We had a chat with Dirac’s CEO Filip Aronshtein to learn more about the engineering solutions to engineering problems, enabled only recently by the developments in AI.

The Gap Between Design and Manufacturing

What’s the core problem you identified?

Mechanical engineers are often not well-versed in the reality of the manufacturing facility. There’s a lot of real-world context that never actually makes it into the design process. While most mechanical engineers are brilliant at CAD, they don’t live with the consequences of those designs on the factory floor.

Therefore, there’s a lot of critical real-world manufacturing context, including clearances, assembly order, ergonomics, and tooling constraints, that never makes it back upstream into the design process.

Between design and execution sits planning. Unfortunately, that world is shockingly static. When something changes on the design side, it often takes weeks or months for that context to propagate to the shop floor. This lag significantly amplifies cost, delay, and risk.

Why does it take so long to get design changes to the shop floor?

Because work instructions are still made like it’s the ‘90s.

Manufacturing engineers manually figure out assembly order, check for clearances, try to make sure it’s actually assemblable, take hundreds of screenshots, and stitch everything together into massive PowerPoint or Word documents. All this takes weeks, or even months.

Now change two parts in a 5,000-part assembly and you’re back to square one: redoing screenshots, revalidating context, and hoping nothing breaks downstream. With constant engineering iterations, you’re re-drafting work instructions, which are the core atomic unit of the factory.

What’s your personal touch with all of this?

My background is in electrical engineering and robotics. I got my start at Northrop Grumman working on radar systems. When they ran out of electrical engineering work to give me, they gave me mechanical engineering work. When they ran out of mechanical engineering work to give me, they gave me technician work.

I did assembly and testing and got to see how ridiculously archaic all the infrastructure was on the manufacturing side of things–even at a really advanced company on the engineering side. I wanted to do something about it.

Who’s the biggest loser currently?

Everyone.

Mechanical engineers don’t know their design isn’t actually assemblable or manufacturable. Manufacturing engineers are spending 50% of their day making PowerPoints instead of improving processes. Operators and technicians are working from outdated work instructions.

The real loser is the business, as everyone is operating on tribal knowledge, with people often guessing and hoping for the best. This results in products getting to market later than they should.

BuildOS, the First AI-Driven Work Instruction Platform

What’s your solution?

We’ve built BuildOS, the first AI-driven platform for work instruction authoring. Instead of taking weeks or months, a manufacturing engineer uploads a CAD assembly, and BuildOS automatically derives an assembly sequence and generates interactive, 3D, animated work instructions.

If you change the sequence, the animations update automatically on the fly. If you add additional context like torque specs, it gets automatically associated with the specific components.

80-90% of the work is automated. The remaining 10-20% becomes captured tribal knowledge that is structured, reusable, and permanently retained by the organization.

The assembly team must be equipped with tablets to check the animations.

Any device with a screen and a browser: tablets, monitors, phones, etc. BuildOS is web-native.

However, we can also export the instructions to a PDF, Word doc, or PowerPoint if you did want to print it out on paper. But we often see in practice that customers who start with the paper instruction set quickly install monitors on their shop floor.

We’re actually a justification for businesses to finally modernize their factory infrastructure and invest in monitors or screens for their shop floors.

How does tribal knowledge retention work?

Under the hood, we’ve built deterministic geometry recognition infrastructure and simulation technology. That allows us to recognize common subassemblies across builds, recognize components whenever they reappear, and build upon previous work done in the software.

Every additional work instruction has a compounding effect on how much faster you can move the next time.

This isn’t just automation. It’s an accumulating production intelligence layer.

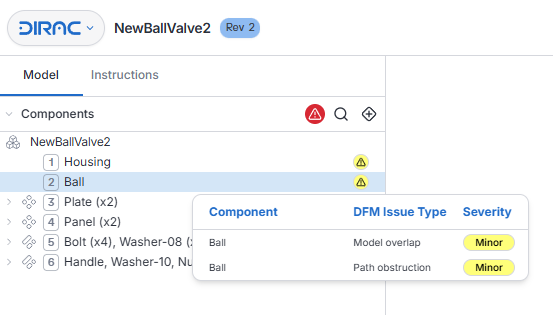

Does the software recognize design issues like interferences?

Absolutely. A core feature is our Design for Manufacturability clearance checker. It flags instances when there’s no clearance for a part to be inserted.

What’s the role of AI in all this?

Under the hood is computational geometry, physics simulation, and mechanically informed heuristics. We’ve figured out a way to make AI that is deterministic.

A lot of fears engineering and manufacturing teams have around AI is that it’s probabilistic and will hallucinate. What we’ve built is a system that is deterministic at its core, allowing you to automate very aggressively without worrying about hallucination.

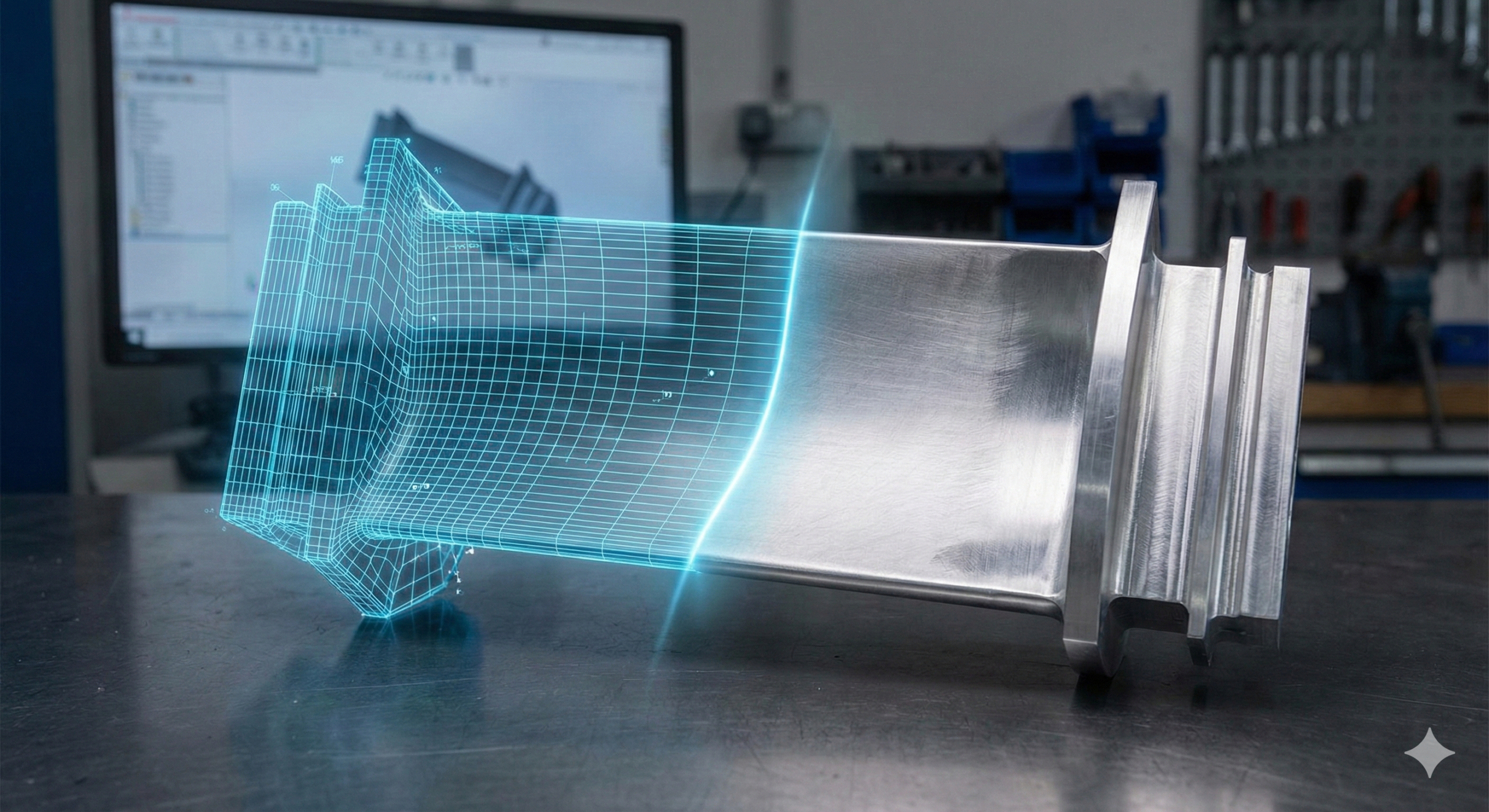

Your website talks about model-based manufacturing. Could you explain that?

For the past 15–20 years on the engineering side, the push toward model-based engineering moved everybody from paper blueprints to 3D CAD. Manufacturing never really caught up.

We close that loop. Across lines, stations, and facilities, BuildOS brings full model-based context, including part information, function, constraints, etc., into production planning and execution.

What’s the role of humans in the process?

We view BuildOS as a power tool and force multiplier for people in the process, not a replacement.

Humans still make the judgment calls. We still want people to check it over and manipulate the structure. There are so many different options for assembling. Humans often have much more context for making the right call in such cases.

What we do is remove the drudgery and amplify their impact. It’s a force multiplier for the people who actually understand how things get built.

90%+ Time Reduction for Customers

When did you launch and who are your customers?

We launched in April 2025. We have many paying customers across the United States, Europe, and Australia.

We work with folks in aerospace and defense, automotive, agriculture and construction machinery, maritime, and complex industrial machinery. Basically, if you build complex assemblies, we’re for you.

What size companies do you work with?

We support anyone from the largest enterprises with hundreds of thousands or millions of SKUs, all the way to the . smaller teams and mid-market manufacturers with just a handful of people and 20 SKUs.

The more SKUs the better, because we become a rubber band around all the variants and configuration management you have at scale for production planning. The bigger the company, the bigger our impact.

What assembly sizes can you handle?

We’re useful starting around 20 parts and we scale cleanly into tens of thousands of parts.

For example, one of the automotive OEMs working with us threw an entire top-level car assembly with 50,000 parts into our platform. We also work with companies making submarines and boats.

That entire spectrum is in scope.

How did it go with the car?

Well. Like really, really well, honestly.

There are so many different people typically involved in that process. When they started using our tool, they could have had just one person doing all those things. It created a shift in the way that company was thinking about their ways of working.

BuildOS is not just like an incremental tool that allows people to go faster. It’s a platform that allows manufacturers to fundamentally rethink the way that they do their production planning.

What benefits are customers actually seeing?

Massive improvement in quality of life. We’ve seen around 90-95% time reduction in time to draft a work instruction. They catch issues earlier, their work instructions look better, and their jobs are more dynamic.

More broadly, they get products to market faster. If you can increase the rate of iteration, you can do more cycles. That increases their pace of innovation.

How do people react when they first see the platform?

In the beginning, what we offer sounds magical, so people are naturally skeptical. Within the first couple minutes, we show them the process with their own CAD files and all that skepticism melts away.

The more veteran engineers are often the biggest skeptics initially. They then become our biggest champions because they see how game-changing this is for their teams. We call them “invertible skeptics.”

Any interesting stories that stand out?

Anduril’s COO mentioned that a key value prop of Dirac is that we help accelerate their sales. This happens especially with our aerospace and defense customers who use us as a centerpiece for why governments should purchase systems from them.

When our customers have their customers coming by to evaluate them, we are a core capability they showcase to demonstrate how advanced their production facilities are.

For suppliers, BuildOS is used to win bids. It becomes a signal of operational excellence.

All CAD Formats Accepted

What’s your pricing model?

We sell annual enterprise subscriptions, typically scoped at the factory or program level rather than individual users.

Pricing is driven by three things: the number of production sites or programs covered, the modules deployed—like work-instruction automation, change propagation, or factory layout—and the scale of engineering and production volume being supported.

Engineer modules are subscription-based; operator access is usually site-wide because the value comes from floor-level adoption. Larger customers typically start in 1-3 sites and expand pretty quickly as value compounds across the full enterprise.

What file formats and integrations do you support?

We take all native CAD file formats. So you can use us without any issues.

We also have partnerships with all the big CAD companies like Siemens and PTC for integrating with their PLMs like Teamcenter and others.

What about security and compliance?

We’re ITAR-compliant and self-hostable on an enterprise’s cloud infrastructure if necessary. Security is table stakes for our customers and we meet them where they are.

Production Orchestration

What’s your expansion roadmap?

Our vision is to be the AI-native system of record for production orchestration. The work instructions component is our first module.

We’re expanding to other workflows, like industrial engineers responsible for workcenters, line balancing, and laying out lines, automating maintenance and repair instructions (MRO), quality/inspection instructions, automating fabrication instructions, etc. Essentially, we want to tackle the critical workflows that aren’t well served by PLM, ERP or MES today, especially around automating production change management.

What else is interesting in the AI for mechanical engineering space?

I think there are very interesting opportunities in fixtures and tooling that AI is capable of helping accelerate. I’ve heard and seen some early promising work, though I don’t think it’s available yet. On the Dirac side, we’re orienting towards using AI to automate change management for the enterprise manufacturer.

AI in quoting workflows has been really successful. Xometry’s been a good example here.

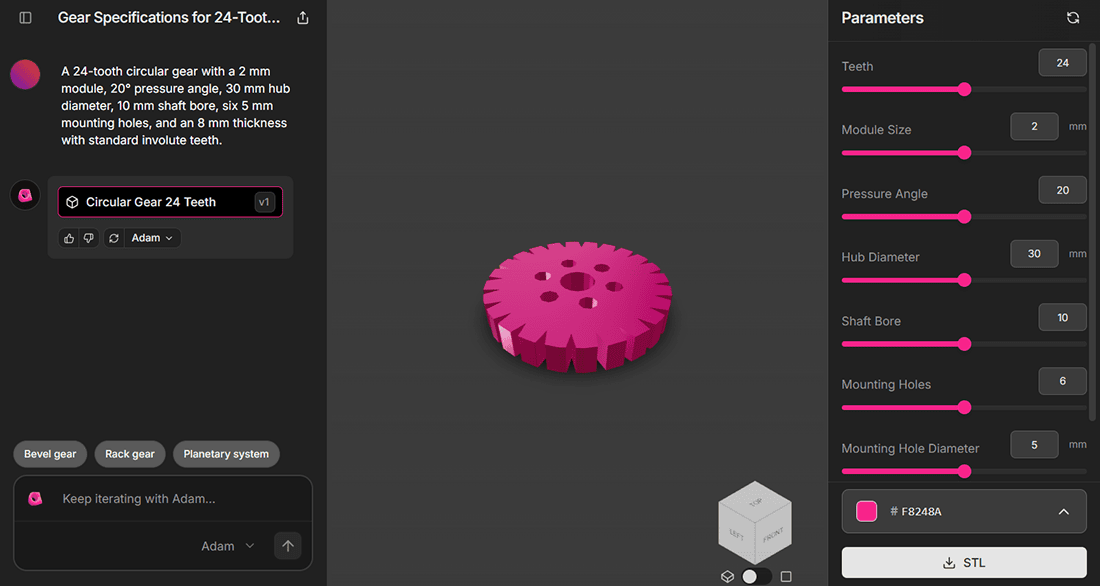

I also think companies like nTop doing generative design for components based on modifiable parameters will be very interesting, especially in the concept design phase.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)