Material Hardness Converter

Convert Rockwell, Brinell (HBW), and Vickers (HV) hardness. Pick a scale, set a value, and compare across methods within valid overlap ranges.

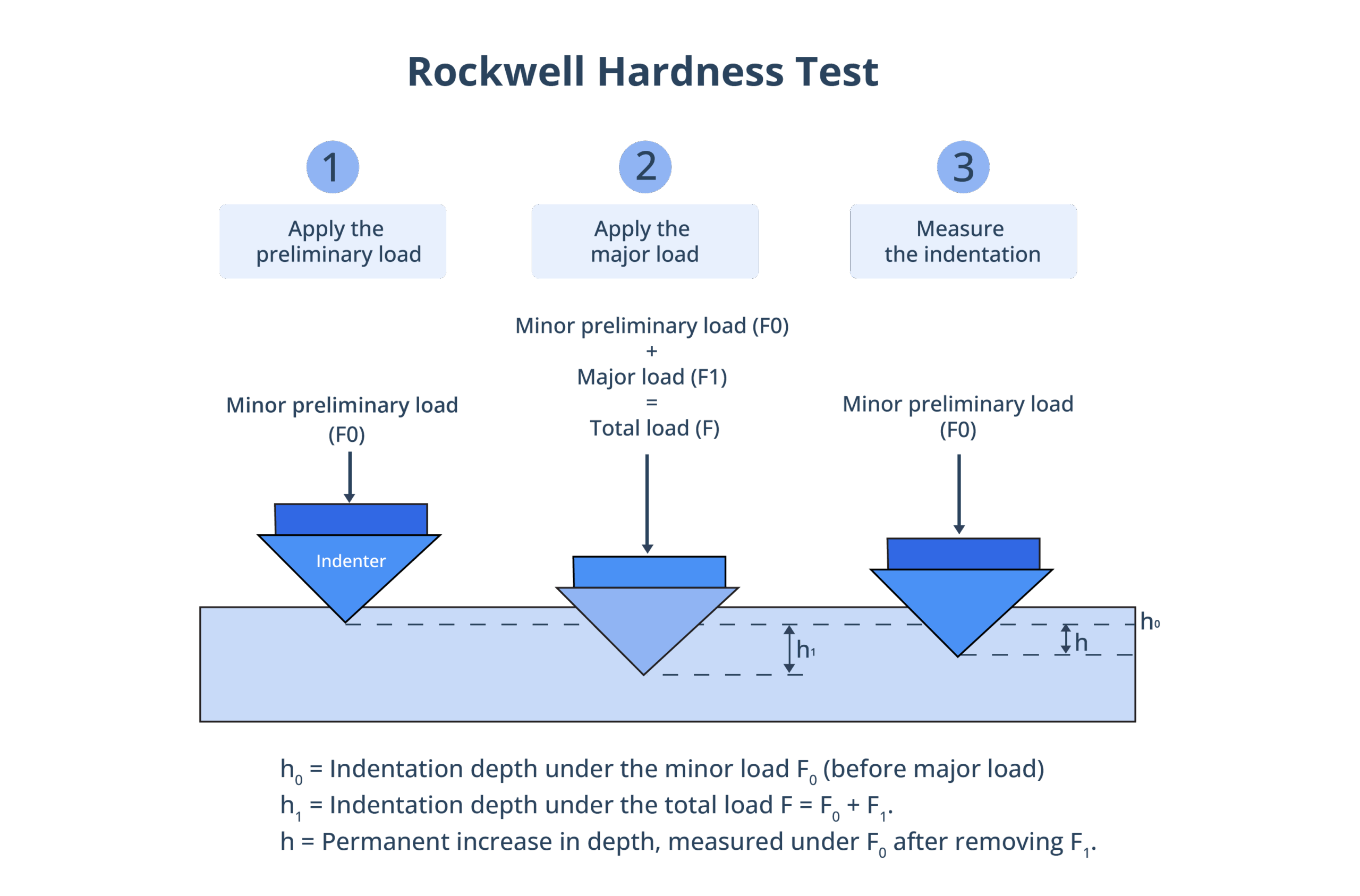

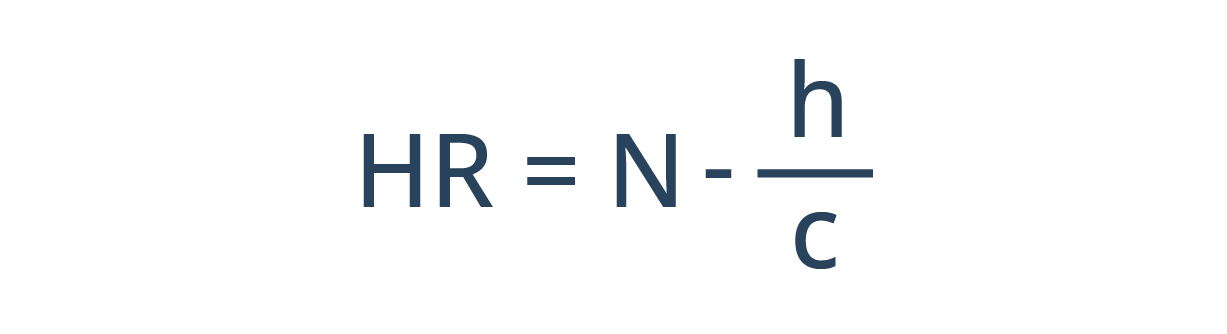

Rockwell

Rockwell Superficial

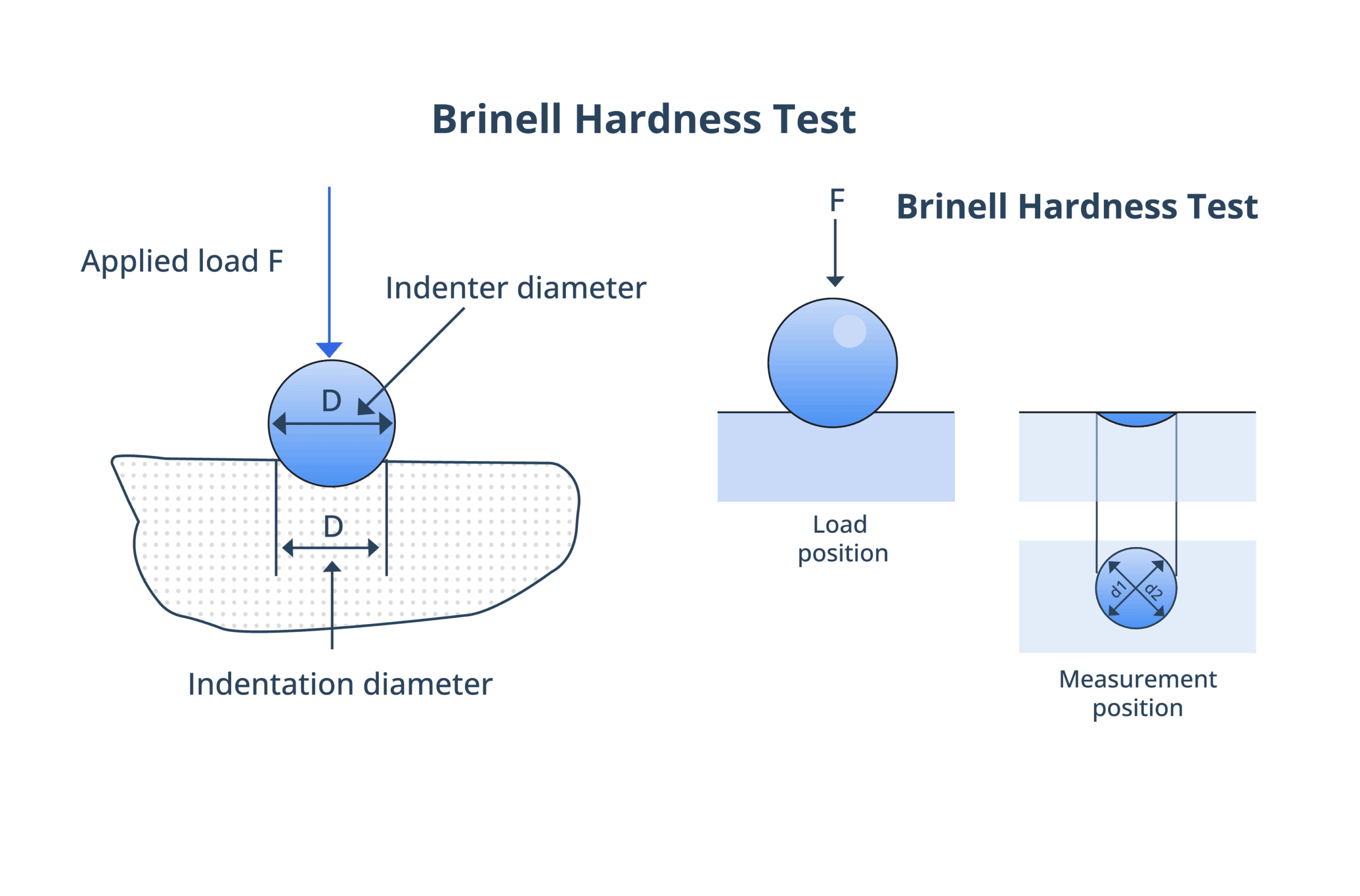

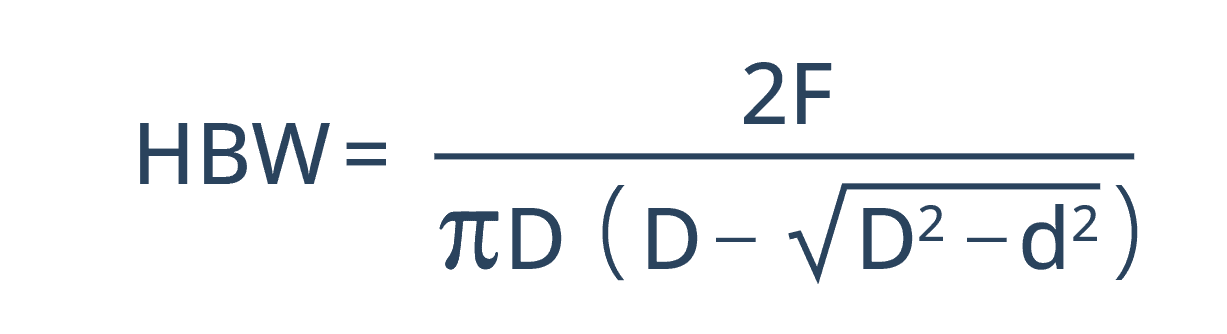

Brinell

Vickers

Explore Hardness Ranges

- Enter a hardness value to see what materials fall within that range and their typical applications.

Please Note:

Please Note:

- Hardness scale conversions are empirical and intended only as general guidance. For engineering or quality-critical purposes, hardness should be measured directly using the method best suited for a specific material class.

- The values in this table may not match those from other conversion charts based on different datasets. Differences in material composition, heat treatment, and testing conditions can lead to variations in measuring results.

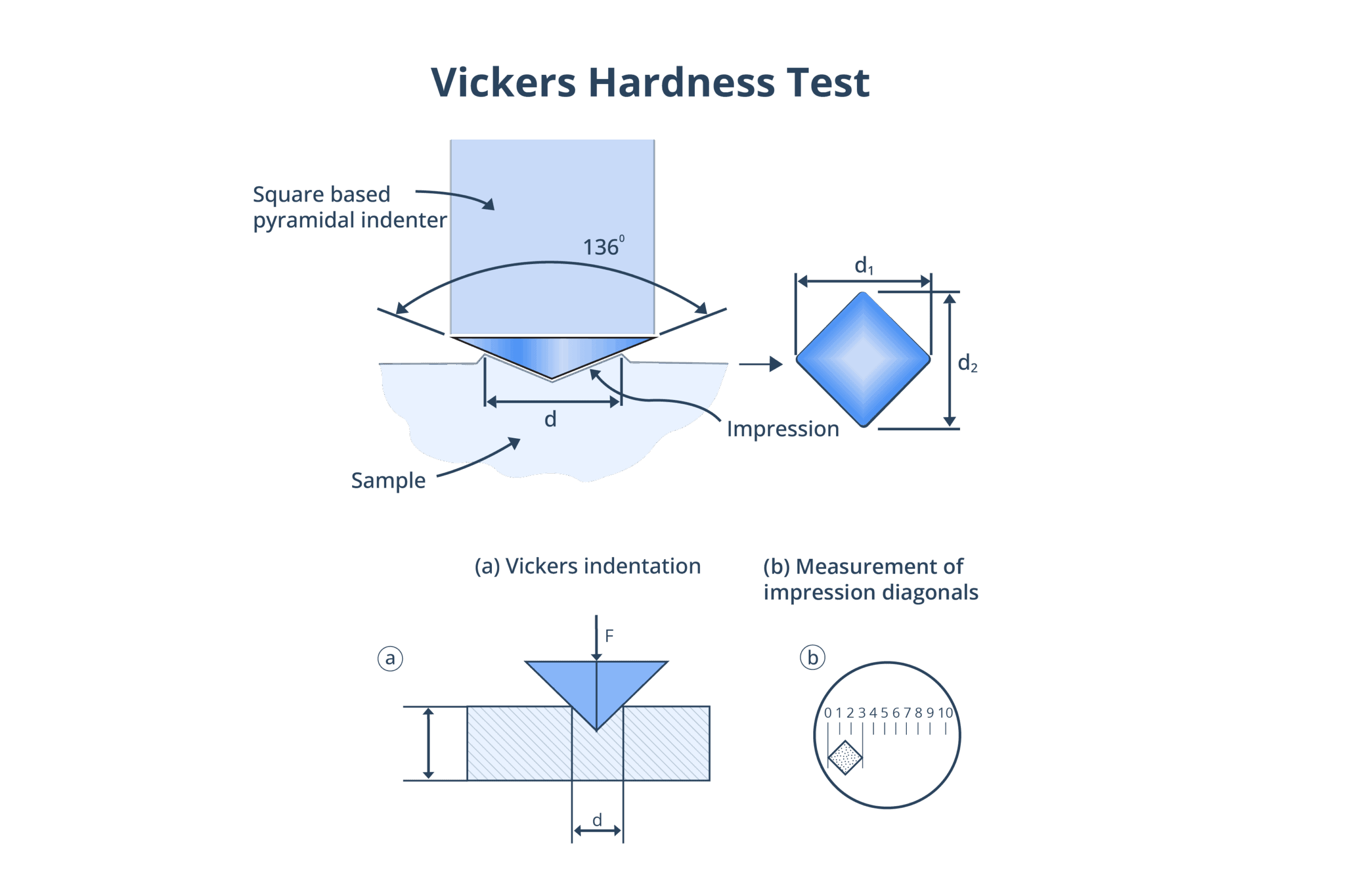

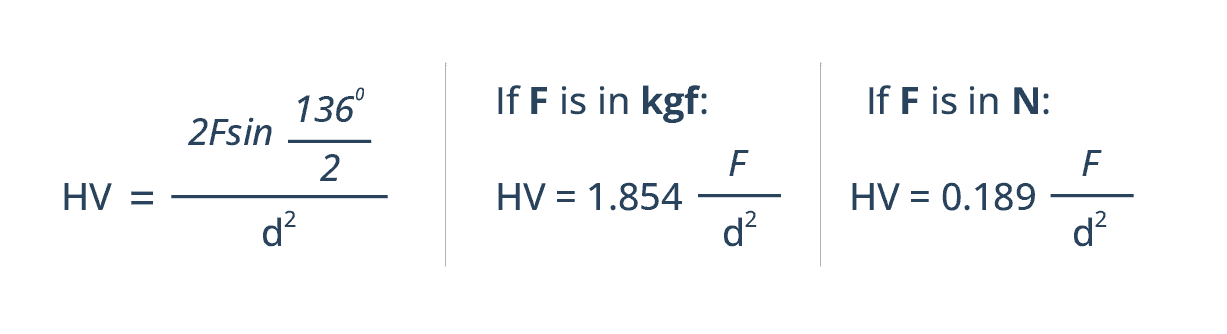

How Each Hardness Test Works

FAQ

Why do hardness values differ across scales (Rockwell, Brinell, Vickers, etc.)?

Different methods use different loads, indenter shapes, and penetration depths, so the same material will read differently depending on the scale. Conversion charts are empirical correlations, not exact equations.

Can I use hardness conversion values in place of actual test data?

Only as an estimate. Conversion tables are useful for quick comparisons and material selection, but if your specification calls for a particular hardness test (e.g., Rockwell C), you must test in that scale. Converted values should not be used for final acceptance in critical applications.

Why does the same steel grade sometimes show different hardness conversions?

Microstructure matters. Two steels with the same chemical composition but different heat treatments (quenched, tempered, case-hardened) can yield different indentation behaviors, affecting conversion accuracy.

Can I convert hardness to tensile strength directly?

Approximate tensile strength correlations exist (e.g., Brinell hardness to MPa), but they are material-dependent. For carbon and low-alloy steels, the relationship is fairly reliable. For aluminum, titanium, or tool steels, it’s less consistent. Use only as a rough estimate.

What is the most versatile hardness scale if I have to choose only one?

Vickers (HV) is the most versatile as it works on thin materials, coatings, and across a wide hardness range. However, it requires a microscope to measure the indent. Rockwell is quicker for shop-floor hardness testing but less universal.

Can I use this converter for non-metals (plastics, ceramics, composites)?

No, conversions are metal-specific. Non-metals require specialized tests (e.g., Shore for plastics, Knoop for ceramics).

Why do some tables show “---” instead of a value?

Not all scales overlap across the full hardness range. For example, Rockwell B is not valid for hardened steels above ca 100 HRB. When the indentation becomes too shallow or too deep for a given scale, no reliable conversion exists.

What are the units for these hardness testing methods?

Hardness numbers are unitless because they’re derived from indentation depth, load, or impression size, and then normalized in the test method’s formula. That’s why you see “HRC 60” or “200 HBW” rather than MPa or psi.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account