Premium E-Scooter Prototype Produced in Rapid Time for Micro Mobility Launch

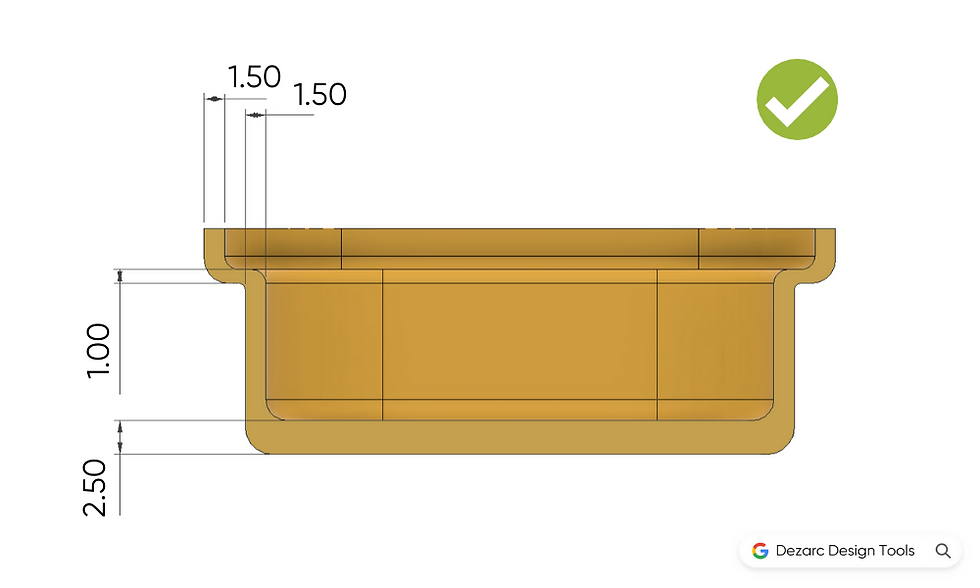

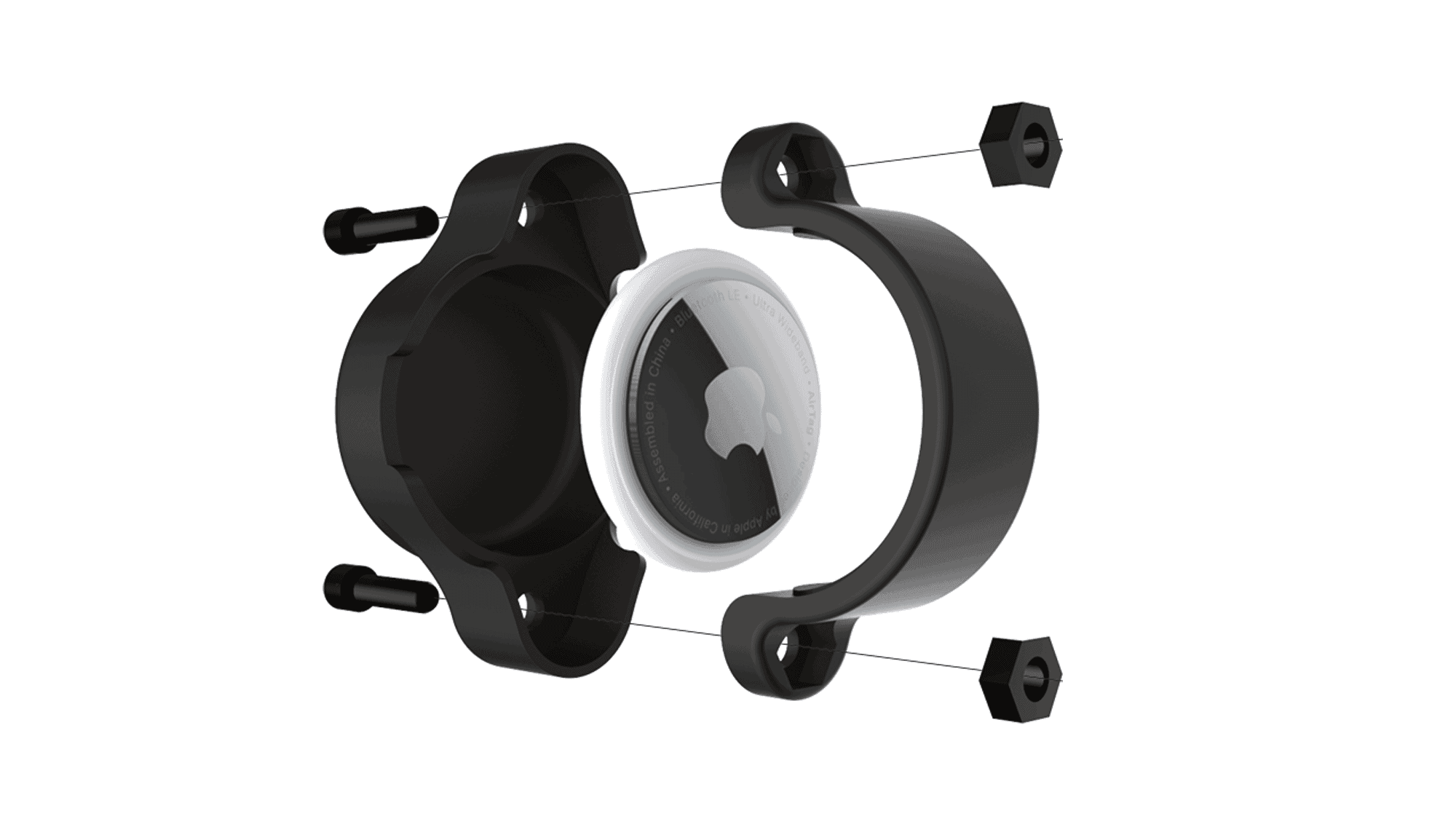

Hilo EV Ltd is a startup micro-mobility company with a mission to deliver intelligent, safety-centric technology that empowers people to move freely, sustainably and with confidence. Xometry plays a crucial role in supporting Hilo EV with the manufacture of high-tolerance CNC machined and 3D printed parts to help build the Hilo One e-scooter prototype.

Read Story

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account

0

0

Download

Download