Polypropylene (PP)

- Alternative Designations: Polypropylene homopolymer (PPHP)

Colors:

- Whitish / Gray

Description:

Polypropylene (PP) is renowned for its excellent surface resolution, feature details, and nearly isotropic mechanical properties, making it comparable to injection-molded PP in terms of toughness, fatigue resistance, and lightweight characteristics. It offers outstanding chemical resistance, low moisture absorption, and exceptionally high elongation at break, ideal for high-volume functional prototypes, limited-run production, and durable components like snap-fit assemblies and living hinges. Common uses include electronic system housings, guides, clips, fuel and oil housings, as well as environmental control system components such as fan housings, ducting, and valves. The properties of this material can vary based on the selected manufacturing process.

Material Properties

Processes:

Special properties

- Chemical resistance

- Density < 1 g/cm³

- Flexibility

- Heat resistance > 100℃

- Impact resistance

- Stiffness

- Water resistance

| Property (SLS) | Value, metric | Value, Imperial | Type |

|---|---|---|---|

| Density | 0.84 g/cm3 | 0.84 g/cm3 | - |

| Elongation at Break (X/Y, Z) | 34%, 16% | 34%, 16% | - |

| Hardness | 70 | 70 | Shore D |

| Ultimate Tensile Strength | 29 MPa | 4.2 ksi | - |

Download datasheets

-

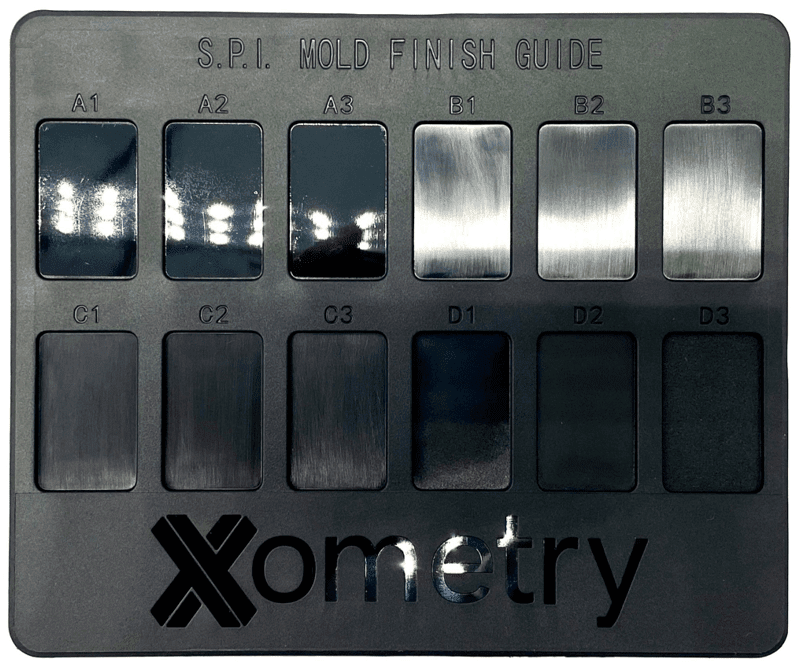

Injection moulding SPI surface finishesInjection Moulding SPI Finishes

SPI

SPI finishes are a set of standard mould finishes with different polished textures for enhanced properties.

Notes:A1, A2, A3, B1, B2, B3, C1, C2, C3, D1, D2, D3

Final result:

- Heavily polished, to semi-gloss to fine and coarse matte depending on the selection

-

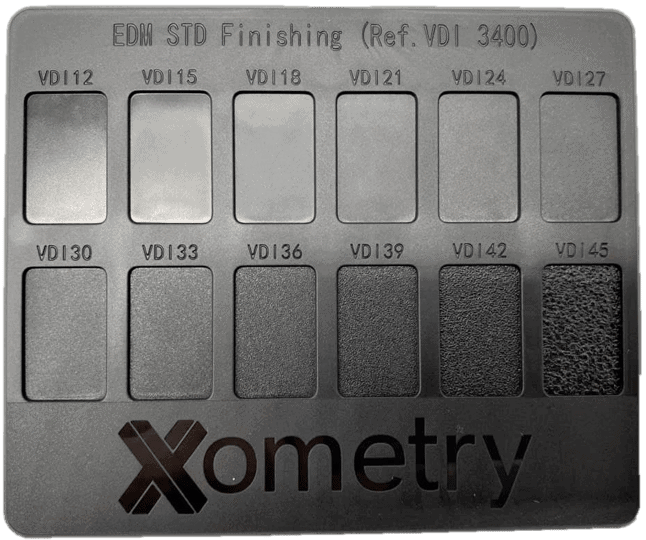

Injection moulding VDI surface finishesInjection moulding VDI surface finishes

VDI

VDI is an international standard for mould texturing of matte surfaces. It is mainly processed by Electrical Discharge Machining (EDM) when mould machining.

Notes:VDI12, VDI15, VDI18,VDI21, VDI 24, VDI27, VDI30, VDI33, VDI36, VDI39, VDI42, VDI45

Final result:

- Fine-to-coarse grain depending on the selection

-

Custom Finishing

If you select a custom finish in the Instant Quoting Engine it will require manual review. Manual quoting usually takes 1-2 business days.

Notes:Submitting for manual review with a custom request does not guarantee a quote.

-

Bead blasting

Depowdering of parts with bead blasting. The final parts are slightly grainy in the touch with a satin-like matte appearance.

Notes:Semi-sintered surface particles remain on the part even after initial depowdering.

Final result:

- Slightly grainy in the touch

- Satin-like matte appearence

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account