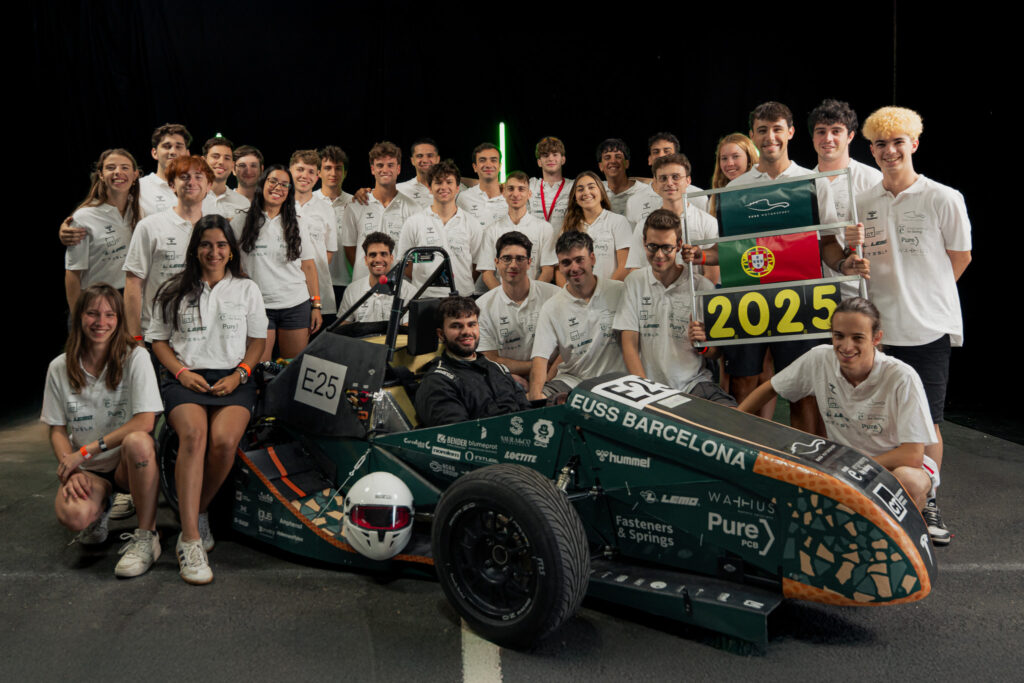

At EUSS Motorsport, I serve as Head of Vehicle Dynamics, where I design the assemblies that complement the chassis, components essential for the car’s performance on track. My fascination with mechanics led me to study engineering, and discovering that my university had a Formula Student team made joining an obvious choice. It gave me the chance to put theory into practice, learn far beyond the classroom, and work alongside people who share the same passion for innovation.

From Combustion to Electric

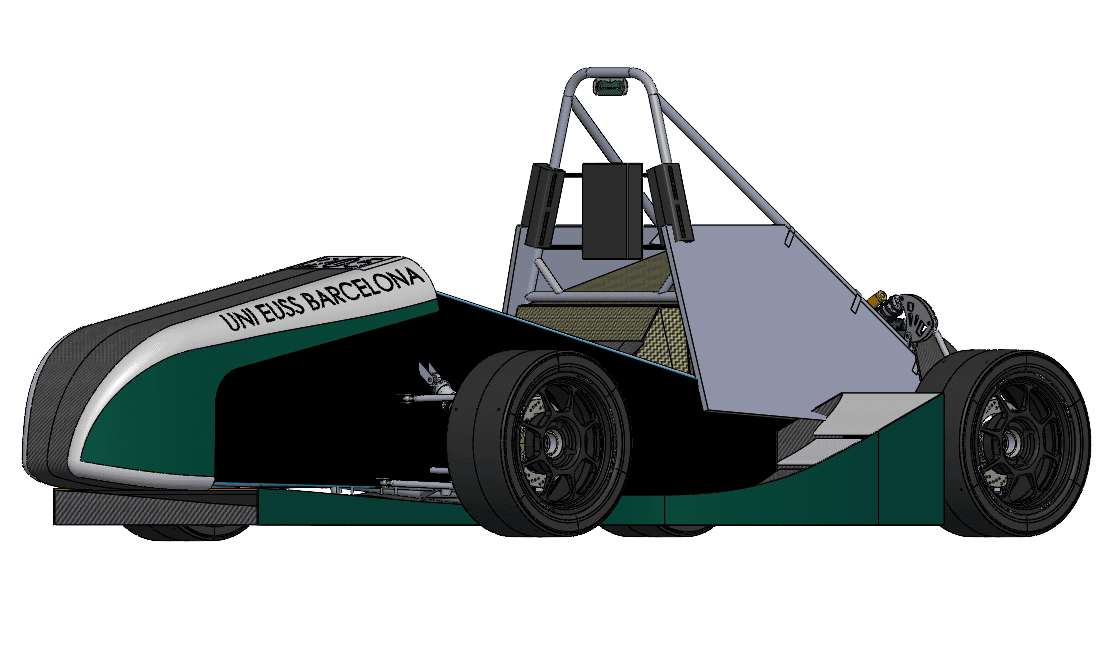

Since its founding in 2017 at the Escola Universitària Salesiana de Sarrià (EUSS) in Barcelona, EUSS Motorsport has designed and built Formula Student single-seaters—small-scale Formula 1 cars. After developing three combustion-engine cars, we made a decisive change: transitioning to electric.

This move wasn’t just about keeping up with the times. It was about aligning with the industry’s shift toward sustainable mobility, challenging ourselves, and staying ahead of competition rules. Formula Student Germany, the most prestigious event, will soon no longer accept combustion-powered cars—so switching early gave us an advantage.

Our first steps into electric racing came with the EM-04 car, which we presented at Formula Student Spain 2024. That experience gave us valuable insights into high-voltage systems, integration challenges, and safety standards, and it became the foundation on which the EM-05 was built.

Still, the transition has been the biggest challenge in our history. Electric propulsion required us to rethink the vehicle’s entire architecture. High-voltage systems, strict safety rules, and new approaches to dynamics meant nothing could be reused from our combustion era. For us in the Dynamics department, this meant not only designing our assemblies but also ensuring they worked seamlessly with electronics, powertrain, and aerodynamics. Every decision had ripple effects, and mistakes often taught us faster than successes.

The Process Behind Our Most Advanced Car Yet: The EM-05

Designing and building a Formula Student car starts with setting our main goals—whether that’s reducing weight, improving lap times, or implementing new technologies. Once the objectives are clear, each department begins the conceptual design phase, brainstorming ideas to reach those targets.

From there, we move to detailed design in CAD, run simulations, and check that all the parts fit and work together. Communication between departments is crucial, because a single change in one system can affect many others. Once the design is finalized, we move into manufacturing, assembly, and finally on-track testing, where real-world performance often reveals details we need to adjust. Seeing the car progress from sketches to reality and then watching it perform on track is, without doubt, the most rewarding part of the process.

The EM-05, our second electric single-seater, is the result of everything we learned from its predecessor, the EM-04. By applying lessons from the past season and competitions, we’ve consolidated a motivated, cohesive team ready to push further.

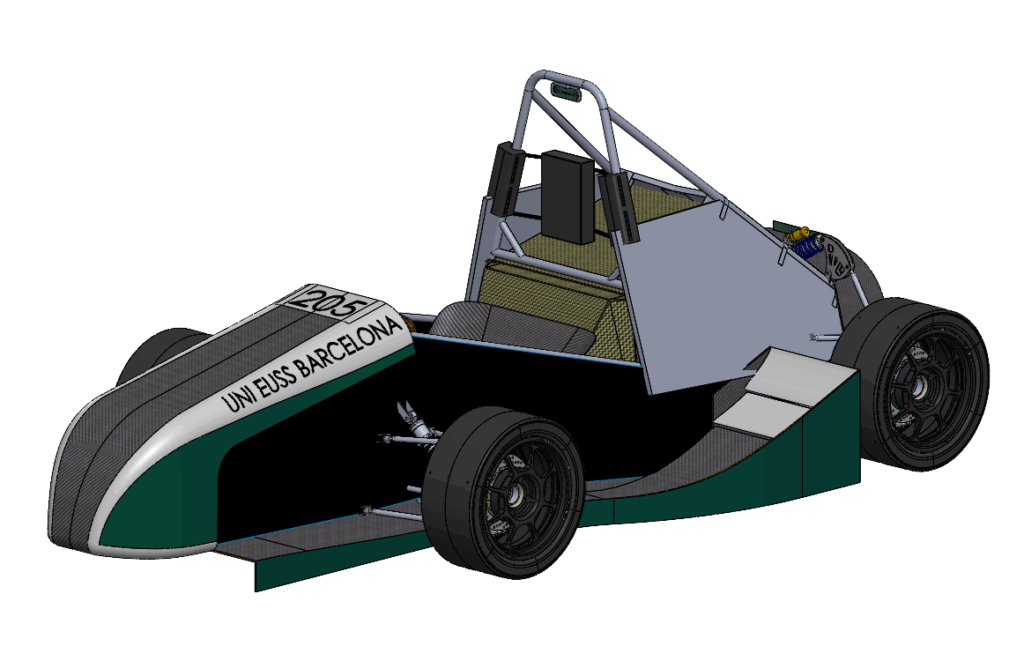

The EM-05 incorporates substantial improvements compared to the EM-04:

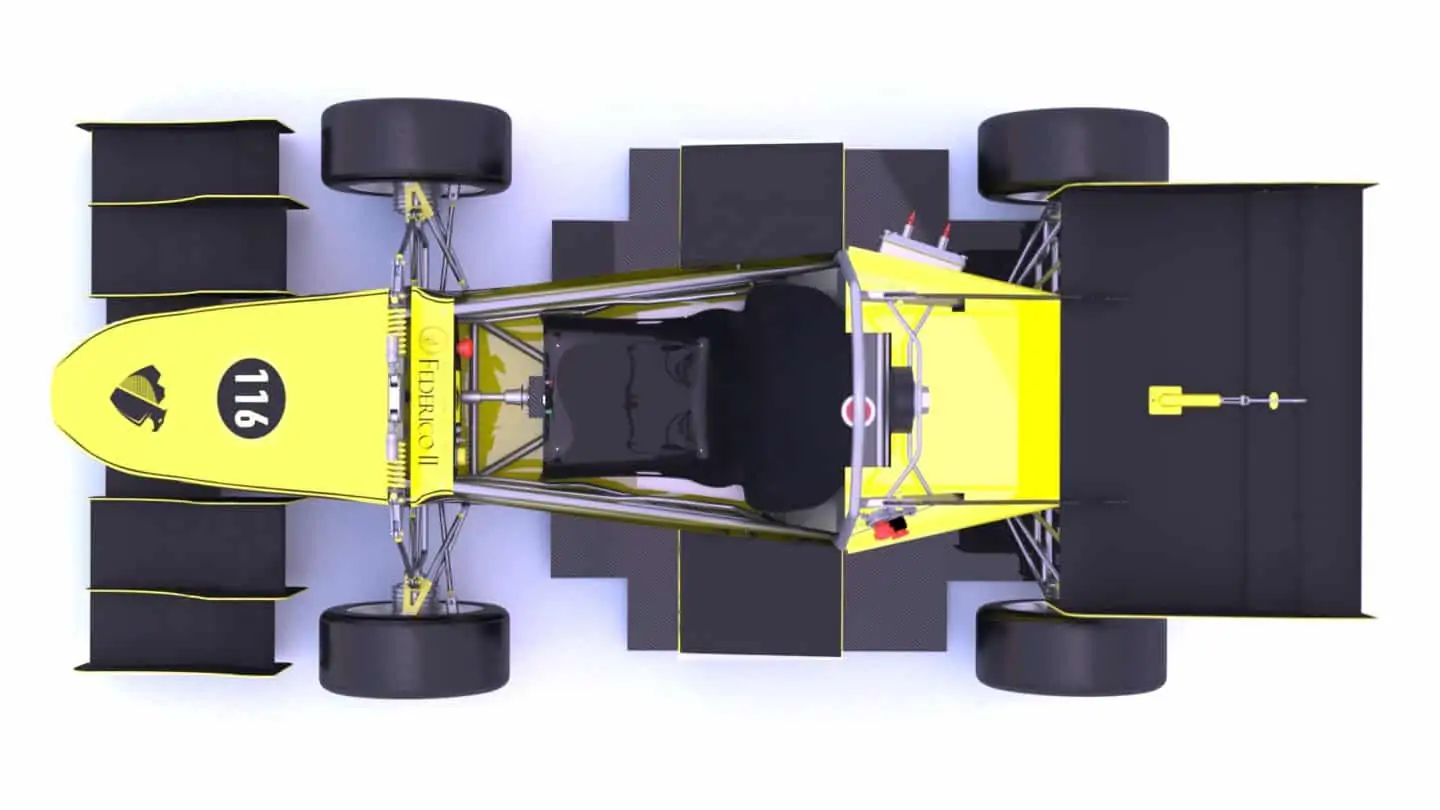

- Aerodynamics: Perhaps the most striking achievement is the new aerodynamic package, which offers a 260% improvement in efficiency. This was made possible by design corrections and the return of our specialized aero team after four years.

- Chassis and packaging: We simplified the general structure of the chassis, optimizing packaging and the distribution of subassemblies to achieve the necessary torsional rigidity while keeping weight down.

- Suspension: We introduced a new rear suspension geometry to improve handling and adaptability.

- Cooling: The cooling system for the motor-inverter assembly has been optimized, boosting performance and reliability.

- Electrical systems: We reinforced safety with new, more reliable plates and an upgraded Battery Management System (BMS)

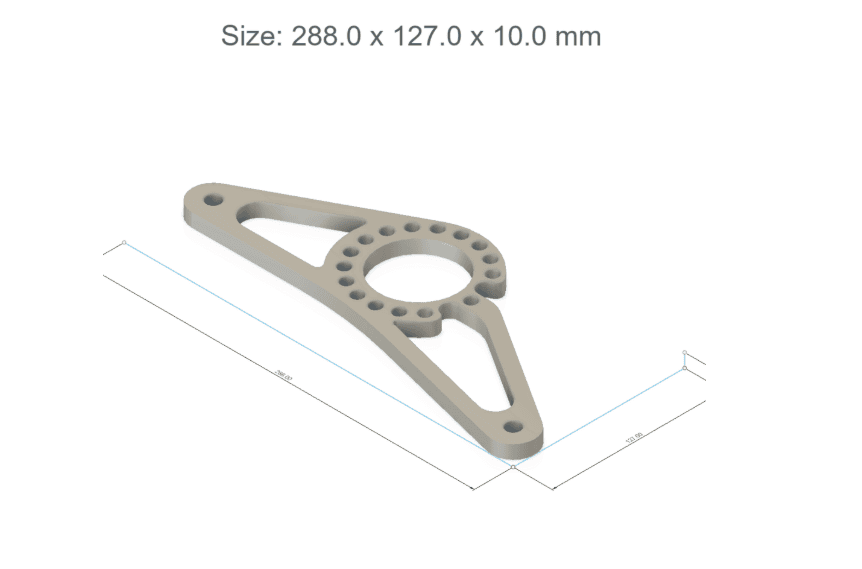

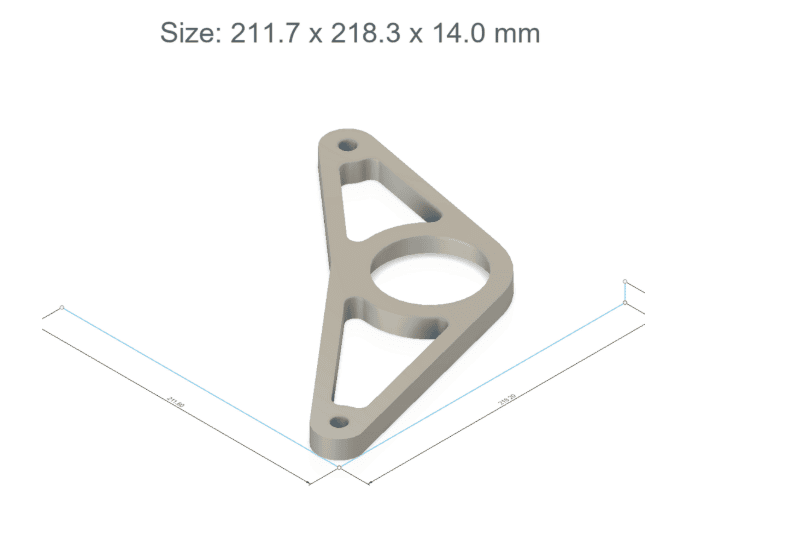

- Drivetrain: We redesigned all the mechanical mounts of the drivetrain to the chassis to ensure correct alignment of the sprocket with the crown. In this process, the parts specifically manufactured were the motor axle, the motor axle support, the motor mount, and the differential mount, key components to guarantee the reliability of the system.

Engineering by Doing

The EM-05 is more than a car. It symbolizes what a group of committed engineering students can achieve when passion, creativity, and technical skill come together. It embodies our motto, Engineering by Doing: learning through practice, trial and error, and teamwork.

We unveiled the EM-05 at our university in Barcelona, at an event attended by industry representatives, students, and faculty.

Shortly after, we brought it to two key competitions: Formula Student Portugal in Castelo Branco and Formula Student Spain at the Circuit de Barcelona-Catalunya in Montmeló. These moments—seeing the car built by our own hands racing on track—were the most rewarding proof of our work.

Facing Challenges Together

One of the biggest challenges we face every season is time and resource management. As a student team, we don’t have the same infrastructure as professional outfits, so careful planning, organization, and communication are essential.

The transition to electric has been a steep learning curve, but what keeps us moving forward is our ability to adapt and to work closely as a team. Every mistake or setback becomes a lesson that makes us stronger. Even when continuity is difficult, with experienced members graduating and new ones joining, the project itself becomes the bridge, carrying knowledge and experience forward.

Looking Ahead

Looking further ahead, our focus is to validate our designs, improve weak points, and keep optimizing every system. We’re already thinking about ambitious goals such as introducing all-wheel drive or experimenting with active aerodynamics in future models.

My advice to anyone starting a similar project is simple: never underestimate the importance of good communication and organization. Even the best design will fail without strong coordination between departments. And don’t be afraid to make mistakes, every challenge is an opportunity to learn and come back stronger.

Have you ever taken part in designing or building a race car? Share your experience and lessons learned in the comments.

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)