Nylon has carved a niche for its remarkable properties in industrial materials. Amongst these, PA 11 and PA 12 stand out as popular choices, each known for their strong resistance and excellent ductility. These thermoplastic polymers, pivotal in various applications and often used with multi jet fusion (MJF) and selective laser sintering (SLS) technologies, are often selected for their unique characteristics.

What are PA11 and PA12?

PA 11 and PA 12, both under the nylon family, are polyamides distinct in composition and usage. PA 11, a bio-based polymer, is derived from renewable sources like castor oil. Its composition aligns with environmental sustainability, making it a choice material in various industries. In contrast, PA 12 is a synthetic polymer primarily made from petroleum sources.

Though similar in appearance, these polymers offer unique properties. In the industry, PA 11 is valued for its superior mechanical properties and ease of use, having applications in automotive, oil and gas, and sports goods. Its use in additive manufacturing is growing thanks to its durability and flexibility. PA 12, on the other hand, is recognized for its dimensional stability, particularly in 3D printing.

Properties and Characteristics of PA12 and PA11

Mechanical Properties and Chemical Resistance

While similar in some aspects, PA 11 and PA 12 exhibit distinct mechanical and chemical properties. PA 11 is chemically resistant to various substances, including hydrocarbons, alcohols, and detergents. It also has a lower environmental impact and uses fewer non-renewable resources.

In contrast, PA 12 shows exceptional strength, heat resistance and resistance to cracking under stress, performing well even in sub-zero temperatures. Its resistance extends to chemicals like hydraulic fluids, oils, and solvents. This chemical resistance is particularly beneficial in automotive and mechanical parts, where exposure to such chemicals is frequent. Its robustness in various chemical environments ensures the longevity and reliability of components.

Thermal Resistance, Flexibility, and Durability

In terms of thermal resistance, PA 11 offers superior stability against light, UV, and weather conditions. Its elasticity and high impact resistance make it ideal for durable and flexible applications.

PA 12, characterized by its high strength and stiffness, maintains consistent performance over time, making it suitable for parts that need to endure stress and wear. Nylon PA12 can withstand higher temperatures, making it suitable for applications requiring better thermal performance.

Water Absorption

When it comes to water absorption, PA 11 exhibits low rates (1.6%), which is advantageous in maintaining the integrity of parts in moist environments. PA 12’s very low moisture absorption (0.5%) further enhances its dimensional stability, making it ideal for applications where consistent performance in varied humidity conditions is crucial.

| Properties | PA 11 | PA 12 |

| Chemical Resistance | Resistant to a wide range | Exceptionally resistant to oils, and solvents |

| Environmental Impact | Lower; uses fewer resources | Higher; primarily petroleum-based |

| Thermal Resistance | Superior stability | High, excellent in low temperatures |

| Flexibility and Elasticity | High elasticity | Strong, less flexible than PA 11 |

| Durability | High impact resistance | Resistant to cracking, high-abrasion resistance |

| Common Applications | Functional prototypes, automotive parts | Full functioning parts, an alternative to injection moulding plastics |

Surface Quality Differences

The surface finish of a material is crucial in determining its aesthetic appeal and functional capability. PA 11 typically provides a smoother finish, enhancing the visual aspect and contributing to functionality, especially in parts where surface friction is a factor.

This smooth finish is advantageous for demanding applications that require a fine, detailed surface, making PA 11 a preferred choice in industries where aesthetics are as important as functionality.

On the other hand, PA 12, while offering a good surface quality, tends to have a slightly rougher finish compared to PA 11. This characteristic can be beneficial in applications where a grip or a non-slip surface is necessary.

Cost Analysis: PA11 vs. PA12

In additive manufacturing, cost considerations play a pivotal role in material selection. PA 11, with its excellent ductility, allows for the design of parts with thinner walls (0.5 mm instead of 0.8 mm for PA12). But even if this results in lighter and lower-cost parts, reduces waste and accelerates production times, PA11 remains on average 30% more expensive than PA12*.

The superior impact and abrasion resistance of PA 11 further contribute to longer service lifetimes of parts, leading to cost savings and minimized downtime in various systems. PA11 is particularly valued for its smoother surface finish and superior overall quality when compared to PA12.

Conversely, PA 12, while offering high durability and resistance, may entail higher costs due to its synthetic petroleum-based origin. The production process of PA 12 can be more resource-intensive, potentially reflected in its market price. However, the material’s strength and processability make it a worthwhile investment for specific applications.

PA 11 and PA 12 hinge on balancing initial material costs and long-term value for businesses. The decision must consider factors such as the product’s intended use, production efficiency, and the lifespan of the parts being manufactured.

*The price difference can be tested in our Xometry Instant Quoting Engine®.

PA11 Vs. PA12: Which One is Better Suited for Clip Features?

The material selection is crucial for ensuring functionality and durability when manufacturing clip features. PA 11, with its excellent ductility and flexibility, is more suited for creating clips.

This flexibility allows the clips to endure repeated bending and snapping actions without losing shape or breaking. Such a property is essential in applications where clips must be sturdy and adaptable.

PA 12, while strong and durable, offers a little less flexibility than PA 11 (20% vs. 30%). Nevertheless, PA12 material remains ideal for clip features that demand a high degree of bending or flexibility.

Applications of PA11 and PA12

PA 11 Applications

- Mechanically Loaded Prototypes: Ideal for prototypes requiring mechanical strength, such as automotive parts.

- Automotive Industry: Used in automotive interior components for crash-relevant parts due to its impact resistance.

- Visible Parts: Suited for abrasively stressed and manually manipulated visible parts, offering aesthetic and functional benefits.

- Specialized Designs: Excelling in small to medium-sized parts, thin walls, and lattice structures.

PA 12 Applications

- Functional Plastic Parts: Commonly used for fully functional plastic parts, substituting typical injection moulding plastics with superior mechanical properties.

- Medical Applications: Biocompatible, making it suitable for 3D printing medical devices like prostheses.

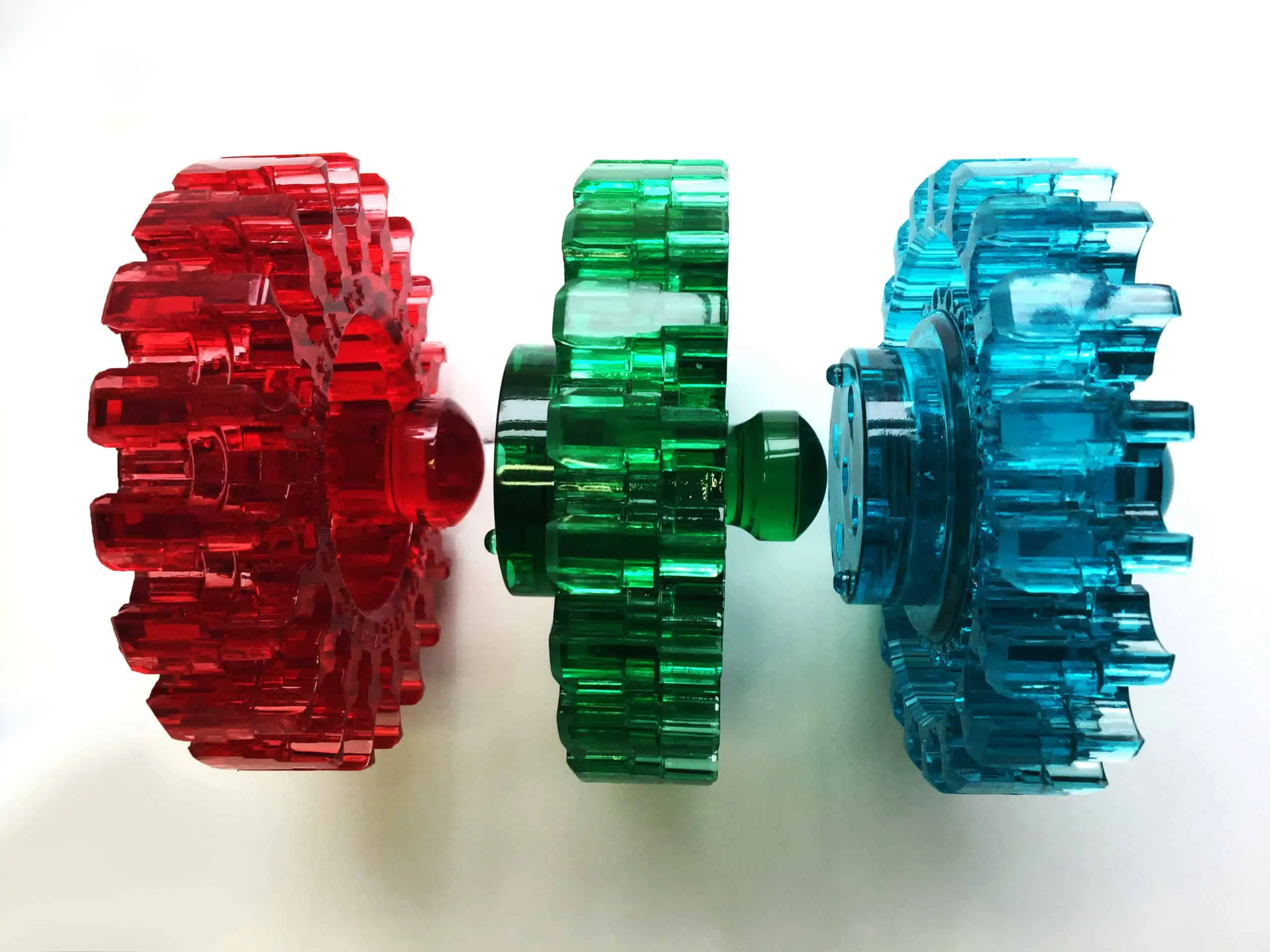

- Movable Part Connections: High abrasion resistance makes it ideal for parts like gears and hinges.

- Weather-Adaptable Parts: Light-stabilized properties allow for creating parts adaptable to various weather conditions.

Balancing Choices: Considering Differences Between PA 11 and PA 12

In conclusion, the choice between PA 11 and PA 12 hinges on carefully considering specific application requirements. While both materials offer commendable properties, each possesses distinct advantages. PA 11 polyamide stands out for its smooth surface finish, making it ideal for applications where aesthetic appeal is paramount. On the other hand, PA 12 polyamide boasts excellent heat resistance, catering to scenarios demanding superior thermal performance.

Engineers and purchasers in the manufacturing industry, encompassing fields like automotive, aerospace, and robotics, must weigh these factors when selecting the most fitting material for their intended application. The nuanced differences between PA 11 and PA 12 empower decision-makers to tailor their choices based on the precise needs of their projects, ensuring optimal performance and longevity.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  2

2

Comment(2)