3B Fab: Where Creativity and Technology Meet

3B Fab is a Turkey-based technology company that develops 3D printers and various industrial resins specifically designed for use in the dental (dentistry) and jewelry industries. Operating across seven different countries, 3B Fab goes beyond hardware development by leveraging its own R&D teams to provide sector-specific solutions for a range of applications.

From dental models required in dentistry to complex jewelry designs, 3B Fab addresses diverse needs with DLP and SLA technologies, delivering both speed and superior surface quality.

The company’s key offerings include 3D printers and customized resins, each tailored to fulfill different requirements for hardness, durability, and aesthetics in the dental and jewelry fields.

Challenges in the Procurement Process

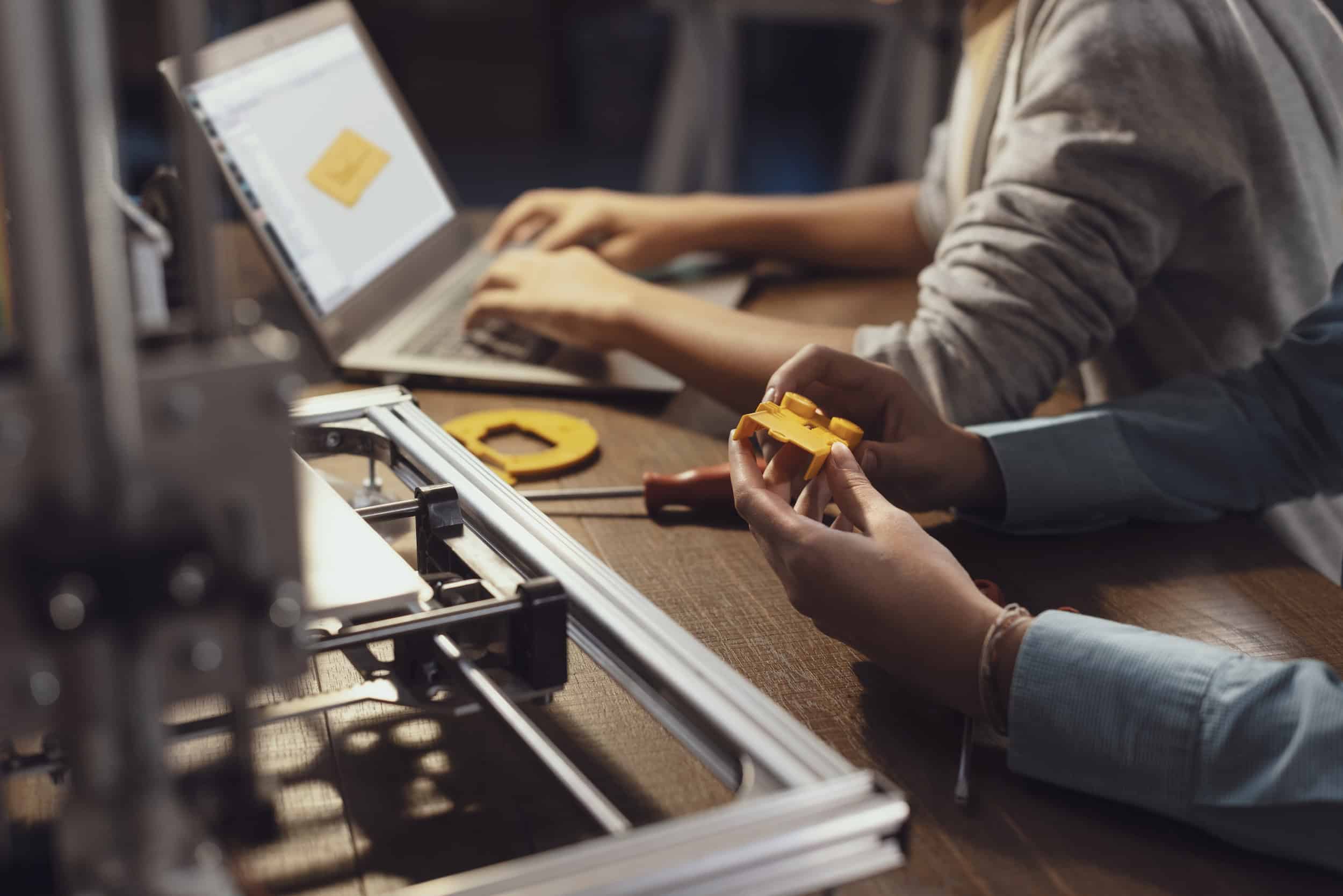

To produce critical parts with tight tolerances—such as build plates and long-lasting tank components—3B Fab previously had to collaborate with multiple suppliers, leading to wasted time, increased costs, and complex logistics. Specifically:

- Managing time became difficult due to the need to coordinate several suppliers simultaneously.

- Instead of incurring mold costs for every new project, they sought flexible solutions such as CNC machining.

According to Onur Öncü Aksakal, 3B Fab’s Production Team Leader, the company was in a phase of rapid growth and needed to focus on R&D. However, dealing with multiple suppliers caused inefficiencies in both time and budget. As a result, they looked for an effective collaboration that would streamline procurement operations, maintain high quality standards, and optimize costs.

Build Plates and Tank Components

3B Fab had been in touch with the Xometry team for some time, but upon discovering Xometry’s ability to offer multiple technologies under a single platform, the scope of their collaboration expanded rapidly.

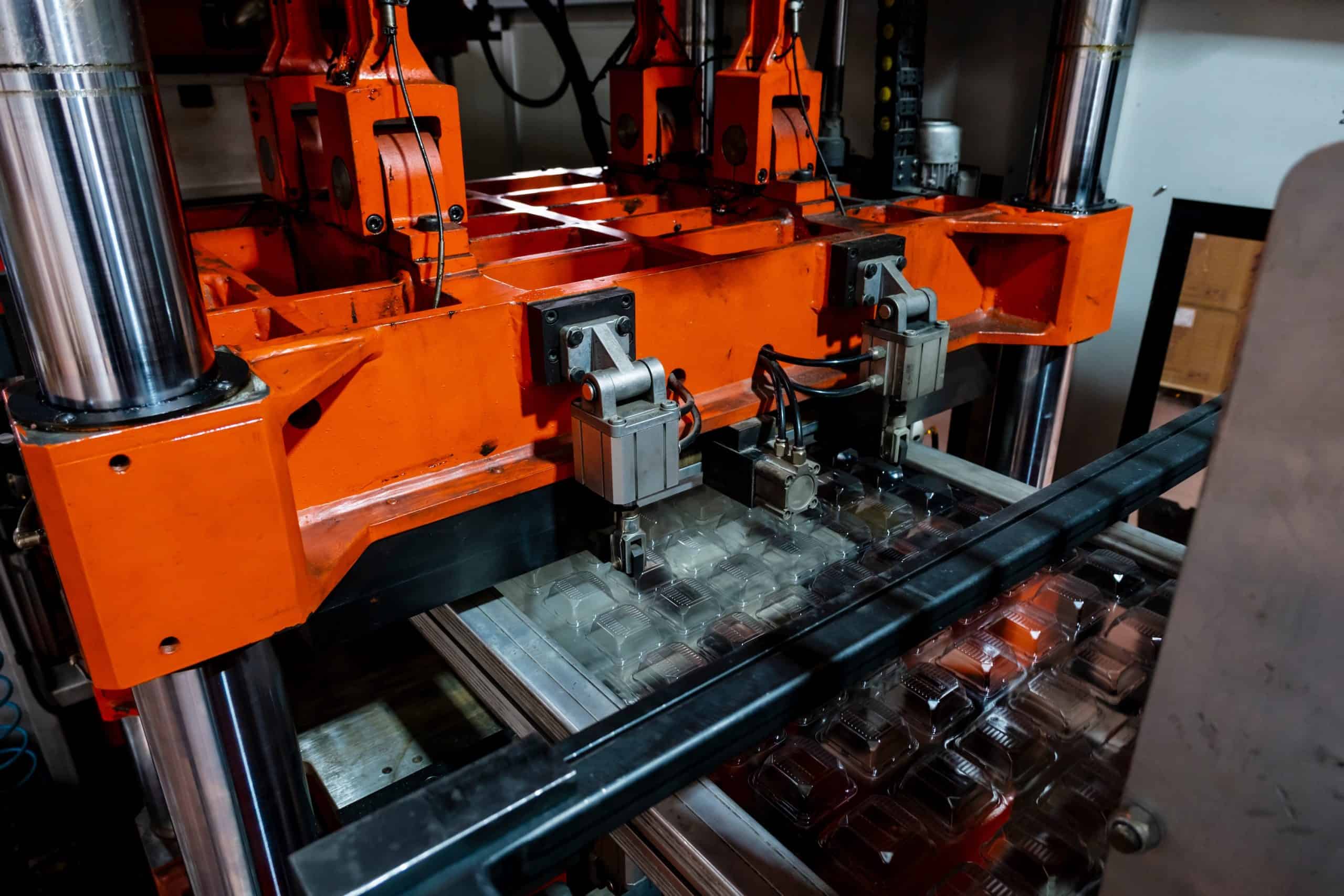

Within 3B Fab’s 3D printers, components such as the build plate and tank components require materials that can withstand high temperatures, chemical exposure, and friction resistance. Any tolerance deviation directly impacts printer performance, making the choice of material, surface quality, and machining accuracy critically important.

Many of these parts are produced using aluminum 6082, 6061-T6, or 5083, then undergo specialized finishing processes like black anodizing or bead blasting to ensure both durability and aesthetics, depending on their intended applications.

Xometry: One Platform for Production, Quality, and Supply Management

Through Xometry’s versatile platform—supported by a global network of qualified manufacturers and robust corporate communication—3B Fab can quickly match its requirements with the right manufacturing partner, without fragmenting its workload.

Whether it’s additive manufacturing or CNC machining with anodizing, the most suitable production method is chosen for each project.

Meanwhile, the TPO (Target Price Order) model provides both cost and time savings for 3B Fab, while Xometry’s quality team identifies potential issues and arranges re-production if necessary.

3BFab’s Future Vision: Innovation and Global Growth

Beyond establishing itself as a leading player in the dental and jewelry markets, 3BFab aims to advance in technology development and global expansion. The company’s core goals include:

- Developing Next-Generation 3D Printer Models: Targeting larger build volumes and finer layer thickness to meet the evolving demands of various sectors.

- Diversifying Materials and Resins: Offering specialized resins with high chemical resistance and sector-specific certifications to serve new markets beyond dental and jewelry.

- Expanding Global Reach: Extending the existing office network to a broader international market, incorporating new sales channels and deepening its impact worldwide.

For further details, explore the innovative solutions provided by NovaFab and DentaFab:

NovaFab Web Site : http://novafab.com

DentaFab Web Site : http://dentafab.com

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)