- Industry: Robotics, Automation, Agricultural Technology

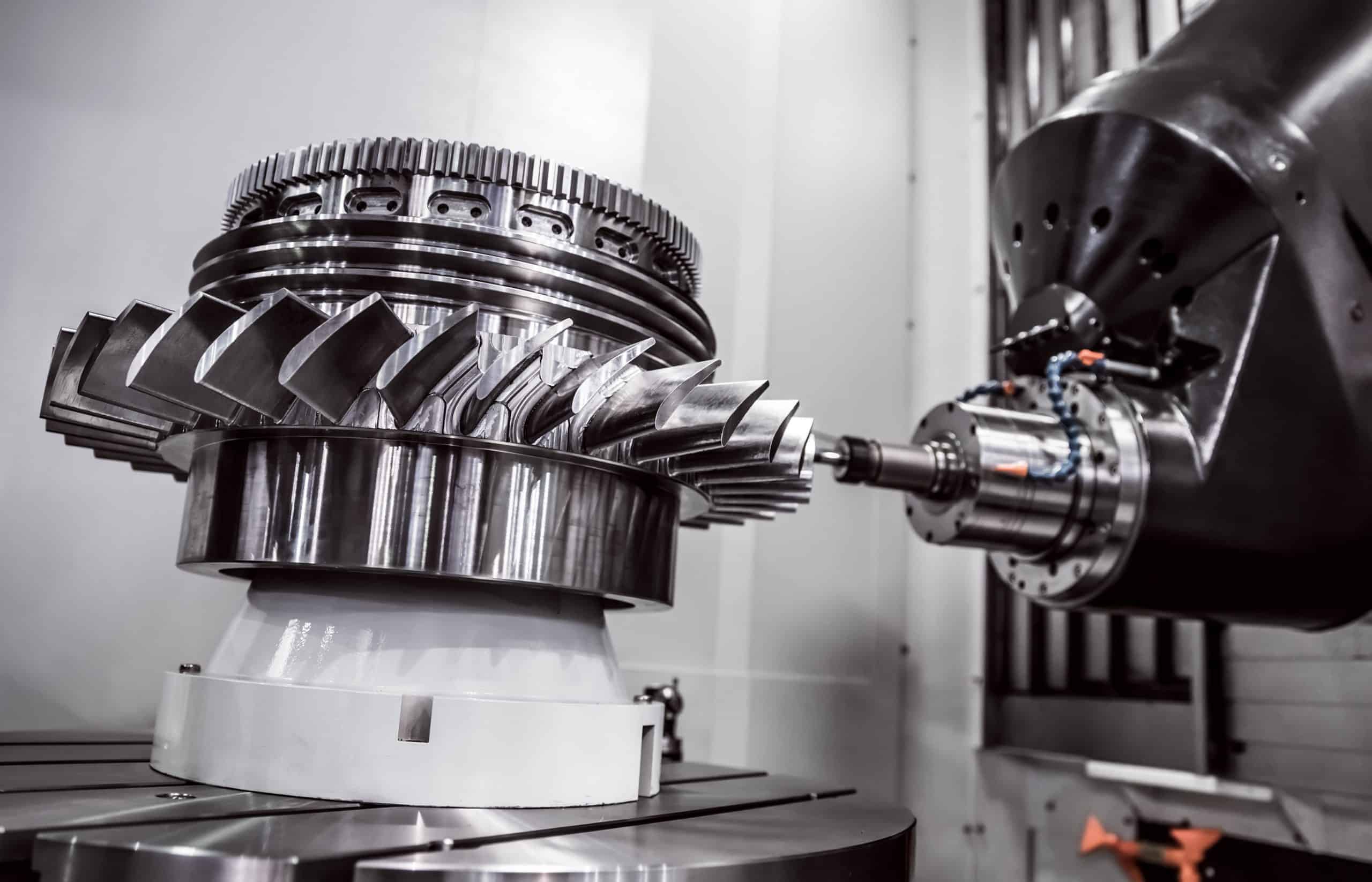

- Manufacturing Processes Used: CNC Machining

- Challenge: Rapid and cost-efficient sourcing of high-precision parts for both prototyping and production.

- Solution: By leveraging Xometry’s manufacturing network, Zauberzeug can quickly and reliably source custom components in small and medium quantities, optimising its iterative development process.

Flexible and Cost-Effective Component Sourcing

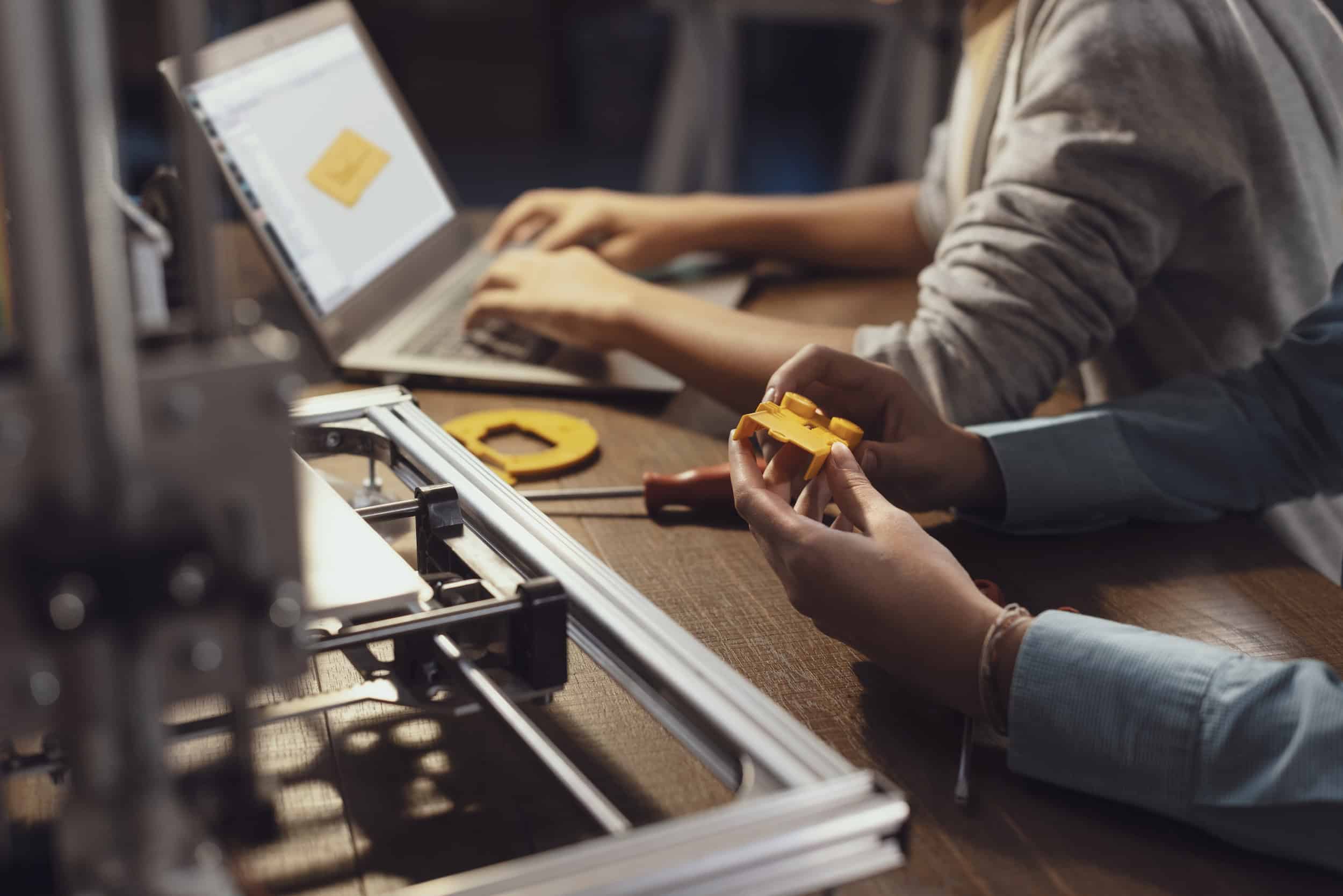

Developing a robot like Feldfreund requires a variety of specialised components. From mechanical elements such as enclosures, heat sinks, and milled parts to custom drivetrain components, all parts must fit together seamlessly. Especially in the early development stages, frequent design iterations demand a flexible manufacturing process.

Traditional sourcing methods often lead to delays. Local suppliers frequently have long production lead times or high minimum order quantities, making iterative development challenging. Additionally, conventional procurement processes create significant administrative overhead. Zauberzeug sought a way to obtain custom parts quickly, cost-effectively, and at a consistently high quality.

Smarter Manufacturing, Faster Delivery: Digital Production with Xometry

With Xometry, Zauberzeug can quickly calculate prices, order custom parts, and receive them within days. The platform enables fast and reliable CNC machining, helping Zauberzeug streamline its development process and accelerate innovation.

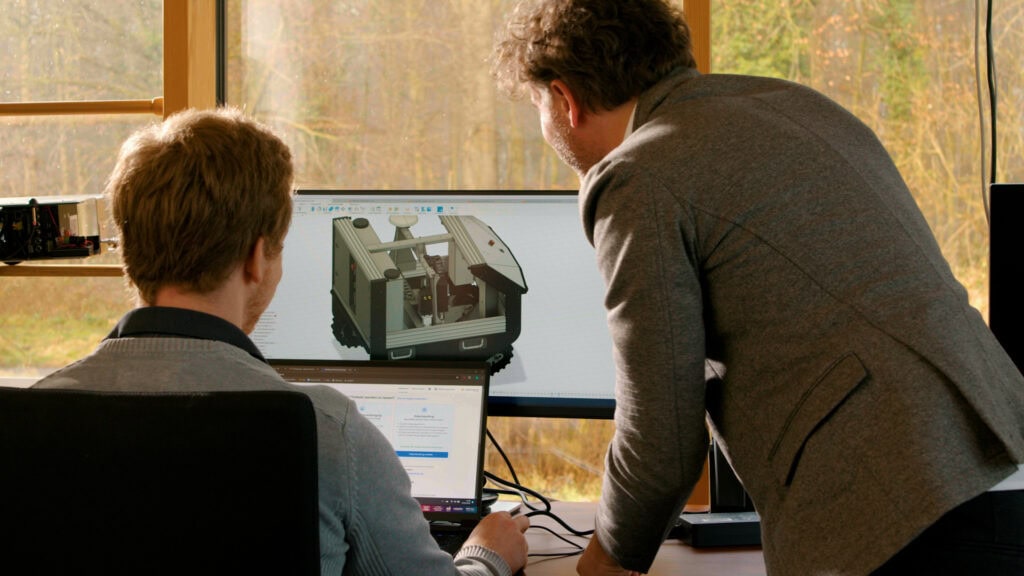

Rodja Trappe, founder and CEO of Zauberzeug, highlights the advantages of working with Xometry:

“We can simply upload a CAD file and get an instant quote. This saves us an enormous amount of time and allows us to test our designs much faster. Sometimes, we even use the platform for small experiments to see how much a particular manufacturing method would cost. This flexibility helps us fine-tune our products with precision.”

Another key benefit is the ability to order both individual parts and small series. During the transition from development to production, it is essential for Zauberzeug to be able to manufacture new designs in small batches economically before moving to full-scale production.

How Zauberzeug Uses Xometry for Innovation

Thanks to Xometry, Zauberzeug has successfully developed several critical components for the Feldfreund robot. One example is the custom-designed track drive, optimised for rough terrain. Standard sprockets did not fit the rubber tracks used, so Zauberzeug developed a bespoke solution. Through Xometry, these components were manufactured with precise specifications.

Another example is the redesign of the robot’s frame system. Initially, the frames were made of steel and had to be welded in-house—a process that was time-consuming and resource-intensive. By switching to milled aluminum frames, produced via Xometry and delivered pre-anodised, Zauberzeug significantly reduced production time while improving both quality and aesthetics.

Xometry also played a crucial role in optimising battery cooling. The original off-the-shelf heat sink did not provide sufficient thermal management. By designing a custom solution with additional cooling fins, Zauberzeug was able to improve heat dissipation significantly, extending battery life and improving overall efficiency.

Faster Development, Greater Flexibility

Working with Xometry has allowed Zauberzeug to accelerate its development cycles and maintain a flexible production strategy. With seamless access to high-quality custom parts, the company can bring ideas to life more quickly—without being constrained by long lead times or excessive order minimums.

Rodja Trappe summarises the collaboration as follows:

“With Xometry, we have found a manufacturing partner that supports our development philosophy. The ability to quickly and precisely order small batches of parts gives us the freedom to iteratively improve our robots. This flexibility is essential to our innovation process.”

Xometry’s digital manufacturing solutions not only streamline Zauberzeug’s prototyping efforts but also facilitate a smooth transition into scaled production. By reducing bottlenecks and enabling rapid iterations, Zauberzeug can continue to grow efficiently and bring new technologies to market faster.

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)