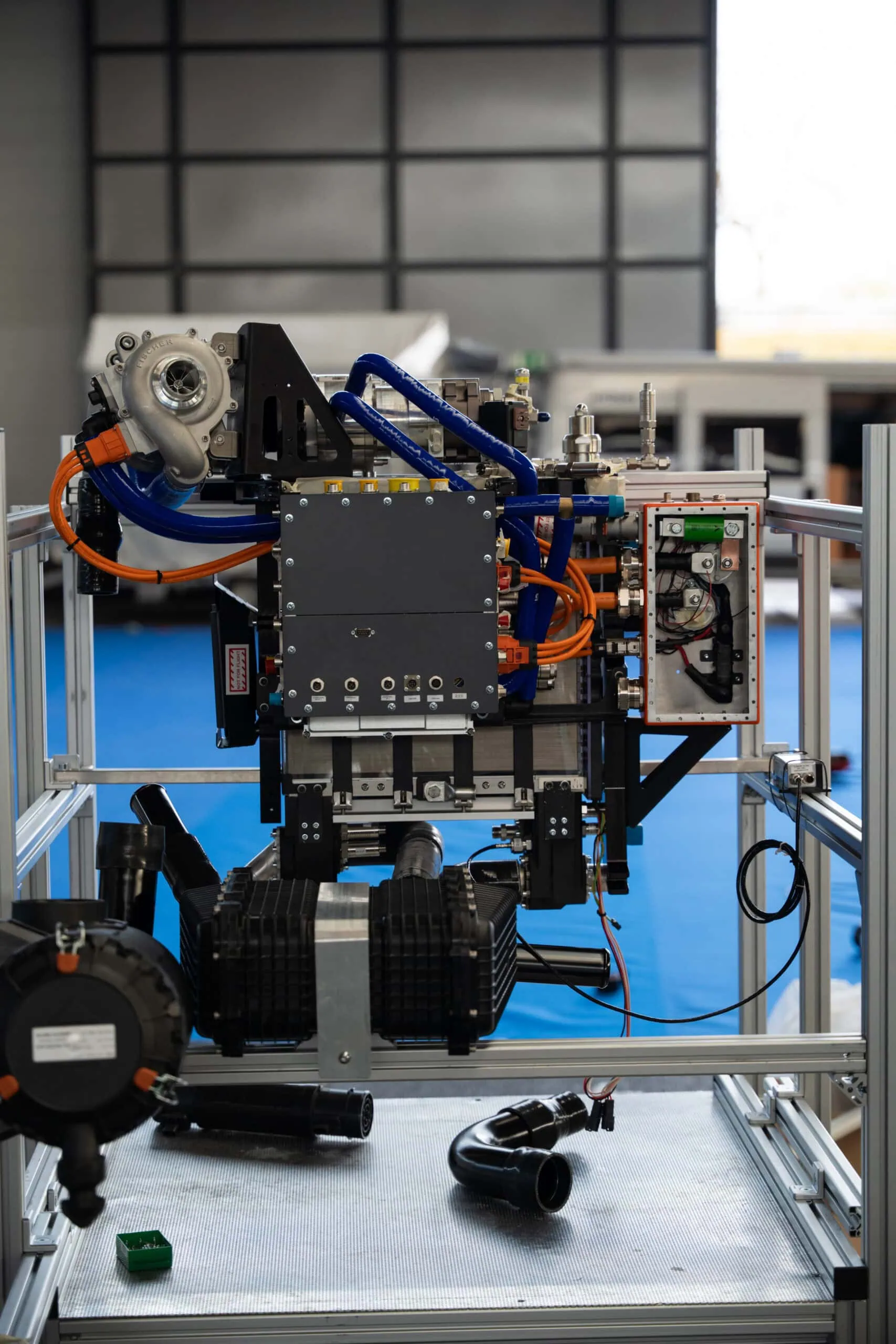

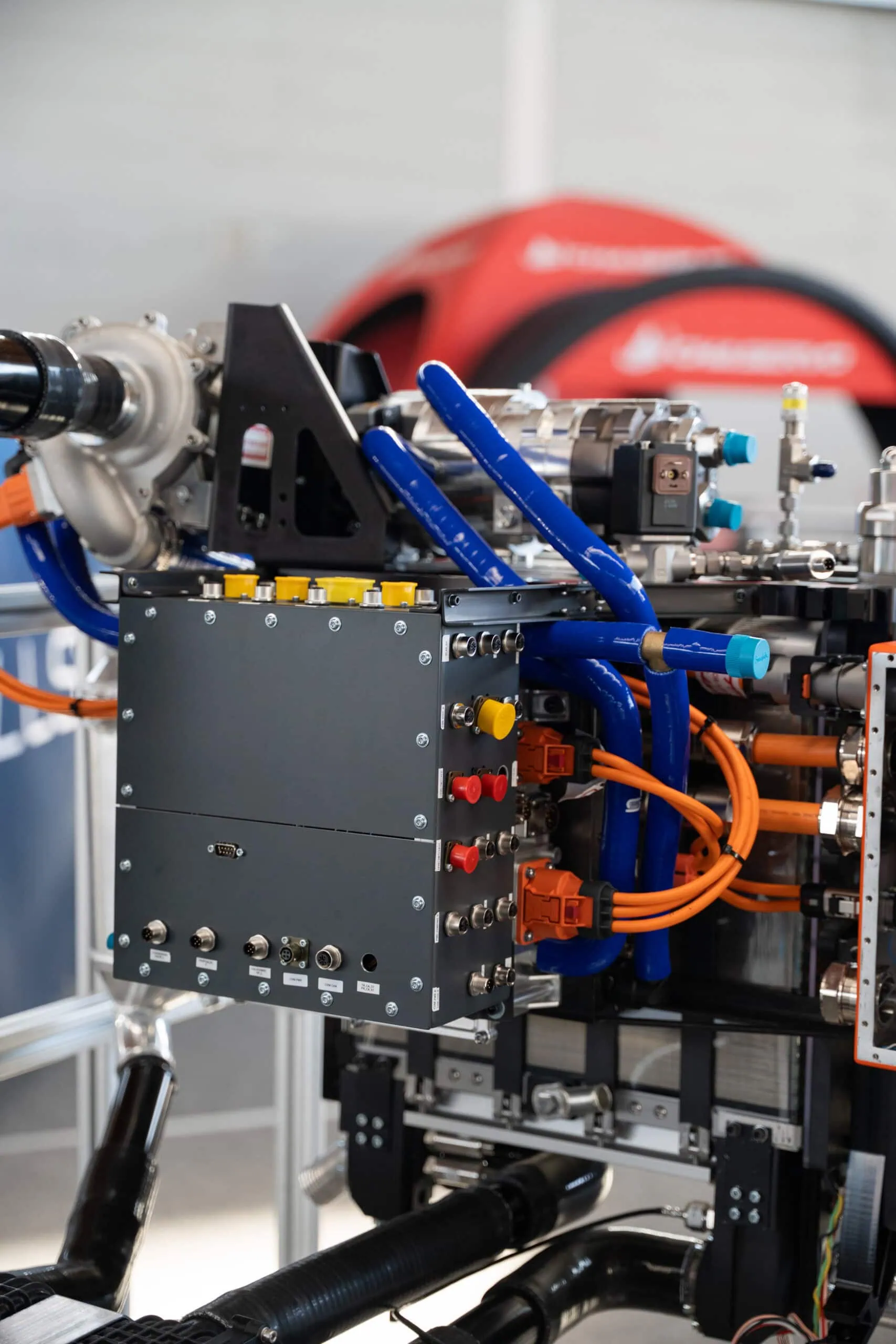

Aviation is under pressure to lower its carbon footprint, and we believe hydrogen offers a clear path forward. The heart of our system is a PEM fuel cell that generates electricity from hydrogen and ambient air—quiet, clean, and efficient. It powers a lightweight electric motor, supported by a buffer battery for dynamic loads and a custom control unit that manages energy flow, diagnostics, and safety.

The aircraft carries 5.2 kg of hydrogen, stored in high-pressure tanks, providing a range of 200 km and a cruise time of 2 hours at a speed of 162 km/h.

Our goal was a system output of just under 100 kW, ensuring safe and stable flight even in alpine conditions. We paid close attention to weight and thermal behavior throughout development—opting for air cooling and continuous thermal monitoring. The biggest challenge was achieving this performance while meeting aviation-grade safety and reliability.

Precision That Makes a Difference

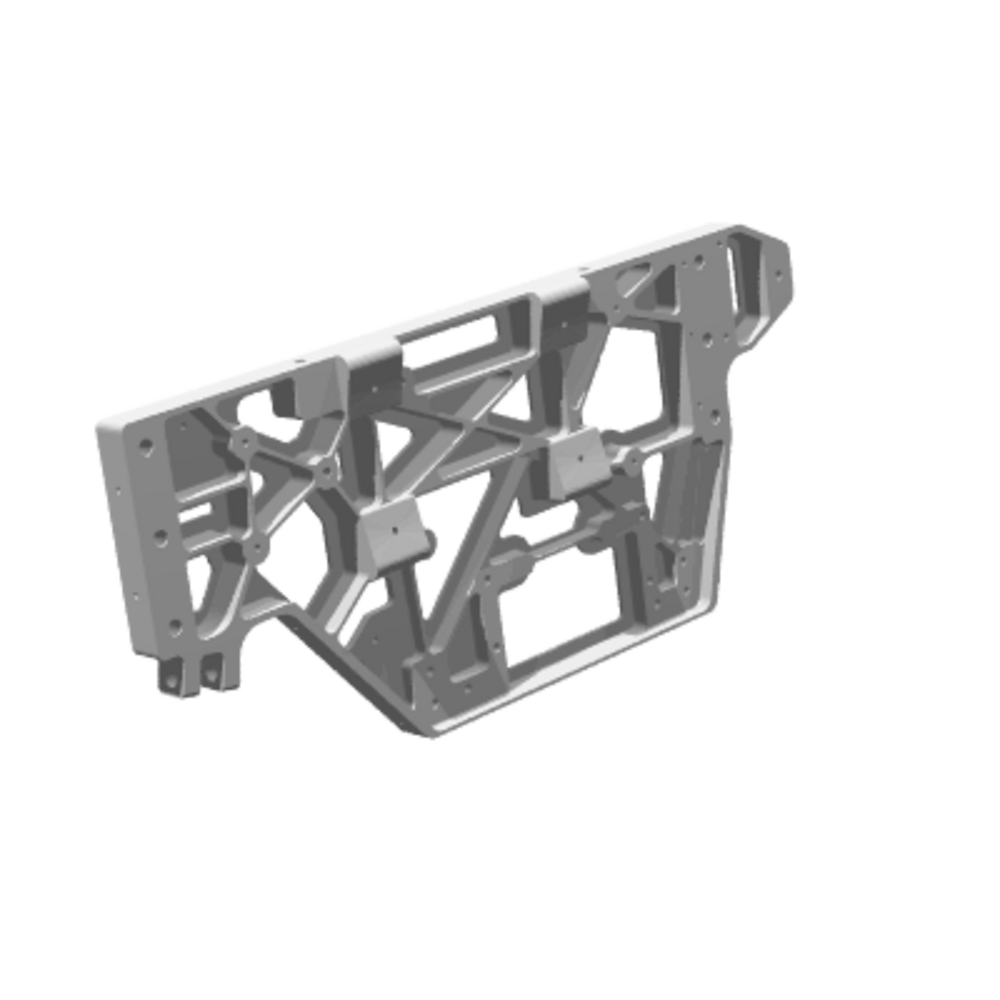

One of the most critical structural components in the entire system is the top plate—a custom-machined aluminium part that connects the fuel cell and the auxiliary components t. It bears mechanical load, ensures structural alignment, and anchors the heart of our energy system.

We designed it with maximum strength-to-weight efficiency in mind, combining tight tolerances with complex geometry. Since producing a part this precise was beyond our in-house capabilities, we relied on external manufacturing to bring it to life. Working with Xometry’s digital manufacturing platform proved to be a practical solution. The ordering process was simple, and the part was delivered exactly to spec, which helped us stay on schedule and move forward with system integration.

Throughout the rest of the build, we developed most structural and system components in-house, using a mix of carbon fibre, milled aluminium, and sheet metal. We prioritised weight efficiency, ease of assembly, and long-term maintainability. Each part was engineered with manufacturing in mind—limiting unnecessary operations and avoiding overcomplication. For components where precision and structural reliability were essential, like the top plate, outsourcing was not just helpful—it was critical to keeping the project moving forward.

Turning Challenges into Learning Opportunities

The work on the fuel cell, especially in the weeks leading up to the winter holidays, became a true test of dedication. Long days and nights were spent preparing for full-load testing. Then came the moment we’d worked for.

After a full year of development, seeing the system finally come to life was magical. It was the moment when theory turned into reality. Beyond the technical accomplishments, we also grew on a personal level. Taking responsibility, solving unexpected issues, and making decisions under pressure—all of this became part of our shared experience.

Looking Ahead: Liquid Hydrogen and Additive Manufacturing

Following the successful first flight, our next major milestone is a hydrogen-powered crossing of the Alps. In parallel, we’re working toward transitioning from compressed to liquid hydrogen—a shift that would significantly improve the system’s energy-to-weight ratio. Achieving this will require new storage solutions, insulation, and fuel handling systems designed for cryogenic conditions.

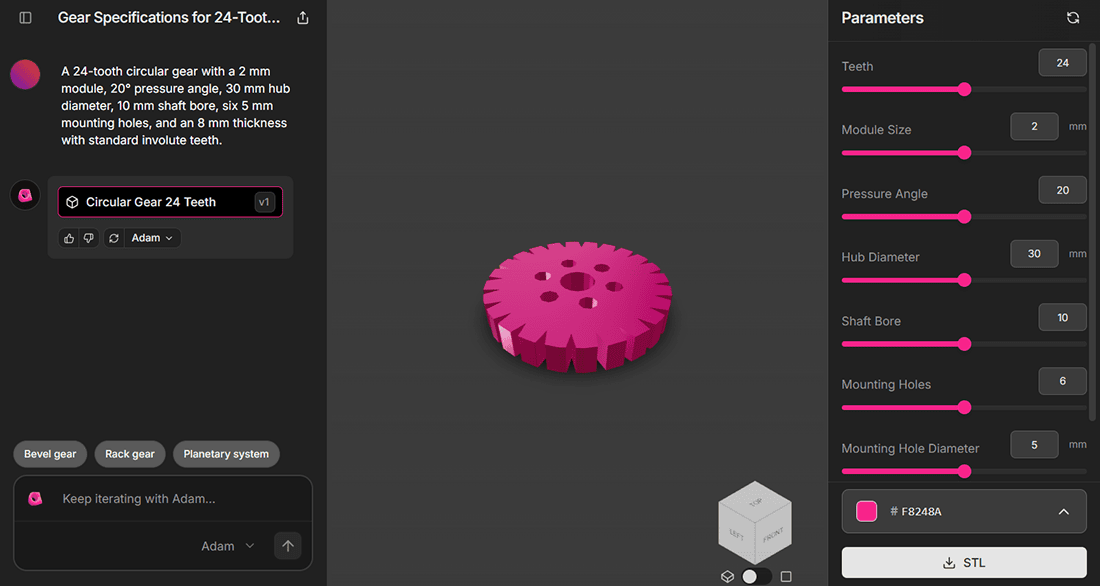

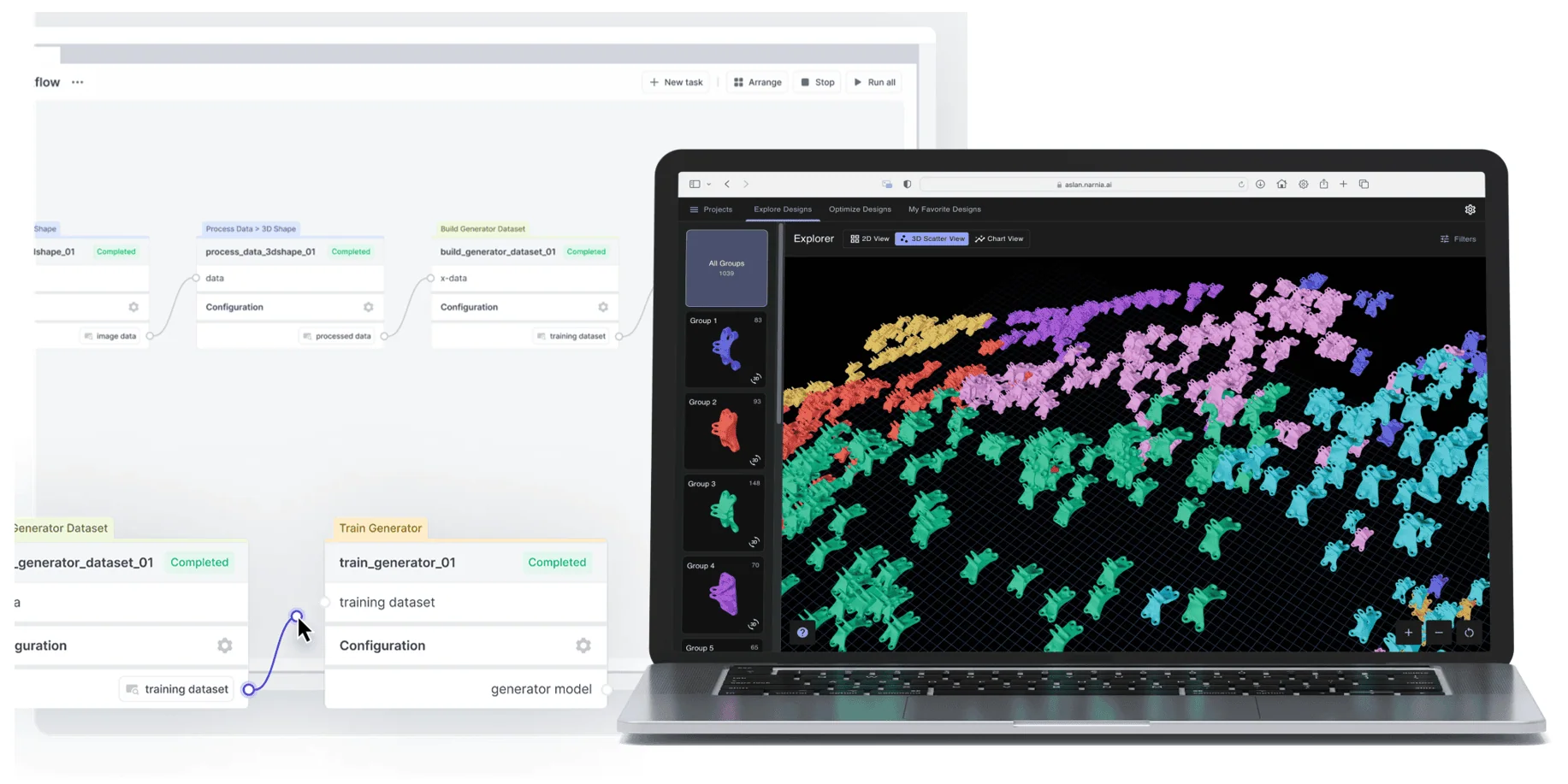

Additive manufacturing will also play a growing role in future development. Combined with AI-driven, generative design, 3D printing allows us to create lighter, more efficient, and structurally complex components—particularly where space is tight and every gram counts. We’re focusing on parts like brackets and mounts, where small improvements in geometry lead to meaningful gains.

Digital manufacturing enables rapid iteration and design flexibility that traditional methods can’t easily match. Together with simulation and in-house prototyping, these tools are helping us move closer to our long-term goal: to make the aircraft not only emission-free, but also quieter, more economical, and a viable alternative for environmentally friendly training and recreational flights.

Have you been involved in developing sustainable energy solutions for engineering projects? Share your approach and key takeaways in the comments.

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)