Hi, we are Elara Aerospace — a student-led team from Munich founded by former members of the TUM Boring project, which made international headlines in 2023 after winning Elon Musk’s Not-a-Boring Competition in Texas.

We aim to show that Europe’s engineers can advance space technology just as fast and fearlessly as their counterparts in the United States. What began deep underground — developing a high-speed tunneling machine — has evolved into a project reaching for the edge of space.

From the Earth to the Edge of Space

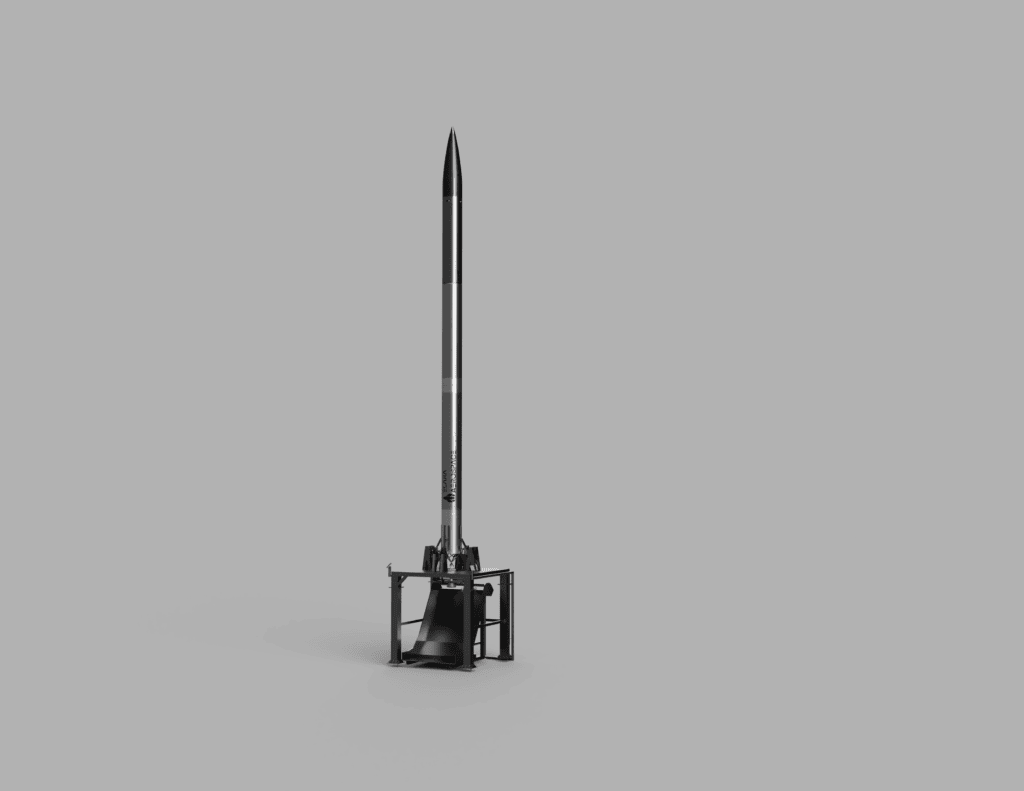

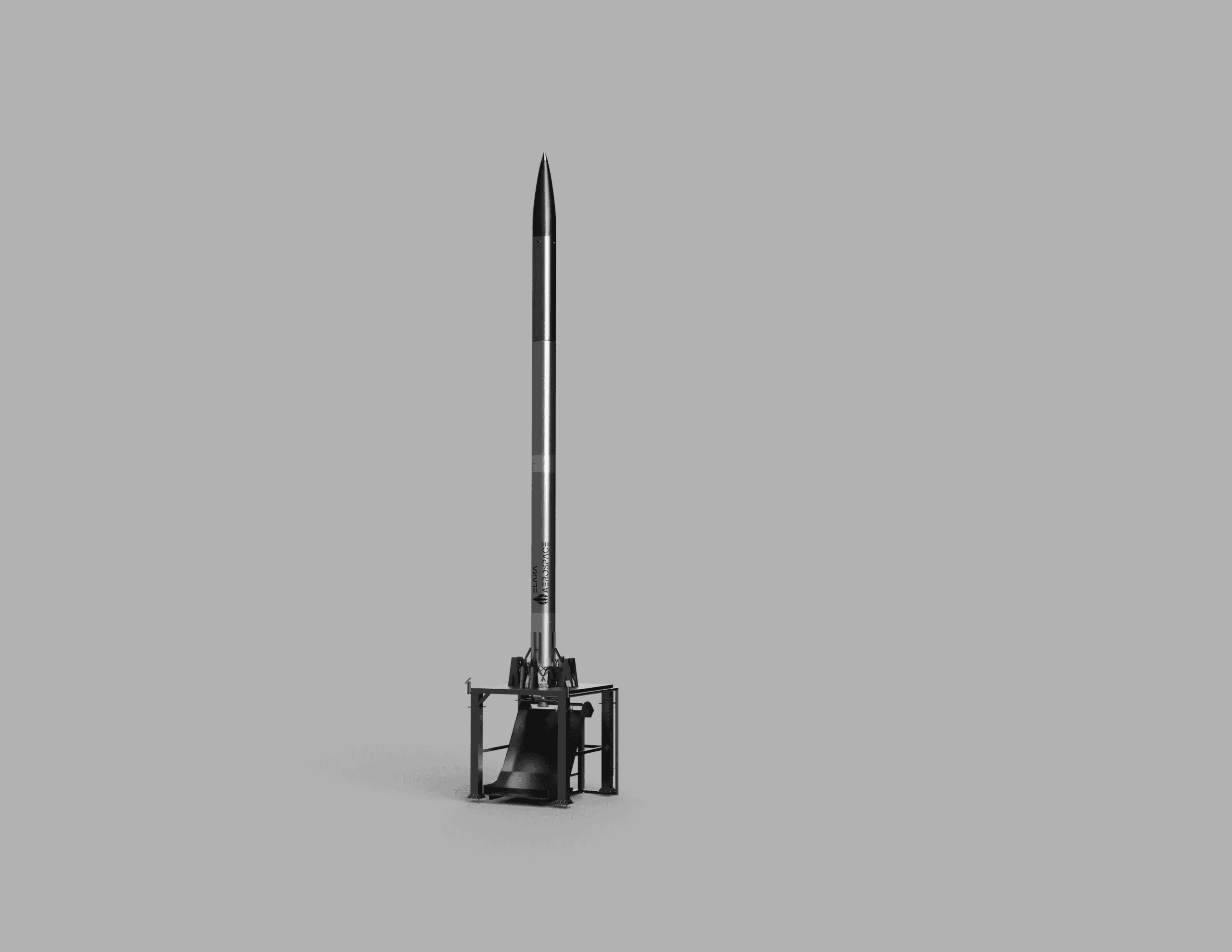

After our success in Texas, we wanted a new challenge, one that would take us beyond the surface and into the skies. Our mission is to build a suborbital rocket powered by a methalox engine, capable of reaching 100 kilometers — the Kármán line, the internationally recognized boundary between Earth’s atmosphere and outer space. Student teams in the United States have already reached that line, and we aim to demonstrate that Europe can do the same and even go further.

But the vision goes beyond records. Elara Aerospace is creating a platform that allows students worldwide to conduct their own experiments on suborbital flights – giving them hands-on access to real aerospace hardware and the opportunity to turn theory into experience.

Inside Our Propulsion System

At the heart of the project lies an electrically driven turbopump — one of the most complex systems in modern rocket engineering. There are almost no off-the-shelf components that can provide the required power density, so we have to design and build nearly everything ourselves.

The combustion chamber alone is a feat of precision engineering: over 600 millimeters in length, machined from a single solid piece.

In parallel, our team is developing the rocket’s structure, test stands, and the software to integrate every subsystem.

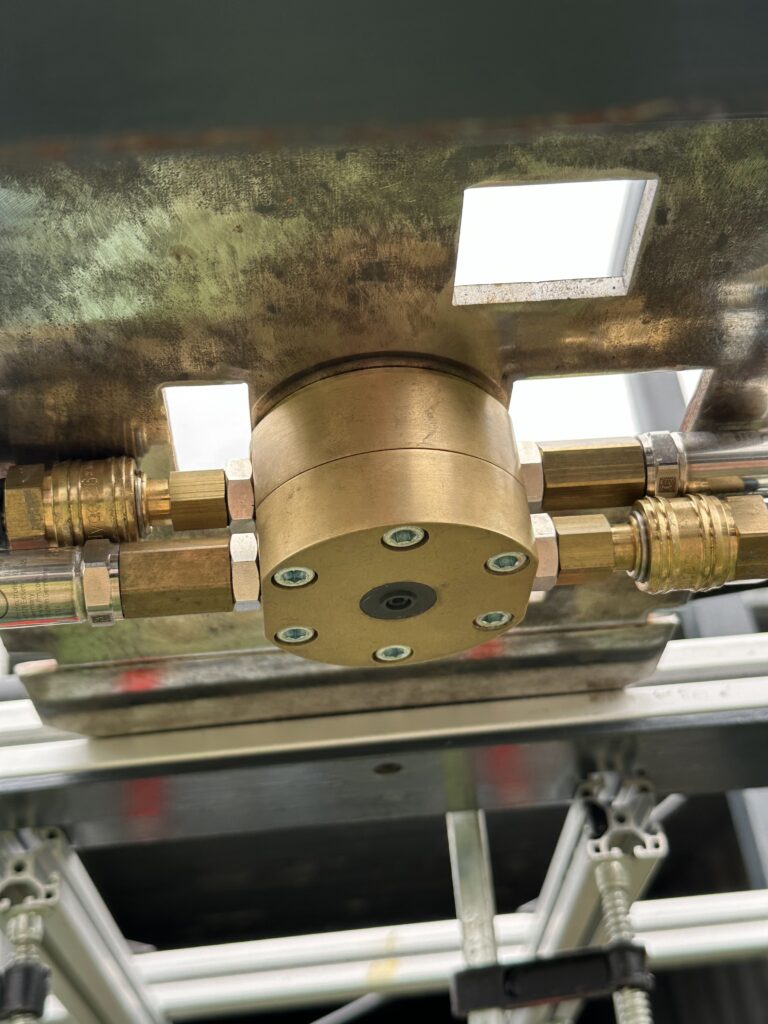

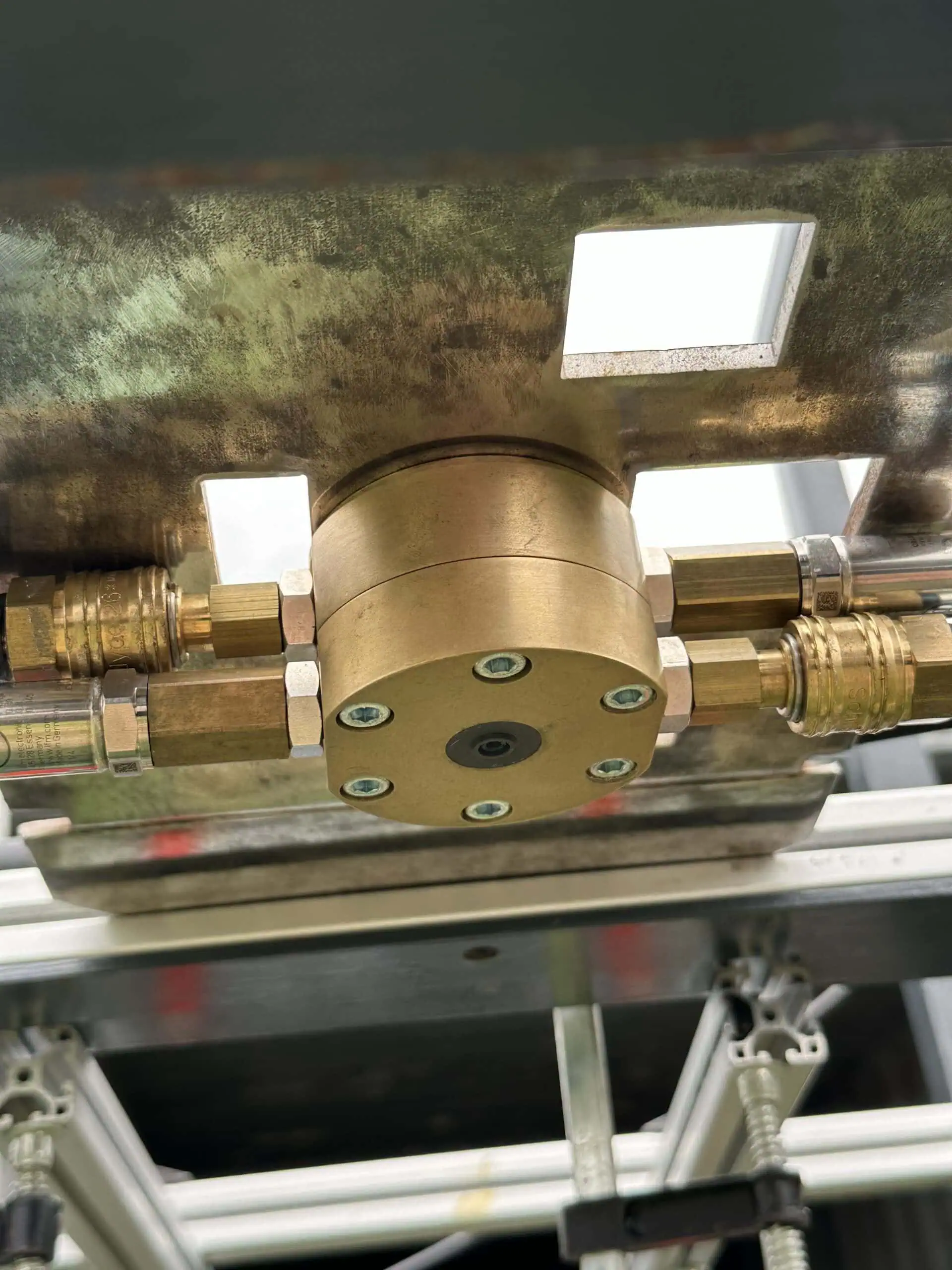

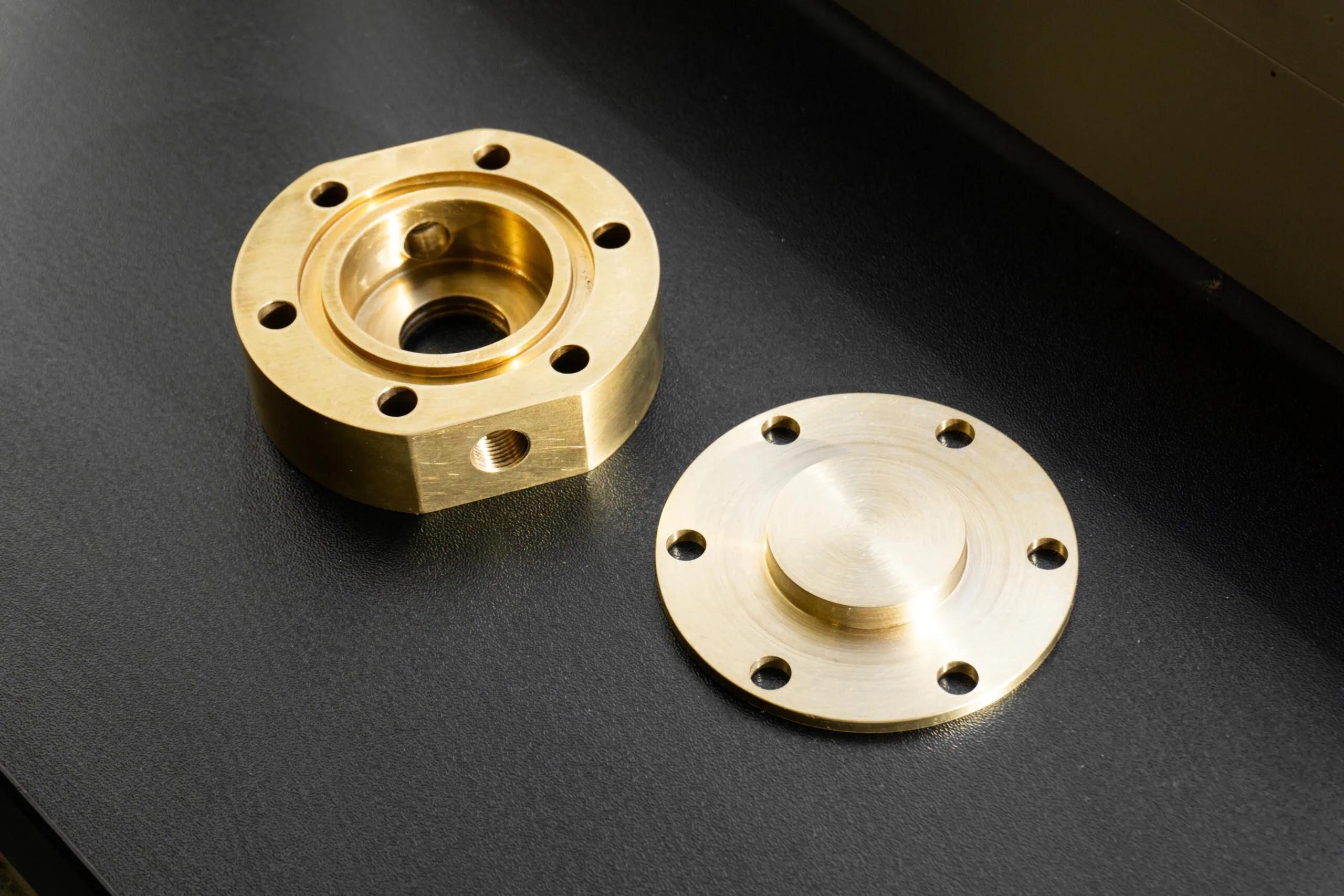

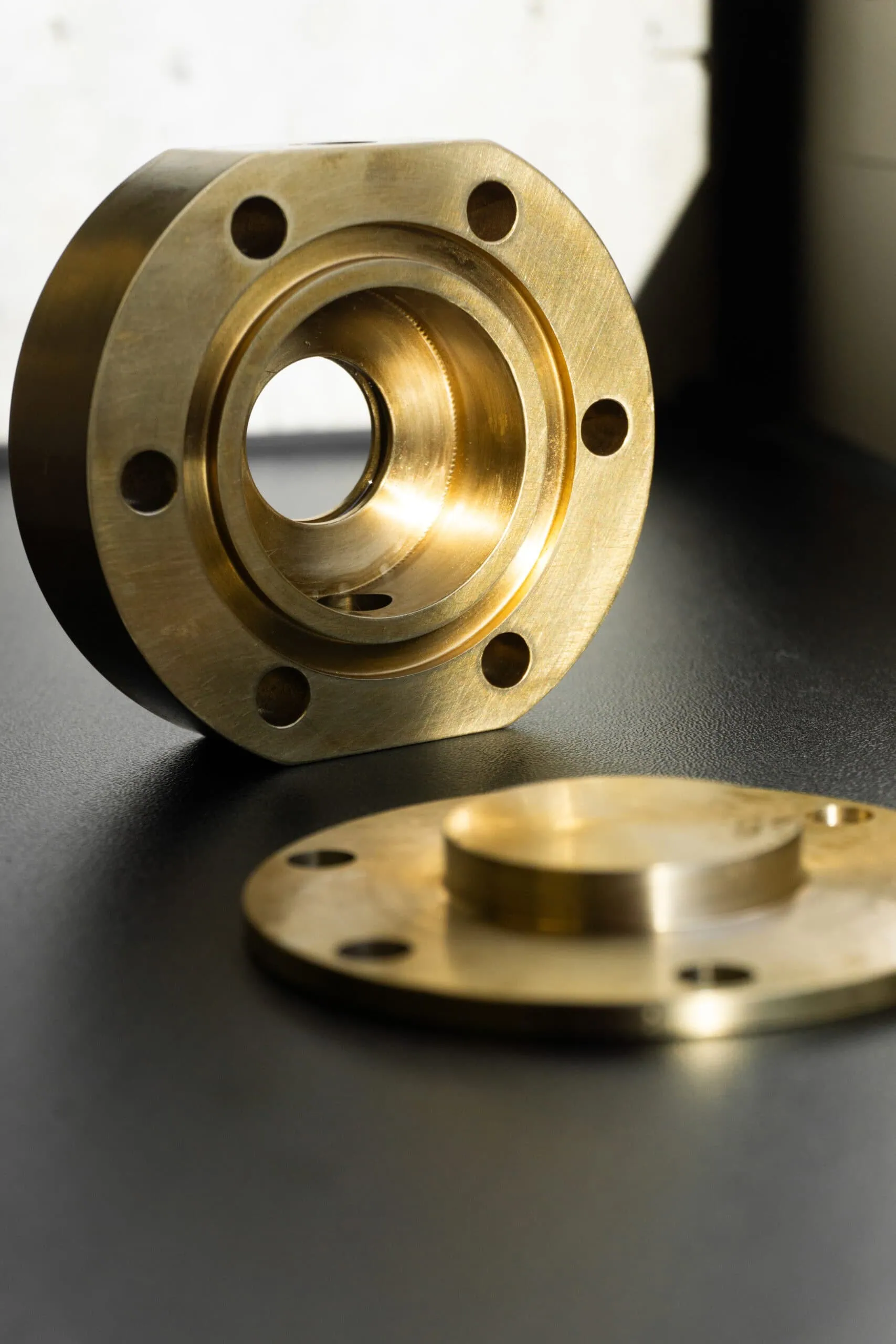

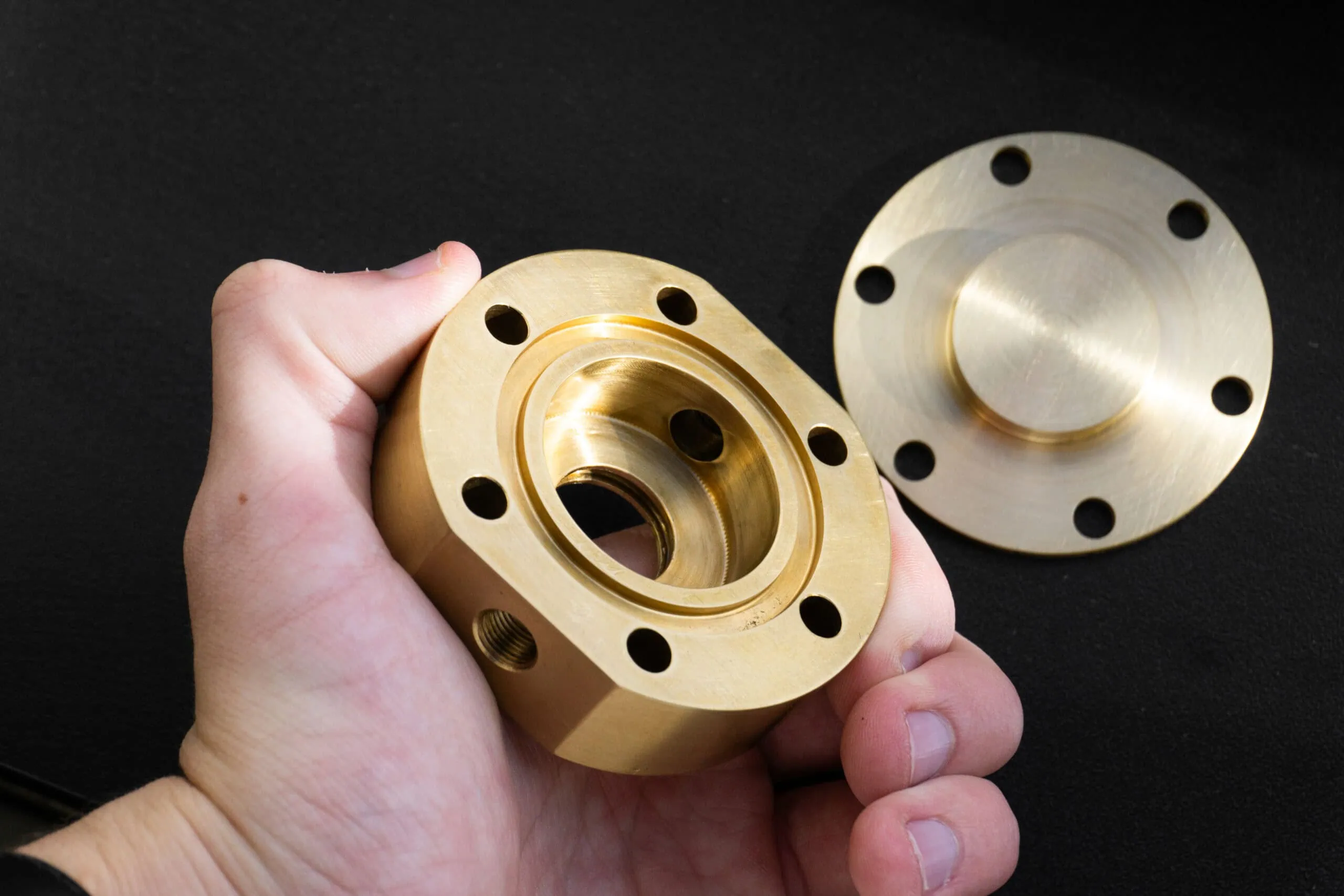

A crucial part of this process is the Injector Test Unit, which enables Elara to test different geometries, measure flow rates and pressure drops, and analyze spray patterns – vital steps toward achieving efficient and stable combustion.

From Design to Precision Manufacturing

To turn these components into reality, we required high-precision manufacturing with fast turnaround times. Through Xometry, we produced a brass test chamber for our injector experiments, machined to the specifications needed for our early-stage testing.

Brass was essential for ensuring safe operation with cryogenic liquids, a key requirement for our future engine work. This setup allows us to iterate quickly during development, especially in phases where every week counts.

The Work Ahead

The next major milestone for Elara Aerospace is the Torch Igniter test – a key system responsible for safely igniting the engine at startup.

Beyond that, the team has an even bolder goal: to launch a rocket reaching 150 kilometers and successfully land it back on Earth.

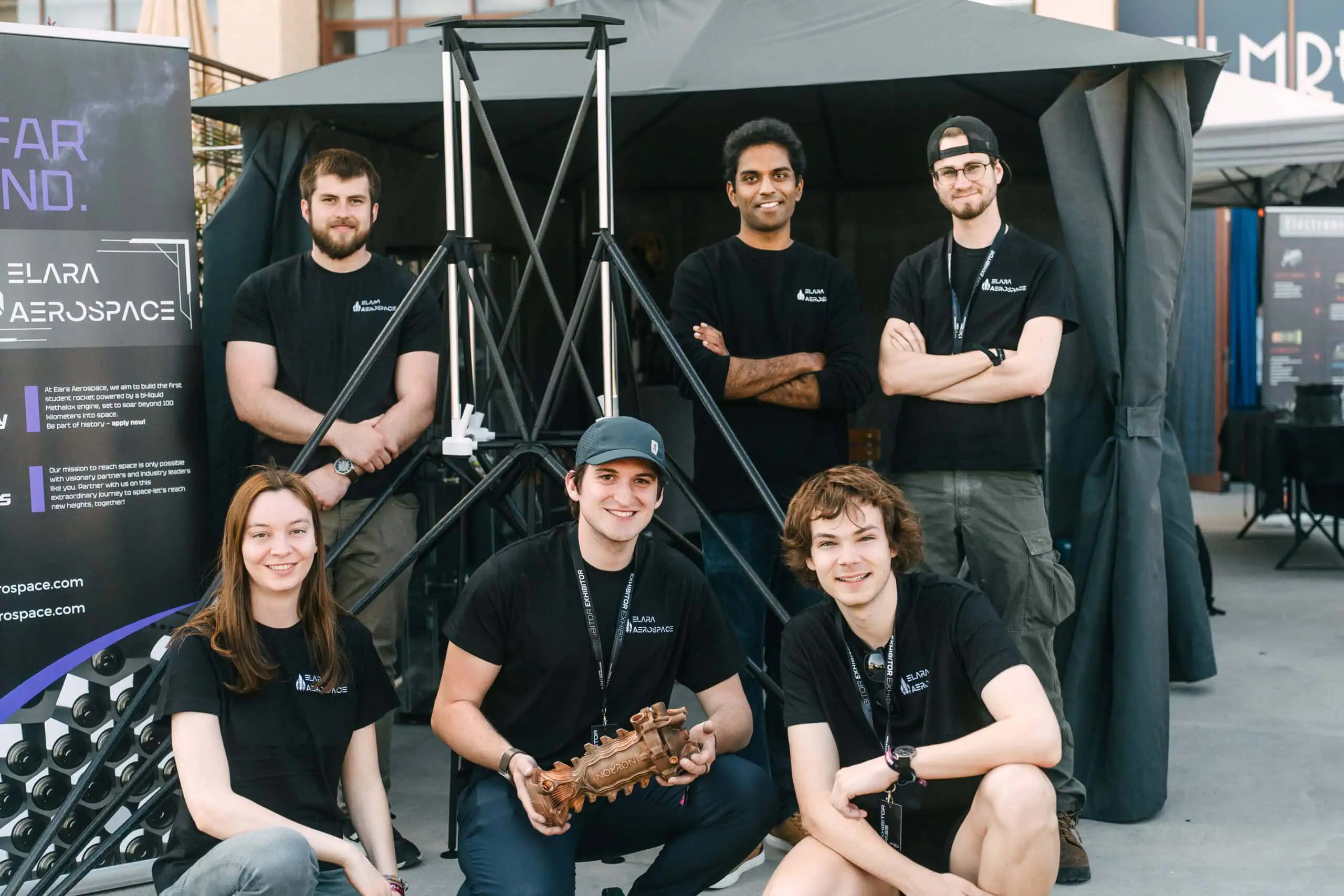

Forty Minds, One Mission

Today, we at Elara Aerospace bring together more than 40 members from over ten nationalities, spanning two continents. Our expertise ranges from engineering and robotics to business and software — united by a shared drive to explore new frontiers.

We get to apply our theoretical knowledge in a field with huge potential, and as students we can contribute meaningfully across every area of the project — from welding and design to presenting at events like Autodesk University.

Balancing studies and rocket science isn’t easy. Days are for lectures; nights and weekends are for building, testing, and collaborating with partners.

“Just Start”

When it comes to advice, we always return to a simple principle: just start. There will always be people who share your passion but never dared to take the first step — be the one who does, and open the door for real innovation.

What began as a tunneling project beneath the earth’s surface could soon mark Europe’s path to the stars, showing that the road to space begins with vision, persistence, and precision.

Learn more and support the project: gotospace.elara-aerospace.com.

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)