Injection molding wall thicknesses - tips?

Hello,

I am a mechanical engineer currently in the design phase of developing rectangular housings using PA66 GF30 material. From my previous projects, I’ve encountered challenges with achieving consistent dimensions, particularly with thin wall sections. In my current design, a critical feature has a specified wall thickness of 0.7mm, which I suspect might lead to warping and strength issues based on past experience.

To preemptively address potential problems, I am considering adjusting the wall thickness. However, this could affect the overall width, initially designed at 80.0mm (+/-0.05mm).

- What is the generally recommended minimum wall thickness for injection molding of PA66 GF30 to ensure structural integrity without compromising dimensional accuracy?

- Given the stringent tolerances required, would it be appropriate to adhere to ISO 20457 for general tolerances in this situation, which is specifically tailored for injection molded plastic parts?

I would appreciate any insights or suggestions on how to best approach this design challenge.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

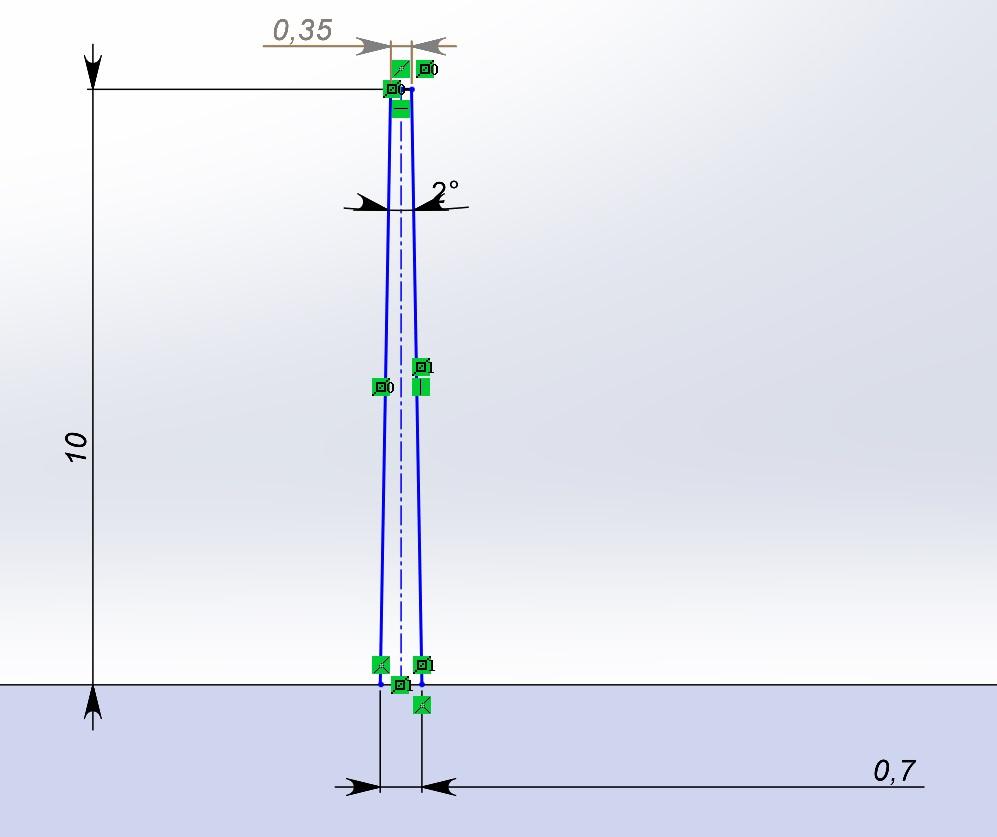

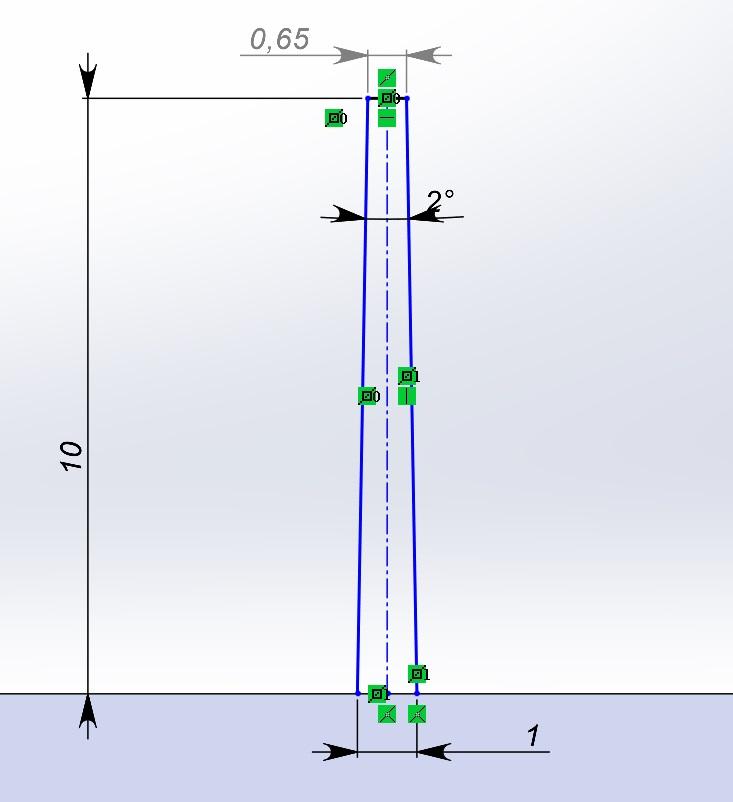

Login with my Xometry account  As you can see in the picture, with a thickness of 1 mm you get a pretty good result at the top of the rib.

As you can see in the picture, with a thickness of 1 mm you get a pretty good result at the top of the rib.

I hope this is helpful to you,

have a good day :-)

I hope this is helpful to you,

have a good day :-)