PC-PBT

- Alternative Designations: Polycarbonate-Polybutylene Terephthalate

Description:

PC-PBT is a high-impact, flame-rated resin known for excellent mechanical strength, chemical and weather resistance, and good processability. Ideal for injection molding, it’s used in automotive components, electrical enclosures, consumer goods, industrial housings, and durable medical device components, making it suitable for demanding applications across various industries.

Material Properties

Processes:

Special properties

- Chemical resistance

- Flame retardanсy

- Heat resistance > 100℃

- Impact resistance

| Property | Value, metric | Value, Imperial |

|---|---|---|

| Density | 1.2 g/cm3 | 1.2 g/cm3 |

| Ultimate Tensile Strength | 55 MPa | 7.9 ksi |

| Flame retardancy (UL94) | HB | HB |

| Hardness | - | - |

-

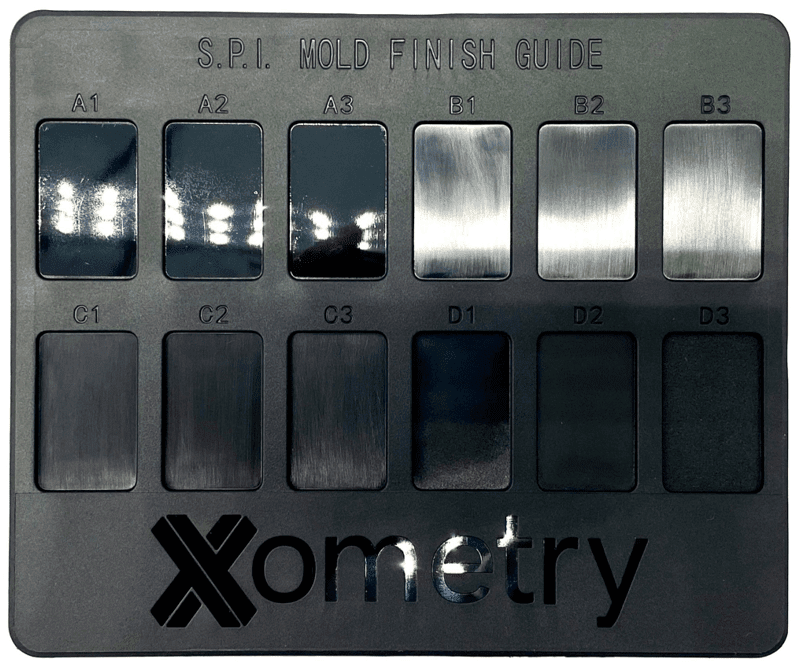

Injection moulding SPI surface finishesInjection Moulding SPI Finishes

SPI

SPI finishes are a set of standard mould finishes with different polished textures for enhanced properties.

Notes:A1, A2, A3, B1, B2, B3, C1, C2, C3, D1, D2, D3

Final result:

- Heavily polished, to semi-gloss to fine and coarse matte depending on the selection

-

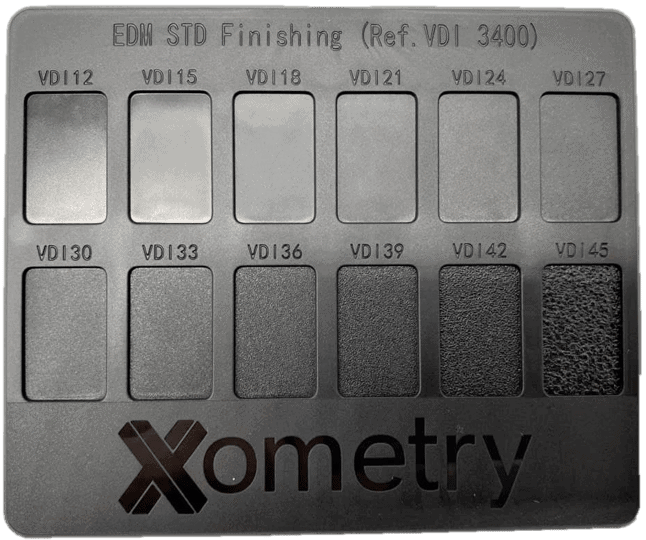

Injection moulding VDI surface finishesInjection moulding VDI surface finishes

VDI

VDI is an international standard for mould texturing of matte surfaces. It is mainly processed by Electrical Discharge Machining (EDM) when mould machining.

Notes:VDI12, VDI15, VDI18,VDI21, VDI 24, VDI27, VDI30, VDI33, VDI36, VDI39, VDI42, VDI45

Final result:

- Fine-to-coarse grain depending on the selection

-

Custom Finishing

If you select a custom finish in the Instant Quoting Engine it will require manual review. Manual quoting usually takes 1-2 business days.

Notes:Submitting for manual review with a custom request does not guarantee a quote.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account