3D printing is a highly versatile manufacturing process that is capable of producing both prototypes and durable end-use parts. Certain applications require 3D printed parts to be extremely strong and durable. These characteristics depend, to a large extent, on the design as well as on the 3D printing materials used to manufacture the part. Let us take a look at the options of the strongest materials for 3D printing for the technologies available at Xometry.

Indicators of Strong 3D Printing Materials

Strong materials or parts produced with them have high tensile, compact, or shear strength. They are able to withstand high stress and do not deform under heavy loads. Strong materials may also have good resistance to impact, chemicals, and harsh weather conditions. The strength of printed parts also depends on other factors, such as design, post-processing, and printing settings.

The Strongest 3D Printing Materials Available at Xometry

Different printing technologies require different plastics or metals to print. Let us see what print material with good strength each technology requires and its properties in detail.

CE 221 (Cyanate Ester)

This material is known for its high-temperature resistance and rigidity. Due to its high heat-deflection temperature, CE 221 can be safely applied in applications with high thermal requirements. The resin has long-term thermal stability with a glass transition temperature of about 225°C.

This material is capable of withstanding high pressure and giving a highly precise surface finish.

- 3D Printing technology: Carbon DLS

- Applications: Industrial products, electronic assembly components, fluid manifolds

Nylon PA 12 Carbon-filled

The blend of Nylon PA 12 resin with chopped carbon fibre gives this material excellent structural properties. The carbon fibre occupies 35% of its weight. This allows for distinct freedom of design, especially for prototyping.

It is quite strong and rigid, capable of replacing metals in certain applications such as jigs, fixtures, drill guides and press-fit inserts. It has wide applications in the automobile, industrial and recreational industries. Nylon PA 12 CF is widely referred to as the FDM material with the highest strength-to-weight ratio available.

- 3D Printing technology: FDM

- Applications: Tooling, prototyping

EPX 82

This epoxy-based photopolymer has an excellent blend of toughness, stiffness, durability, temperature resistance and a high tensile strength of 82MPa. Its ultraviolet and thermal stability make it suitable for a wide range of applications. The EPX 82 resin is capable of giving accurate prints.

Its high impact and heat-resistant property allow for continuous use in applications with varying temperatures.

- 3D Printing technology: Carbon DLS

- Applications: Jigs, light fixtures, brackets, connectors

Polycarbonate (PC)

Polycarbonate is a tough and amorphous material with high impact strength, stability and good electrical properties. This material allows the transmission of light internally in almost the same capacity as glass. It has a wider temperature range of usage with a heat deflection temperature of 140°C.

It is widely used for the production of safety helmets, lenses for car headlamps and bulletproof glasses. It can be combined with flame retardant materials without any significant material degradation.

- 3D Printing technology: FDM

- Applications: Medical equipment, industrial products, electronic components

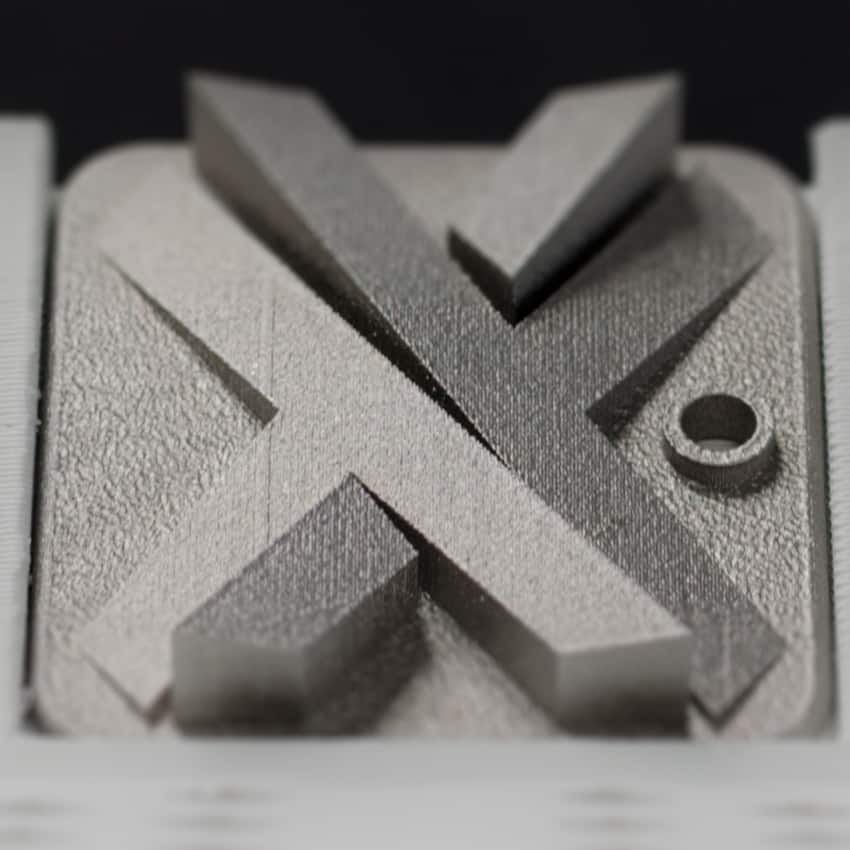

Stainless Steel 17.4 / 1.4542

This is chromium-nickel copper steel with high strength and excellent toughness. It has a tensile strength of 1070N/mm2. Stainless Steel 17.4 has good corrosion resistance. Due to its high strength, it is heavily employed in the aerospace and high-technology-driven industries in components such as gears, turbine blades, shafts, and moulding dies.

This material can be heat treated to a wide variety of hardness and toughness levels. Direct metal laser sintering (DMLS) is the standard form of printing with stainless steel. However, other methods such as binder jetting and selective laser melting (SLM) are also used.

- 3D Printing technology: DMLS, binder jetting, SLM

- Applications: Aerospace, high-technology industries

ULTEM 1010

This material has the highest heat resistance, chemical resistance and tensile strength compared to other FDM thermoplastics. ULTEM 1010 is available in transparent, opaque and glass-filled grades. It has broad applications in custom tools for metal or plastic parts fabrication, medical tools and temperature-resistant dies.

It is a high-performance polyetherimide thermoplastic and can be said to be the strongest FDM printing material available. It has the lowest coefficient of thermal expansion. It has food-contact and biocompatibility certifications, which makes it ideal for applications in the food industry.

- 3D Printing technology: FDM

- Applications: Food industry, tooling

PEEK

It has excellent resistance to harsh chemicals with high mechanical strength and dimensional stability. It has the ability to retain its stiffness at elevated temperatures and can be employed for continuous use at temperatures up to 170°C.

PEEK, also known as Polyetheretherketone, has excellent fatigue and stress-crack resistance. It is used in aerospace, oil and gas and semiconductor production.

- 3D Printing technology: FDM

- Applications: Bearings, seals, valves, tubes

ULTEM 9085

This has a high strength–to–weight ratio, high impact strength with good heat resistance. It is highly flame-retardant. It is used in the production of prototypes as well as tools in the aerospace and automotive industries. It is comparable to nylon 6.68 (9800).

ULTEM 9085 with its superior mechanical strength and lightweight is suitable for the production of end-use components.

- 3D Printing technology: FDM

- Applications: Jigs, fixtures, composite moulds

Aluminum AlSi10Mg / EN 1706: 1998

This material has excellent strength at elevated temperatures (about 200°C). Aluminum AlSi10Mg has good corrosion resistance and can be easily polished. It has good workability and good heat crack resistance. The fatigue strength is excellent at 110N/mm2.

It has good weldability and is widely applied in parts for vehicles, machines and aircraft. It has a tensile strength of 290MPa at room temperature.

- 3D Printing technology: DMLS

- Applications: Automotive, Aerospace

Stainless Steel 316L / 1.4404

This material has low carbon content and is chromium-nickel-molybdenum stainless steel. Stainless Steel 316L has excellent corrosion resistance and stability against chlorine-based media and non-oxidizing acids. It has a high tensile strength of about 500N/mm2.

It is typically used in food processing and laboratory equipment, heat exchangers, nuts and bolts. It is the smoothest material when compared with other metal materials.

- 3D Printing technology: DMLS

- Applications: Food and beverage equipment, pharmaceutical equipment

3D Printing Strongest Materials Cost Comparison

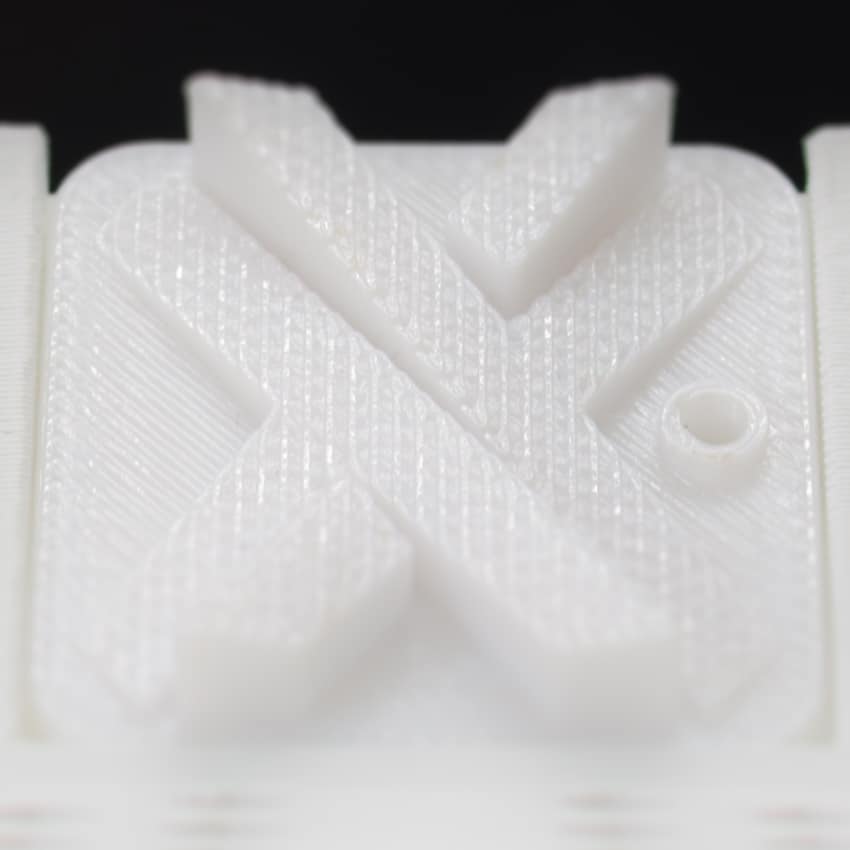

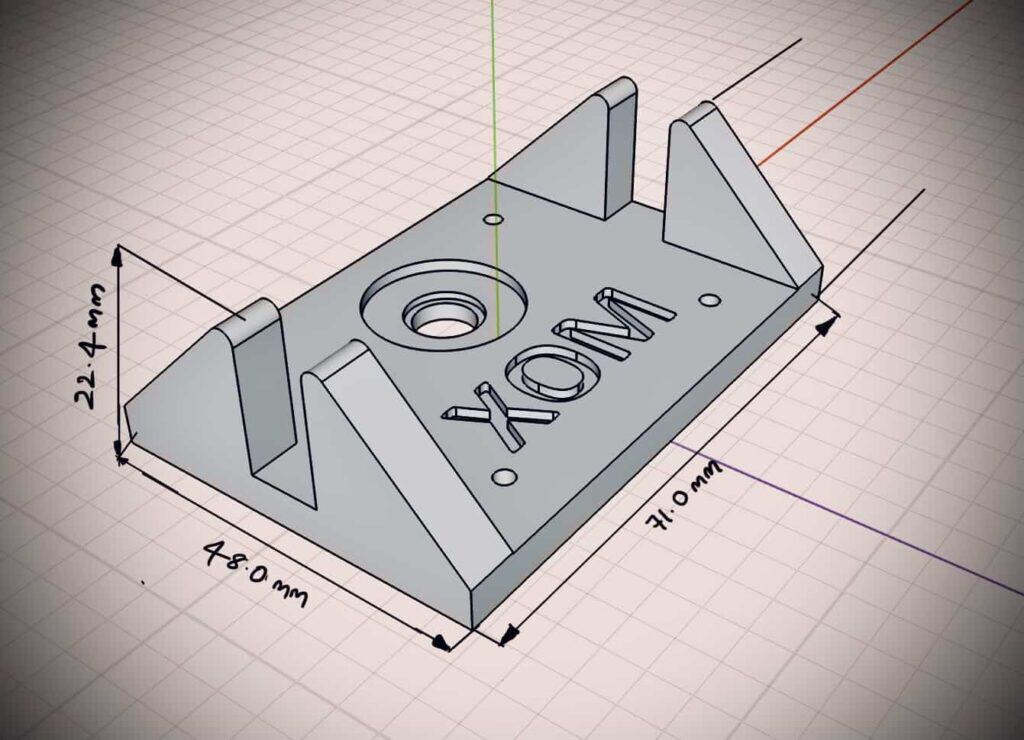

Let’s have a cost comparison of the three resins from Xometry’s quoting engine for the CAD model:

| Material | Technology | Tensile Strength (MPa) | Cost per one unit (€) | Unit cost per 10 pieces (€) | Unit cost per 100 pieces (€) |

| CE 221 | Carbon DLS | 92 | 645.21 | 171.58 | Price on demand |

| Nylon PA 12 CF | FDM | 76 | 24.60 | 18.49 | 14.31 |

| EPX 82 | Carbon DLS | 82 | 201.85 | 46.38 | 46.38 |

| PC | FDM | 60 | 34.45 | 25.89 | 25.03 |

| Stainless Steel 17.4 | DMLS | 1103 | 387.12 | 294.83 | Price on demand |

| ULTEM 1010 | FDM | 105 | 50.03 | 35.80 | 34.61 |

| PEEK | FDM | 110 | 44.21 | 32.32 | 23.56 |

| ULTEM 9085 | FDM | 70 | 47.64 | 35.80 | 34.61 |

| Aluminum AlSi10Mg | DMLS | 230 – 290 | 174.76 | 89.19 | 87.80 |

| Stainless Steel 316L | DMLS | 490 – 690 | 387.12 | 294.83 | Price on demand |

Try out Xometry’s Instant Quoting Engine to source your parts with the strongest 3D printing materials.

Conclusion

There are two main types of strong materials for 3D printing: plastics, which can be printed with FDM, SLS, SLA, Carbon DLS, MJF and metals (DMLS). Xometry Europe offers fast, reliable, and highly accurate 3D printing services with these technologies and materials. Through our Instant Quoting Engine and our network of over 2,000 manufactures, we ensure that you experience a seamless part production process, from quoting to doorstep delivery.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)