TRÖTE: Where Glass, Technology, and Sound Become a Sculptural Experience

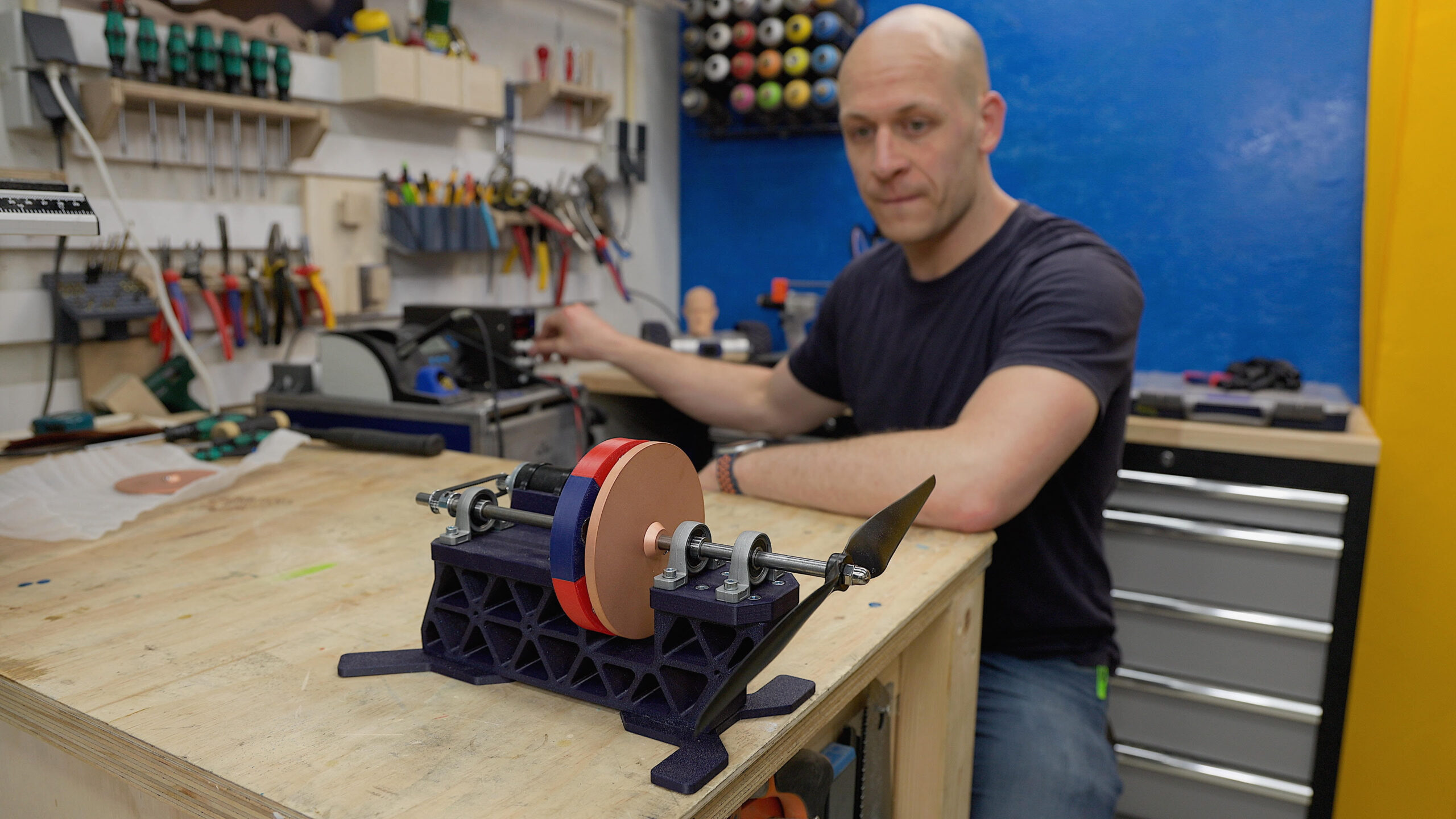

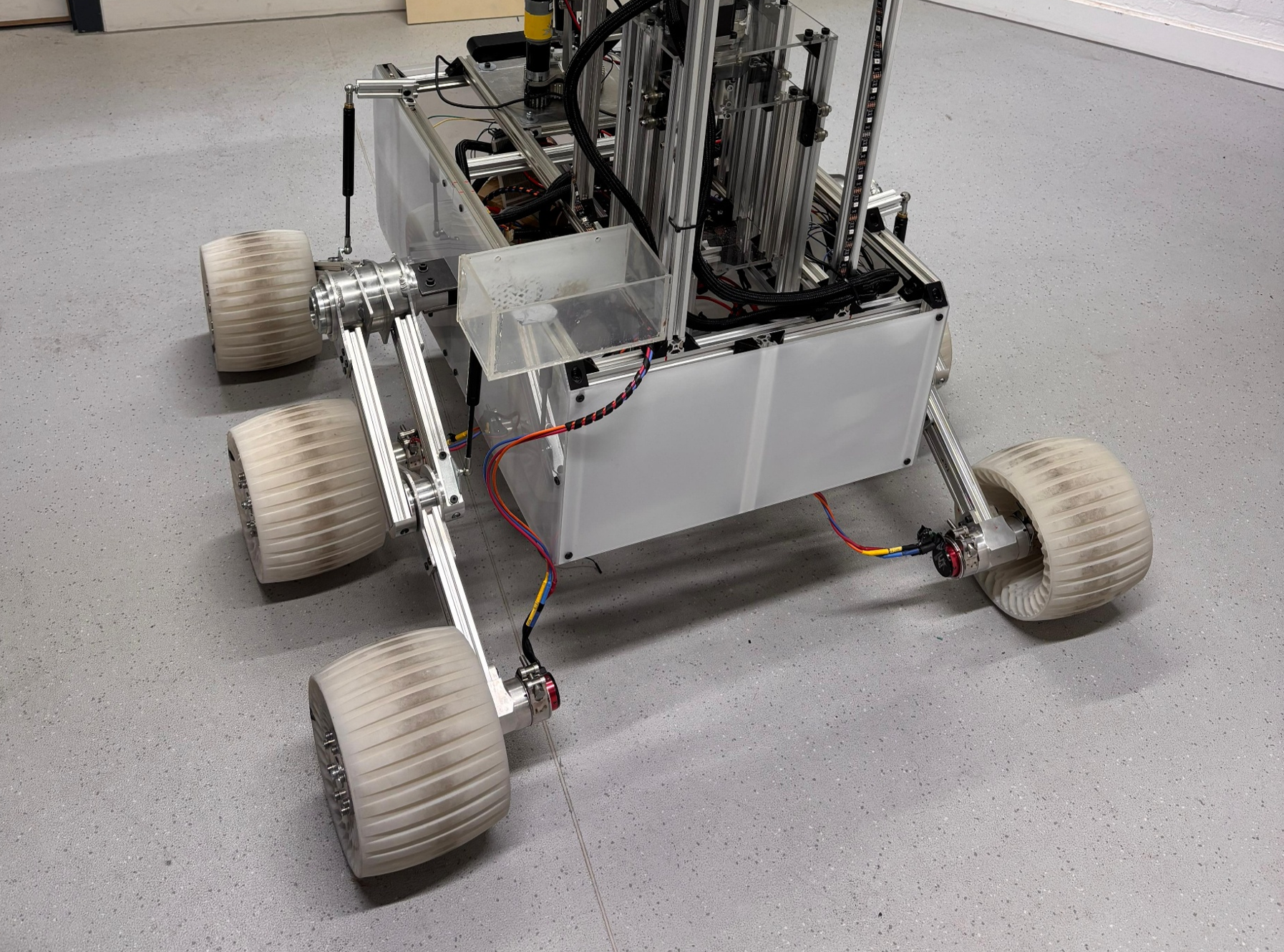

Hi, I’m Nils — a designer and a student at the Weißensee Academy of Art in Berlin (Germany), driven by curiosity and a love for merging craft with technology. In a world where most speakers focus purely on technical performance, with TRÖTE I set out to make sound visible, transforming it into a sculptural experience. TRÖTE is more than a high-end audio device; it’s an exploration of material, form, and acoustics brought together in a singular object that’s as much a sculpture as it is a speaker.

Read Story

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account

0

0

Download

Download