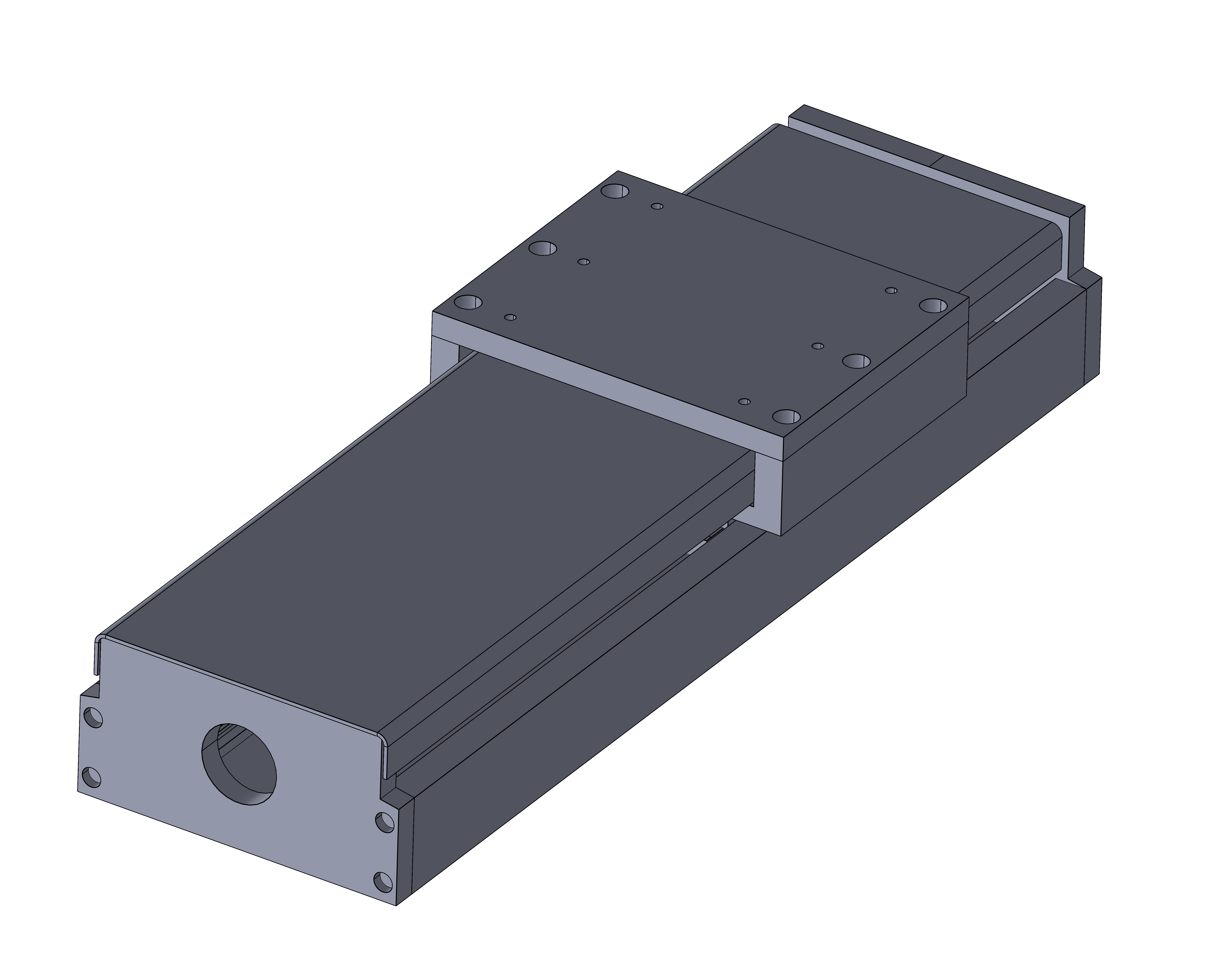

I’m designing a compact linear stage for a lab automation setup, used to move a microplate (about 300 grams) precisely along a 150 mm travel. The system needs to achieve repeatability under ±0.05 mm and run at moderate speeds (~200 mm/s).

The main challenge is keeping the guide system very slim (max width 25 mm) while maintaining smooth motion and minimal play. I’ve considered miniature profile rails and crossed roller slides, but they either exceed my width limit or introduce too much friction at this scale.

Has anyone worked on a similarly tight linear guide design for lab or precision applications? I’d really appreciate any suggestions on rails, bushings, or alternative approaches. Thanks!

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account