This story is about a faculty project turned into a small (but real) business venture, “Hose-lock Clip”. About a year ago, we were assigned a semester-long challenge: design, produce, and present a device for attaching a flexible hose to a liquid container—ensuring that the fluid pressure wouldn’t knock the hose out of the vessel. No specific constraints were given, encouraging each team to pursue a unique solution.

While other teams focused on swimming pool equipment or aquarium devices, we chose to target the food and beverage industry, specifically wine-making and beer-making. That meant our design needed to be food-safe, durable, and large enough to avoid falling into the beverage. We had to ensure the material would not corrode when in contact with food or liquids like water or wine, would not leach any substances into the beverage, and would require no lubrication to remain safe and functional.

From Idea to Prototype: Iterating the Hose Clip Design

Our first goal was to make the clip usable with one hand and avoid screws or bolts for attachment. Wine fermentation vessels typically have a thick flange, so our design had to grip that flange securely—but still be compatible with vessels with thinner walls.

We initially experimented with a large, bent-wire clothespin concept. However, we soon faced manufacturability issues: bending wire into complex, functional shapes was too difficult and the result was not robust enough.

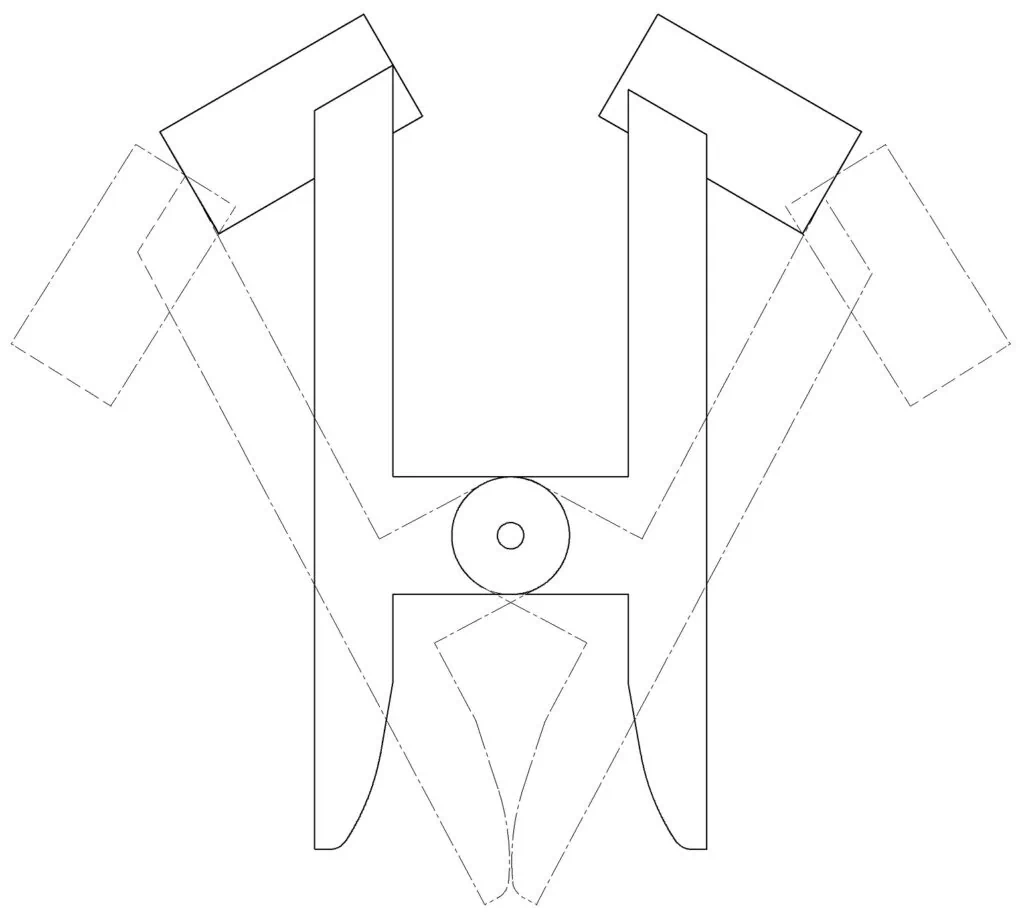

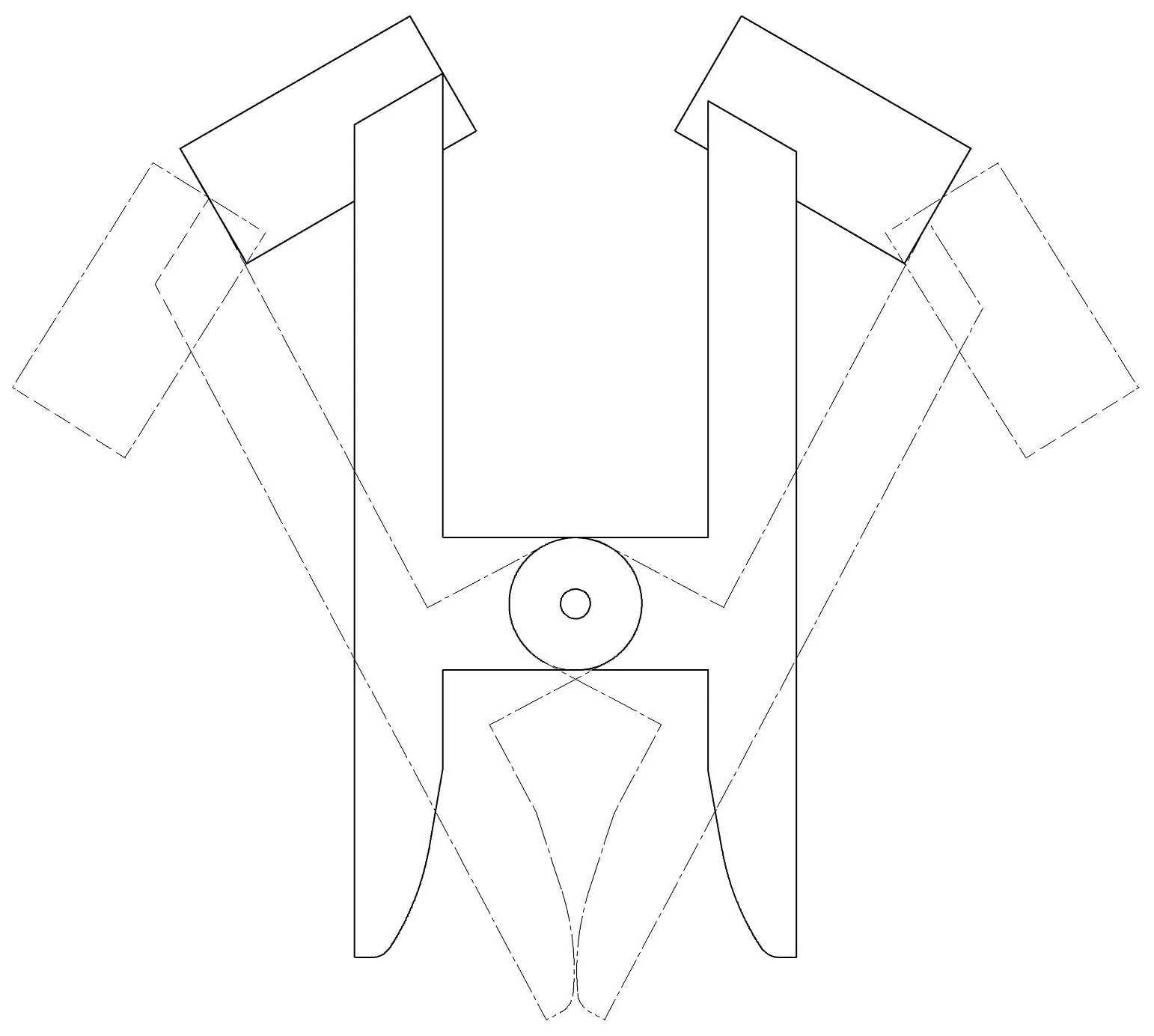

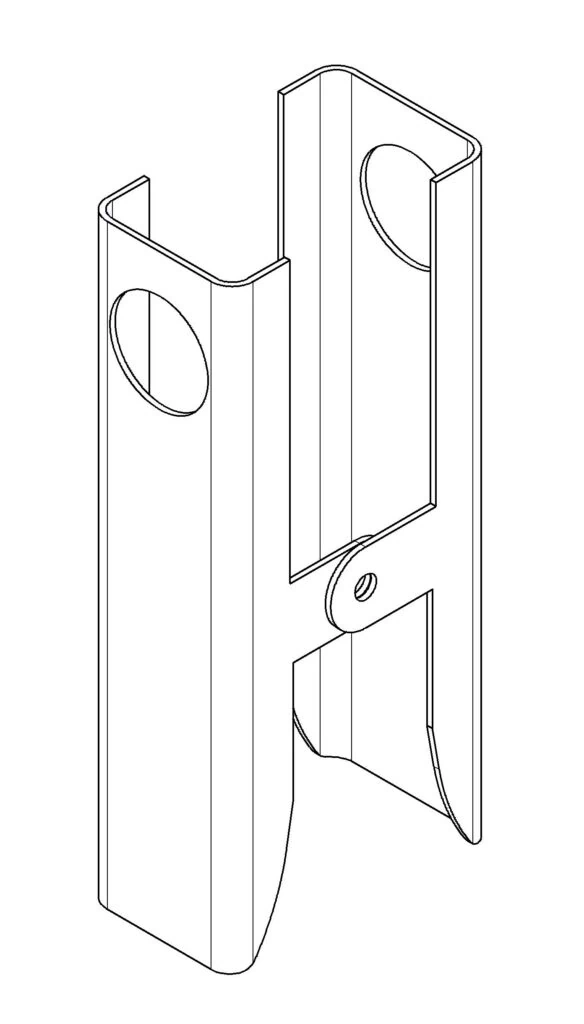

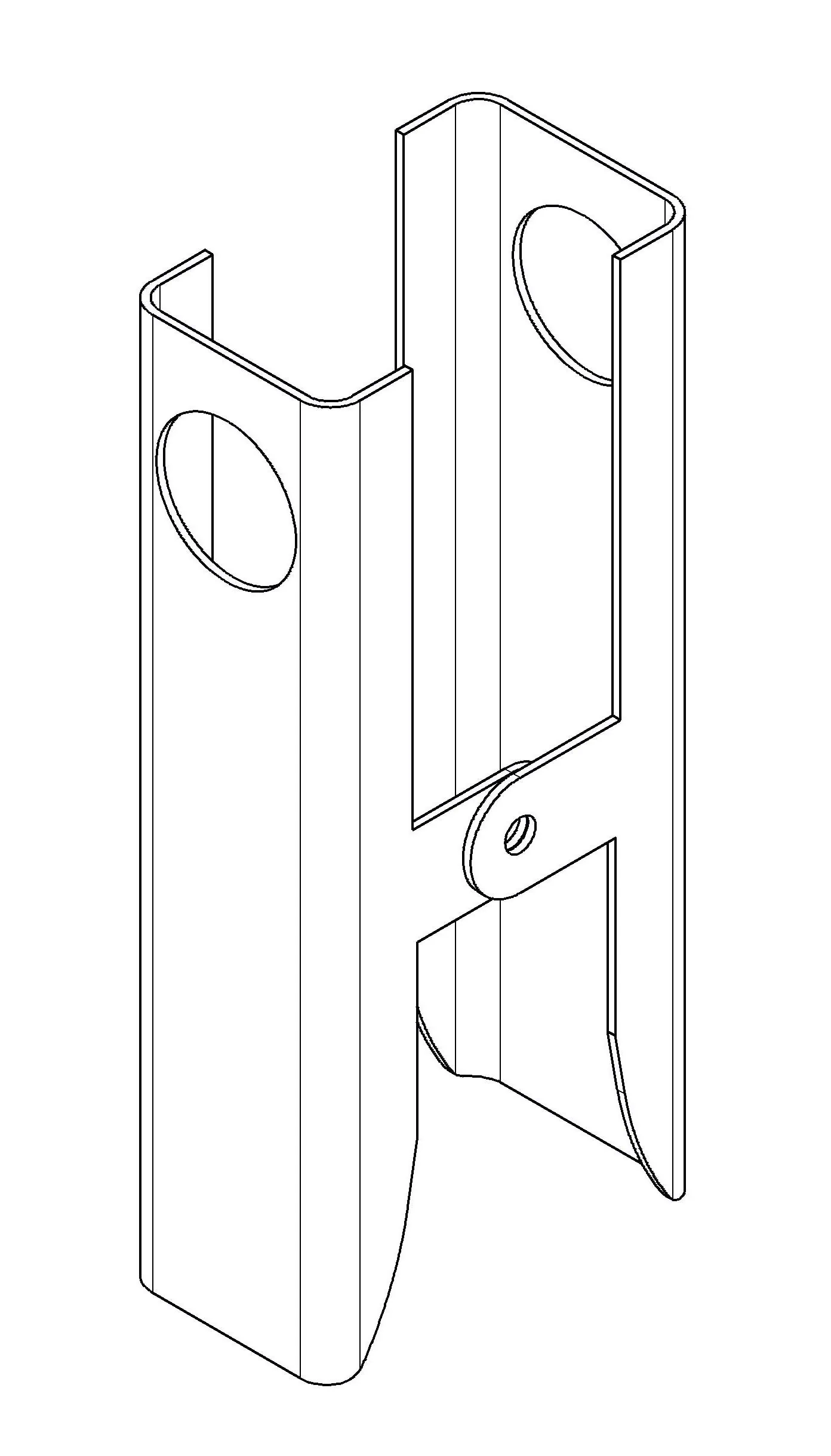

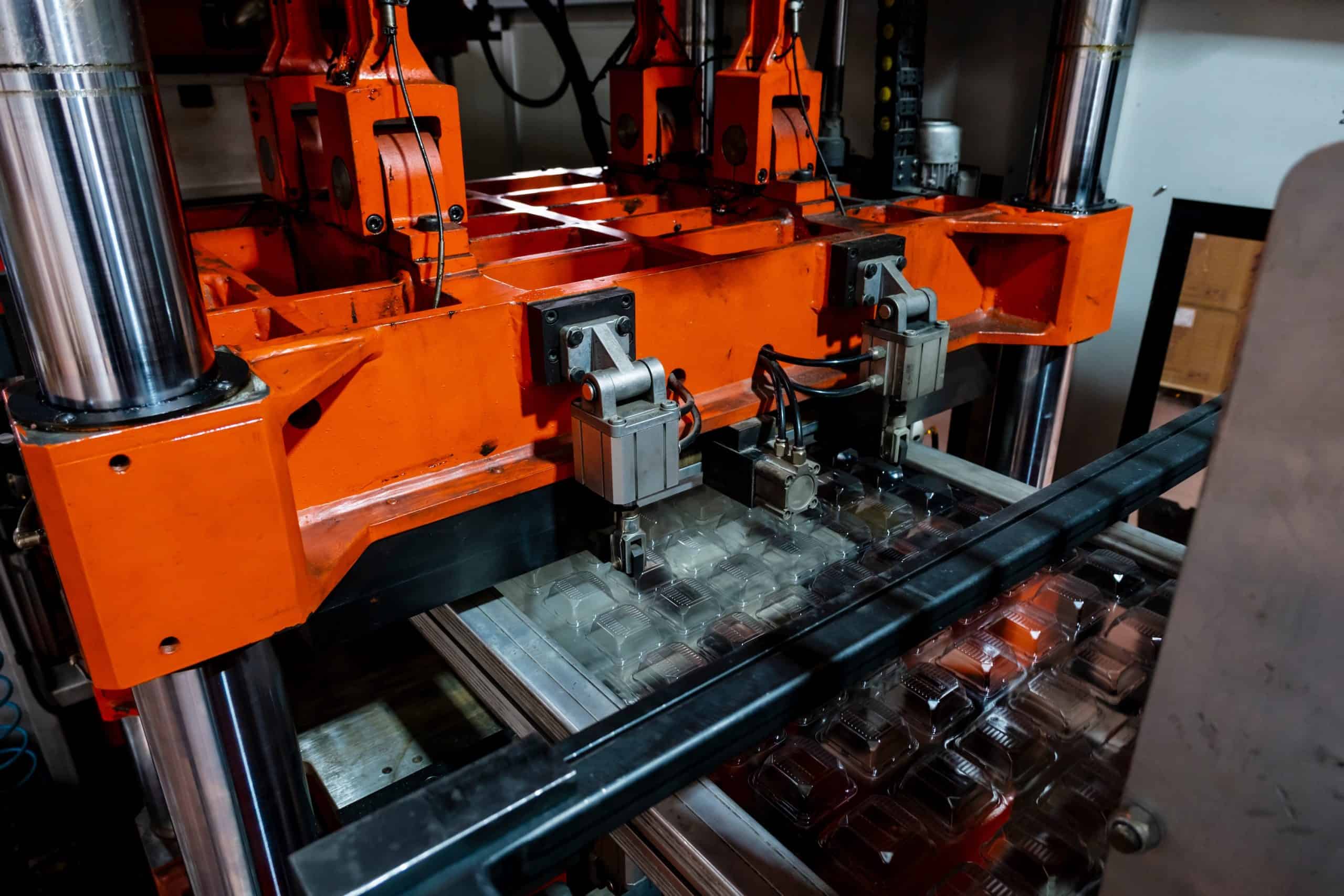

We pivoted to a new solution: a clothespin-style clip made from two laser-cut sheet metal shells joined by a shoulder screw and closed with a torsion spring. Initially, we added two hose ducts—one on each handle—to hold the hose. But this made the device heavy and awkward to use with one hand.

We built a first prototype and replaced the ducts with round holes to thread the hose through. Unfortunately, the round shape only provided one contact point, which wasn’t enough to hold the hose reliably.

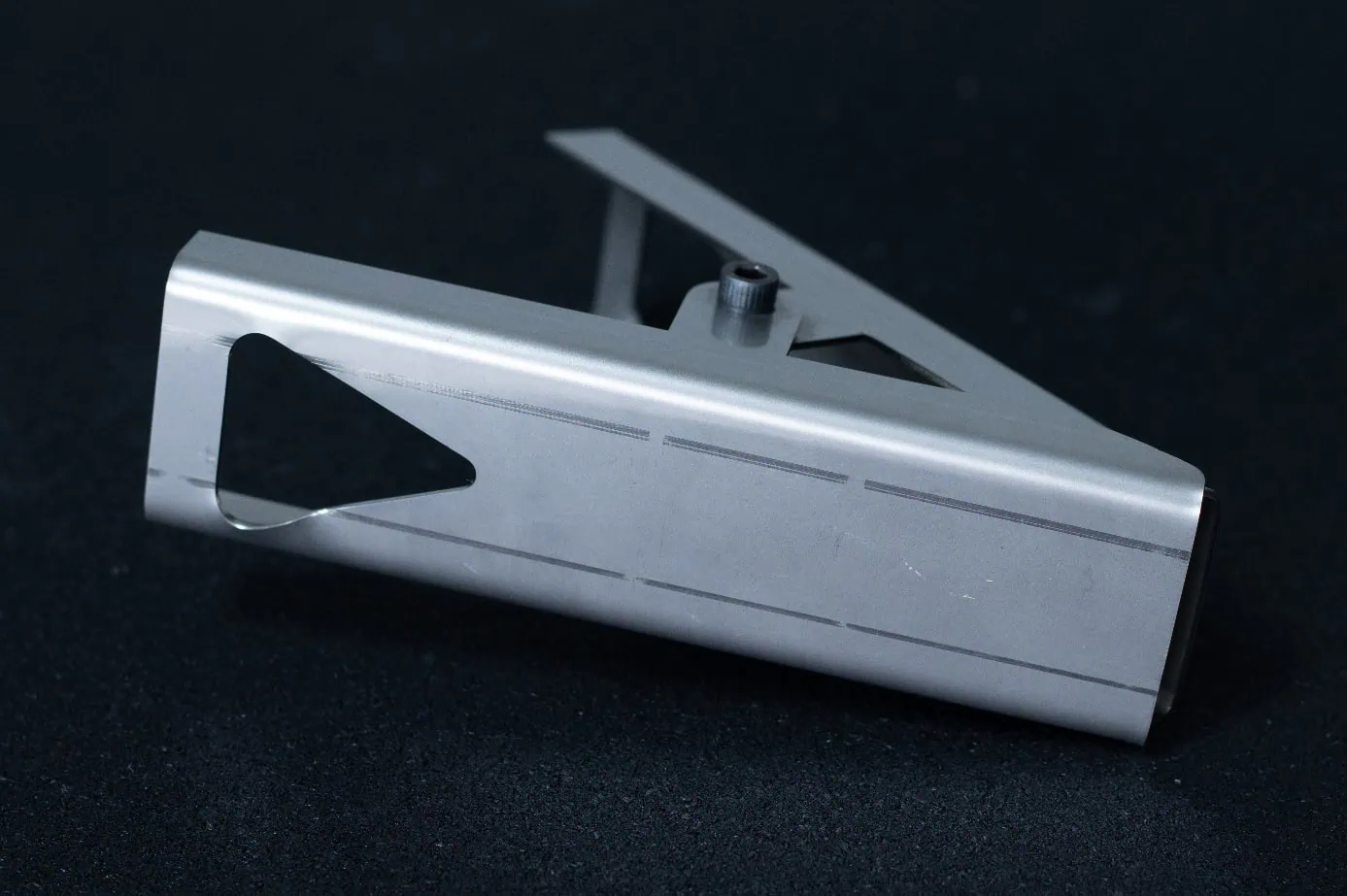

Eventually, we arrived at our final design: elongated, upside-down teardrop-shaped holes that pinched the hose in two spots. This solution was simple, universal (fitting multiple hose diameters), and held the hose in place even with strong fluid flow. Eventually, we arrived at our final design: elongated, upside-down teardrop-shaped holes that pinched the hose in two spots. This solution was simple, universal (fitting multiple hose diameters), and held the hose in place even with strong fluid flow. Made from 1.5 mm thick stainless steel, the final clip measures 80 × 45 × 170 mm and offers both durability and food safety.

From Prototype to Protection: Filing for a Utility Model

Once the design was finalized, we filed for a Slovenian national utility model—similar to a patent—to protect the concept. Around the same time, we presented our final project and received an excellent grade. The evaluators appreciated the sturdy feel of the clip in hand but recommended considering thinner sheet steel in future iterations to optimize material use.

But we weren’t done. Seeing commercial potential, we decided to bring the product to market.

Going to Market: Small-Scale Production and Big Lessons

We took the next steps: creating promotional photos and videos, setting up an online store, and launching a social media campaign. We partnered with suppliers for laser-cut stainless steel parts and got ready to ship.

But after a week of ads, we had zero sales.

Analytics showed people were clicking through, but they dropped off at checkout. The price—€20 per clip plus €6 shipping—was a barrier. With production costs close to €15 (for 100-unit batches), we felt the price was fair. But the market didn’t agree.

We experimented with bundles and e-books, and even considered switching to anodized aluminum to cut costs. However, that would compromise the product’s sturdy feel, and reducing the price would only highlight the relatively high shipping cost. Increasing production volume was too risky.

So, we made the hard decision to stop.

Although we didn’t sell a single hose clip, the project gave us a lot in return: a granted utility model and bonus points for a scholarship.

We still believe in the product and may one day publish the design as open source to help others facing a similar challenge.

Have you ever tried bringing a student project to market? What design choices would you have made to keep this product affordable—without compromising on quality? We’d love to hear your thoughts on how Filip and his team approached this real-world challenge. Share your ideas, or similar experiences in the comments!

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)