Injection moulding is a plastics manufacturing technology that is capable of very high production volumes. The process works by injecting liquid plastic into a mould at very high pressure. Compression moulding, on the other hand, is better suited to medium-volume production and is typically used with rubbers and silicones.

Injection moulding is better suited to creating complex parts, whereas compression moulding is better suited to simple geometries and large panels. Injection moulding is highly automated and does not need constant human supervision, while compression moulding often requires human intervention to load a charge and remove completed products. Tooling is also cheaper for compression moulding.

Injection Moulding Definition and Comparison to Compression Moulding

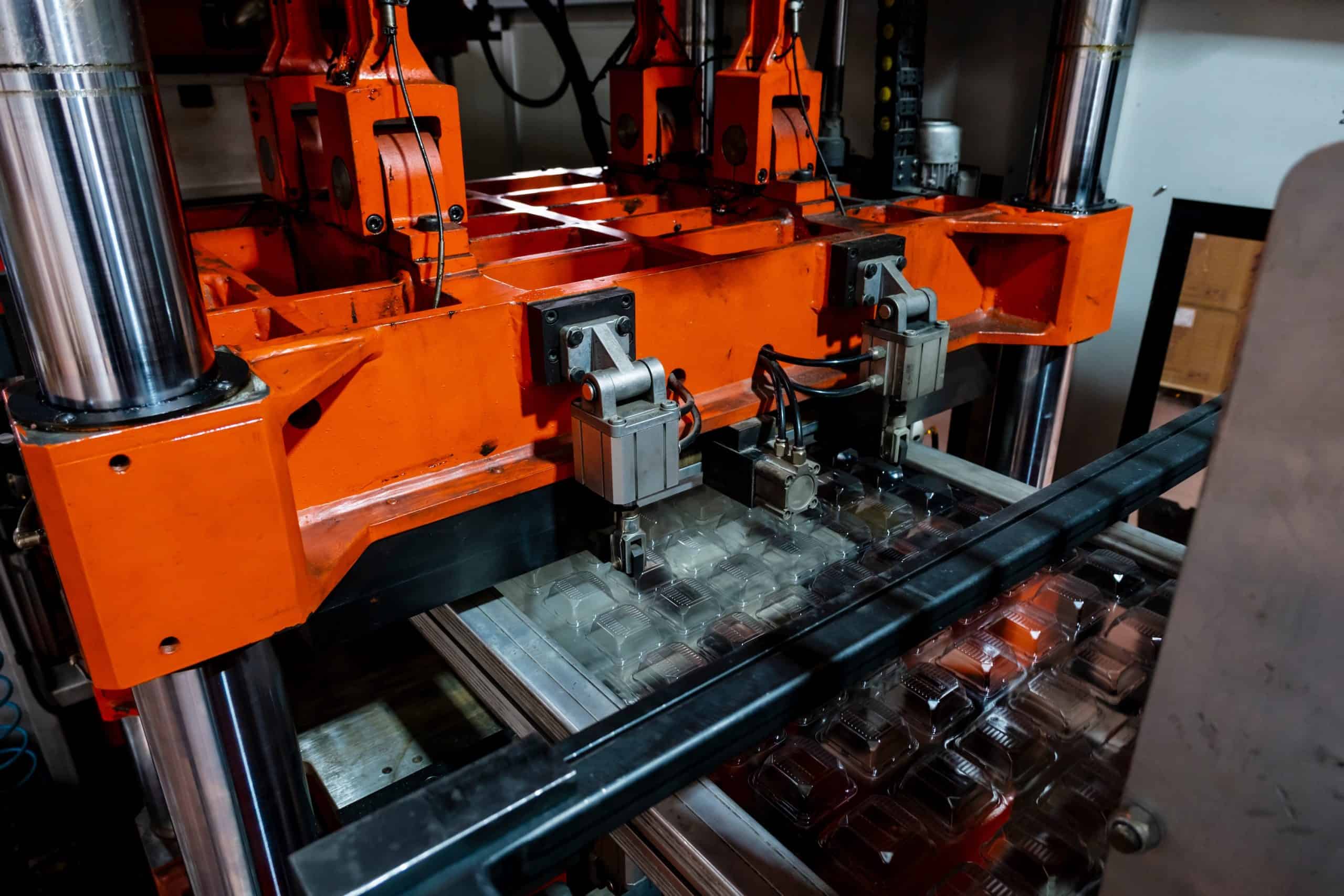

Injection moulding works by injecting molten thermoplastic into a mould cavity. During the plastic injection process, the plastic resin pellets are melting inside a barrel. The barrel contains a screw with a shaft whose diameter increases along its length. As the screw rotates, plastic is forced into an incrementally smaller volume. This compression is the primary mechanism responsible for melting the plastic. The barrel is also heated to supply additional heat. Once enough plastic to fill the mould has melted, the screw retracts and then is pushed forward to force the plastic resins into the mould at very high pressures.

Moulds are made from at least two components and are held together with hydraulic rams so that the high-pressure plastic injected into the mould cannot escape from the parting line. The mould has cooling channels that cool the part enough so that it can be ejected from the mould without damaging it. Injection moulding can achieve high production volumes unmatched by any other plastic processing technique. Compression moulding, on the other hand, is better suited to medium-volume production.

Advantages of Injection Moulding Compared to Compression Moulding

Listed below are some advantages and disadvantages of injection moulding compared with compression moulding:

- Injection moulding is a method for large production runs that can produce millions of parts per machine annually.

- Due to the high levels of automation and rapid manufacturing speed, injection-moulded parts are cheaper than compression moulded parts.

Disadvantages of Injection Moulding Compared to Compression Moulding

Listed below are some disadvantages of injection moulding compared with compression moulding:

- Injection moulding requires very high plastic injection pressures. The mould must therefore be built to withstand these high pressures. This adds cost to the tooling.

- Injection moulding is not well suited to manufacture large, thin parts like vehicle panels.

Compression Moulding Definition and Comparison to Injection Moulding

Compression moulding is a process most often used to manufacture parts from pliable materials. This moulding technique typically employs a two-part mould, with one part fixed to the base of the compression moulding tool while the top half is free to move up and down. The moulds are usually heated to help cure the final product while also heating the charge before compression. A precisely weighed-out charge is heated until it is pliable. It is then placed into the bottom half of the mould.

The top half then moves down and forces the charge to conform to the desired shape of the mould. The heated mould stays closed while the material is allowed to cure. This typically takes a few minutes. Once cured, the part is removed from the mould. Post-processing is required to cut off any flash. Flash (or excess material at the parting line of the mould) is a common occurrence for compression-moulded parts.

Compression moulding is used for creating reinforced panels. The process involves laying out fibre-filled plastic sheets in the bottom half of the mould. Thereafter, the top half of the mould compresses and heats the material to force the plastic throughout the mould, creating a composite part. This is how large plastic car bumpers are made.

Advantages of Compression Moulding Compared to Injection Moulding?

Listed below are some advantages of compression moulding compared to injection moulding:

- Compression moulding can make use of SMC (Sheet Moulding Compound) and BMC (Bulk Moulding Compound) to create composite panels. These panels do not have continuous fibre-impregnated sheets, but rather chopped fibre strands that are distributed throughout the bulk material. The injection moulding method cannot make composite material parts.

- Compression moulds do not need to withstand high internal pressures as do injection moulds. Instead, the only load they experience is a compression force from above. This means that compression moulds tend to be less expensive.

Disadvantages of Compression Moulding Compared to Injection Moulding

Listed below are some disadvantages of compression moulding compared to injection moulding:

- Compression moulding is a very manual and slow process. Even if a robot arm is used to add the charge and remove the product, the cycle time between parts is still much slower than injection moulding due to the need for the parts to be set before being removed.

- Compression moulding cannot create plastic parts with high levels of complexity. The materials used are typically very viscous and as a result, they don’t flow well into small, complicated features.

Comparison Table Between Injection Moulding and Compression Moulding

Attributes of compression moulding and injection moulding are shown in the table below:

| Attribute | Injection Moulding | Compression Moulding |

| High-volume production process | Yes | No |

| Materials | Thermosets, thermoplastics (including fibre and metal-filled), thermoplastic elastomers, metal-filled polymers, fibre-filled thermoplastics | Thermosets, thermoplastics, silicone, unvulcanized rubber, BMC, SMC |

| High tooling cost | Yes | No |

| Can produce large, thin-walled panels | No | Yes |

| Post-processing required | Yes | Yes |

Injection moulding is better suited to high-volume production whereas compression moulding is better suited to pliable and flexible materials. Compression moulding also has cheaper tooling costs.

Injection Moluding Vs. Compression Moulding: Lead Cost Comparison

When it comes to individual part cost, injection moulding can produce inexpensive, complex parts. However, this manufacturing process is only cost-competitive if production run volumes are large enough to spread the high cost of injection moulding tooling over a sufficient number of pieces. At lower volumes, compression moulding is cheaper than injection moulding due to the lower initial mold costs.

Injection Moulding Vs. Compression Moulding: Speed Comparison

Injection moulding is significantly faster than compression moulding. The cycle time for injection moulded parts can be a few seconds, whereas compression moulding cycle times can easily reach a few minutes. This is because compression moulded components often need to cure thanks to the heating process before they are removed from the mould.

Injection Moulding Vs. Compression Moulding: Volume Comparison

Injection moulding is a high-volume production method that is unmatched by any other manufacturing technology. Injection moulding processes can be fully automated, while compression moulding often requires a person to place the raw materials into the mould, remove it, and post-process it.

Injection Moulding Vs. Compression Moulding: Materials Comparison

Injection moulding can make use of rigid thermoplastics as well as thermoplastic elastomers. Compression moulding more often makes use of flexible elastomers like rubber and silicone, but can also produce rigid composite components by making use of SMC and BMC.

Summary

This article presented the comparison of injection moulding to compression moulding, explained what they are, and discussed the different attributes of each.

Xometry provides a wide range of manufacturing capabilities, including plastic injection moulding, compression moulding and other value-added services for all of your prototyping and production needs.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)