We spoke with DraftAid’s CEO Mohammed Al-Arnawoot about solving a pain point felt by every engineer.

Wasting Time on Drawings

What problem are you solving?

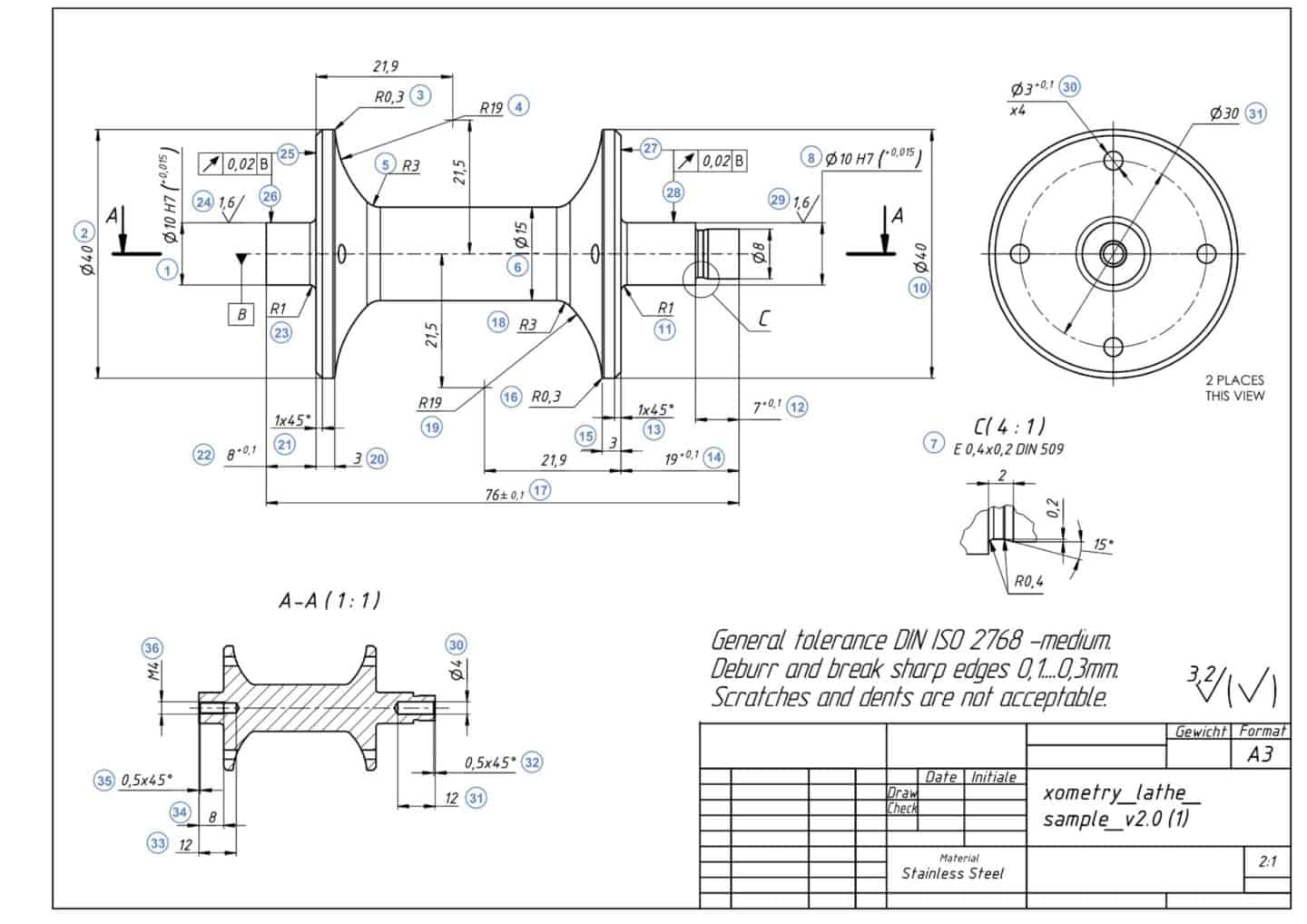

I think everybody in the industry knows the problem. Engineers typically spend 20-40% of their time making drawings from 3D models. It’s time-consuming, tedious and error-prone. A single mistake in a drawing can end up with the wrong part and sometimes significant time delays.

Inconsistency is another one. 2 engineers sitting side-by-side can do drawings very differently.

I only learned the full extent of this issue 2-3 years ago when I met my cofounder Abdullah. He told me he worked in a room with 40 drafters making drawings all day. And that was just one of five such teams in North America at this company. He asked the obvious question of “Why isn’t this automated if we already have the 3D models?”

I’d been VP of Engineering at a startup acquired by Autodesk, then Director of Engineering at a construction tech company. Thus, my answer was “We will automate it.”

Why hasn’t anyone solved this yet? In-CAD drawing generation has existed for a long time but it’s still quite useless.

Recent AI advancements play a role, but everyone has access to the same tools. Strong AI talent matters, and that’s not universally available.

I think the biggest issue is that people aren’t talking to engineers and manufacturers. Abdullah and I spend half of each month doing exactly that. We really want to understand what they’re doing, and how they’re doing it.

When you talk to them, you feel the importance of details. A dimension that is off really matters. A lot. This communication helps us understand what the market needs and then we can plan how to deliver.

Parts First, then Assemblies

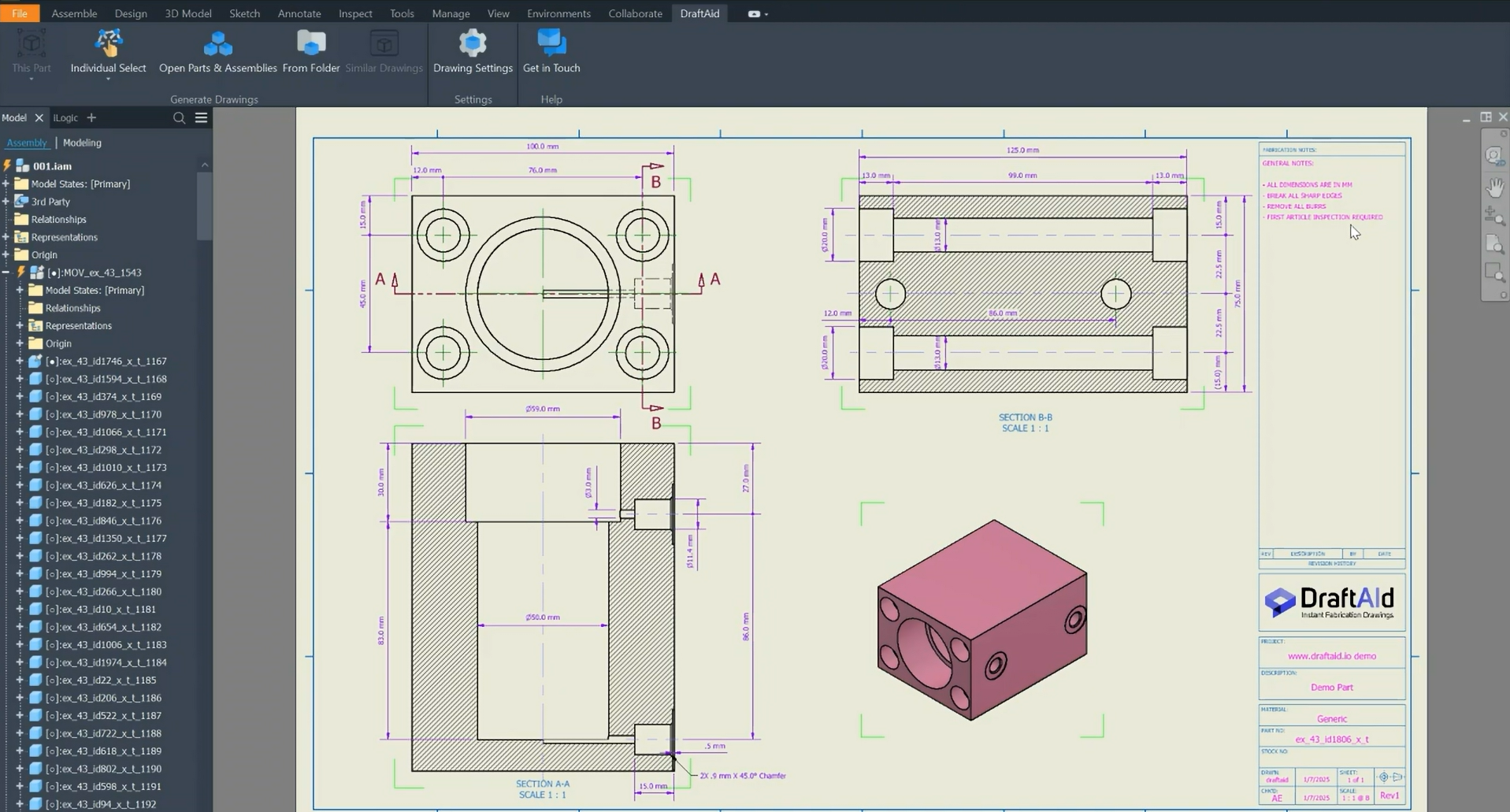

What does drawing creation with Draftaid look like?

The customer pushes a button. The geometry goes to the cloud where our AI analyzes it. The feature tree doesn’t matter, so STEP files work fine. Then it generates the drawing.

We’ve designed it to be as close to one-click as possible. Some companies integrate it with their PDM systems to run completely in the background.

What types of drawings can you make?

Today we support part drawings only. 70-80% of the sheets in a drawing package are part drawings, so we prioritized that. However, in the new year we are launching assembly and weldment drawings.

Are these drawings actually production-ready?

A customer told me recently that a drawing that used to take 15 minutes now takes 2 minutes total. About 30 seconds for generation, then quick checking and minor tweaks. Since we’re fully integrated into the CAD software rather than being standalone, the tweaking part is simple.

The accuracy varies by part type. A customer told me earlier today that 95% of sheet metal parts go directly into production. We’ve heard similar numbers about extruded parts. For 3-axis milling, we’re at about 70%.

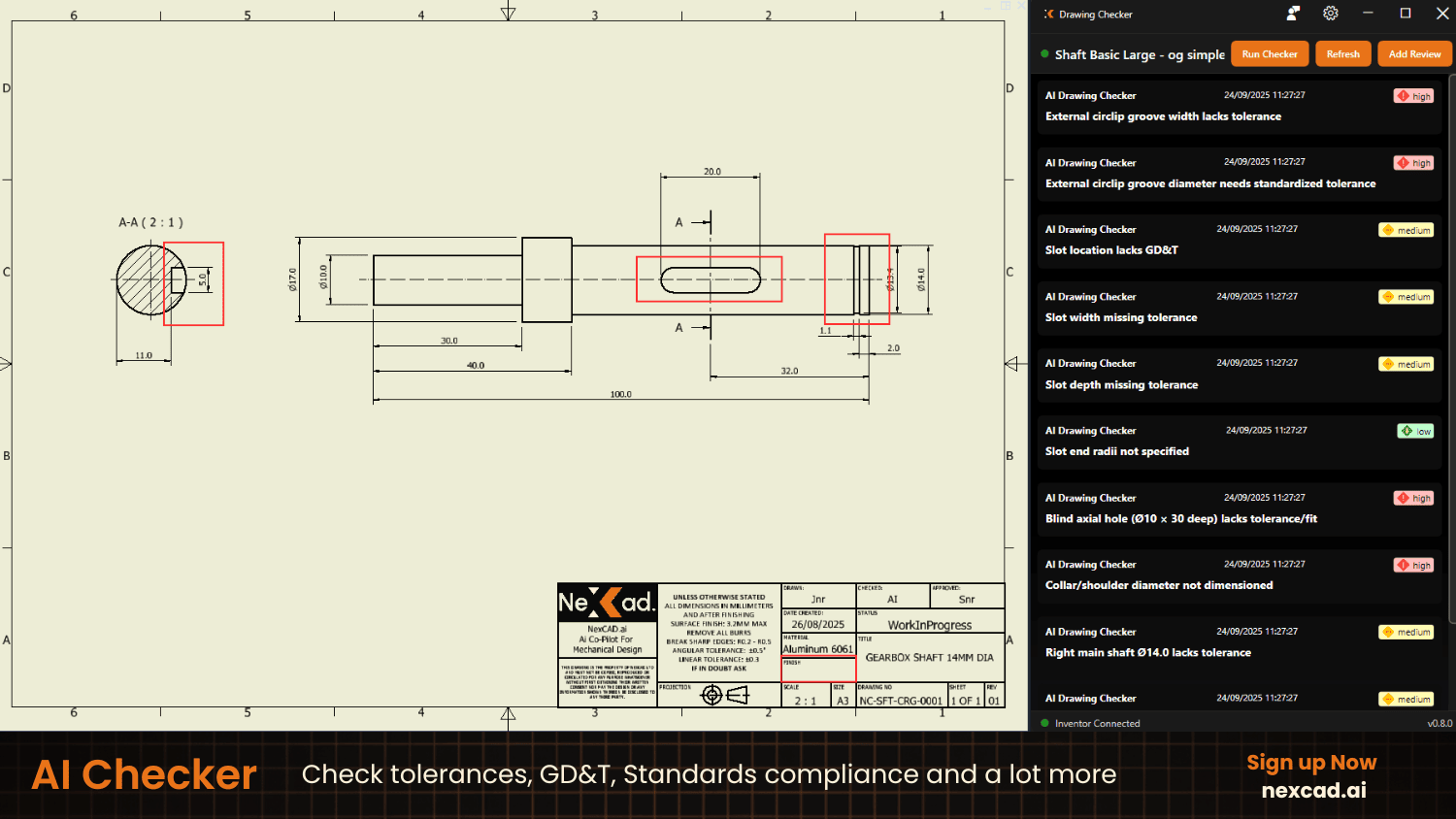

What about GD&T and tolerancing for CNC drawings?

We don’t automatically generate GD&T or tolerancing yet. We do datum selection though.

We have two modes – fully automated where the AI learns your drawing style, and human-in-the-loop where a person is involved. With CNC drawings, the second option will help you move faster while controlling the process. Additionally, if you add any model-based definitions, we’ll use that for the drawings.

We’re developing a GD&T prediction model, but we won’t launch until we’re confident in the results. It may still need some user inputs but we’re going to minimize that as much as possible.

Are revisions recognized and annotated?

It will generate the revisions and note it. This is table stakes for anyone automating drawings. Engineers expect that.

Company-Wide Standards and IP

Companies have their own templates and even standards. How customizable is the output?

Enterprise customers like automotive OEMs and Tier 1 suppliers need customization. They want their own style, so we train our AI to learn their specific standards. Smaller companies skip this because it’s expensive.

Everyone gets title block customization, that’s standard. Most companies use ASME or ISO standards with configurable options like isometric view location, sheet count and sizes, view positions, dimensioning types, and more. The regular offering has to include some flexibility for sure.

Enterprises like GE or BMW have internal standards that they’ve followed for decades. Asking them to change how they’ve made drawings for that long is like asking them to speak another language. It’s not reasonable. We have to conform to their needs instead.

How is security guaranteed? Engineers are protective of their IP.

We’re SOC-2 compliant, with the audit finishing in February. Our cloud uses the same security infrastructure as your bank. If you trust your bank, you can trust DraftAid.

Data is segregated and encrypted both in the cloud and in transit. We can’t even see most of the data ourselves.

For companies with heightened concerns, we offer on-premise deployment.

180,000+ Drawings in 2025

Do you have any user stories to share?

One customer with three engineers spent 150 hours on drawings for a project. The next project with DraftAid took 20 hours. Same engineers, same work—just 130 hours saved. 130 hours probably costs around €8000 for them. And that’s one project, and one team. The company does 500-600 projects a year!

We’re on 5 continents now, having reached Australia just recently. Both big and small teams are cutting their drawing time by 80-90%, even when including reviewing and making changes where necessary.

The biggest thing is buying back their time. In 2024 we generated about 10,000 drawings. In 2025, we’ve autogenerated over 180,000 drawings so far. And the year is not over.

You’re proud.

Of course! Let’s be conservative in our math. Assume 75% of these drawings needed no modification at all, and would manually take 15 minutes each. We’ve taken that time to 30 seconds. Okay, 1 minute for the example. That means we’ve saved those engineers over 30,000 hours!

This morning a CEO of a customer emailed me unprompted to say 95% of the automated drawings go straight to production. He was genuinely happy. So of course I’m proud, Andreas.

Has anyone told you they enjoy putting on their headphones on a Friday and just make drawings?

I’ve actually heard that one a few times. This was one of the two fears I had when we started. The other one was people being afraid of using the cloud. At large, neither of those fears has turned out to be founded.

Engineers are largely overworked. I’ve seen so many cases where engineers are doing overtime all the time. And the overtime ends up being the drawings. So they are the ones championing us within the company.

Availability and Pricing

Can anyone start using DraftAid right away?

Early next year you’ll be able to sign up and start the same day. We’re currently enterprise-only but launching our first public version in early January on the Inventor marketplace.

What’s the pricing structure?

Three tiers – free, Pro, and Enterprise. Enterprise is customized based on needs. We’re still finalizing Pro pricing for the January launch.

The free tier will be limited to our templates, certain file sizes and 100 parts per month. Which is still plenty for smaller companies making standard parts. Upgrading to paid will be available through self-checkout.

Which CAD platforms do you support?

Inventor and SolidWorks currently. They cover significant market share. We’re selecting the next platform now and will expand through the major CAD programs over time.

AI in Mechanical Engineering

Where does AI in mechanical engineering stand right now?

Many startups are trying to solve CAD model creation. I have a degree in mechatronics and know the AI space, so I understand both the capabilities and the engineering challenges. I just don’t think the technology is ready yet. It might be eventually, but there’s a long way to go.

Some startups solve problems that aren’t actually problems. Others are software developers solving engineering problems from their own perspective, which doesn’t translate. Some tackle real but extremely difficult problems, like building new CAD kernels or text-to-CAD. That’s premature.

Then there are companies solving real problems with current technology. Microsoft’s CTO said, “Work on problems that used to be impossible but now they’re very hard.” Drawing automation fits that category perfectly.

Any other AI tools you’d suggest?

When I talk to customers, the only one that gets frequent mentions is CloudNC. I’ve heard both negative and positive feedback. But they’re solving a real problem, so there are plenty of companies out there using them.

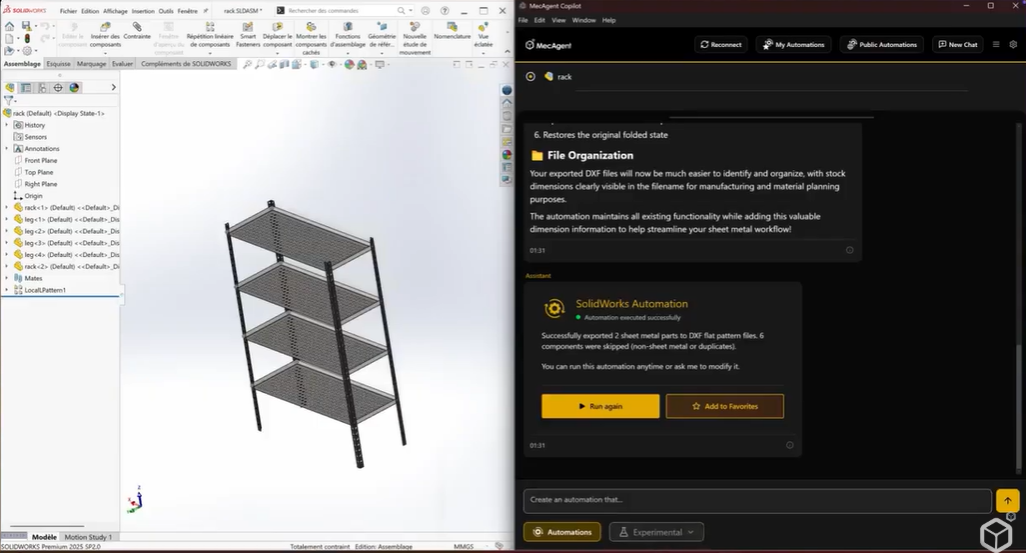

Mecagent is another I’ve heard mentioned. I’ve been surprised by teams of 20-30 engineers that don’t have a “macros guy”. Mecagent solves that. And I have first-hand experience with the efficiency gains this kind of automation offers.

There are others but they’re rarely mentioned by actual users.

What’s on the roadmap?

Our goal is to bridge the gap between 3D design and CNC machining. Accurate drawings are essential for manufacturing without errors and back-and-forth communications with the supplier.

We’re also releasing something exciting early next year that automates one of manufacturing’s most annoying aspects. It’s still too early to announce as we’re fine-tuning it. But I’m excited.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)