We will be presenting the 3D printing technology MJF and the manufacturing material PA12, which is the most preferred 3D printing technology by our corporate customers who receive 3D printing services. MJF is one of the most ideal technologies for the mass manufacturing of complex functional models with plastic materials in low volume mass. Let’s look at the preferred multi jet fusion technology and PA12 material for products with surface mechanical and surface properties.

What is an MJF (Multi Jet Fusion)?

First and foremost, let’s familiarize ourselves with the MJF technology used in 3D printing technologies. The Multi Jet Fusion (MJF) gathers a “fusing agent” on top of the white polymer dust layer by scanning the print area with its inkjet nib. The fuse agent increases the heat soak and allows the dust to be locally sintered thanks to the white powder that thickens the material. It also leaves a “detailing agent” that prevents sintering at the boundaries of the part.

With that principle, the multi jet fusion technology offers you susceptible mass manufacturing. Thanks to its water-proof mechanical strength, you can acquire unmatched parts with high heat resistance. You can also have parts of varying flexibility depending on your design needs.

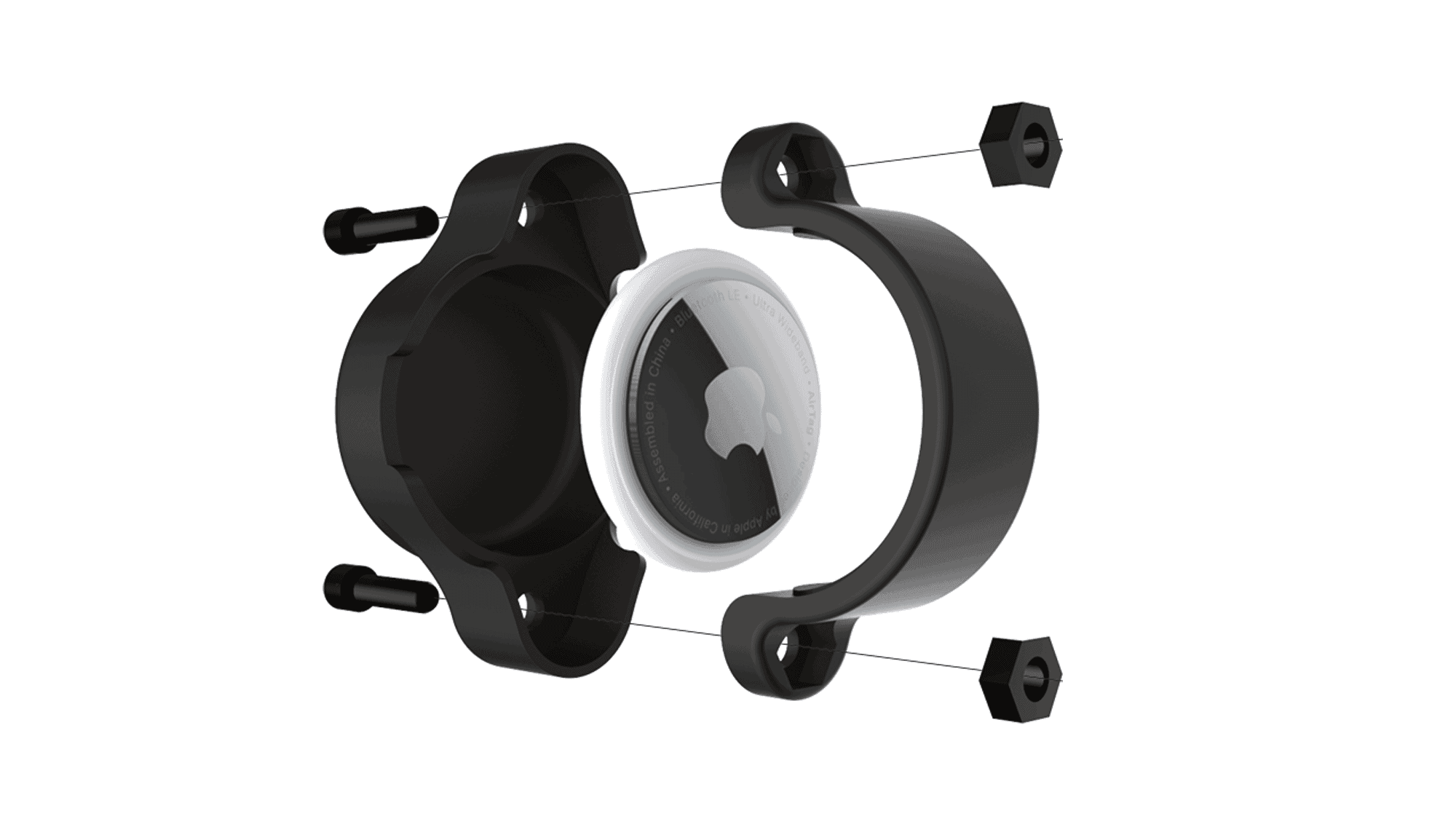

Since the multi jet fusion 3D printing works with a powder bed fusion additive manufacturing principle, it doesn’t require a support structure. The plastic material in the form of dust is put down on the manufacturing platform and created with a model fusion effect. That is why multi jet fusion is an excellent option to produce complicated structures, unlike other alternatives like FDM. Allows assembly manufacturing of moving parts. The multi jet fusion technology also increases productivity by saving material and speeding up manufacturing.

Based on the working principle of MJF, it is printed in ultra-thin layers such as 80 microns. Thanks to the ultra-thin layer, the gaps in the product’s structure to be printed are filled. That way, the product is printed with low porosity and high density. The produced parts will have high resolution and dimensional accuracy with this method. If dimensional tolerance and performance play a critical role in your design, then multi jet fusion is an ideal approach.

Nylon, Also Known as Polyamide (PA)

Polyamide, commonly known as nylon, is a popular thermoplastic material known for its toughness and flexibility. It is also a rigid material that provides high impact and abrasion resistance. Nylon also has a low cost, making it ideal for 3D printers’ functional part manufacturing. Nylon can produce perfect parts in 3D parts; however, choosing the right 3D technology is essential.

Polyamide dust is one of the materials specially produced for the multi jet fusion technology by HP. Additionally, the parts printed with the MJF polyamide material tend to be isotropic, and the anisotropic effects of the nylon can be removed with the correct configuration. That way, parts can benefit from the excellent properties of nylon.

MJF technology generally uses the PA12, PA11 and PA Glass Beads variants; however, PA12 is commonly preferred.

PA12

When we look at the properties that make the PA12 widely popular, we’re drawn to the fact that it is highly durable and flexible. Having high rigidity, PA12 is highly resistant even at shallow temperatures. Thus, it has a high mechanical and thermal resistance and is resistant to chemicals.

One of the fundamental properties distinguishing PA12 from other variants is that PA12 absorbs very little moisture compared to other variants. The surface treatment of the part after 3D printing is done efficiently and quickly since PA12 absorbs very little moisture. You can achieve perfection in your design with the unique harmony of PA12 material and multi jet fusion 3D printing technology.

You can acquire highly durable, high surface quality and waterproof products. You can produce your structurally complicated models with ease. You make prototypes for your form, fit and function tests. Thanks to the superior mechanical properties of the products produced, you can use the products in functional parts in different sectors.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Download

Download