Suggested Topics

Topic

Replies

Views

Activity

Feasibility of using DMLS aluminum parts for pressure-test prototypes

I’m testing the idea of using DMLS Aluminum parts as pre-production prototypes for a high-pressure fluid system. These would be static housings only, not moving parts. Has anyone validated 3D-printed aluminum components under realistic... read more

0

103

Nov 24

Process for a low-volume stainless steel pump impeller

Hi all, I’m designing a stainless steel impeller for a small pump (diameter around 80 mm). Would you go for metal additive manufacturing or casting if you need tight tolerances on the blades and... read more

1

196

Nov 24

Minimum letter size for raised text on SLS nylon parts

I’m working on a medical device enclosure that needs raised lettering (product name and serial number) on the lid, printed in SLS nylon. The letters are around 2 mm high with a stroke width... read more

4

514

Oct 30

2 mm stainless sheet bend radius

I’d like some help with a project. I’m designing a stainless steel 304 enclosure with multiple 90° flanges (sheet thickness ~2 mm). For strength and edge alignment, I want the inside bend radius to... read more

4

404

Oct 24

Urethane casting for sensor housings

Hello all, I’m looking for some advice. I’m working on a prototype of a handheld casing for an outdoor sensor (approx. 20×10×5 cm) that needs to be rigid, weather-resistant, and have fine surface details.... read more

6

208

Nov 13

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

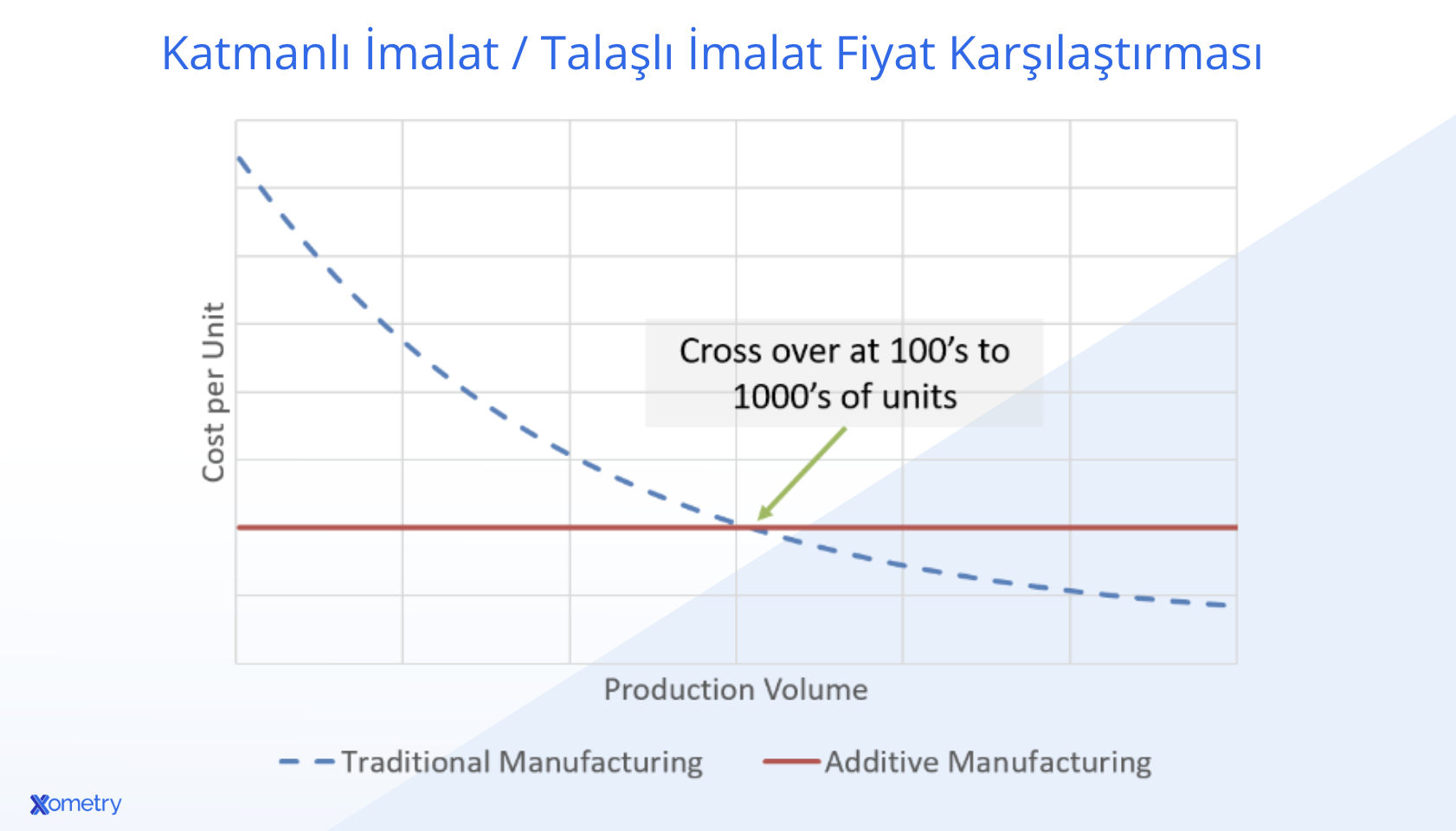

Login with my Xometry account  However, remember that this graph only shows the change in unit cost depending on the quantity. If you notice, the intersection point is somewhere between 100-1000 units. At Xometry, we can recommend the most suitable production method for you according to the part design, delivery time, material properties, and project requirements. Important Notes:

However, remember that this graph only shows the change in unit cost depending on the quantity. If you notice, the intersection point is somewhere between 100-1000 units. At Xometry, we can recommend the most suitable production method for you according to the part design, delivery time, material properties, and project requirements. Important Notes: