Our team tackled this challenge by creating Solar EVA Panel, an initiative focused on giving a second life to ethylene vinyl acetate (EVA) encapsulants from retired solar panels, transforming them into eco-friendly insulation and soundproofing materials.

Giving Solar Waste a Second Life

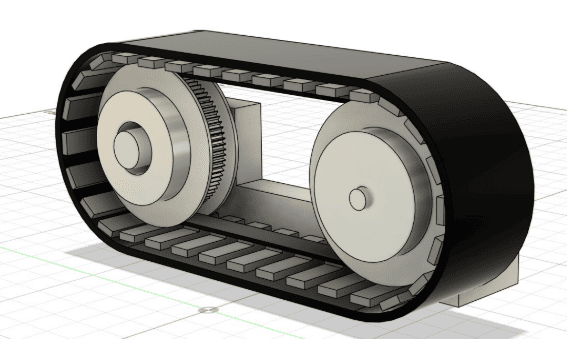

By 2050, over 60 million tons of solar panel waste are expected to accumulate in landfills worldwide. While solar panel recycling is becoming more prevalent, EVA encapsulants—which shield solar cells from moisture, dust, and UV exposure—are often overlooked in recycling processes.

Despite its protective role, EVA remains highly valuable even after a solar panel’s end of life. Currently, EVA recycling is minimal, leading to missed opportunities for reducing carbon footprints, landfill waste, and material costs.

A Hidden Resource in the Solar Industry

Most current recycling systems focus on reclaiming valuable metals and glass from solar panels, leaving EVA behind. Yet EVA retains its material properties even after years of exposure, making it a viable candidate for reuse. Today, EVA recycling is minimal, which means we are missing significant opportunities to reduce emissions, lower material costs, and create new revenue streams from solar waste.

Producing virgin EVA from petrochemicals is energy-intensive and expensive. In contrast, our process allows for the recovery of EVA at nearly zero raw material cost—while reducing emissions by up to 85%. This makes repurposed EVA a more sustainable and economically viable alternative, especially for industries in search of thermal and acoustic insulation materials.

From Extraction to Application

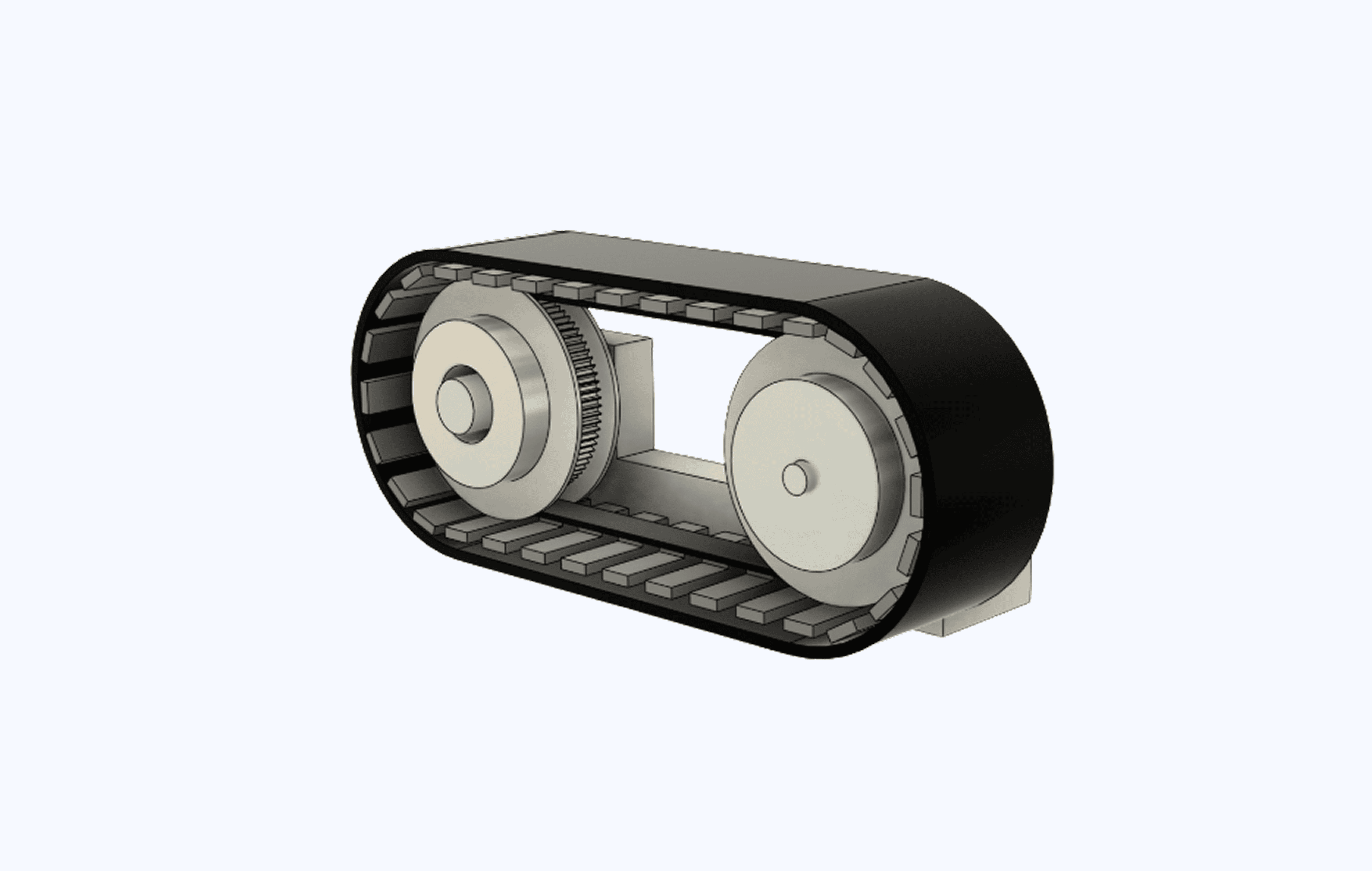

At the heart of our project is a scalable extraction system that can be implemented directly in solar panel decommissioning plants. The process starts with feeding retired solar panels onto a conveyor system. A heating element then softens the EVA layer, loosening it from the panel’s surface. A suction mechanism gently peels the EVA away, while an integrated air filtration system captures any gases emitted during the process. What remains is a clean, reusable EVA sheet ready for a second life.

Once recovered, the EVA is processed and shaped for a variety of applications. Its thermal insulation and soundproofing qualities make it ideal for use in housing insulation, school buildings, and even packaging materials. These applications are especially valuable in low-income communities, where affordable energy efficiency upgrades can significantly improve living conditions.

Exploring Advanced Applications: Transparent Solar Panels

In addition to its uses in construction, we identified another compelling application for repurposed EVA: transparent solar panels. These newer-generation panels offer reduced efficiency—about 40% less than traditional opaque ones—but open the door to wider integration in urban environments. When embedded in windows, doors, and building facades, they can turn surfaces into energy-generating systems.

A one-square-meter transparent panel can generate roughly 272 kWh per year—enough to meet about 10% of an average UK household’s energy needs. With transparent panels, energy production becomes more decentralized and seamlessly integrated into everyday infrastructure.

EVA plays a key role in these designs, and by reusing it, we can make transparent solar panels even more sustainable.

Real-World Feasibility and Industry Integration

In early tests, repurposed EVA has shown high thermal insulation capabilities, making it particularly Our project has already sparked interest from industry professionals. During our presentation, Baninder Kaur, Key Account Manager at Xometry, raised the question of whether our system could be adopted directly by solar panel manufacturers. We confirmed that the process is designed with modularity in mind—it can be integrated into existing recycling workflows without requiring a full overhaul of infrastructure.

Another audience member, Joao Clemencio, inquired about what happens to the recovered EVA after extraction. We explained that manufacturers have two main options: they can reuse the EVA in new solar panels, including transparent ones, or sell it to industries that rely on foam-based materials for insulation, packaging, or acoustic solutions.

Currently, most solar panel recycling does not include EVA recovery, which means our approach introduces an entirely new step in the process—one that not only improves sustainability but also offers economic advantages for solar companies and downstream industries.

Unlocking Market Value Through Circularity

The solar panel recycling market is expected to reach an estimated value of £11 billion by 2050. Within this landscape, EVA represents a largely untapped revenue stream. By recovering and repurposing EVA, manufacturers can reduce emissions and raw material costs while selling surplus EVA foam to other sectors. For construction companies, the access to low-cost, high-performance insulation materials is a clear win.

We see EVA recovery not just as a recycling initiative but as a strategy to create closed-loop systems in the solar industry—turning waste into value, and environmental responsibility into market opportunity.

Scaling Up With Industry Partners

Looking ahead, we believe that the Solar EVA Panel system can scale globally. Its core components—solar panel processing, heat-assisted EVA separation, and air filtration—can be replicated in decommissioning facilities around the world. From solar manufacturers and renewable energy companies to construction and packaging sectors, the demand for circular, sustainable materials is growing.

With support from Xometry, we plan to refine our extraction technology, enhance efficiency, and explore partnerships with solar panel producers to bring EVA recycling into mainstream operations. Our vision is to embed sustainability at every stage of the solar lifecycle—from manufacturing and deployment to responsible end-of-life management.

Do you see potential for this solar-powered heating solution? Comment with your insights on feasibility, use cases, or design improvements.

Discover the other UCL Hackathon projects:

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)