How does vapor polishing effect 3D prints' tolerance?

D

Hi everyone,

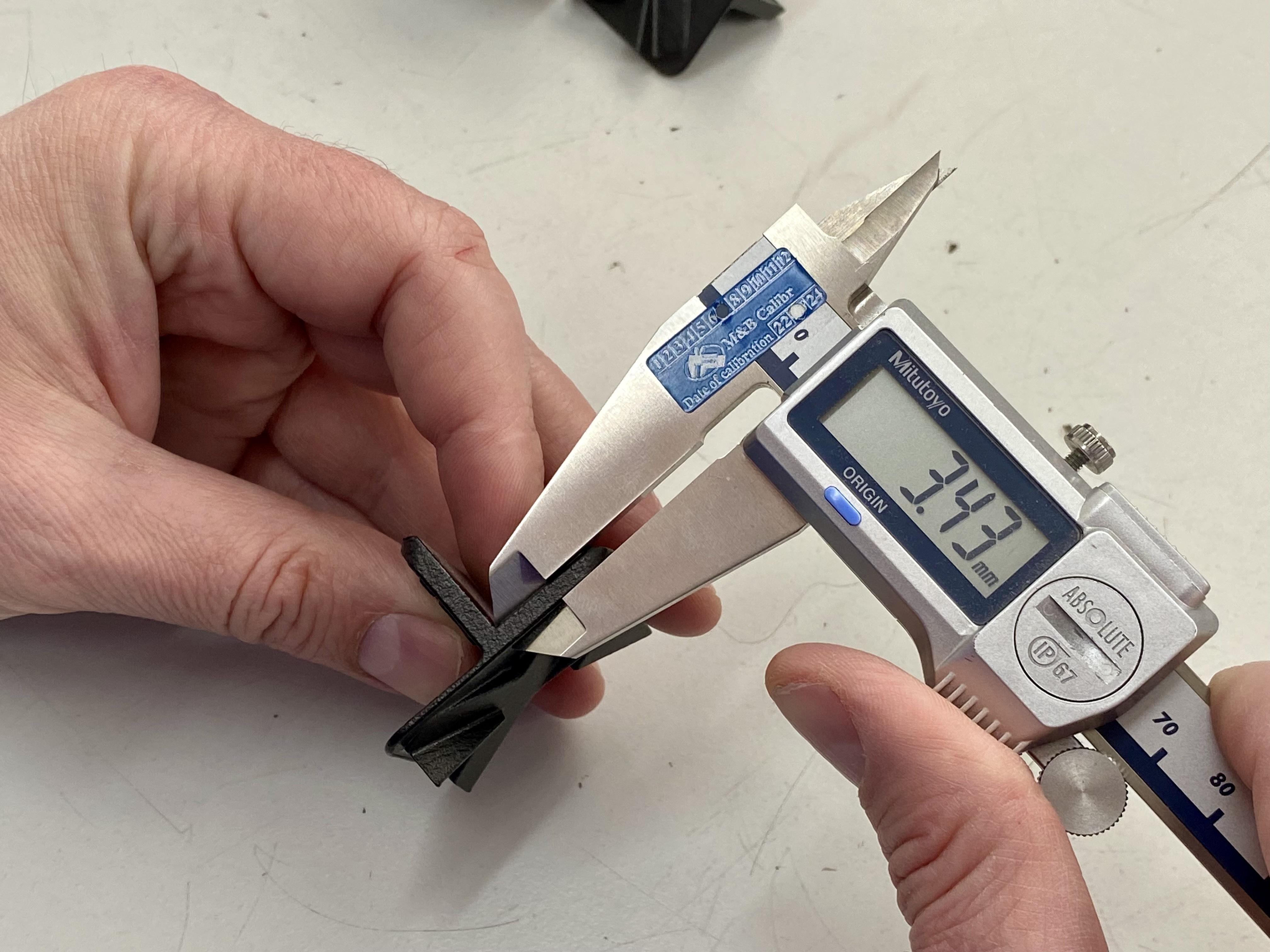

I’m exploring vapor polishing for PA11 SLS parts. Concerned about how it might affect part tolerance and dimensional accuracy. Does anyone have insights or experiences on the dimensional changes to expect for PA11/PA12 (SLS or MJF 3d printing)? Tips on maintaining tight tolerances while improving surface finish would be great too!

Thanks in advance!

Suggested Topics

Topic

Replies

Views

Activity

Fastener size choice for a through-hole in 4 mm anodized aluminum plate

Hi! Designing a lightweight enclosure for a small UAV component, using 4 mm thick anodized aluminum sheets. For the assembly, I need to fasten this plate to a 3D-printed ABS bracket underneath, which acts as... read more

3

93

Jun 30

Cracking at snap-fit hook base in SLS PA12

Hello everyone, I'm using SLS 3D printing (PA12, 0.12 mm layer height) to create a snap-fit enclosure for a handheld sensor device. The enclosure has three internal hooks that flex about 1.5 mm during... read more

2

109

Jun 24

Choosing sheet metal thickness for a lightweight bracket

Hey, working on a small mounting bracket for a consumer electronics housing, cut and bent from stainless steel sheet (304 or 316). The part needs to stay under 200g, but it also has to... read more

2

138

Jun 24

Visibility of parting line on GF30 PA6 injection molded handle

Hello everyone, how visible can the parting line be on final molded parts? My team is currently designing a handle cover for an industrial machine, injection molded in PA6 with 30% glass fiber. Aesthetics... read more

2

159

Jun 20

Minimum embossed text size for TPU molding

Hey there, I'm designing a flexible watch strap that will be injection molded in TPU (Shore 85A). I want to include some small embossed text (branding and serial number) directly on the strap, but... read more

3

279

Jun 24

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account