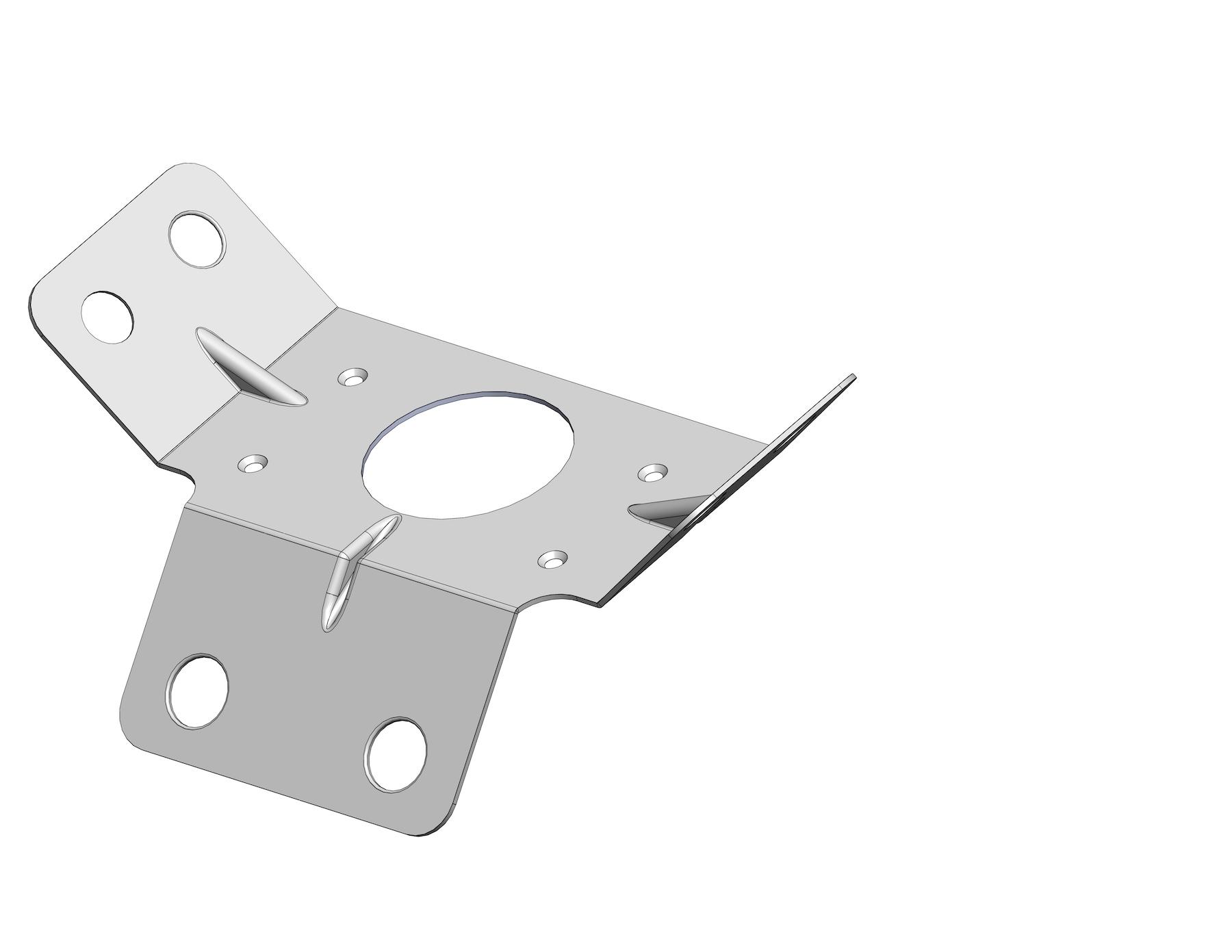

Adding countersinks to formed stainless sheet metal

D

Hello, I’m working on a sheet metal enclosure (as in the image) that requires flush mounting for M6 countersunk screws. I need to add a countersink on a few holes, but the part is already flat-cut and formed. Has anyone successfully added a countersink post-process in this kind of setup without warping the part? Looking for the most practical approach, either manual or otherwise.

Suggested Topics

Topic

Replies

Views

Activity

Thermal expansion modelling for a braced rectangular steel tank

hi, for a welded steel coolant reservoir for a test stand - 4 m × 2 m × 1.5 m with internal bracing I need to account for thermal expansion. Fluid runs at 80–90... read more

2

253

Feb 04

Designing holes for M3 threaded inserts in an ABS enclosure

Hi! In my design for a small ABS enclosure for an onboard sensor module I want to switch from molded bosses to heat-set M3 inserts for the lid screws. Before I finalize CAD, what... read more

1

337

Dec 23

Airtight joint between two aluminum frame enclosures?

Hi, I have two 400 mm cubical enclosures from 20×20 mm aluminum profiles with glass on all sides except one. I need to connect them into a single temperature-controlled unit and keep the joint... read more

2

545

Dec 29

SLA wall thickness issue for microfluidic channels

Hi, I created a 3D design for a small microfluidic part using SLA (Clear Resin) with internal channels ~0.4 mm wide and wall thickness around 0.5 mm. The function relies on optical inspection through... read more

1

1.4k

Jul 29

Embossed vs. engraved text for outdoor molded parts

Hi there, I need to add a part number and recycling symbol on the surface of molded parts in PP GF20 for outdoor use. I initially planned to use engraved text for aesthetic reasons,... read more

3

3.2k

Aug 08

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account