Hi, my name is Isak, and I’m a materials technology student at the Norwegian University of Science and Technology (NTNU) in Trondheim. As part of Fuel Fighter NTNU‘s Production team, I work with 40 volunteer students in one of the most challenging engineering competitions in the world: the Shell Eco-Marathon. Our mission is to build ultra-energy-efficient vehicles that push the absolute boundaries of what’s possible with electric propulsion.

The Intersection of Materials Science and Extreme Efficiency

What drew me to Fuel Fighter is the obsession with optimization. In materials science, we study how microstructure affects macroscopic properties.

In Fuel Fighter, we apply that same thinking to an entire vehicle system: How can we extract maximum performance from minimum energy? It’s optimization taken to the extreme, and that’s exactly what excites me.

Reviving a Champion

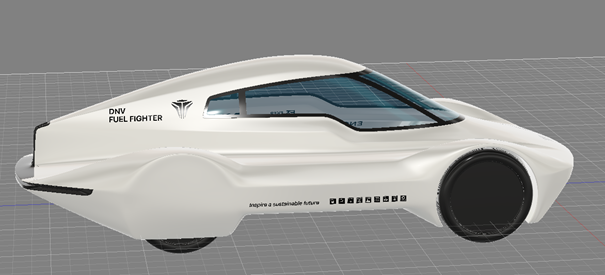

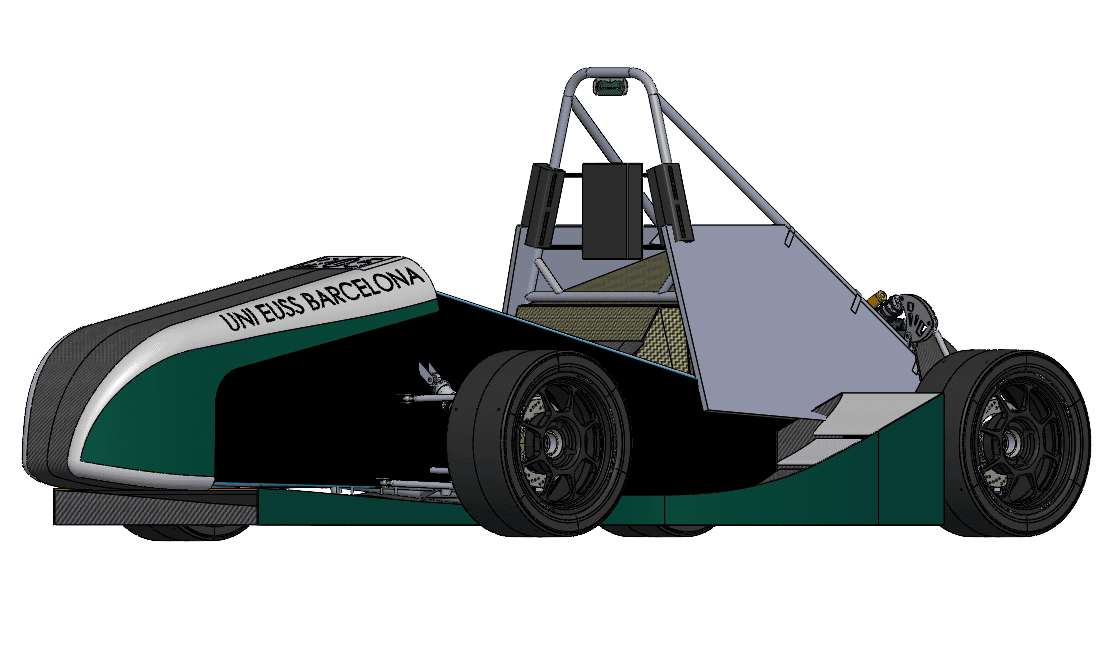

In 2019, Fuel Fighter 5 achieved something remarkable: 181 km/kWh—the equivalent of driving from Trondheim to Oslo on just 0.3 liters of gasoline. The car weighed only 73 kg and won the Shell Eco-Marathon design award.

For the 2025-2026 season, we’re taking a different approach. Rather than starting from scratch, we’re bringing back the Fuel Fighter 5 chassis and applying everything we’ve learned to make it even better. Our goal is ambitious: to create one of the most energy-efficient electric vehicles in Europe and secure a podium finish at the 2026 Shell Eco-Marathon.

We’re reusing a proven chassis, but pushing it further. Every gram matters. Every millimeter of space is precious. And every component must be both lightweight and robust enough to withstand competition demands.

The Challenges Behind the Redesign

The Steering System

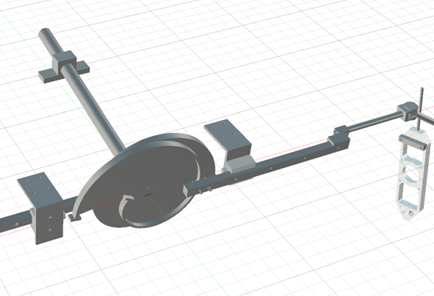

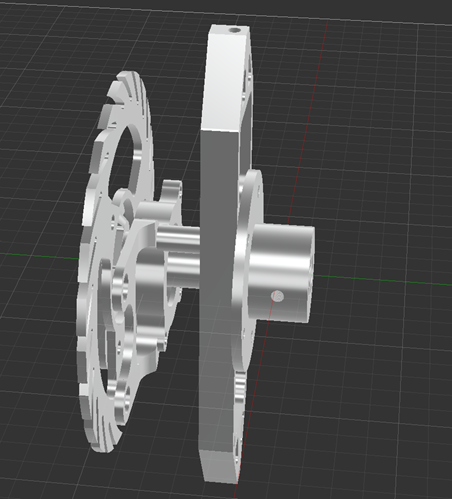

Our steering system uses a worm gear mechanism that converts rotational input directly to linear motion at the wheels. The challenge is dimensioning it correctly—we need the smallest possible design to minimize weight, but it must still handle the steering loads.

The worm gear requires extremely tight tolerances. We’re talking about thread profiles and geometries that must fit perfectly under load while maintaining smooth operation throughout the entire steering range. The critical dimensions need to be held to ±0.01-0.02 mm, with backlash controlled to around 0.05 mm for precision steering response and all this on components weighing less than 100 grams.

Traditional manufacturing struggles with this combination of precision and weight reduction. This is where partnerships with precision manufacturing services like Xometry become invaluable.

The Braking System

The braking system is even more demanding. Safety regulations require redundant braking on two separate wheels, and the system must function flawlessly, but our entire vehicle weighs less than a typical adult human.

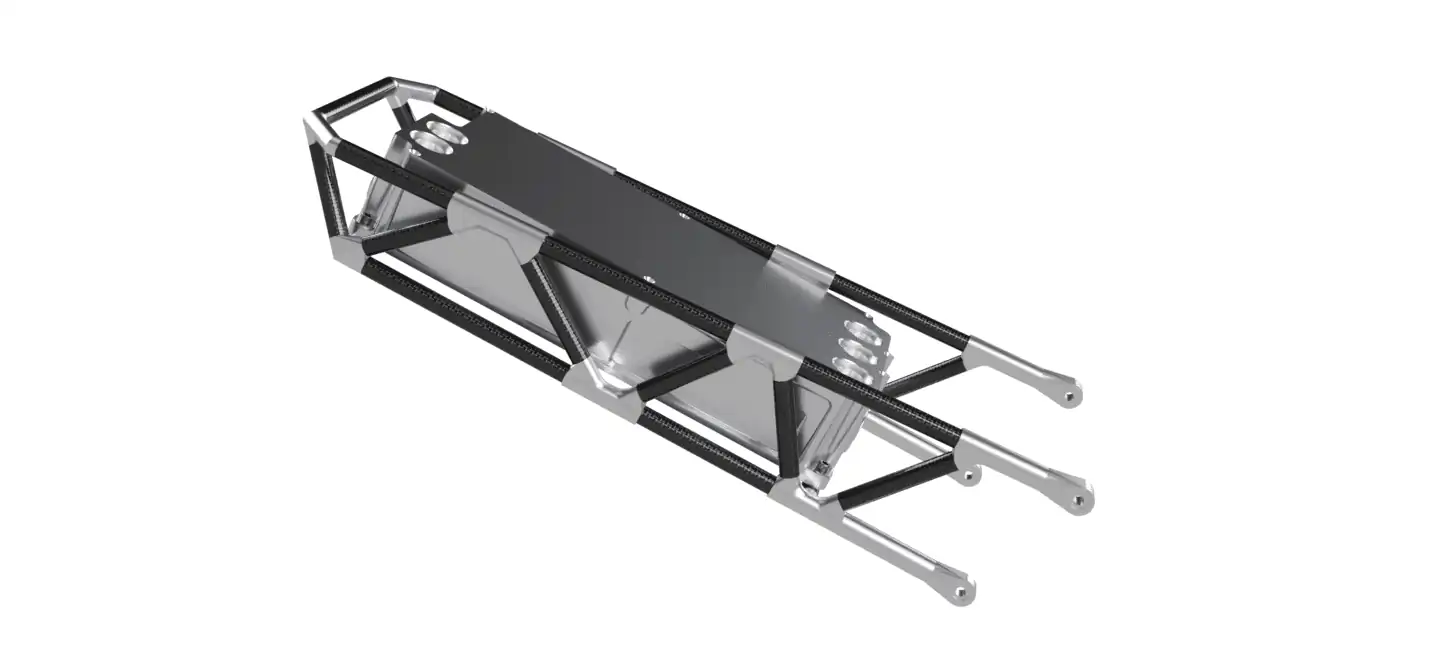

We’re designing a lightweight braking system with multiple moving components, calipers, brackets, and linkages that must operate with minimal friction and perfect alignment. The caliper mounting brackets have complex geometries with pockets and ribs that follow stress paths identified through finite element analysis.

The manufacturing challenge is significant: these components have multiple critical dimensions that must all be held to tight tolerances simultaneously. A deviation of even 0.1 mm in the wrong place can cause binding or reduced braking efficiency. There’s no room for ‘good enough’ when safety is at stake.

Balancing Lightweighting and Manufacturability

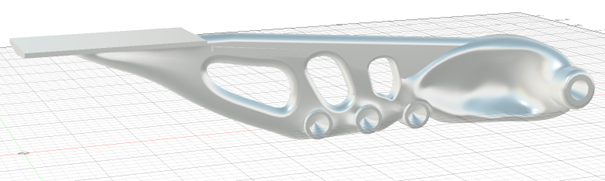

Perhaps our most persistent challenge: we extensively use topology optimization to create ultra-lightweight components. These computational studies can reduce mass by 40-50% by removing material from low-stress regions.

The results are beautiful—organic, flowing forms that look like they’ve been grown rather than designed. But they’re also difficult to manufacture. Complex undercuts need specialized tooling, and the more aggressive the optimization, the more expensive the part becomes to produce.

We’re learning to find the balance: using generative design to identify optimal load paths, then manually refining the geometry to be manufacturing-friendly. A part that’s 5% heavier but 50% faster and cheaper to produce is often the right engineering choice.

What Makes This Project Special

What sets Fuel Fighter apart is the integration of advanced engineering analysis with extreme weight consciousness. We’re building a car where every component has been analyzed, optimized, and refined to serve its purpose with minimal material—targeting component masses measured in tens of grams while maintaining the precision required for competition.

Beyond the technical specs, what makes this meaningful is the scale of the challenge relative to our resources. We’re volunteer students with academic equipment and limited budgets, competing against teams with professional engineering support. Every manufacturing partnership makes a tangible difference in our competitive capability.

Moving Toward the 2026 Competition

Our immediate goal is the 2026 Shell Eco-Marathon competition. We’re confident that the Fuel Fighter 5 chassis, combined with refined systems and lessons learned, will allow us to compete for a podium position.

For students taking on similar engineering challenges, one lesson stands out: manufacturing partnerships matter more than you think. Advanced CAD and FEA software can show you what’s theoretically possible, but actually making those parts requires real-world manufacturing expertise. Find partners who understand both precision and efficiency—services that can translate complex geometries into physical components that meet your tolerances without breaking your budget.

As we prepare for the 2026 season, we’re excited about what precision manufacturing partnerships can unlock for our team. With the right tools and the right partners, we believe Fuel Fighter can showcase the best of Norwegian engineering talent on the European stage.

Manufacturing stories & cases

Share your engineering or manufacturing story

If you want to share your story with others on xometry.pro, just fill out a short form

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)