vents. In response, our student team developed Geocell Grid — a sustainable and affordable ground stabilisation system that merges recycled materials with the proven performance of geocells and geogrids.

Tackling Erosion with Recycled Engineering

Floods, landslides, and storms have become increasingly common in the UK, affecting millions of properties and costing the country billions in damages. For example, in 2025, 2.4 million properties were estimated to be at risk of flooding. Storm Angus alone caused £56 million in damages, impacting 266 residential and 113 business properties.

Weak soil conditions, exacerbated by heavy rainfall and wet terrain, contribute to erosion and ground sinking, posing significant challenges to roads, railways, and flood-prone areas. The construction and geotechnical industries are under increasing pressure to adopt sustainable, high-performance materials while maintaining cost efficiency.

Combining Geocells and Geogrids for Stronger Ground Support

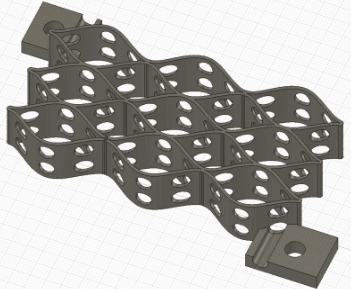

To address these challenges, we designed an integrated geocell and geogrid system that provides superior soil stabilisation and erosion control.

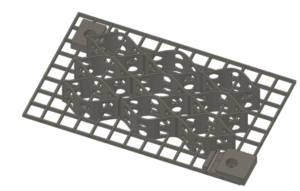

- Geogrid Component: Inspired by synthetic polymer grids, our geogrid is made from repurposed fishing nets. The optimised square mesh design offers high tensile strength and enhances soil interlocking, reducing lateral movement and increasing stability.

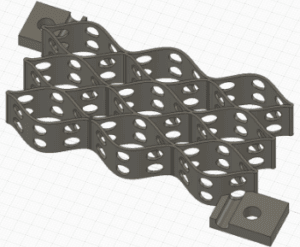

- Geocell Component: Our geocell design consists of a flexible honeycomb structure that confines soil within its cells, preventing both vertical and horizontal displacement. The perforated cells allow water to pass through, reducing waterlogging and improving drainage.

Slider

| Image | Image widthExample: 300px | Slide text | ||

|---|---|---|---|---|

| 1 |  | Add MediaVisualTextFile Edit View Insert Format Tools Table ParagraphGeorgia12pt | ||

| 2 |  | Add MediaVisualTextFile Edit View Insert Format Tools Table ParagraphGeorgia12pt |

By integrating these two components, the Geocell Grid enhances load distribution, reduces lateral movement, and significantly improves drainage. Lab studies suggest this hybrid design can reduce the height of reinforced soil layers by over 40% compared to traditional methods.

Sustainable Design, Scalable Applications

Each part of the Geocell Grid is engineered with sustainability in mind. The geogrid uses discarded fishing nets — a major source of ocean plastic — while the geocell structure is formed from post-consumer HDPE waste like shampoo bottles and milk jugs.

The system is also designed for real-world practicality. Its modular format makes on-site installation fast and flexible. The components adapt easily to uneven terrain without requiring extensive ground preparation, and orientation slots allow for both horizontal and vertical applications.

Prototyping and Performance Testing

To test its effectiveness, we created a 1:200 scale prototype simulating slope stabilisation in landslide-prone conditions. In trials, areas protected by the Geocell Grid showed significantly less soil displacement than untreated zones — validating both the structural logic and scalability of our solution.

Feedback from industry mentors during our presentation was positive. Baninder Kaur, key account manager, praised the project’s multifaceted environmental benefits. Joao Clemencio, sales engineer, noted the flexibility of the geogrid and explored the mechanical properties of the recycled materials used.

Efficient, Cost-Competitive Manufacturing

Our manufacturing approach is designed to be both sustainable and cost-efficient, relying on low-energy processes like compression molding and heat bonding. Every component of the Geocell Grid is produced from recycled materials, giving waste a second life in critical infrastructure applications.

For the geogrid, we start by collecting and thoroughly cleaning discarded fishing nets. These nets are then stripped into workable segments and bonded using a low-density polyethylene (LDPE) binder. Through heat and compression molding, the material is transformed into robust geogrid panels with a high-tensile mesh structure.

The geocell component follows a similar path. Recycled high-density polyethylene (HDPE) is sourced from everyday household plastics, such as milk jugs and detergent bottles. After cleaning and drying, the HDPE is cut into sheets and compression-molded into honeycomb-like panels. Each unit undergoes structural testing and quality checks to ensure it can withstand demanding field conditions.

Our cost breakdown shows that:

- Fishnet-based geogrid material costs around £2.50/m²

- Recycled HDPE for the geocell structure costs £1.50/m²

- The combined Geocell Grid unit is estimated at £5/m², placing it competitively within the erosion control market.

Looking Ahead

As the demand for sustainable geosynthetics grows, Geocell Grid is positioned to offer an eco-friendly, scalable solution for ground stabilisation. From roads and railways to construction sites and flood-prone zones, the applications are vast.

By partnering with Xometry, we aim to scale up production and expand the reach of our product, enabling more businesses and governments to benefit from our low-cost, high-impact solution.

How would you improve this modular ground support system? Let us know in the comments — whether it’s design tweaks, material ideas, or use cases we haven’t thought of.

Discover the other UCL Hackathon projects:

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)