The CEO of Narnia Labs, Namwoo Kang gave us a good overview of the problems they’re solving and why Korean manufacturing and engineering giants have decided to adopt their solution.

Engineering Design Creates Value, but Where Are the Engineers?

Explain the “smile curve” to us. What does this mean in economic terms?

The smile curve illustrates how value added is distributed across a product’s life cycle. When you look at manufacturing beyond the narrow “production” step—extending the view to planning, R&D, design, manufacturing, distribution, maintenance, and end-of-life—value added is typically highest at both ends: the pre-production phase and the post-production phase.

Economically, this means that product development, R&D, design, and branding (pre-production), as well as services and marketing (post-production), tend to generate greater profits for companies and nations than the manufacturing/assembly step alone. For Korea to remain competitive in manufacturing, we need to drive AI transformation (AX) in these high-value areas—especially in product development.

So what are the problems when it comes to innovation in the pre- and post-production phases?

Today, many AI companies focus on the production phase. But if you cannot design a great product upstream, no amount of downstream production efficiency will create meaningful value. That is why Narnia Labs is focused on AI transformation of the product development stage in pre-production—more specifically, the engineering design phase.

With population decline and shrinking workforce in Korea, how acute is the problem of creating value in the engineering design phase? Are companies literally unable to hire enough engineering talent?

It is extremely acute. In Korea, population decline and a shrinking young workforce mean that, as experienced engineers retire, companies struggle to hire and retain the next generation of experts. This is more than a headcount issue—it creates a structural risk, because Korean manufacturers can be outcompeted by countries like China on price and scale.

As a result, AI adoption in manufacturing is no longer optional; it is becoming a prerequisite for survival. This is especially true for SMEs, which have an even harder time attracting highly skilled engineers than large enterprises. For them, AI is critical to mitigate engineering talent shortages and expand capability.

Your talks touch on optimal design. Can you explain the limitation of the current optimal design phase we are in?

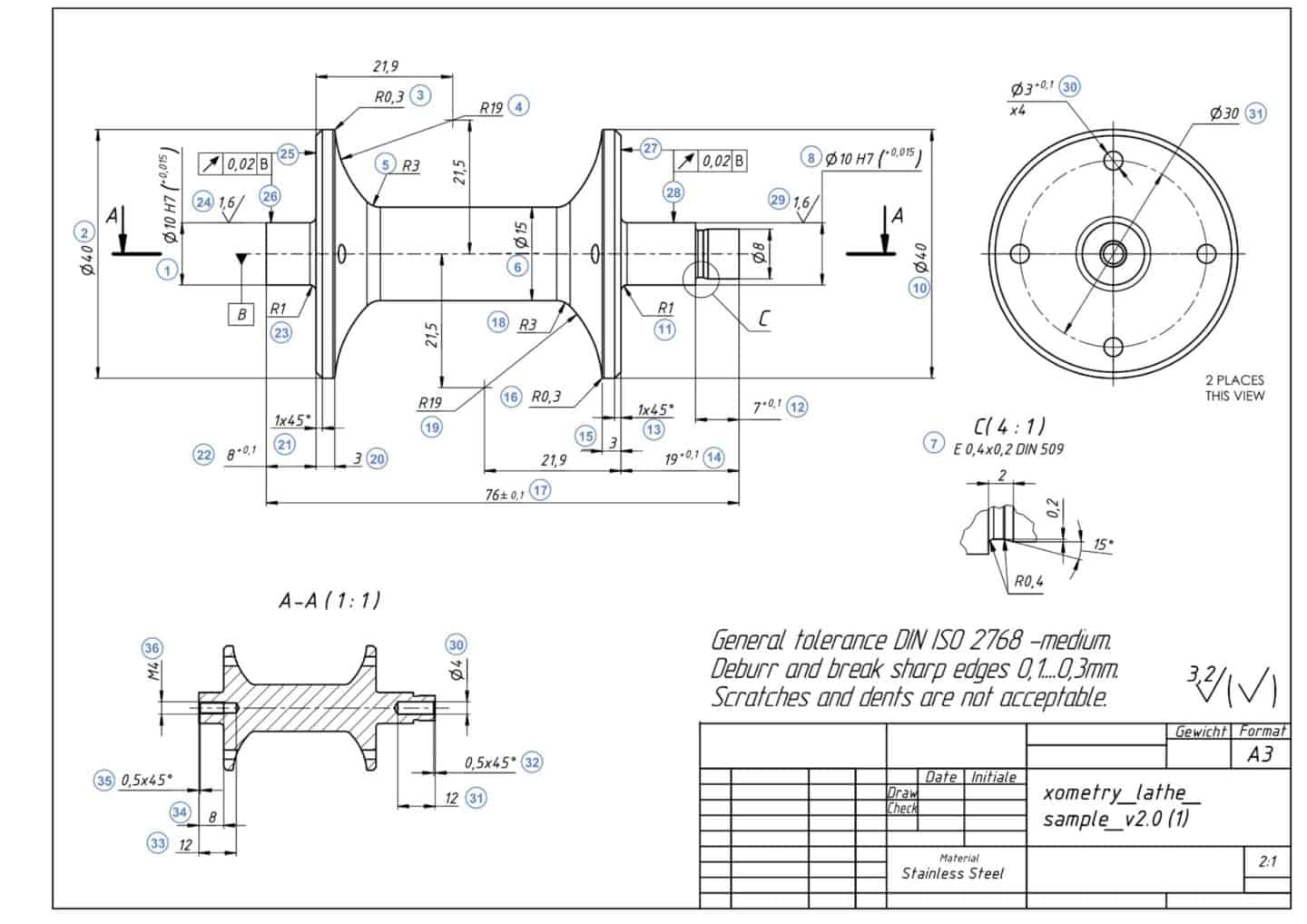

Simulation-based optimal design is widely used in industry and has delivered real value, but it has clear limitations. First, the geometries we want to design are often too complex to parameterize with traditional approaches (e.g., a small set of variables like x1–x10).

Second, even if you can express the design with variables, the input/output dimensionality is often so high that it becomes difficult to build reliable surrogate models with conventional machine learning.

Third, the underlying physics and design space are highly nonlinear and complex, making it very difficult to find global optima. In short: real industrial design problems are high-dimensional, so efficient search is not feasible with traditional methods.

AI to Generate, Predict and Optimize

Walk me through your solution to the problem.

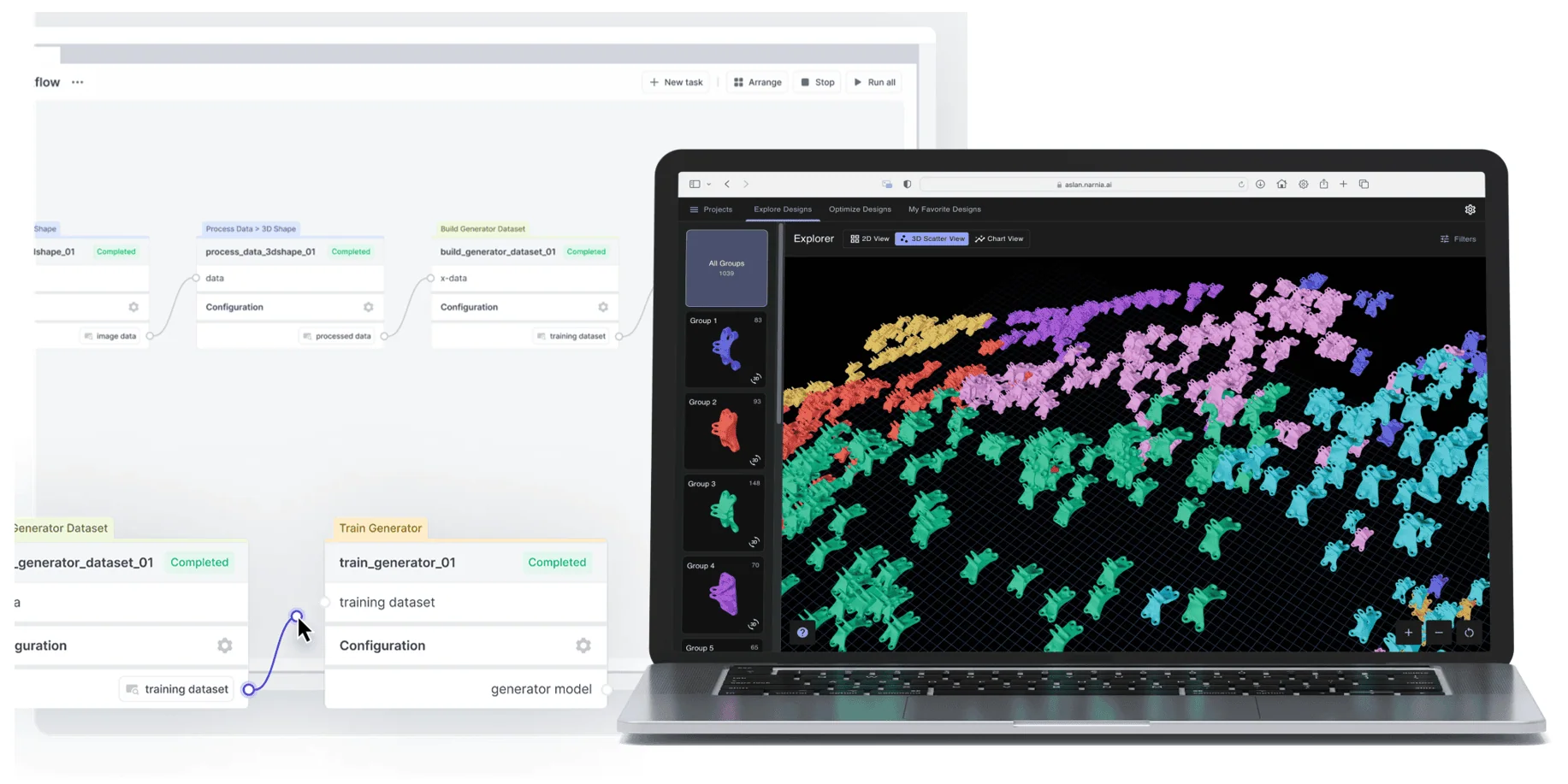

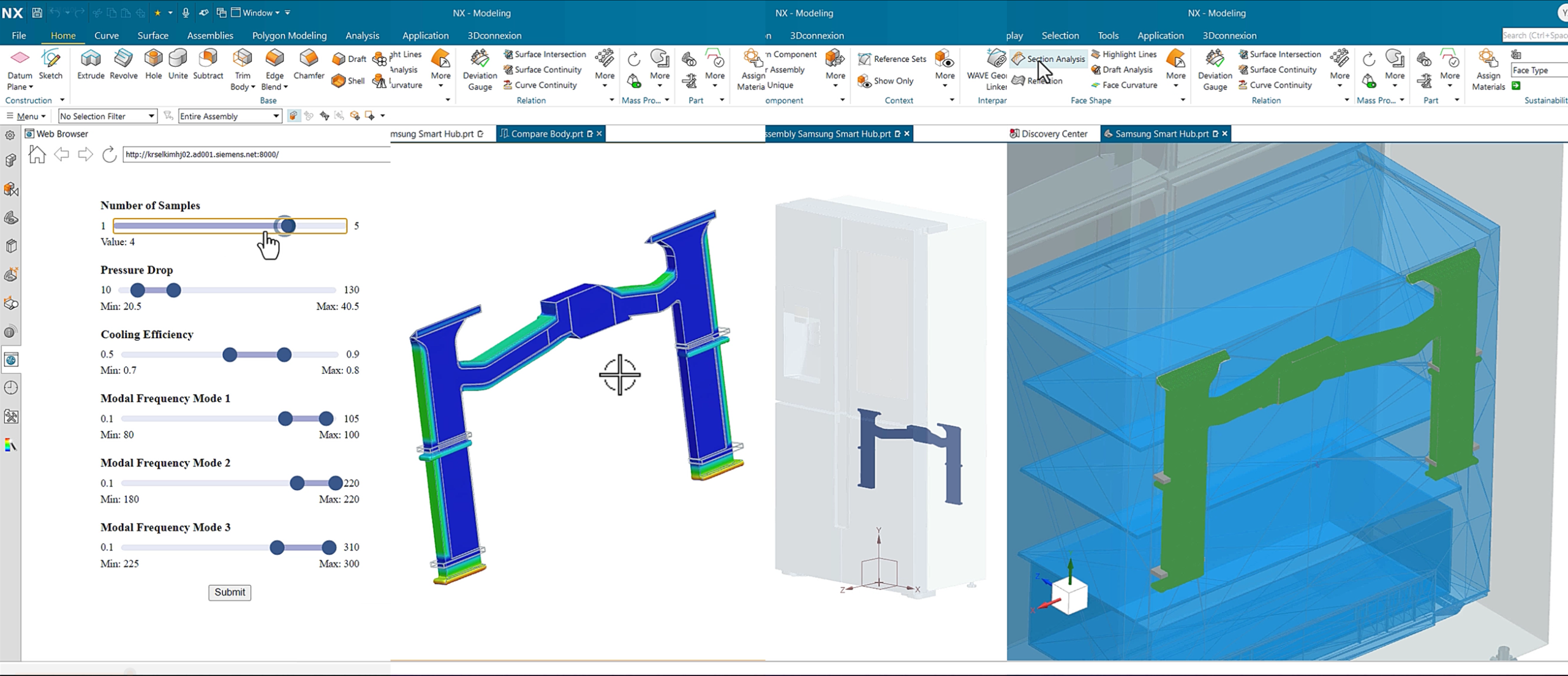

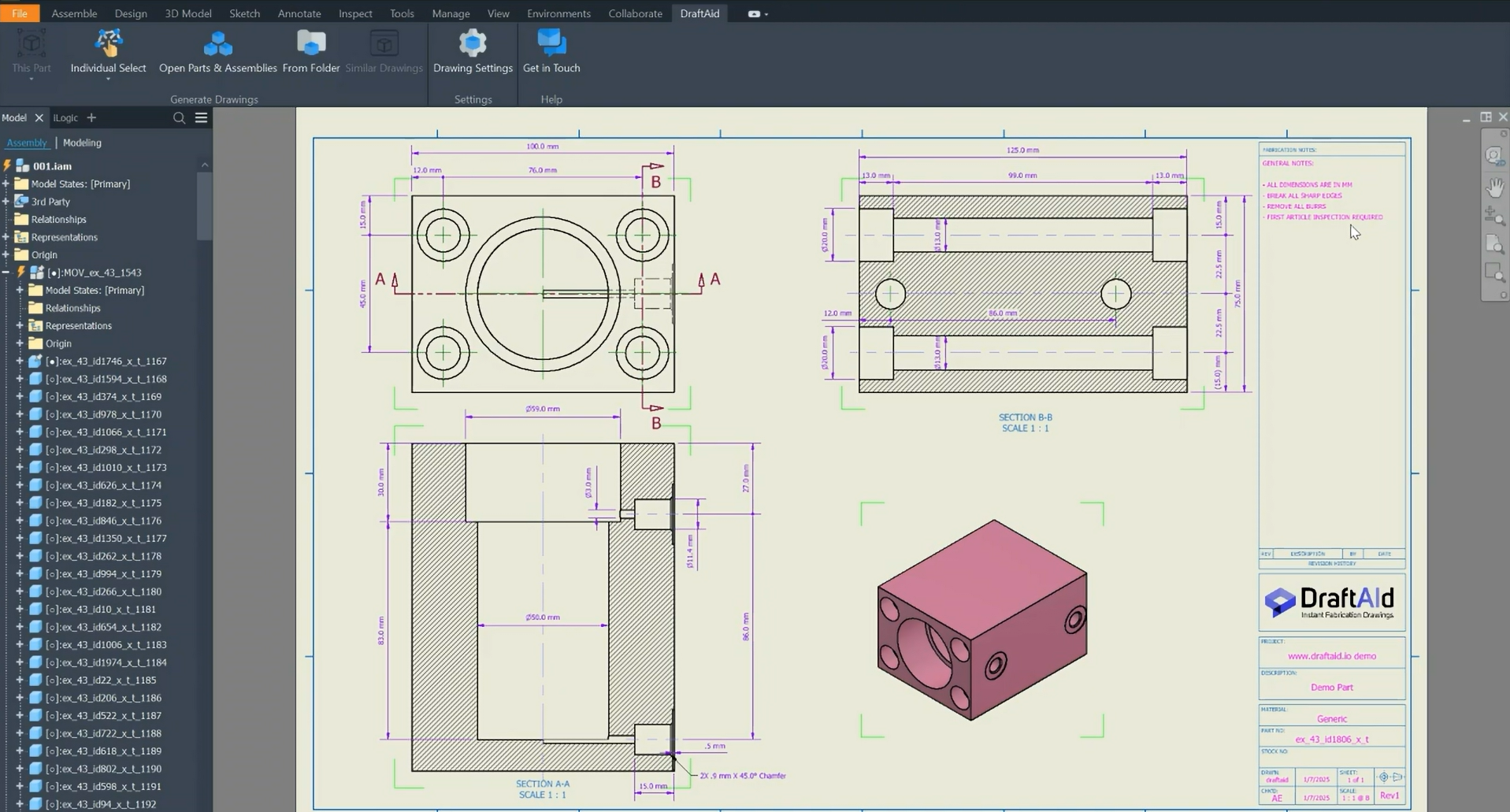

Our solution, AslanX, is an independent platform that enables design, simulation (CAE), and testing engineers—without being AI specialists—to build and apply AI models easily. It does not replace existing CAD and CAE; rather, it acts as a generative AI platform and collaborative partner that supports engineering decision-making through generation, prediction, and optimization.

AslanX provides a no-code workflow where users can ingest data, train models, and deploy them with minimal friction. Trained models can be delivered via an API or as a GUI-based app and, when needed, integrated into existing CAD systems through APIs.

Can you handle assemblies or individual components?

For prediction, we already support assemblies in production deployments. For generation, while further R&D is still needed, we have the underlying capability and are actively productizing it. We have already applied assembly generation to a real-world problem with LG Electronics and have built substantial, practical know-how through that work.

You are tackling design, performance, manufacturability, cost, etc. – basically all the Design for X topics – at once. Isn’t this too ambitious? Why not focus on one thing at a time?

This is precisely what makes engineering design hard: you rarely optimize for a single requirement. You must satisfy multiple constraints and objectives.

Connecting tools across different domains and running optimization end-to-end is difficult, which is why traditional workflows typically evaluate requirements sequentially through repeated iterations.

With AI, we can build predictive models for each requirement and use them within a single generative or optimization model to solve multi-objective problems more effectively. It is not easy—but we have validated this approach across more than 70 industrial problems.

How far along the development curve is the current AI to really solve for all these different areas?

AI is not yet effective for every complex design problem end-to-end, but for specific domain problems it is already producing tangible results. For example, Narnia Labs recently worked with LS ELECTRIC to develop a power component (MCCB, molded case circuit breaker) using a generative AI model that improved fracture strength by 19%, and we completed both tooling (mold) fabrication and manufacturability validation. The output is now being evaluated for deployment in real data centers. This demonstrates that the technology has moved beyond research and into commercialization.

Topology optimization has existed in CADs for years. What can AslanX do that current CADs can’t?

Traditional rule-based approaches—such as topology optimization—do not learn from data; they rely on FEM-based iterative optimization, which can be time-consuming and often yields designs that are difficult to manufacture.

In contrast, AslanX is data-driven. By learning from historical data and understanding the distribution of feasible designs, it can generate and recommend tens of thousands of creative alternatives in real time—something that is not practical with conventional methods. In other words, it is optimized not just to find a single ‘best’ solution, but to explore the design space and uncover new possibilities.

How do you ensure the availability of the necessary training data? Seems like many AIs in this space are struggling with that.

One of the biggest bottlenecks to applying AI in manufacturing is the lack of 3D training data. Even large enterprises often do not have enough historical design data to train deep learning models at scale, and open-source datasets rarely match real manufacturing contexts.

We address this with synthetic data technology: we generate large volumes of high-quality, engineering-grade 3D data—data that is physically meaningful and meets engineering requirements—to train AI models.

For example, in a Samsung Electronics project (which has been using AslanX since last year), we generated roughly 8,000 synthetic samples before developing the AI model.

Could you explain the autonomous design vision?

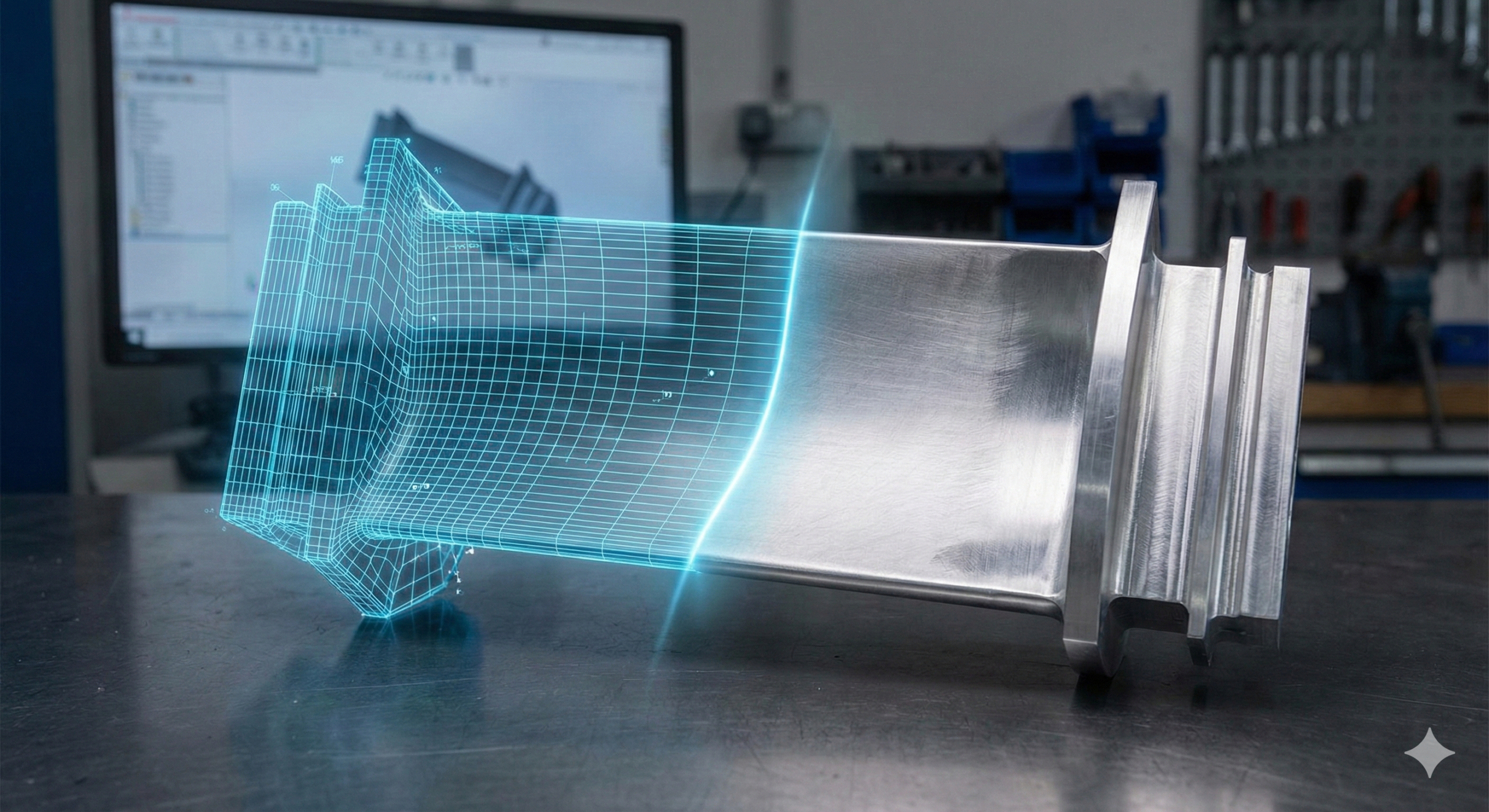

Autonomous design is the next step beyond generative AI—toward agentic AI. In generative AI, humans use AI as a new tool to design. In autonomous design, AI uses tools (including other AI tools) to carry out the design process.

Historically, humans selected tools and made decisions. In the future, engineers will provide goals and constraints, and AI agents will select tools, collaborate, and orchestrate workflows to find optimal designs. Humans will shift to supervising the outcomes and providing final approval. That is the vision we are building toward.

How accurate are your designs today? Are the models parametric, so engineers can continue working on them after AI has created them, or are they meant to be final?

It depends on which stage of the design process you want to use the output. For early concept design, we often generate results in mesh form, which allows us to express a wide range of topologies.

For detailed design, however, we need B-rep representations. In that case, we either convert mesh outputs into B-rep, or we train models to generate B-rep directly. In the LS ELECTRIC example I mentioned earlier, we generated B-rep outputs, which made the result directly usable for production.

Korean Ecosystem

You seem to have a lot of interesting ties, like the AI Manufacturing Service Alliance and KAIST. What does this offer?

I serve as the chair of the ‘AI Manufacturing Service Alliance’ subcommittee within M.AX, a manufacturing AX (AI transformation) alliance under Korea’s Ministry of Trade, Industry and Energy. It is a public–private council that brings together roughly 1,300 companies, research institutes, and universities to lead manufacturing AX in Korea. Through this alliance, we help shape technical standards and act as a hub for disseminating practical AI models into real manufacturing environments through industry–academia–research collaboration.

Korea is a manufacturing powerhouse, and it also has the data and domain know-how required for manufacturing AI. I see Korea as one of the best testbeds for building a manufacturing AI startup—if you can succeed in Korea, you can succeed globally.

KAIST is Korea’s leading engineering university and also very strong in AI. Through the KAIST Smart Design Lab that I lead, I can continuously work with top talent and stay at the forefront of the technology. KAIST also provides strong startup support systems, such as its ‘one lab, one venture’ policy.

Is Korea tackling AI adoption in manufacturing as a national priority? What does this mean for you?

Yes—Korea is treating manufacturing AI transformation (AX) as a national priority, with the goal of fundamentally innovating manufacturing through AI by 2030. This creates a major opportunity for us. Narnia Labs initially built credibility through PoC-style System Integration (SI) projects with a range of companies, but we have since shifted our business model—based on what we learned—toward a scalable platform product. Rather than pursuing linear, project-driven growth, we are targeting “J-curve” growth through our product, AslanX.

The government is also supporting multiple programs that enable companies to purchase and adopt startup solutions at scale. Personally, I do not believe it is sustainable for AI companies in our space to rely on headcount-heavy SI projects for short-term revenue—using larger and larger investment rounds simply to offset growing costs and maintain runway as the team expands. In the end, the startups that survive will be the ones that own a product.

Is there anything else you’d highlight as a key difference between Korean and Western startup ecosystems? Who benefits and how?

Compared with Western markets, Korea’s venture investment market is smaller, and valuations for Korean startups can be 10x—and sometimes up to 100x—lower than comparable U.S. companies.

However, Korea is a manufacturing powerhouse, with manufacturing accounting for over 24% of GDP, and it is also a strong AI-infrastructure country with world-leading GPU capacity. Where Western ecosystems are often centered on general-purpose AI startups, Korea is an ideal testbed for vertical and physical AI, where advanced AI technology meets real manufacturing domain problems directly.

In this ecosystem, technology suppliers like us gain abundant opportunities for real-world validation and data, while manufacturing champions (demand-side companies) use AI to improve productivity and design capabilities, strengthening global competitiveness. A mutually beneficial structure emerges.

Customers Seeing Revenue Uplift from Better Designs

Hyundai invested in you. How interested are other Korean tech giants in AslanX?

Hyundai Motor Group has been a core partner since our seed round. To date, most major Korean conglomerates have become our customers. This includes Hyundai Motor, Hyundai Mobis, Hyundai Transys, Kumho Tire, Samsung Electronics, LG Electronics, LG Innotek, LG Display, LS ELECTRIC, HD Hyundai Electric, Samsung Heavy Industries, POSCO, HD Hyundai Heavy Industries, Hanwha Ocean, LIG Nex1, and more—over 20 customers in total. Interest from Korea’s manufacturing giants is very high.

How deep is your working relationship with such behemoths at the moment?

With Korean conglomerates, we have run a range of PoCs, and we are now moving into the phase of signing formal software (AslanX) subscriptions and driving internal rollout. We are also entering a stage where AI-designed outputs are being taken to market, as in the LS ELECTRIC case.

What is the biggest benefit your users are seeing right now?

The purpose of using AI is to develop better products faster. The two biggest benefits users see today are time reduction and a dramatically expanded design search space.

For example, tasks that used to take a month can be completed in a minute, and teams can evaluate 1,000+ design candidates instead of ~20, finding solutions with significantly better performance. Both prediction models (for speed) and generative models (for better designs) create value, but customers tend to be most satisfied when AI leads to a superior product.

In other words, revenue uplift from better designs often matters more than cost savings from time reduction.

What kind of companies benefit the most? How could companies know if they are a right fit for adopting your tools?

Manufacturers in industries such as automotive, electronics, shipbuilding, and heavy industry—where complex 3D design and rigorous engineering validation are essential—benefit the most.

AslanX is a strong fit for companies that face bottlenecks in the design–simulation–revision loop; that have accumulated data but cannot effectively leverage it; or that are struggling due to shortages of experienced engineers.

Who is the end user?

The primary end users are design engineers responsible for product development, CAE specialists, and test engineers. Depending on the use case, product designers and technical sales teams can also use the platform.

What is the most surprising bit of feedback you’ve received from your customers?

The most memorable feedback was: “We validated that the AI-designed result outperforms the human-designed one. This is a design that would be hard for a person to imagine.”

Engineers initially thought of AI as an efficiency tool, but when AI began proposing designs that broke human assumptions, they started to embrace it as a catalyst for creativity.

Have you gotten any feedback that has made you change course, even a bit?

We heard repeatedly that enterprise engineers have a strong desire to internalize AI capability. Rather than relying on external vendors indefinitely to solve problems, they want an environment where they can solve problems themselves. That feedback further reinforced our focus on providing AI tools, not service projects.

Pricing and Availability

Do you serve customers outside of Korea?

We do serve customers outside Korea. Leading automotive OEMs in the U.S. and Europe are already customers, although we cannot disclose names due to NDAs, and some have already started AslanX subscriptions.

Until now, our global customers have primarily reached out to us inbound. Starting this year, we are establishing a Japan office and beginning a more proactive international go-to-market. Japan is a strong manufacturing country like Korea, and it is geographically and culturally close, which gives us confidence that we can execute better there than many other global AI firms.

What is your pricing model?

AslanX is offered on an annual subscription basis.

Industrial-Grade Autonomous Design

What developments are in the pipeline for 2026?

In the first quarter of 2026, Narnia Labs plans to unveil “AslanX 2.0,” a major upgrade to our current product. The new version enables more flexible and advanced training, and it helps users deploy inference apps more easily and quickly—so AI can be adopted faster in real engineering workflows.

If you succeed, what will product development look like in 5 years?

In five years, we aim to make industrial-grade autonomous design a reality. An engineer will be able to input a prompt like, “Design a product that meets these requirements and constraints,” and AI agents will analyze data from prior solved problems, select the right tools, construct the most effective workflow for the design task, propose the resulting designs, and explain why those decisions were made.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)