TPV (rubber)

- Alternative Designations: Thermoplastic vulcanizate

Description:

TPV is a thermoplastic vulcanizate (TPV) designed for soft, flexible components requiring good mechanical durability and elastic recovery. Unlike standard TPEs, this TPV offers improved resilience, chemical resistance, and long-term flexibility under stress, making it ideal for dynamic sealing and cushioning applications. It combines rubber-like softness with the processing efficiency of thermoplastics, allowing for cost-effective injection molding of flexible parts such as gaskets, bellows, overmolded grips, cable boots, and vibration-damping mounts.

Material Properties

Processes:

Special properties

- Flexibility

- Heat resistance > 100℃

- UV resistance

| Property | Value, metric | Value, Imperial |

|---|---|---|

| Density | 0.89-1.04 g/cm3 | 0.89-1.04 g/cm3 |

| Elongation at Break | 200-750% | 200-750% |

| Hardness | - | - |

| Ultimate Tensile Strength | 5-29.2 MPa | 0.7-4.2 ksi |

-

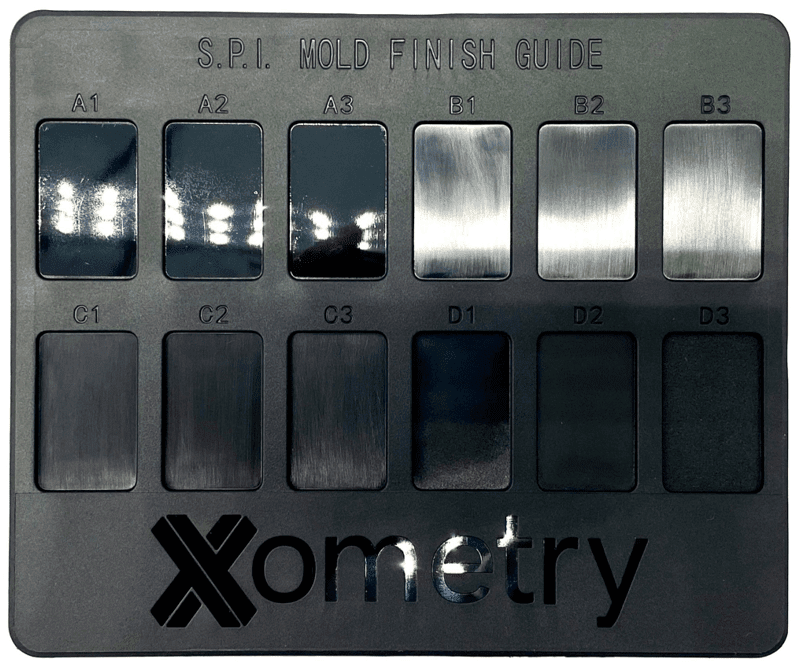

Injection moulding SPI surface finishes

Injection Moulding SPI Finishes

Injection Moulding SPI Finishes

SPI

SPI finishes are a set of standard mould finishes with different polished textures for enhanced properties.

Notes:A1, A2, A3, B1, B2, B3, C1, C2, C3, D1, D2, D3

Final result:

- Heavily polished, to semi-gloss to fine and coarse matte depending on the selection

-

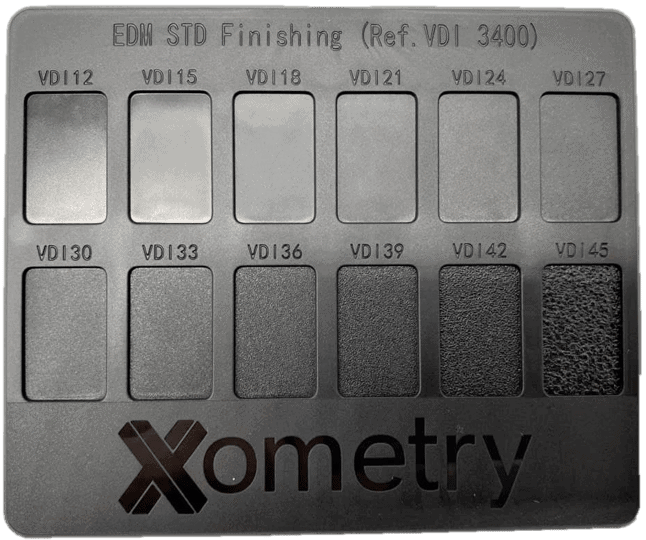

Injection moulding VDI surface finishes

Injection moulding VDI surface finishes

Injection moulding VDI surface finishes

VDI

VDI is an international standard for mould texturing of matte surfaces. It is mainly processed by Electrical Discharge Machining (EDM) when mould machining.

Notes:VDI12, VDI15, VDI18,VDI21, VDI 24, VDI27, VDI30, VDI33, VDI36, VDI39, VDI42, VDI45

Final result:

- Fine-to-coarse grain depending on the selection

-

Custom Finishing

If you select a custom finish in the Instant Quoting Engine it will require manual review. Manual quoting usually takes 1-2 business days.

Notes:Submitting for manual review with a custom request does not guarantee a quote.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account