This article covers 10 essential tips for CNC machining design.

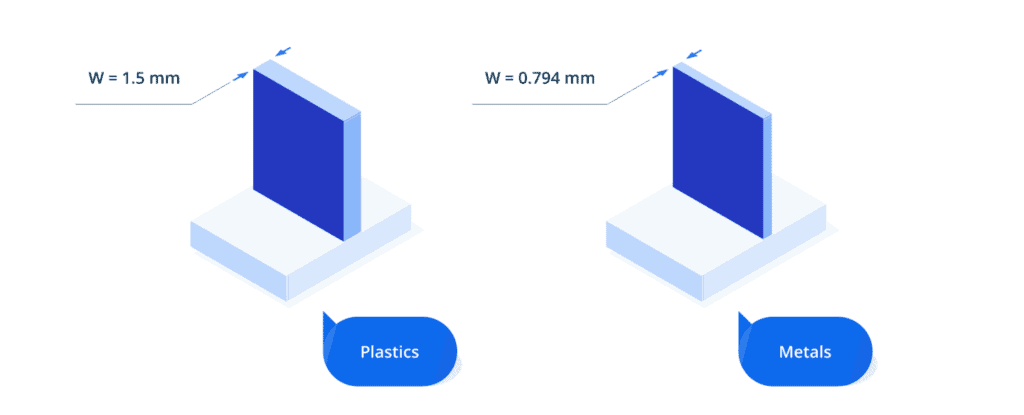

1. Avoid Excessively Thin Walls

Decreasing the wall thickness affects the stiffness of the material and reduces achievable accuracy as a result of inevitable vibrations during machining. The standard minimum wall thickness is 0.794 mm for metals and 1.5 mm for plastics. If you require thinner walls, you can use other suitable and cost-effective manufacturing processes like sheet metal fabrication.

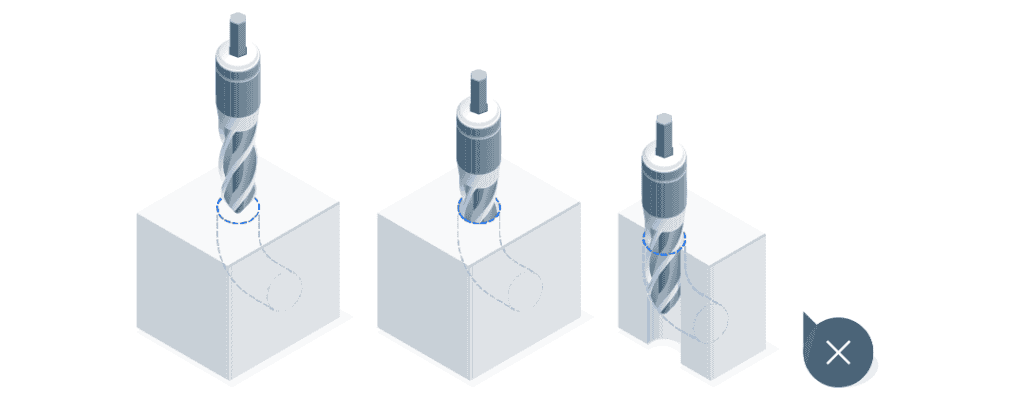

2. Avoid Designing Features That Cannot Be CNC Machined

An example of a feature in CNC machined parts that CNC mills, lathes or drills cannot produce is “curved holes”. If you require this feature or others that can’t be machined for your design, you can use electrical discharge machining (EDM) instead.

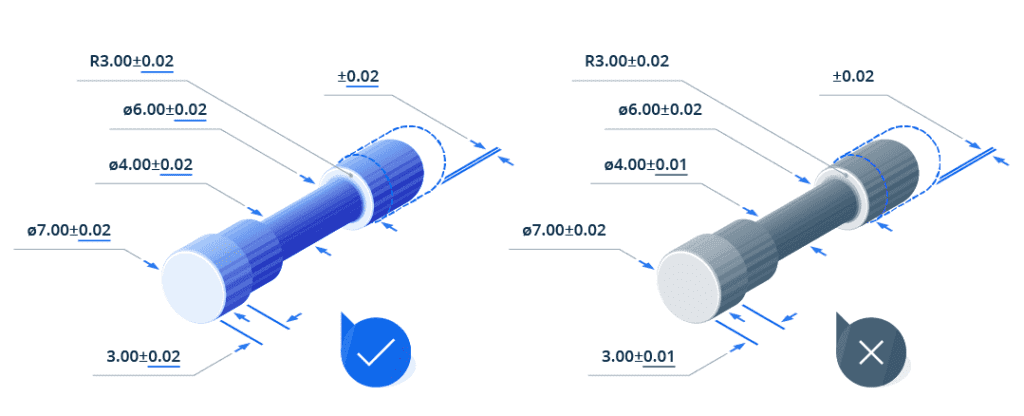

3. Avoid Excessive Use of Tight Tolerances

If you don’t specify tolerances in your design, the machine would simply use its standard tolerance. This helps save time and money. You should only specify tight tolerances when absolutely necessary. If you do specify tight tolerances, you should maintain consistency throughout your design. This helps reduce machining time.

4. Avoid Unnecessary Aesthetic Features

Some aesthetic features cannot be efficiently machined. As a designer, you should ask yourself: “What CNC machining process would this feature require?” or “Is it a 5-axis or a 3-axis machining process?”

You can improve your design by focusing on the accuracy of required features rather than aesthetics. It is best to use post-machining processes to change aesthetics.

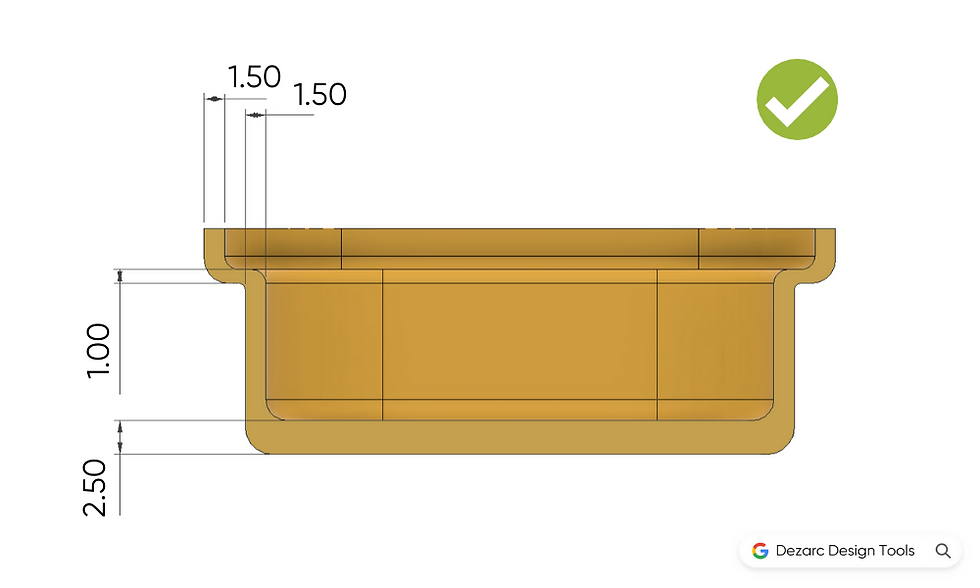

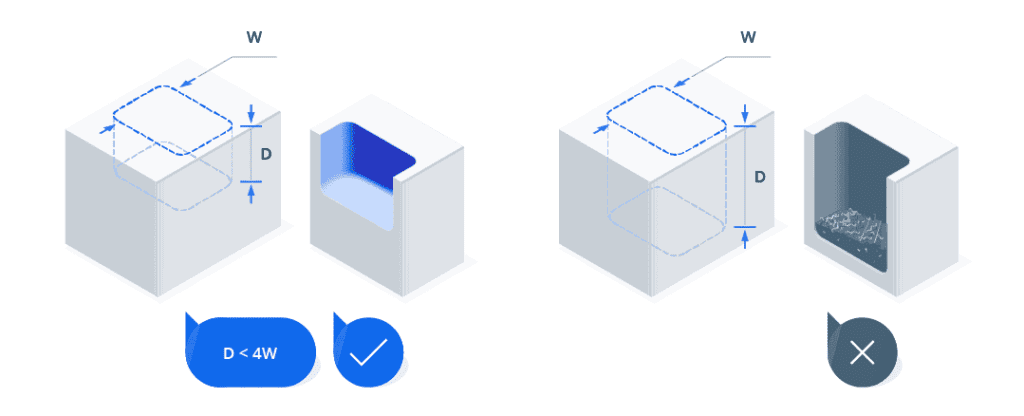

5. Design Cavities With Accurate Depth-to-width Ratios

Cavities that are too deep can result in tool hanging, tool deflection, chip evacuation issues, and tool fracture. Cavity depths should not exceed 3-4 times their width. If larger depths are required, you should consider designing your part with a variable cavity depth. Cavity depths higher than six times their width are considered deep.

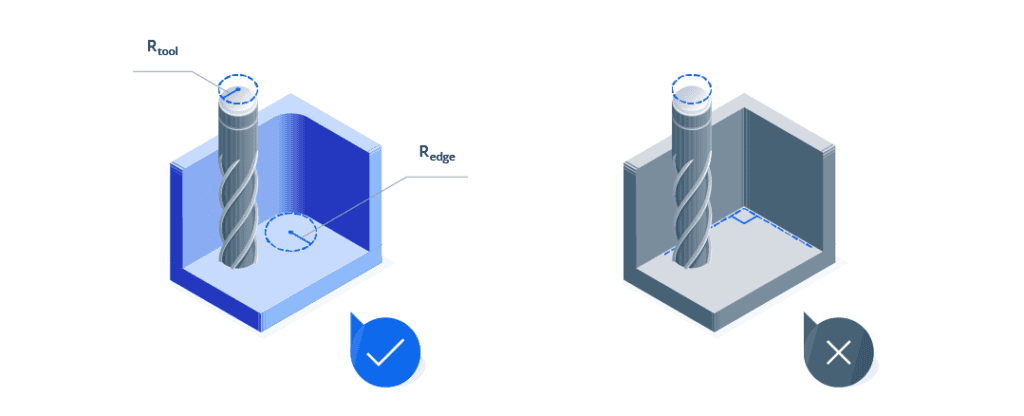

6. Add a Radius When Designing Internal Vertical Edges

Most cutting tools are cylindrical and cannot machine sharp internal edges, meaning it is important to add a radius to internal edges in your design. To avoid unnecessary wear and tear of the tool, a good rule of thumb is to add a radius of 130% of the milling tool radius. If you need sharp internal corners, consider adding undercuts instead of reducing the edge radius.

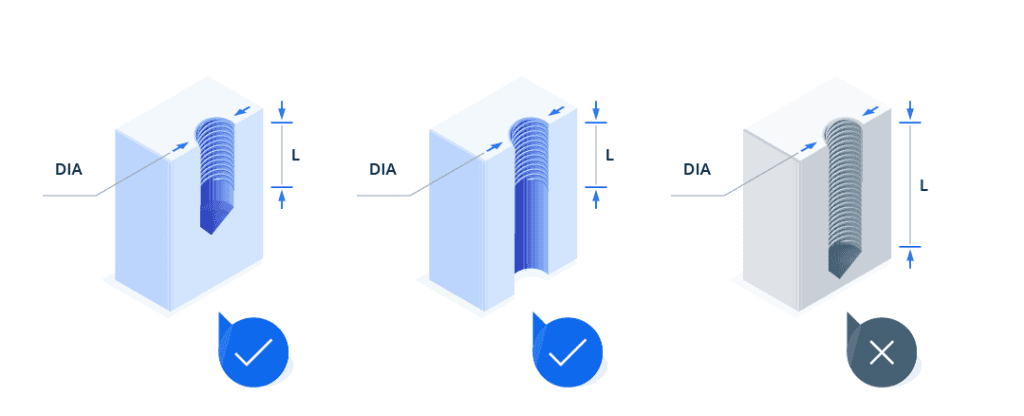

7. Limit Thread Length

Unnecessarily long threads increase machining costs. The strength of the connection does not increase any when the thread length exceeds the size of the diameter by more than 1.5 times.

- Design threads should be no longer than 2 times the hole diameter

- For blind holes, add an unthreaded length of at least half the diameter at the bottom of the hole

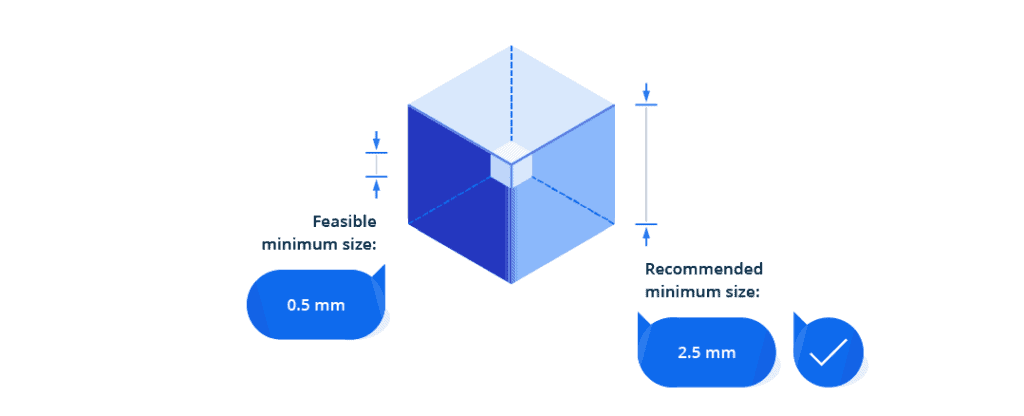

8. Avoid Extremely Small Features

Most CNC machines have a minimum tool diameter of 2.5 mm, meaning any feature smaller than 2.5 mm would be difficult to machine and would require special tools, which increases machining costs and time.

9. Design Holes With Standard Sizes

Holes are machined quickly and accurately when standard drill bits are used. This means you won’t need end mills or reamers to finish the hole size to a non-standard dimension.

Usually, increments of 0.1 mm are used for holes up to 10 mm in diameter, and increments of 0.5 mm are used for larger holes.

You should also limit the depth of holes to four times their diameter. It is possible to machine deeper holes (up to 10 times the diameter), but this will increase costs.

10. Avoid Unnecessary Text and Lettering

Any required text can be painted or laser engraved on the surface of the machined part during the finishing process. If machined text is required, adhere to the following rules:

- Choose engraving instead of embossing. This way, less material is removed.

- Use 20-point Sans Serif fonts to help keep costs low. Also, many CNC machines are already programmed for these fonts

CNC Machining Services at Xometry

At Xometry Europe, we offer CNC milling and CNC turning online services, as well as high-precision, fast, and quality CNC machined parts made of aluminium, stainless steel, steel, copper alloys, and many others. For any questions regarding CNC machining design, you can also refer to our CNC machining design guide.

We also carry out surface finish operations upon request. To get an instant quote, upload your models on our instant quoting platform.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Download

Download