During our hackathon, our team set out to address this gap in hygiene and usability with a practical, sustainable, and user-friendly innovation. The result was SaniPedal, a hands-free system designed not just to improve public restroom hygiene—but to do so using recycled construction materials.

Public Restroom Sanitation Challenges

It’s a familiar scenario: stepping into a public restroom, hesitating before touching the door handle, flushing the toilet with an elbow, and avoiding unnecessary contact with surfaces that thousands of people have touched. The World Health Organization (WHO) has emphasized the importance of clean and sanitary public toilets, yet hygiene remains a pressing concern. With only 650 public toilets serving London’s growing population, sanitation is far from ideal.

Research shows that an average restroom visit involves making contact with eight different surfaces, each a potential hotspot for bacteria and viruses. This issue became the driving force behind SaniPedal, a solution we designed during the hackathon.

A Simple, Contactless System

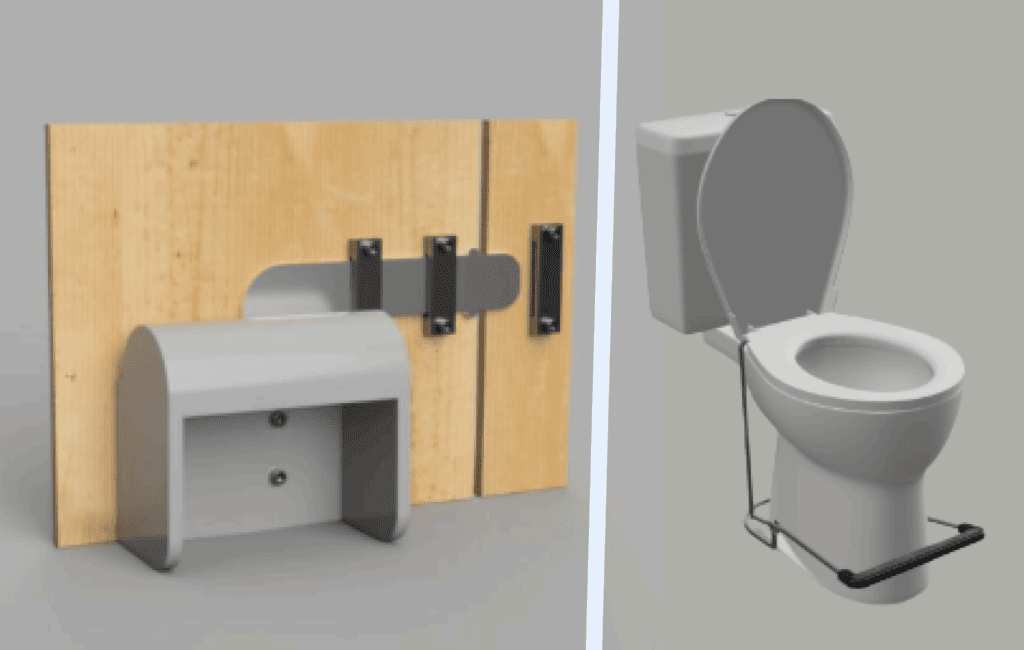

SaniPedal is made up of two intuitive foot-operated mechanisms that eliminate the need to touch key bathroom surfaces:

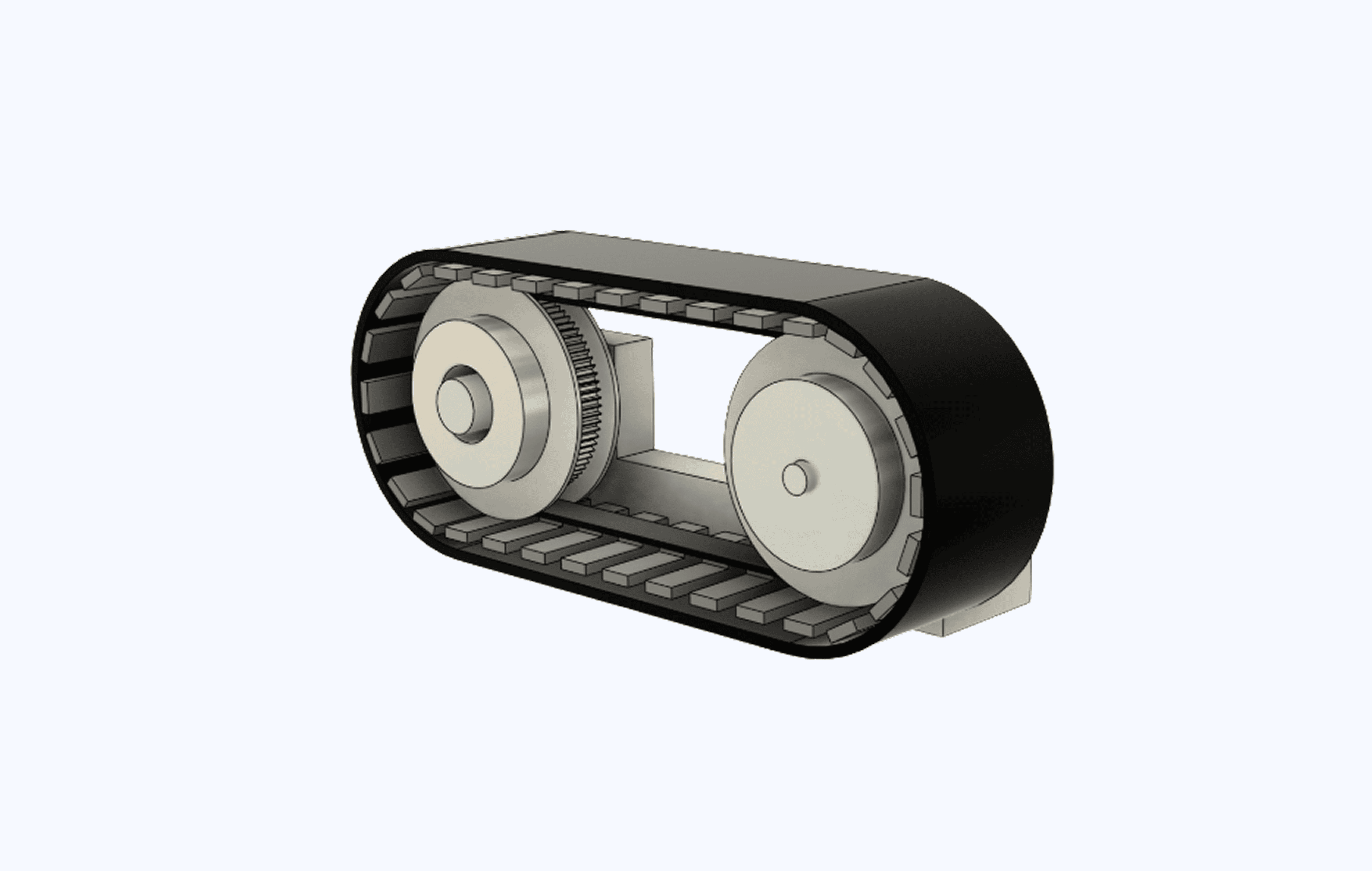

- The door slider lets users lock, unlock, and open restroom doors using only their foot—removing three of the most common contact points in a bathroom visit.

- The toilet pedal enables users to lift and lower the toilet seat without touching it. A hinge mechanism ensures the seat returns to its original position gently, using gravity and a rubber stopper system.

The idea is simple: the less you touch, the less you spread. By removing the need for hand contact in critical areas, SaniPedal directly tackles the hygiene issues that make public restrooms uncomfortable—and sometimes unsafe.

Building with Waste, Not Wasting Materials

From the start, sustainability was at the core of our design. The UK’s construction industry is responsible for more than 60% of the country’s total waste, much of it reusable. Instead of sourcing new materials, we repurposed discarded components to build SaniPedal.

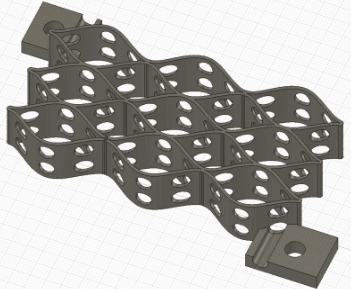

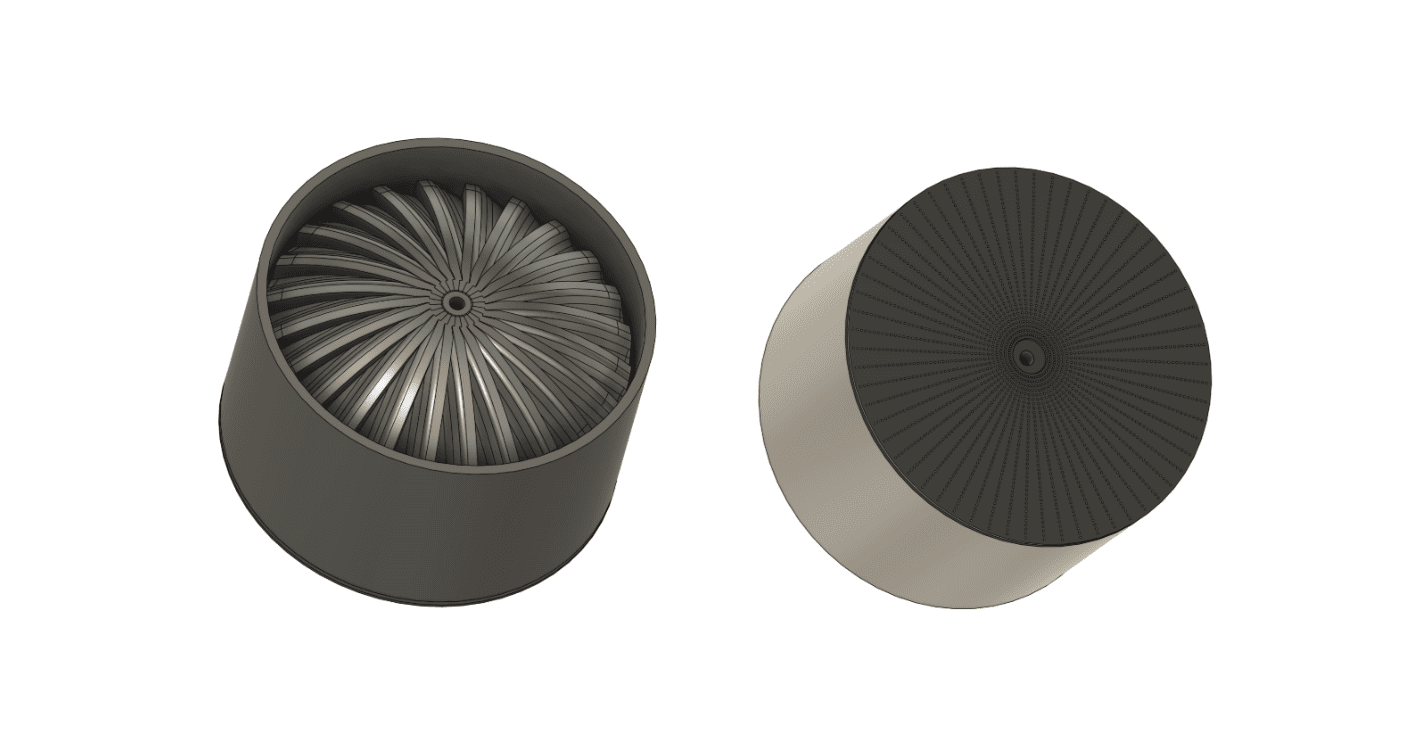

We used steel rebar for the structural frame of the door and toilet mechanisms, recycled PVC for the foot pedal, and re-rollable steel for brackets and hinges. These materials, often seen as waste, became part of a solution that serves both public health and environmental goals.

To ensure durability and safety, all components would be cleaned via sandblasting and coated for protection—keeping hygiene at the forefront even in the material prep stage.

From Prototype to Reality

Throughout the hackathon, we rapidly prototyped the two mechanisms using 3D printing and laser-cut parts. The door slider was built from recycled sheet metal and injection-molded plastic. The toilet pedal relied on steel plates for stability, with rubber stoppers guiding smooth seat movement.

During our final presentation, Joao Clemencio, a sales engineer at Xometry, raised thoughtful questions about the functionality of the toilet pedal and its ability to operate consistently. We demonstrated how the pedal pushes the seat just past vertical, letting gravity take over and bring it back into place. His feedback highlighted the importance of intuitive, clear mechanical interactions—something we’ve taken into account as we refine the design.

Joao also requested a hands-on look at our 3D-printed door slider prototype, which we were able to demonstrate. The interaction underlined the value of prototyping in communicating not just the idea, but how it would feel and function in everyday use.

Scaling Hygiene

London alone is home to more than 570,000 toilets across public spaces, businesses, and institutions. With a lightweight design, simple installation, and the ability to scale production through partners like Xometry, SaniPedal has the potential to transform hygiene standards across shared facilities.

This project started as a response to a simple problem: people shouldn’t have to feel uncomfortable or unsafe in a public restroom. But with the right mix of engineering, sustainability, and usability, we believe SaniPedal can become part of the solution—one step at a time.

What do you think of this hands-free hygiene solution? Share your thoughts on where it could be most useful and how you might improve the design.

Discover the other UCL Hackathon projects:

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)