- Industry: Consumer goods / Electronics

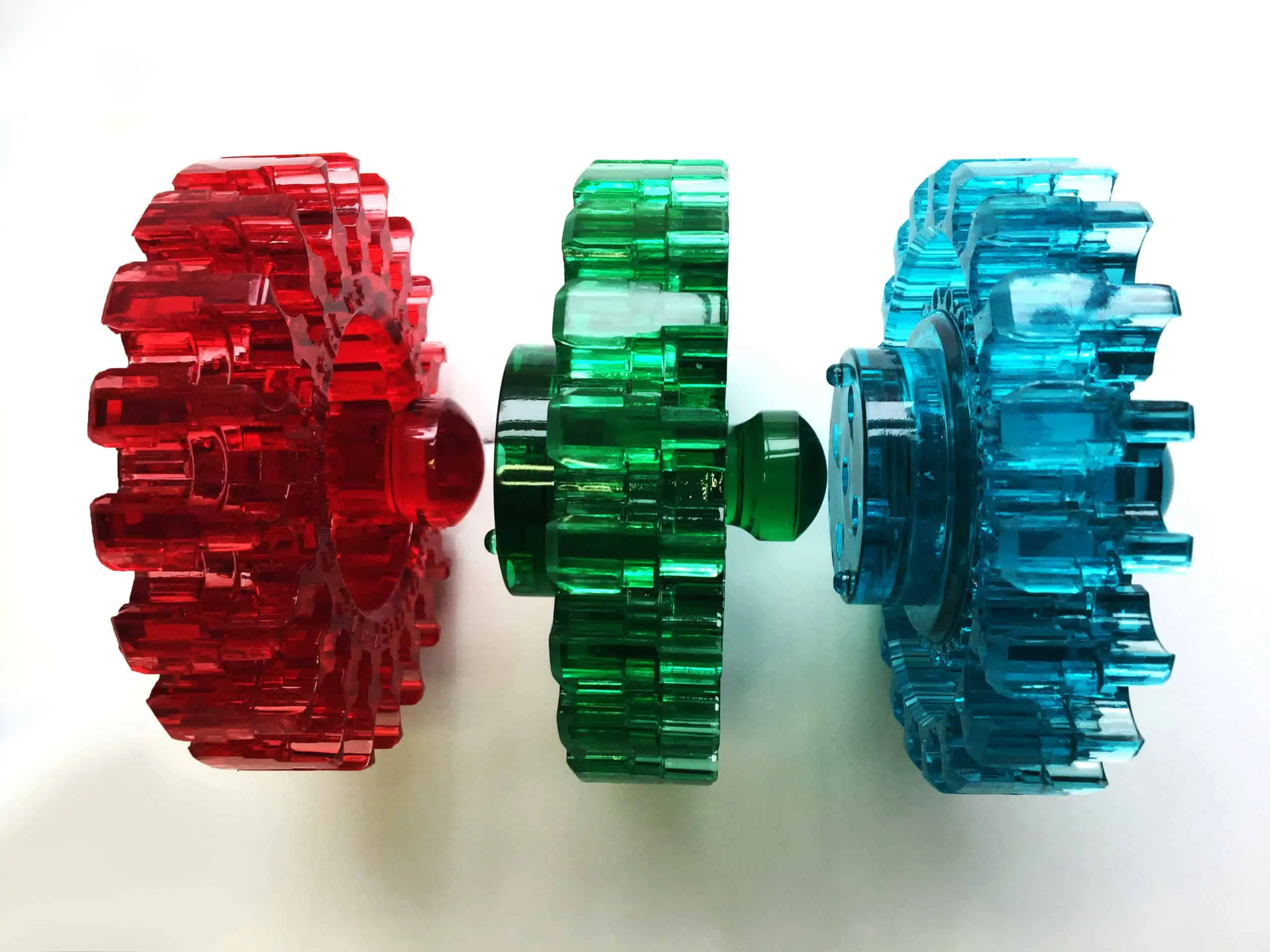

- Manufacturing process used: Vacuum casting

- Challenge: Making a silicone shell prototype to validate a POC (“proof of concept”) before launching a new product on the market

- Solution: The quoting platform and the responsiveness of the Xometry team allowed Lunii to find a suitable manufacturing solution for producing a prototype at a reasonable cost and within a reasonable timeframe

Some believe that children are often deprived of individual and collective imaginations because of the visuals that they are shown, particularly through screens. This made us want to free the imagination of these children. This is how Lunii and its My Fabulous Storyteller came into being in 2014, offering children an audio storyteller that lets them create their own stories but also listen to their favourite tales in an independent and safe way.

Thomas Krinbarg is one of the four founders of Lunii. He mainly works on the design and conception of My Fabulous Storyteller, the brand’s flagship product. This audio storyteller was the first of its kind launched on the market and is based on a simple principle: the child turns on the box and chooses the four defining elements of their story (universe, main character, secondary character, and object). These four choices determine which of the 48 pre-recorded stories will be told. In addition to these stories, Lunii also offers classic childhood stories.

The Silicone Shell: a New Storyteller Accessory

Given the success of My Fabulous Storyteller, the Lunii team decided to diversify with the launch of a publishing house, stories adapted to different ages, headphones, and more recently a silicone shell (“La Coque Odile”) designed to protect the storyteller. “You shouldn’t underestimate a child or their parents,” Krinbarg jokes.

Although the idea of making a shell came to him in 2021, it wasn’t until the end of 2022 that the co-founder seriously tackled this project. He first designed what he called a “brick” big enough for the storyteller. Then came the question of the manufacturing process, the material, and the shore hardness for the shell, which he wanted to be both flexible and durable.

Krinbarg quickly finalised his 3D file and started looking for a new partner to produce a POC (“proof of concept”) to present to the team, as he wasn’t happy with the first 3D printed test.

Xometry’s Technical Advice and Production Capabilities

While doing some research on the Internet, Krinbarg discovered Xometry and requested a quote for the shell from the 3D design he had imported onto the platform. He was immediately contacted by Lison, Key Account Manager for France, who helped him choose the most suitable manufacturing technology.

She suggested using vacuum casting to produce the prototype instead of 3D printing. This process is ideal for producing flexible parts that are extremely close to the output in mass production in terms of mechanics and aesthetics. “Instead of letting me simply complete my order as it was, Lison contacted me and suggested an alternative solution more suited to my project,” says Krinbarg.

They discussed the choice of material and the shore hardness that could be suitable for the product and lastly chose to make the shell out of a rubber-like material with three shore A hardnesses (40/50/60) to compare the final result. “In some places, the shell is quite thin and if the shore is too low, the material doesn’t perform well enough and there was a risk of having a strip that was too soft.”

To give their product an ideal look and feel, Krinbarg adds an SPI-C1 surface finish that lightly polishes the part to give it a pleasant feel.

“It was fast and competitively priced – exactly what I wanted,” says Krinbarg. He also appreciated how easy it was to understand things he wasn’t particularly familiar with thanks to Xometry’s expert guidance. This POC allowed him to validate the project within the team and to launch serial production of the brand new shell.

The Story Continues

Launched in summer 2023, the shell will join the panoply of accessories now available. The Lunii team is continuing to revolutionise children’s imaginations and has no intention of stopping there.

About Lunii

Lunii awakens the imagination of children aged 3 to 8. Founded in 2014, its My Fabulous Storyteller now lets children worldwide create and listen to audio stories so they can dream, explore, and learn while having fun.

Website: https://lunii.com/

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)