Wondering if 3D printing is the right fit for your production run? Use the checklist below to see if it aligns with your goals in terms of design flexibility, lead times, and cost-efficiency.

Consider 3D printing for serial manufacturing when:

- Your budget or volume doesn’t justify the cost of injection molds

- You need functional end-use parts in under 10 days

- Your design is still evolving, or you offer mass customization

- Your parts include complex features (lattices, undercuts, internal channels)

- You can integrate hinges, joints, or snap fits directly into the part

- You want to reduce warehousing costs through on-demand production

We’ll explore six key reasons why 3D printing may be the best choice for your next production run, supported by comparisons with other manufacturing methods, and tips to maximize its advantages.

1. Fast Prototypes = Faster Development

Whether you’re developing new products or iterating on existing ones, shorter lead times mean faster time-to-market. It also shortens lead times for pilot runs, bridge production, and early launches.

For low-to-mid volume parts (<1,000 units), 3D printing can cut development time drastically:

| Process | Typical Lead Time | Tooling Required |

| Injection Molding | 4–8 weeks | Yes €3,000–€50-000 depending on the mold complexity) |

| CNC Machining | 1–3 weeks | No (but limited to subtractive geometries) |

| 3D Printing (MJF) | 3–7 days | No (direct-to-print from CAD) |

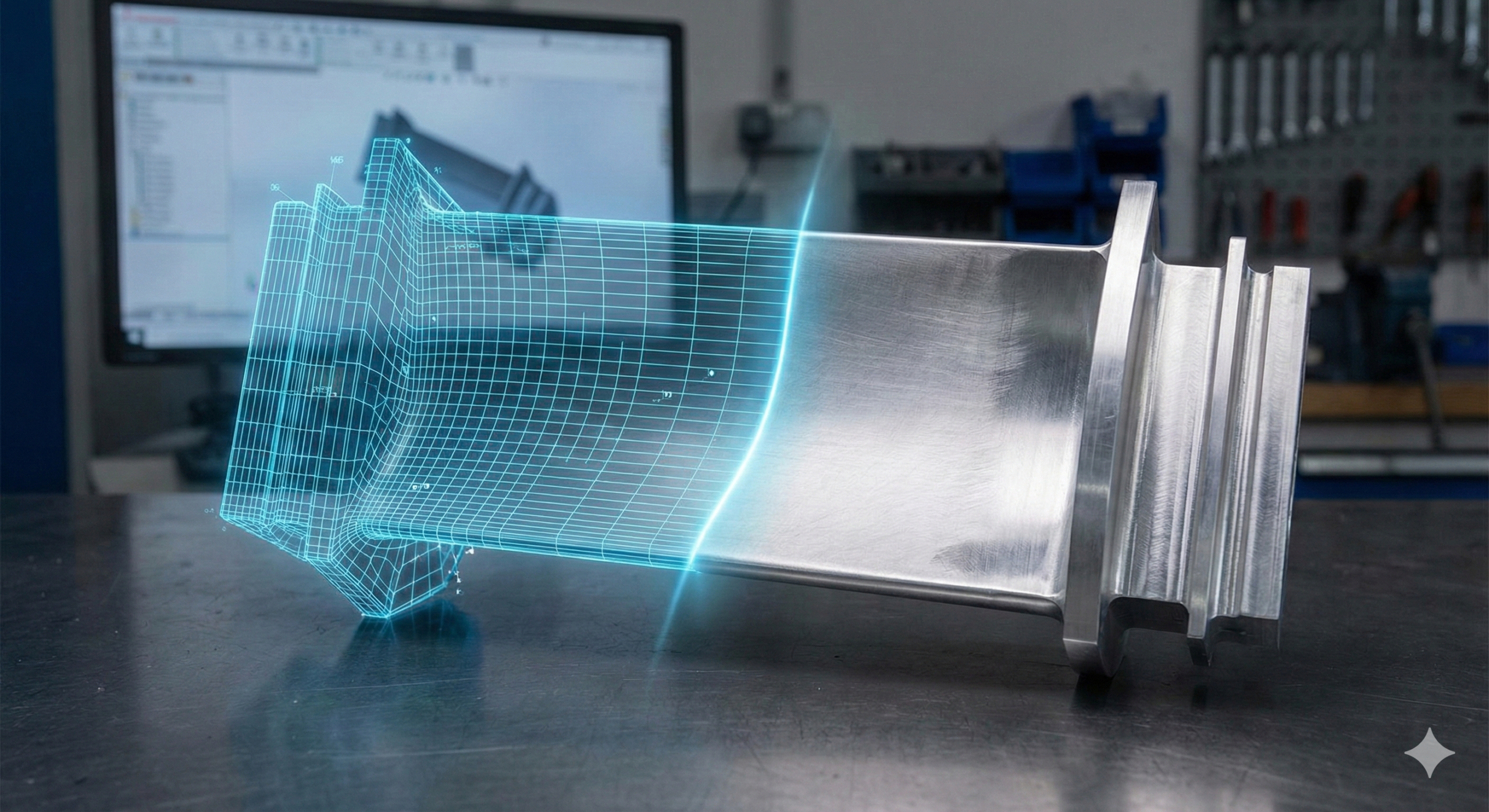

2. Design Flexibility Without Tooling Constraints

3D printing removes design constraints tied to tooling. With 3D printing, you can produce:

- Undercuts and internal channels: Easily create enclosed pathways for airflow, cooling, or fluid transport without needing side-actions or complex mold assemblies. For example, in aerospace or electronics, conformal cooling channels printed in one piece can drastically improve thermal management.

- Lattice structures: Reduce part weight while maintaining structural integrity. These are especially valuable in automotive and medical applications, where performance-to-weight ratio is critical. 3D-printed lattices are also used in sports equipment for energy absorption or cushioning (e.g., helmets, insoles, bike saddles).

- Complex and organic shapes: Freeform, topology-optimized geometries that are impractical to produce with CNC or molding. This allows engineers to design for performance first, not manufacturability.

3. Integrated Assemblies: Snap Fits, Living Hinges & Print-in-Place

3D printing allows the production of fully functional, multi-part assemblies in a single build, without the need for fasteners, adhesives, or manual assembly steps.

3D printing enables integration of:

- Snap fits: With flexible materials like PA12, PA11, or TPU. Ideal for housings, covers, and enclosures that must be frequently opened or replaced, especially in consumer electronics, IoT devices, and sensor housings.

- Living hinges: Using ductile thermoplastics such as polypropylene-like resins or flexible nylons, you can design hinged lids or flaps directly into the part. This is especially useful in packaging, containers, and access panels.

- Print-in-place joints and moving mechanisms: With sufficient clearance, joints, sliders, and articulated parts can be printed in a single build, ready to move right out of the printer. SLS and MJF are particularly suitable here due to their self-supporting powder bed.

- Enclosures with integrated clips or latches: No need for mold draft angles or manual insert designs—complex locking systems can be directly printed, saving time and simplifying assembly lines.

Compared to CNC or injection molding, this eliminates the cost of secondary assembly, screws and fasteners, and molded inserts redesigns.

4. Easy Design Changes

Updating an injection mold can cost thousands and take 1-3 weeks. With 3D printing, changes are as simple as updating the CAD file. This is especially valuable when:

- You’re developing consumer products with evolving designs, where rapid iteration improves usability and speed to market

- You’re creating multiple versions or customized parts per user, such as in wearables, medical devices, or electronics enclosures

- You need snap fits or living hinges — features that can be updated across iterations without tooling

- You’re building modular or interlocking systems

In serial production with 3D printing, version control and agile product development become viable. Instead of batch manufacturing the same part for months, revise the design every 200–300 units to incorporate feedback and improve usability.

5. On-Demand Production = No Inventory Costs

3D printing eliminates the traditional manufacturing inventory concern by enabling on-demand production, so you only print what’s required.

With 3D printing, you manufacture when you need:

- No warehouse costs

- No overproduction

- No risk of obsolete inventory

Injection molding only becomes economical above ~10,000 units, which often results in overproduction. By contrast, 3D printing supports distributed, just-in-time manufacturing.

6. Broad Material Availability with Production-Grade Properties

3D printing supports a wide range of engineering-grade materials suitable for end-use parts in serial production:

| Material | Compatible Technologies | Key Properties | Typical Applications |

| Nylon PA12 | SLS, MJF | Strong, durable, excellent dimensional stability | Enclosures, gears, brackets, jigs & fixtures |

| TPU (e.g. BASF Ultrasint) | SLS, MJF, FDM | Flexible, abrasion-resistant, rubber-like | Seals, gaskets, straps, soft-touch parts |

| ULTEM 1010 (PEI) | FDM | Flame retardant (UL 94 V-0), high heat resistance | Aerospace ducts, electrical housings |

| PEEK | FDM | Chemically resistant, high-temperature thermoplastic | Medical implants, high-temp tooling |

| Carbon-filled Nylon | FDM, SLS | Lightweight, stiff, high tensile modulus | Structural parts, drone arms, racing components |

| Photopolymer Resin (e.g. Clear, Tough, Flexible) | SLA, DLP, PolyJet | Smooth surface, detail-rich, some flexible | Cosmetic prototypes, small connectors |

| 316L Stainless Steel | DMLS | Corrosion-resistant, excellent mechanical strength | Food-safe tools, marine components, brackets |

| Aluminum AlSi10Mg | DMLS | Lightweight, conductive, good strength-to-weight ratio | Heat sinks, housings, lightweight structures |

3D Printing vs. Other Serial Manufacturing Methods

Still unsure whether 3D printing is the right fit? This side-by-side comparison shows how it stacks up against CNC machining and injection molding for serial production.

| Factor | 3D Printing | CNC Machining | Injection Molding |

| Lead Time | 3–7 days | 7–15 days | 4–8 weeks |

| Tooling | None | None | Required |

| Geometry Freedom | High | Medium | Low |

| Cost per Unit (<1k pcs) | Low | Medium | High |

| Design Iterations | Easy | Moderate | Expensive |

| Minimum Volume | 1 | 5–10 | 500–1,000 |

| Assembly Integration | Excellent (snap fits, hinges) | Poor | Moderate |

| Use When… | You need small-to-mid volumes fast, with flexibility in design and geometry; ideal for evolving or customized parts | You need precise, rigid parts from solid blocks with tight tolerances and simple geometry | You need high volumes of identical parts at the lowest cost per unit over time |

Which 3D Printing Technology for Serial Production?

Ready to take the next step? Here’s how to match your manufacturing goals with the right 3D printing process.

| Technology | Max Build Size | Speed | Recommended Batch Size | Part Quality | Cost per Part | Use When… |

| MJF (HP) | 380 × 284 × 380 mm | Fast | 100–1,000 | Very high | Medium | You need small-to-mid volumes of functional plastic parts quickly, with good mechanical properties and fine detail |

| SLS | 340 × 340 × 605 mm | Medium | 50–1,000 | High | Medium | You want strong, isotropic plastic parts with complex geometry and no support structures |

| FDM | 900 × 600 × 900 mm | Fast | 1–100 | Medium | Low | You’re producing large-format or cost-sensitive components for internal tools, fixtures, or industrial use |

| SLA | 736 × 635 × 533 mm | Medium | 1–100 | Excellent | Medium–High | You need high-resolution or cosmetic-grade parts for visual models or fine features |

| DMLS | 400 × 400 × 400 mm | Slow | 10–200 | Excellent | High | You need low-volume, high-complexity metal parts for aerospace, automotive, or healthcare applications |

| PolyJet | 490 × 391 × 200 mm | Medium | 1–50 | Excellent | High | You’re producing multi-material, small-batch end-use parts requiring soft-touch, color, or transparency features |

| Carbon DLS | 189 × 119 × 300 m | Fast | 50–500 | High | High | You’re manufacturing elastomeric or biocompatible parts for consumer, dental, or medical use |

Optimization Tips: Is 3D Printing Serial-Ready?

Transitioning from prototyping to serial production with 3D printing requires specific design and process adjustments to ensure consistency, cost-efficiency, and throughput at scale.

Here’s how to fine-tune your approach:

Surface Finish & Post-Processing

For visual or customer-facing parts, consider scaling your finishing techniques:

- Bead blasting is ideal for smoothing SLS or MJF nylon surfaces in bulk.

- Vapor smoothing enhances surface quality and seals porous structures, improving aesthetics and moisture resistance.

- Dyeing or painting can be applied in batch post-processing for consistent color and branding.

Splitting Large Parts

Use modular design for parts exceeding the build size:

- Use mechanical joints, press fits, dovetails, or snap fits to join sections after printing.

- Add alignment features like tabs or pins for precise assembly.

Final Thoughts

3D printing isn’t here to replace injection molding or CNC machining — it complements them. For batches between 1 and 1,000 parts, especially with complex designs or evolving features, it offers unmatched speed, flexibility, and cost-efficiency. Engineers can use 3D printing to iterate faster and reduce production steps.

Curious how 3D printing fits your production goals? Upload your CAD file and request a custom quote for your serial manufacturing project.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)