As an aerospace engineering graduate with a passion for hands-on design, I spend most of my time experimenting and building functional things. Through my YouTube channel, I share engineering challenges like this one to inspire others to get creative and start building themselves.

Why Build a Motor With No Contact?

I’d heard of magnetic couplings before, mainly in the context of stirrers at the bottom of lab beakers, where the spinning magnetic field drives a tiny bar in a sealed container. But I had never built one myself.

It seemed like the perfect hands-on challenge: how strong and functional could these non-contact connections actually be? Could I spin a shaft with nothing but magnetic force — and could I control it?

As I was researching different setups, I stumbled upon a curious variant that didn’t rely on a second magnet at all. Instead, it used a solid copper plate and rotating magnets to generate motion. That’s when the real excitement began.

This setup makes use of eddy currents — swirling loops of electric current induced in conductors, which in turn generate opposing magnetic fields. It’s the same principle behind magnetic braking in roller coasters or high-speed trains.

My goal was simple: build both versions, test them, and get a feel for the forces involved.

From CAD Sketch to Copper and Magnets

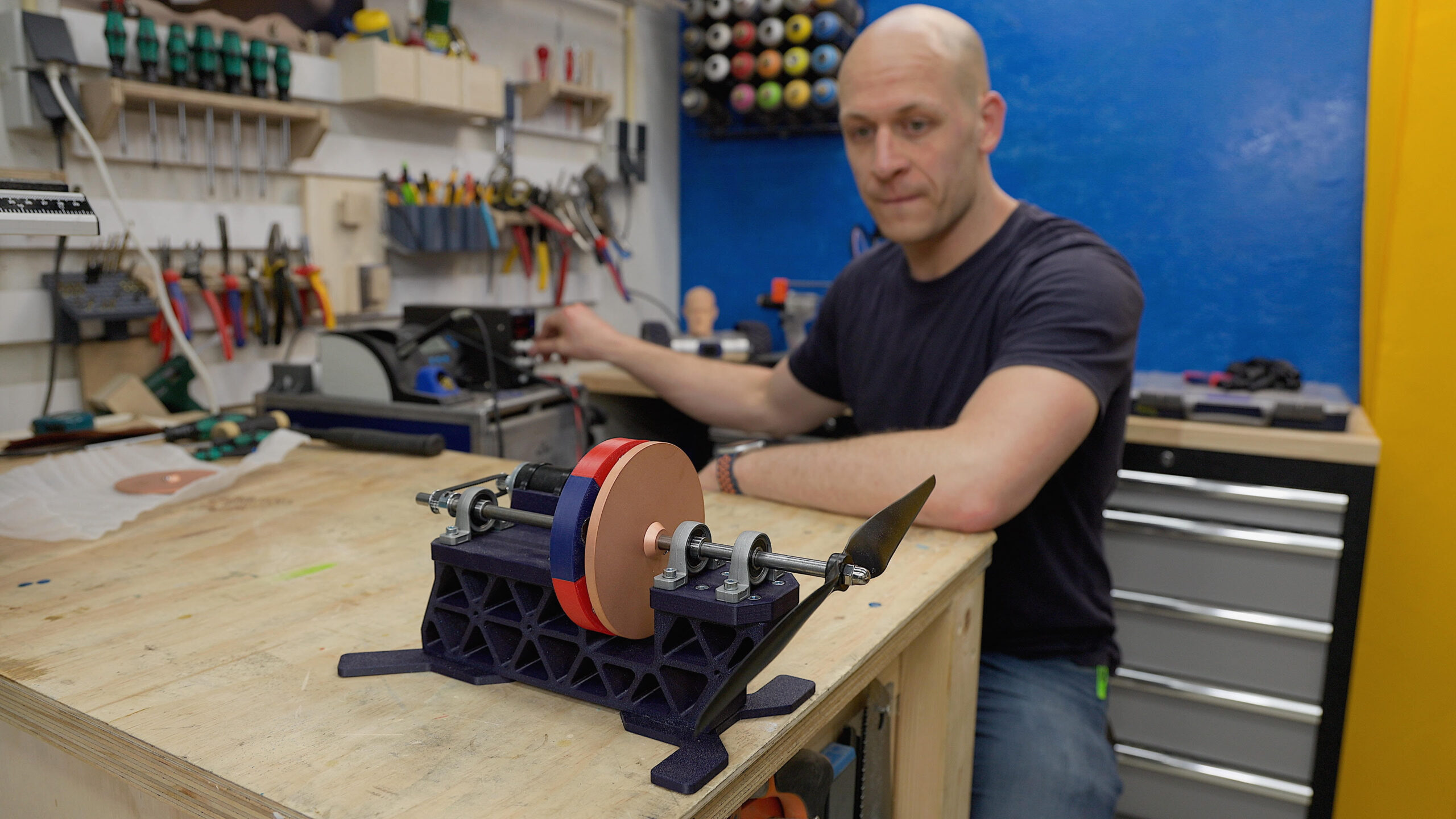

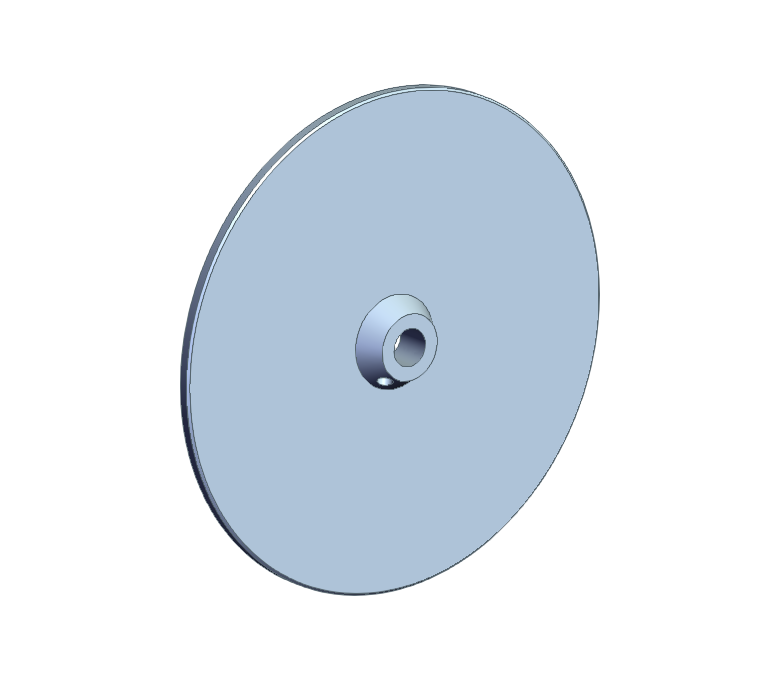

Everything started as a sketch in Fusion 360. I modeled two rotating disks, each holding six neodymium magnets in alternating polarity: north pole up on one disk, south pole up on the other. The idea was that when one disk spun, magnetic forces would transfer that motion to the other.

I 3D printed the housings using my Bambu Lab printers and sourced the copper plates from Xometry.

Version 1: Magnet vs Magnet

This version used two identical magnetic disks placed face to face. When one disk spun, the magnetic field pulled the second one into rotation with it. The coupling was surprisingly strong and extremely responsive.

However, the connection was rigid, too rigid. If anything jammed or encountered resistance, the entire system halted. There was no slip, which is great for torque transfer, but not ideal in applications where flexibility or safety is needed.

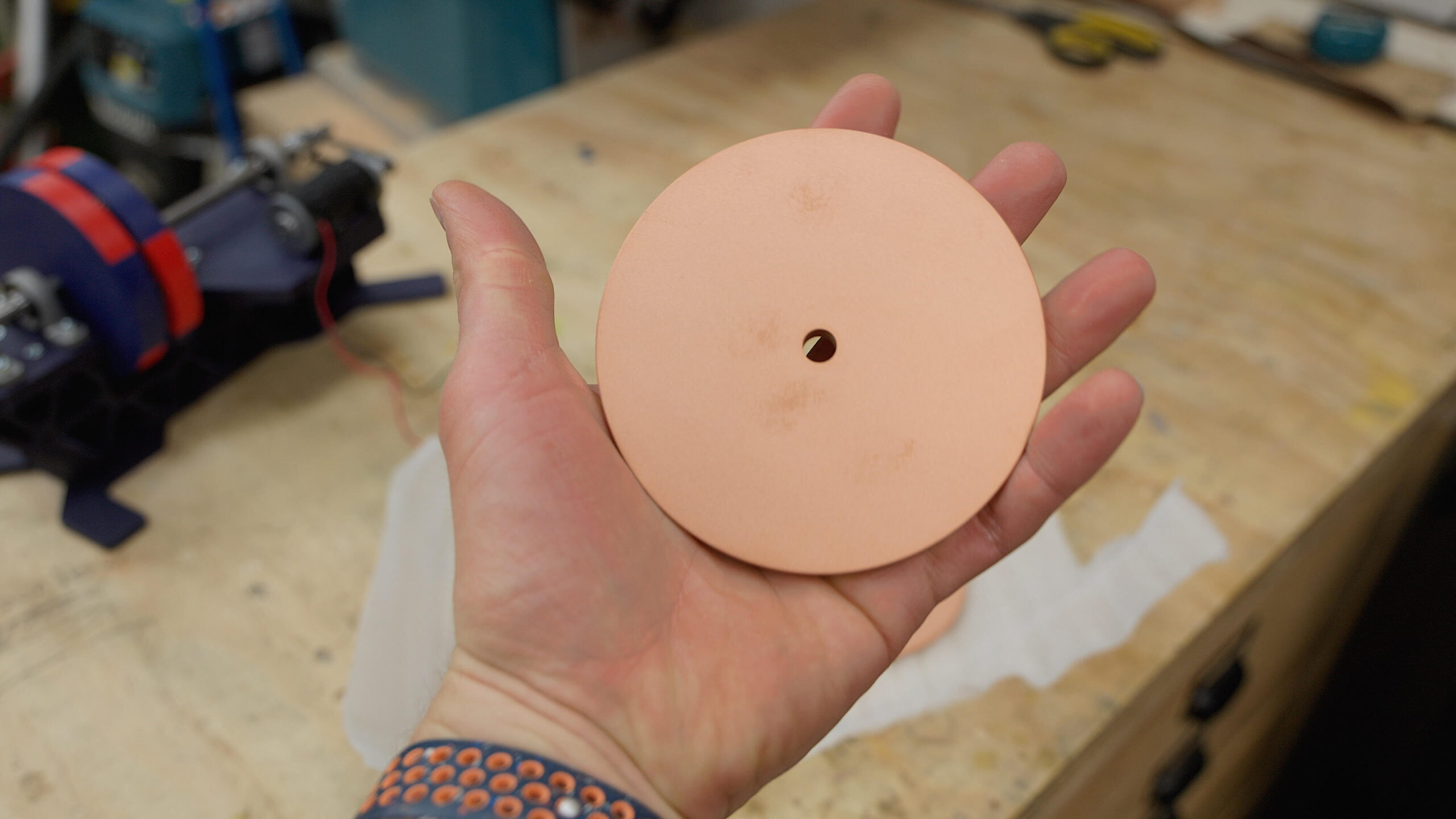

Version 2: Magnet vs Copper Plate

This is where it got really exciting. When I spun the magnetic disk near the copper plate, the plate started to rotate, without touching anything. That’s the magic of eddy currents in action.

It felt like turning a paddle through honey. The connection was smooth, resistant, and self-regulating. The faster the magnets moved, the stronger the induced currents and torque. The closer the magnets were to the plate, the more force they could transfer.

Too far, and the coupling weakened. Too close, and the system tried to pull itself forward. The effect was surprisingly strong — even with a gap of over 8mm, the interaction still worked.

One thing that amazed me: the copper setup also worked in reverse. When I spun the copper plate, it started rotating the magnet disk. I didn’t expect that.

I even tried different thicknesses — a 6mm plate versus a 3mm one. The thinner one responded faster, likely due to its lower inertia.

Real-World Potential

Could this have real-world applications? Definitely.

Think about situations where you need to drive a shaft through a sealed wall — for example, in chemical processing, underwater systems, or food production lines. These environments benefit from non-contact torque transfer, since there’s no risk of contamination or leaks.

The copper version’s natural slip could even act as a safety feature — providing soft starts or disengaging when overloaded.

What’s Next?

If I build a next version, I’d design a system that lets me adjust the spacing between the magnet disk and the copper plate on the fly. That way, I could fine-tune the amount of torque transferred.

I’d also like to try out different magnet configurations or materials, maybe even turn this into a real-world application.

For now, I’m just glad I gave the copper version a shot — even though I didn’t believe in it at first. Turns out, sometimes the best results come from the ideas you doubt the most.

Want to see it in action? Check out the full video on my channel. And if you’ve got an idea for where magnetic couplings could be useful, I’d love to hear from you.

Manufacturing stories & cases

Share your engineering or manufacturing story

If you want to share your story with others on xometry.pro, just fill out a short form

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)