Sheet metal forming?

d

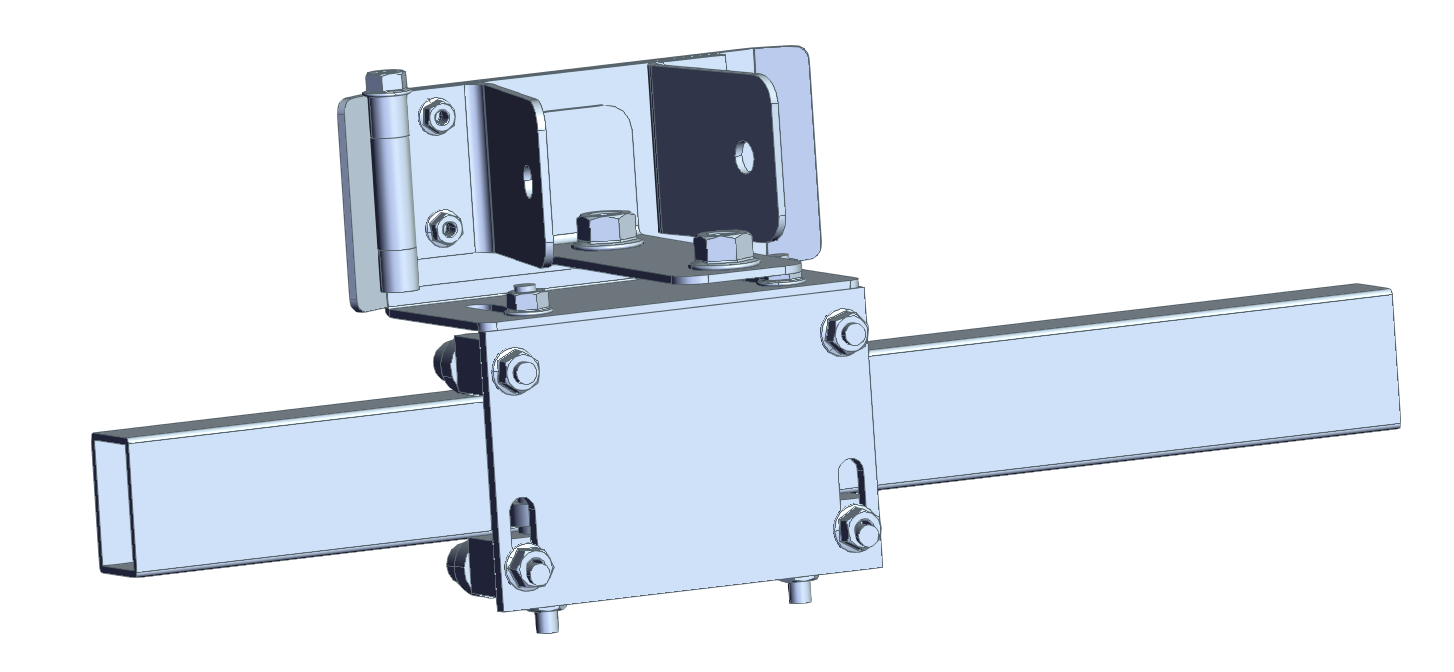

Hello, can anyone tell me if sheet metal forming is a reliable process for the production of parts like this one? Not for the entire piece on the model, but only the central bar. I don’t know if forming can provide the necessary precision and structural integrity for our project. Maybe machining is more appropriate?

Automatically translated from: Français

See original

Suggested Topics

Topic

Replies

Views

Activity

stainless steel bolts with brass inserts for a plastic intake manifold

hello, I’m redesigning an intake manifold joint on an IC engine where the upper and lower manifolds are plastic, and the factory setup uses M6 class 8.8 screws threading directly into plastic bosses. The... read more

1

94

Feb 24

Selecting the Molding Process for a GSXR 1000 Half-handlebar

Hello, I am currently working on the design/manufacture of a half-handlebar for a sports motorcycle (GSXR 1000). What is the best type of process that I could establish for the manufacture of the handlebar... read more

1

136

Feb 19

Laser cutting pc panels for machine safety enclosures

Hi, I’m producing clear polycarbonate panels for a machine safety enclosure, cut from 4 mm sheet with small mounting holes and tight internal radii. Optical clarity and edge integrity matter more than cosmetics. From... read more

2

250

Feb 20

Printing a 3D Model Purchased from a Third Party

Hello, I was wondering if there would be any issues in requesting the production of a print from a model purchased from a third party.Thank you and keep up the good work! read more

4

670

Jan 23

Manufacturing Wheels for Fingerboards

Hello,I am writing because I am developing fingerboard wheels as a new product within my own brand. I professionally manufacture fingerboard decks and concrete obstacles, and now I am expanding my catalogue with cast... read more

2

612

Jan 20

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account