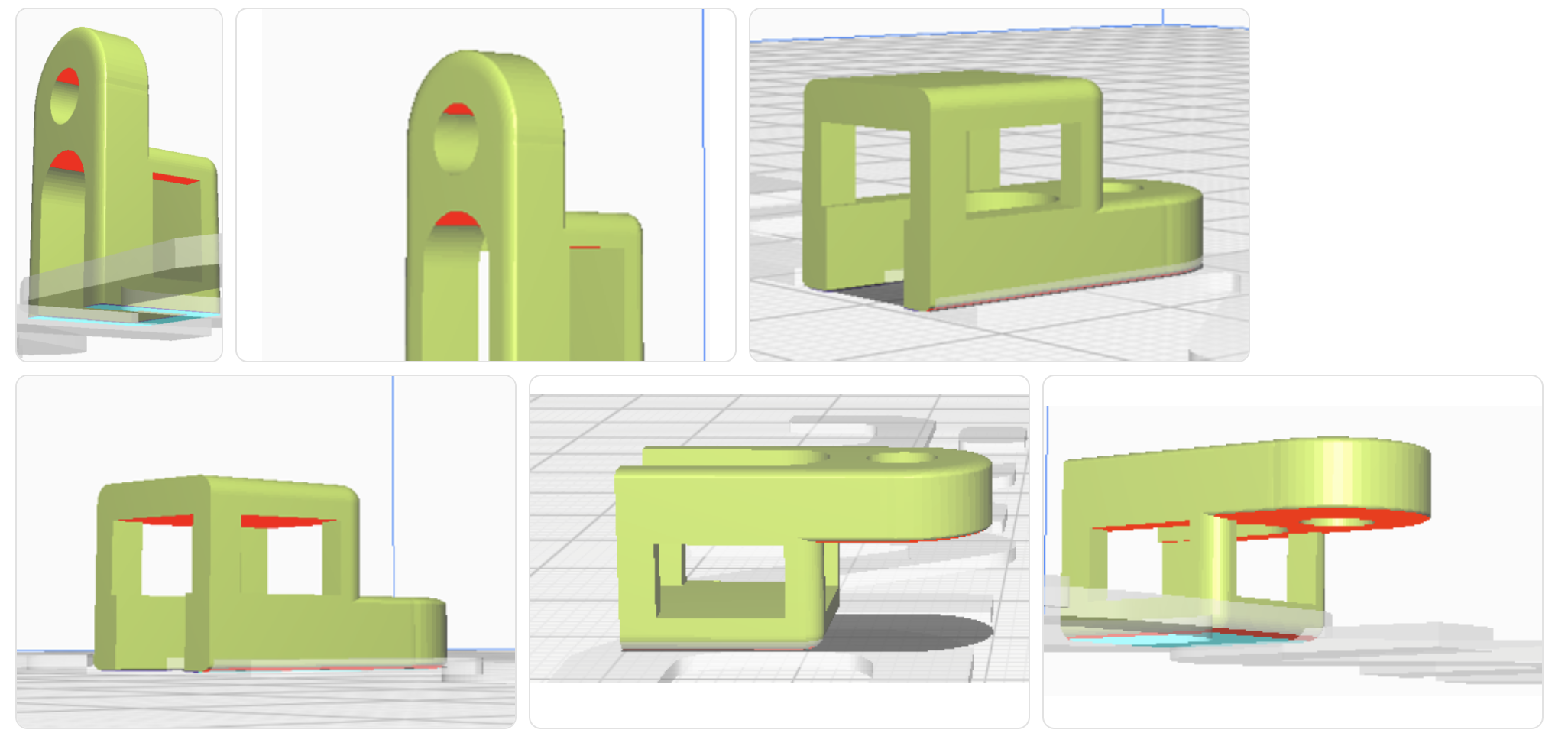

Optimizing part orientation for 3D printing

E

Hello, I am new to 3D printing and am trying to understand how to optimize part orientation to reduce the need for support structures and production times. Does anyone have effective tips/strategies for doing this? In particular, I’m considering a model similar to this https://www.printables.com/model/622078-screw-cable-zip-tie. Any advice will be greatly appreciated!

Automatically translated from: Italiano

See original

Suggested Topics

Topic

Replies

Views

Activity

Thermal expansion modelling for a braced rectangular steel tank

hi, for a welded steel coolant reservoir for a test stand - 4 m × 2 m × 1.5 m with internal bracing I need to account for thermal expansion. Fluid runs at 80–90... read more

2

271

Feb 04

Designing holes for M3 threaded inserts in an ABS enclosure

Hi! In my design for a small ABS enclosure for an onboard sensor module I want to switch from molded bosses to heat-set M3 inserts for the lid screws. Before I finalize CAD, what... read more

1

354

Dec 23

Airtight joint between two aluminum frame enclosures?

Hi, I have two 400 mm cubical enclosures from 20×20 mm aluminum profiles with glass on all sides except one. I need to connect them into a single temperature-controlled unit and keep the joint... read more

2

573

Dec 29

SLA wall thickness issue for microfluidic channels

Hi, I created a 3D design for a small microfluidic part using SLA (Clear Resin) with internal channels ~0.4 mm wide and wall thickness around 0.5 mm. The function relies on optical inspection through... read more

1

1.5k

Jul 29

Embossed vs. engraved text for outdoor molded parts

Hi there, I need to add a part number and recycling symbol on the surface of molded parts in PP GF20 for outdoor use. I initially planned to use engraved text for aesthetic reasons,... read more

3

3.3k

Aug 08

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account