Hi, we are a team of three students from the Higher Department of Mechanical Engineering – Robotics & Smart Engineering at Technologisches Gewerbemuseum (TGM) in Vienna, Austria, developing a desktop filament recycling machine as part of our diploma project. As active users of 3D printing, we see how quickly filament waste accumulates through failed prints, leftover spool ends, and support structures.

Although this waste still represents valuable material, most users have no practical way to recycle it at home. This gap became the starting point for our project: designing a compact desktop-scale machine that converts PLA and PETG filament waste into new, printable filament and makes material reuse more accessible.

An Integrated Approach to System Design

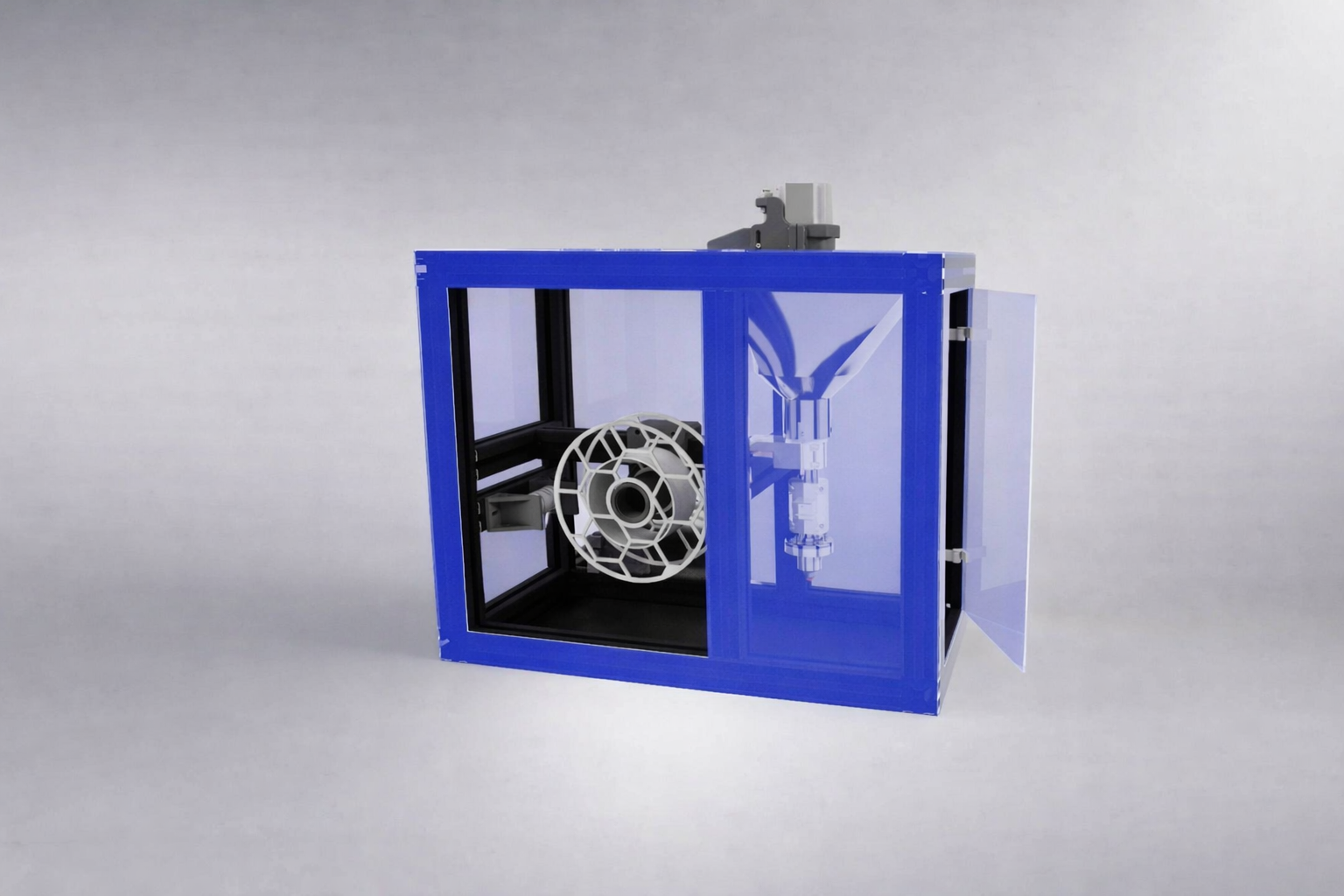

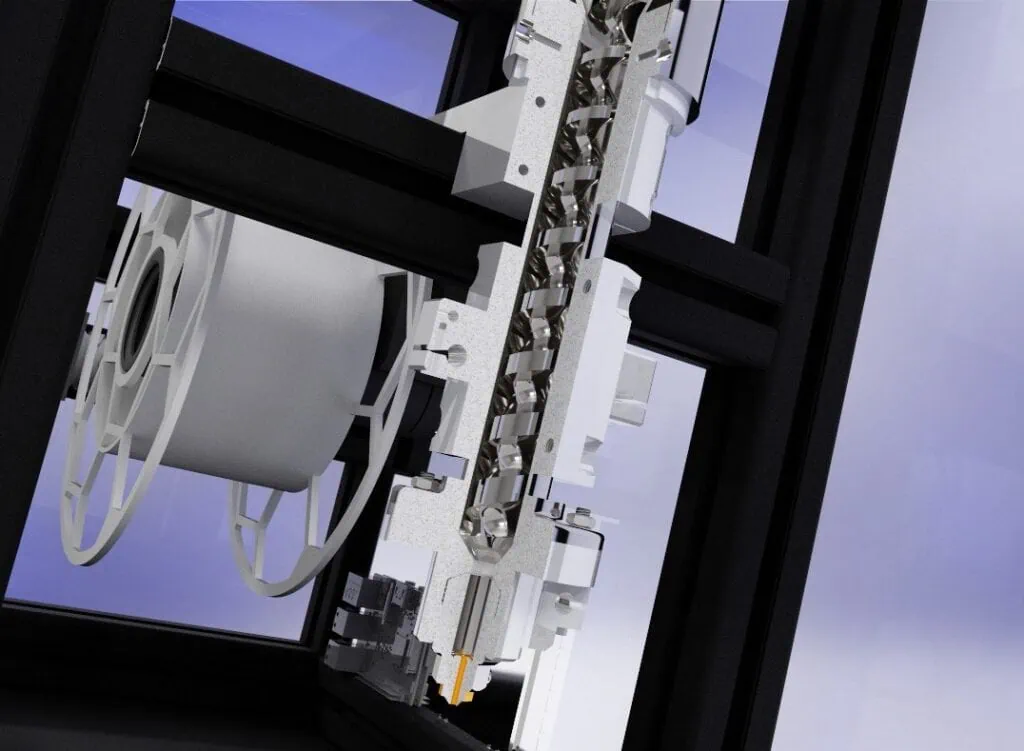

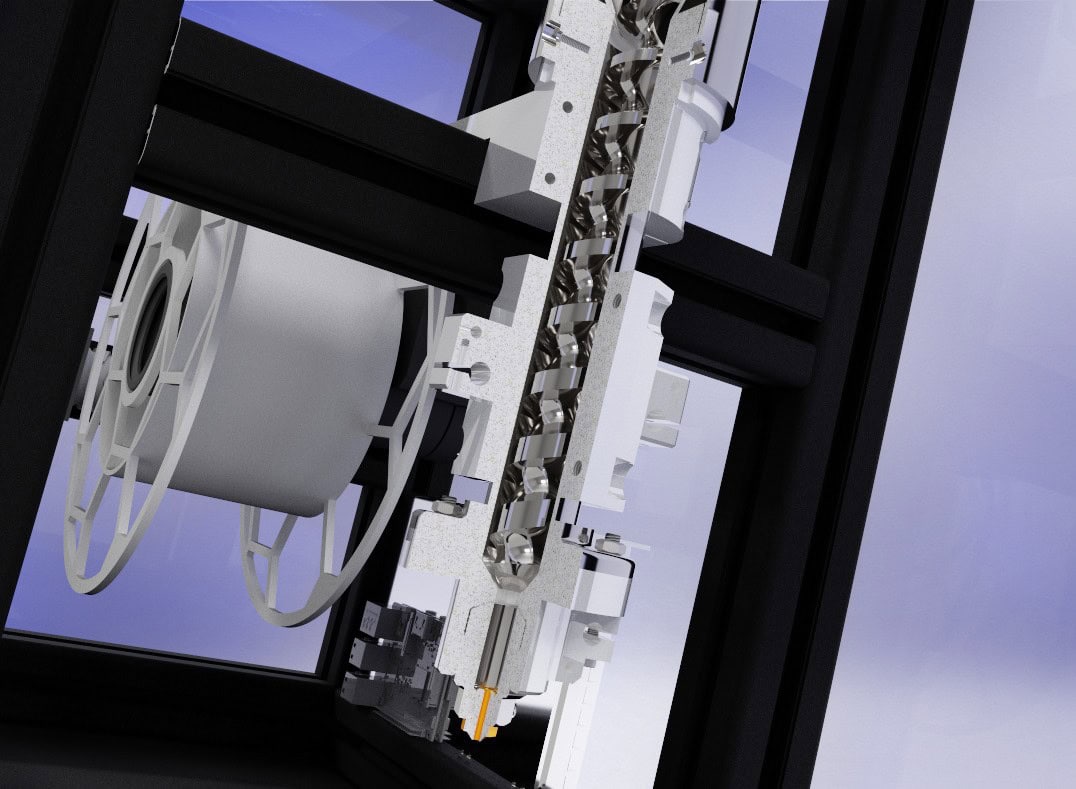

The complete machine was designed using Autodesk Inventor Professional 2026. Throughout the development process, we combine mechanical engineering, electrical engineering, programming, and materials science. This interdisciplinary approach allows us to address the system as a whole rather than as a collection of isolated components.

In addition to reducing environmental impact, the project aims to make 3D printing more cost-effective. By recycling their own material, users can reduce dependence on new filament spools and gain better control over material usage.

Recycling Process and Machine Operation

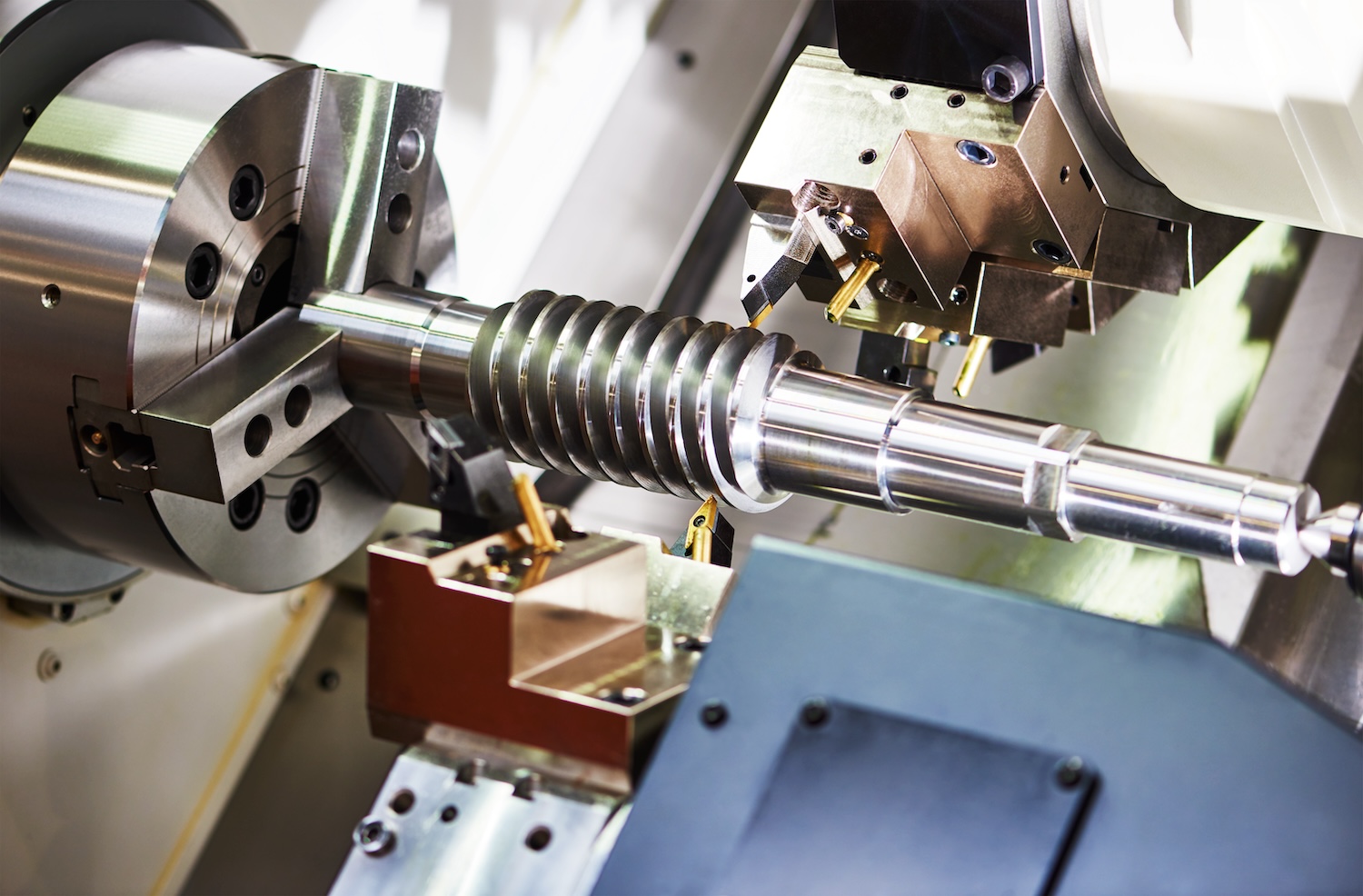

The machine processes previously shredded filament waste made from PLA or PETG. These small fragments are fed into a hopper and guided into a heated extrusion unit. At the core of this system is a complexly designed extruder screw, manufactured by Xometry using CNC machining from Steel 1.0038 / S235JR.

As the screw rotates, it transports the material through the barrel, compressing and melting it until a homogeneous polymer melt is formed. This melt is then pushed through a precision-manufactured nozzle, producing a continuous filament with a defined and consistent diameter.

After leaving the nozzle, the filament passes through a cooling section, where it solidifies completely. It is then guided into an automatic winding mechanism that evenly spools the filament onto a standard filament reel.

How the System Is Divided Into Engineering Modules

The project is structured around clearly defined engineering modules, each reflecting the different technical requirements of the overall system.

Development of the extrusion unit focuses on the extruder screw, heating elements, nozzle interface, and drive components. This module requires precise geometric design as well as a solid understanding of material flow behavior and heat transfer within the extrusion process.

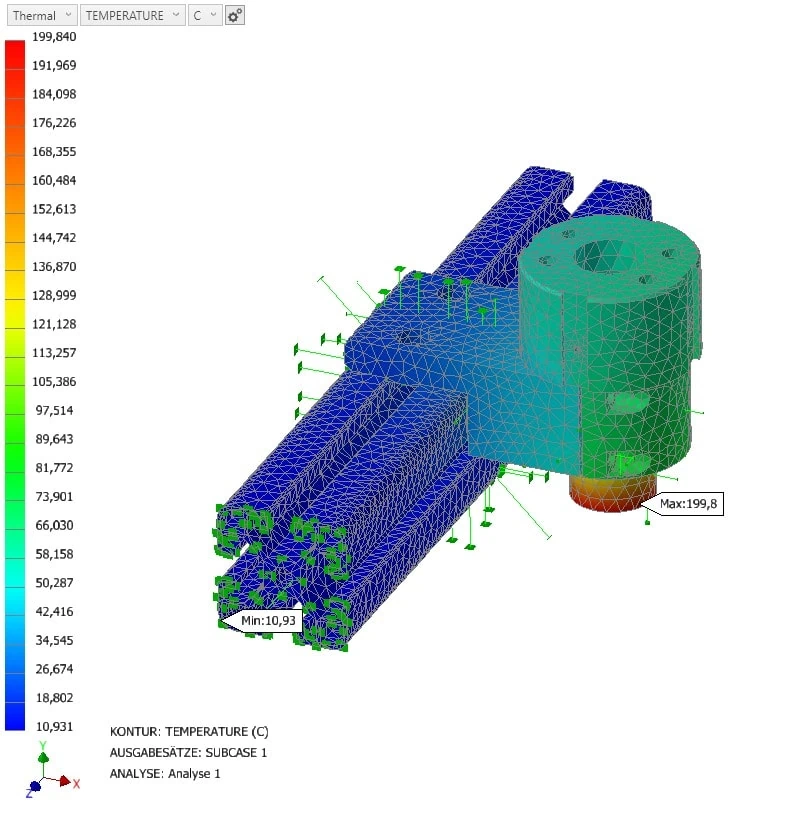

The machine frame and housing are designed in parallel with detailed thermal simulations conducted using Inventor Nastran. These analyses are used to evaluate heat distribution throughout the system and to ensure that temperature-sensitive components are adequately protected during operation.

Work on the winding mechanism and electronic systems covers sensor integration, control hardware, temperature regulation programming, and the implementation of a safe and reliable filament winding process. Together, these elements ensure consistent filament handling and stable operation of the machine as a whole.

Project Outcomes and Key Learnings

This project demonstrates how hands-on engineering work can be implemented within a technical education context while addressing a practical engineering challenge. By combining mechanical engineering, electronics, materials science, and digital design, we developed a functional filament recycling machine that offers both ecological and economic value.

Working through the technical challenges—from extrusion behavior and thermal management to control systems and filament winding—enabled us to build a complex system with clear relevance for everyday 3D printing. At the same time, the project provided practical experience in how different engineering disciplines come together to turn a concept into a working machine.

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)