Rapid prototyping is a product development method used to produce an exemplary model before realizing the mass manufacturing of a designed product. Usually made with MJF, FDM or SLA 3D printing technologies, sometimes rapid prototyping can be done with CNC machining and urethane casting techniques.

Let’s take a look at the five essential advantages that the rapid prototyping method will bring to your company on the axis of 3D printing while minimizing all possible problems before obtaining the final product.

1. Speed

A CAD (computer-aided design) file that has been designed won’t require preliminary preparation and can be produced immediately, unlike traditional manufacturing methods. This technology, also a layered manufacturing technology, can build a 10 cm model in 4-6 hours and a 20 cm product in approximately 20 hours. You will be saving a lot of time since you can physically examine the model that you designed in a concise time.

2. Cost

Prototype manufacturing allows for the cost of manufacturing done with 3D printers to be much lower than traditional methods. If the maintenance of the fully automated printers is done correctly, then all that is required after uploading the model is to press a button. This brings the cost of the operation almost down to zero. In addition, it significantly reduces the price with its cheap raw material and low rate of waste compared to other methods. With its low cost, the prototype can be examined before mass manufacturing.

3. Testing Facility

The prototype produced at a low cost can go through the necessary testing processes by the engineer or designer before going into mass manufacturing. After exposing the model’s shortcomings that have been tried in a working system or aspects that can be changed, the design is remodelled and a new prototype is produced. No matter how complex the model is, a great number of models can be produced very fast and be tested cheaply. Thus, avoiding mistakes like these can prevent defective manufacturing and will save you a lot of money.

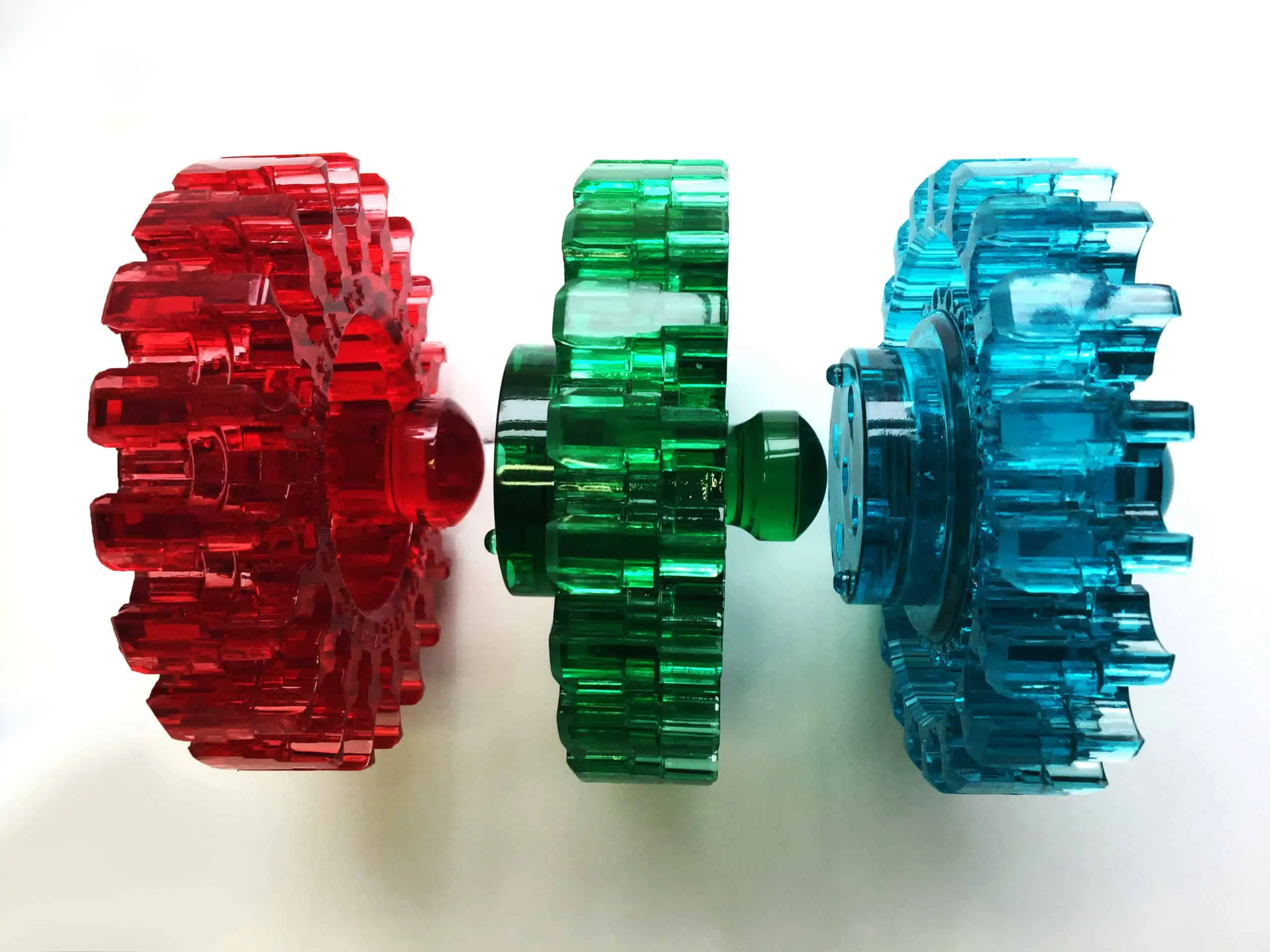

4. Material Range

The 3-dimensional printing technology offers product developers a crucial opportunity with its wide range of materials. After the model is produced with different materials and tested with prototypes, the material that gives the most efficient result will be the way to go. For example, if you need to ensure impermeability in a product you produce with ABS material, you can rapidly make another manufacturing with PET. Similarly, if you are not satisfied with the durability of your prototype made with PC material, you can print again with ULTEM and have a more durable product.

5. Final Product Usage

A part that has been produced by rapid prototyping can also be used as a final product. It can be produced both as a stand-alone part or as an add-on to a system. You can cut the part from anywhere in the design program and add it to the model with various methods to fill the missing place in the primary model. In the final product, we can find the use of materials like PA12, PC, and PEEK, which give excellent results in terms of strength.

Conclusion

Considering all these advantages, using rapid prototyping on a product before going into mass manufacturing will save you a considerable amount of money and time. These days many companies developing products use rapid prototyping as a standard procedure in manufacturing.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)