How does vapor polishing effect 3D prints' tolerance?

D

Hi everyone,

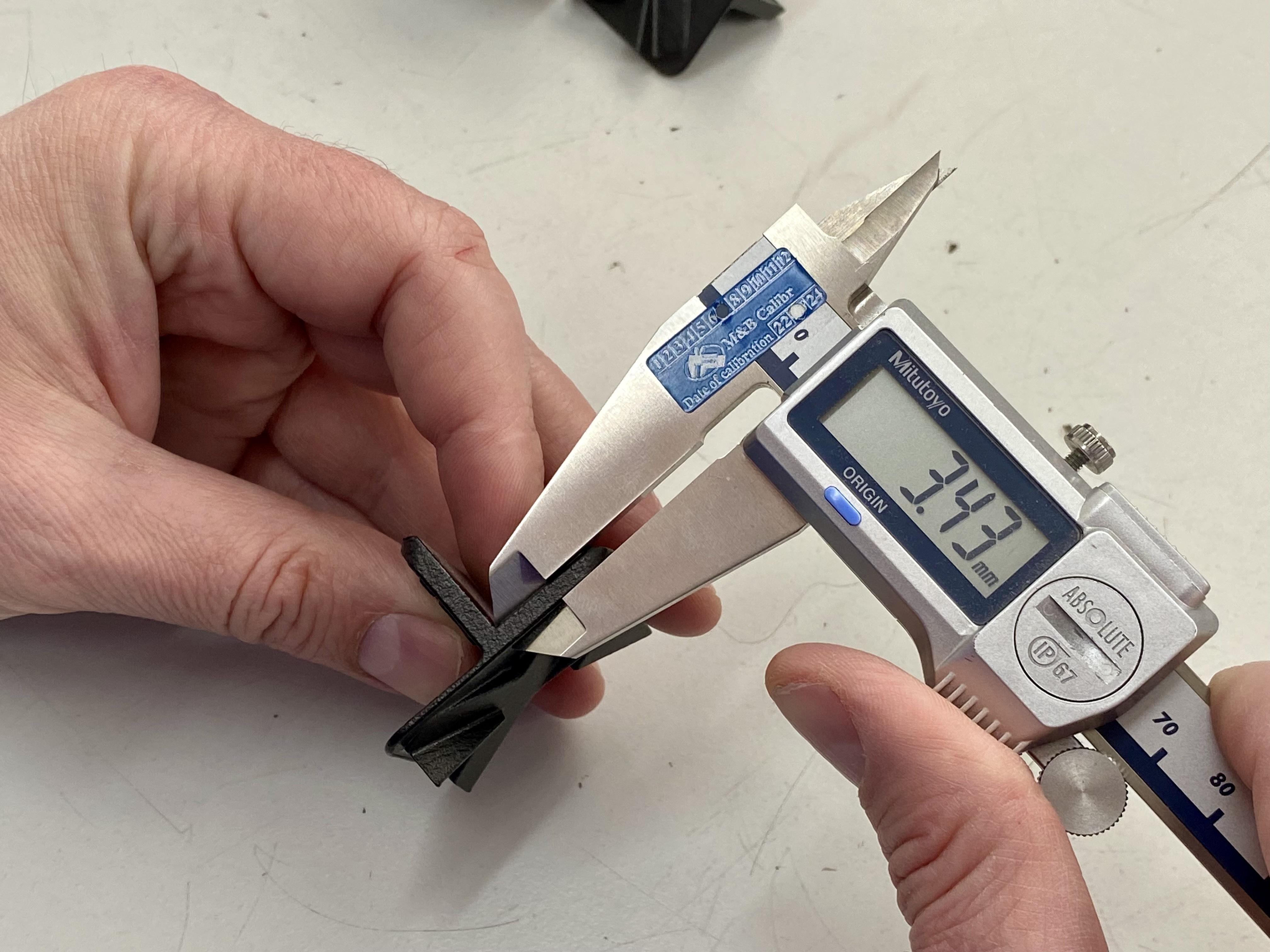

I’m exploring vapor polishing for PA11 SLS parts. Concerned about how it might affect part tolerance and dimensional accuracy. Does anyone have insights or experiences on the dimensional changes to expect for PA11/PA12 (SLS or MJF 3d printing)? Tips on maintaining tight tolerances while improving surface finish would be great too!

Thanks in advance!

Suggested Topics

Topic

Replies

Views

Activity

Flatness GD&T for 6061 plates

For a mounting plate for a precision sensor (about 200 mm × 200 mm) I was going to call out a flatness of 0.05 mm, but my senior engineer says that’s overkill and will double the machining... read more

1

18

Mar 06

ISO 2768-mK vs specific tolerances

Hey guys, I’m getting some pushback from our shop lead. I’ve been dimensioning every single feature on a new manifold block because I’m paranoid about fitment, but he says the drawing is "unreadable" and... read more

1

98

Mar 02

Thermal expansion modelling for a braced rectangular steel tank

hi, for a welded steel coolant reservoir for a test stand - 4 m × 2 m × 1.5 m with internal bracing I need to account for thermal expansion. Fluid runs at 80–90... read more

2

505

Feb 04

Designing holes for M3 threaded inserts in an ABS enclosure

Hi! In my design for a small ABS enclosure for an onboard sensor module I want to switch from molded bosses to heat-set M3 inserts for the lid screws. Before I finalize CAD, what... read more

1

715

Dec 23

Airtight joint between two aluminum frame enclosures?

Hi, I have two 400 mm cubical enclosures from 20×20 mm aluminum profiles with glass on all sides except one. I need to connect them into a single temperature-controlled unit and keep the joint... read more

2

857

Dec 29

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account