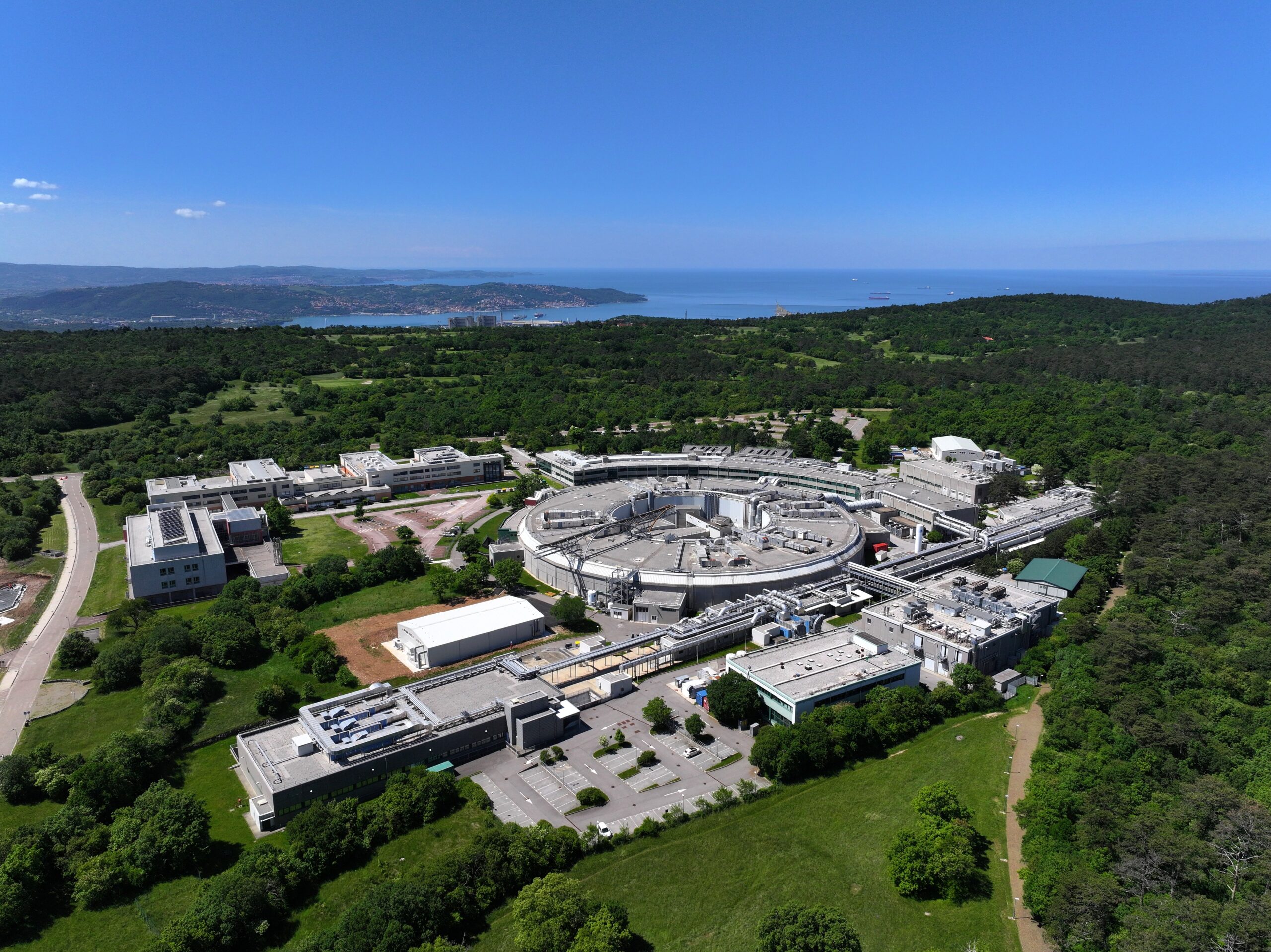

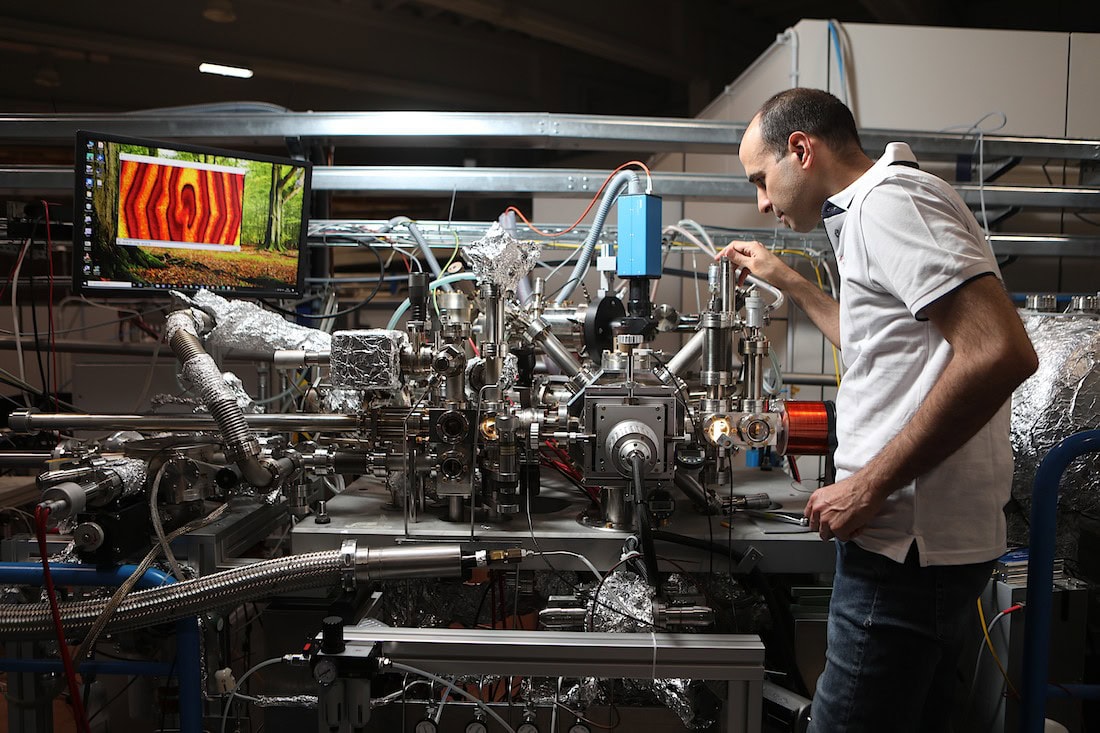

Elettra Sincrotrone Trieste is an international research center founded in 1986 and operational since 1993, located in Trieste, Italy. The center operates two flagship light sources:

- Elettra synchrotron, a third-generation storage ring supplying over 30 beamlines

- FERMI, a world-class free-electron laser that delivers ultrashort, fully coherent UV to soft X-ray pulses lasting just a few dozen femtoseconds.

These tools help scientists and engineers explore materials and processes at the atomic level—unlocking innovations in microelectronics, energy storage, aerospace, and more.

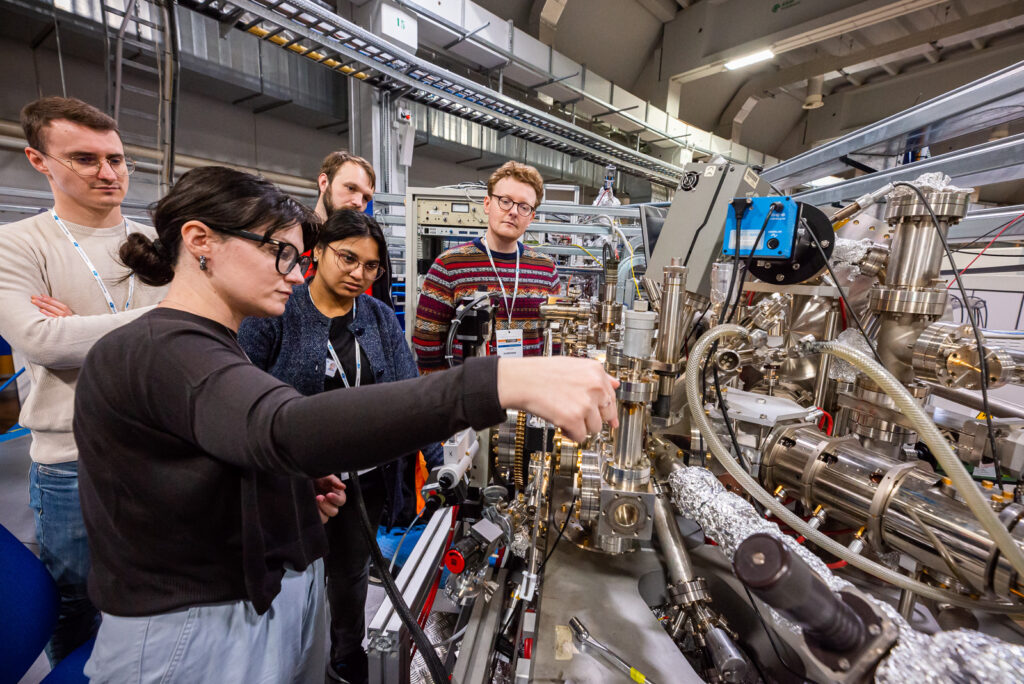

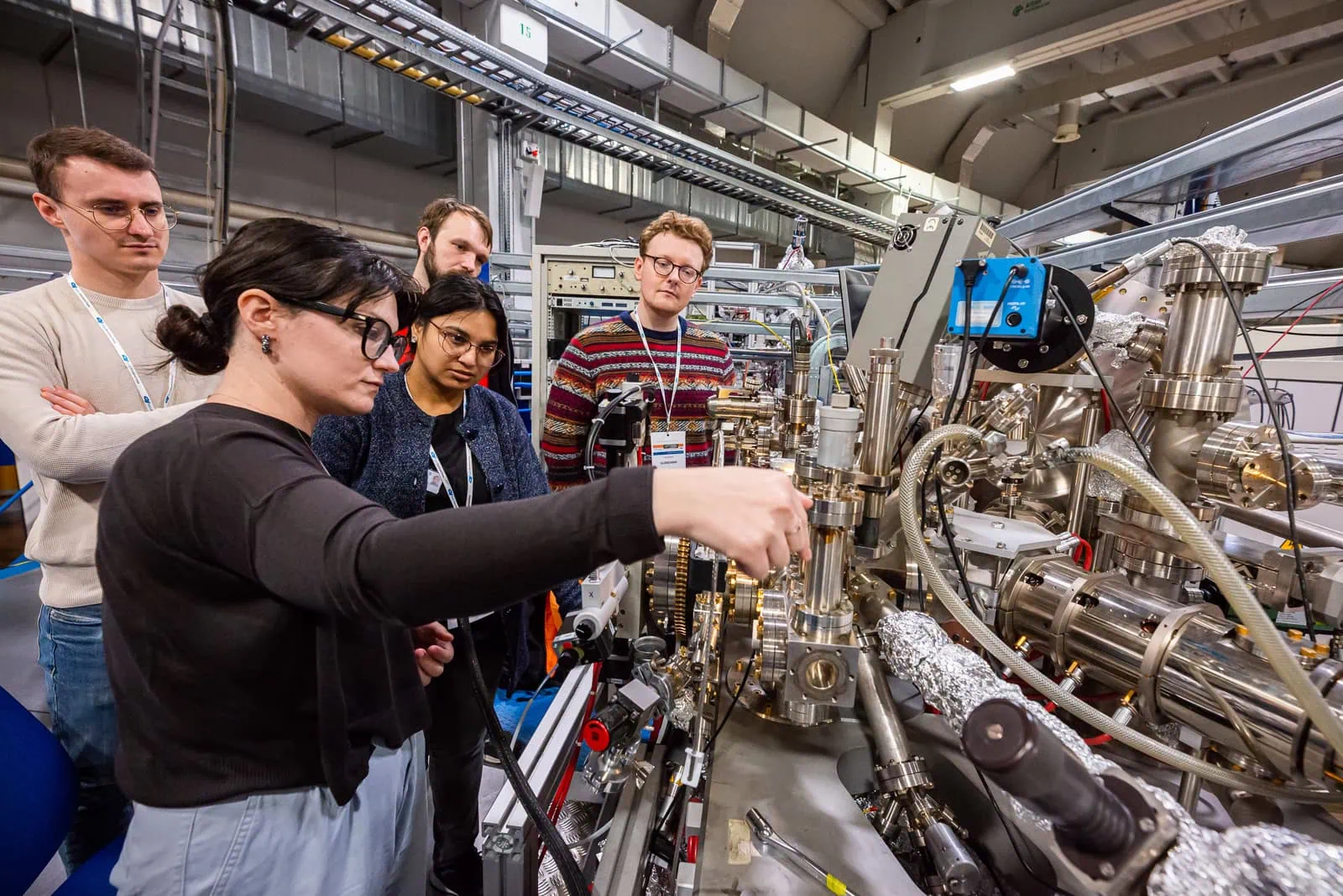

Many of our beamlines, including Spectromicroscopy, play a key role in applied industrial research. Techniques such as X-ray spectroscopy and nanoscale imaging are used to investigate surfaces, thin films, and nanostructures—critical in optimizing materials for semiconductors, energy storage devices, and catalytic systems. This direct link between experimental science and real-world applications helps accelerate innovation in both manufacturing and advanced technology development.

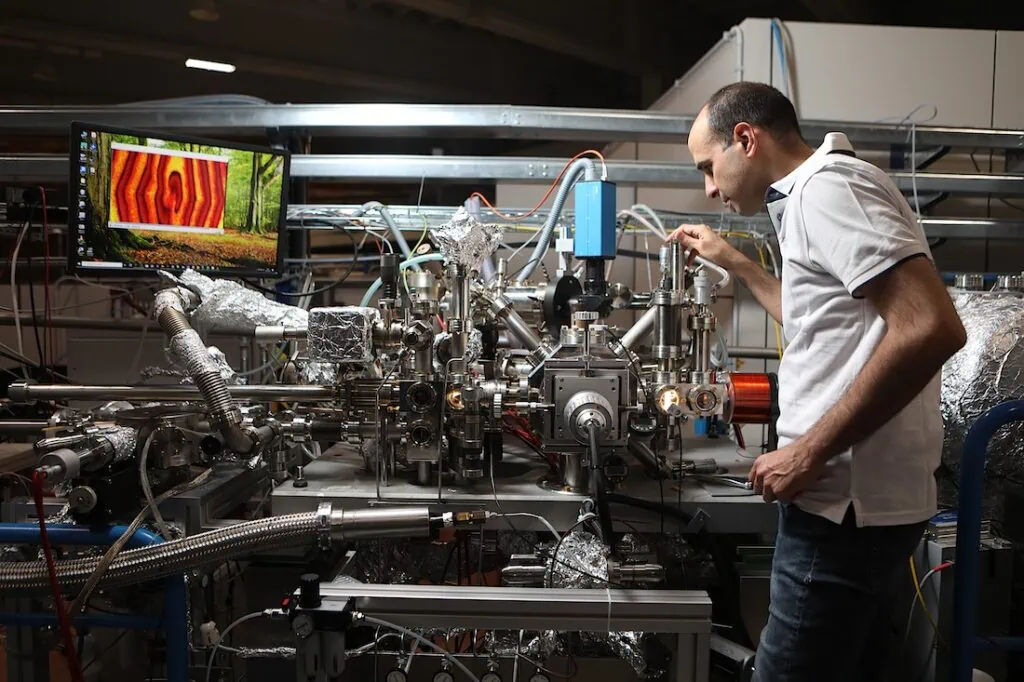

Our history is marked by bold engineering achievements. For instance, constructing FERMI demanded precise mechanical and thermal stabilization systems, custom high-precision components, advanced diagnostics, and femtosecond synchronization. Managing daily beamline operations also requires the same hallmarks of high-end manufacturing: reliability, customization, CAD/CAM integration, and fast problem-solving.

A Bold Engineering Challenge for Next‑Gen Science

Elettra 2.0 is a comprehensive upgrade of our synchrotron light source into a fourth-generation facility, designed to deliver fully coherent, diffraction-limited light. At the heart of this transformation is a new 12-arc lattice (S6BA-E) that reduces horizontal emittance by a factor of 50—achieving ultra-focused, stable beams.

This leap in performance translates into a 100-fold increase in brilliance at 10 keV and up to 60× improvement in coherence at 1 keV. All while reusing the original infrastructure—making Elettra 2.0 both a scientific and engineering milestone.

Delivering on this vision calls for ultra-precise mechanical systems spanning vacuum chambers, beamline supports, and beam steering elements—each designed and built with exacting attention to detail.

Into the Beamline: The System Behind Elettra 2.0

Engineering systems for Elettra 2.0 means working at the intersection of extreme stability, ultra-high vacuum, and photon beam quality. Every component—mechanical stages, supports, interfaces—must operate with nanometric accuracy, resist thermal and vibrational perturbations, and preserve vacuum integrity over long experimental cycles.

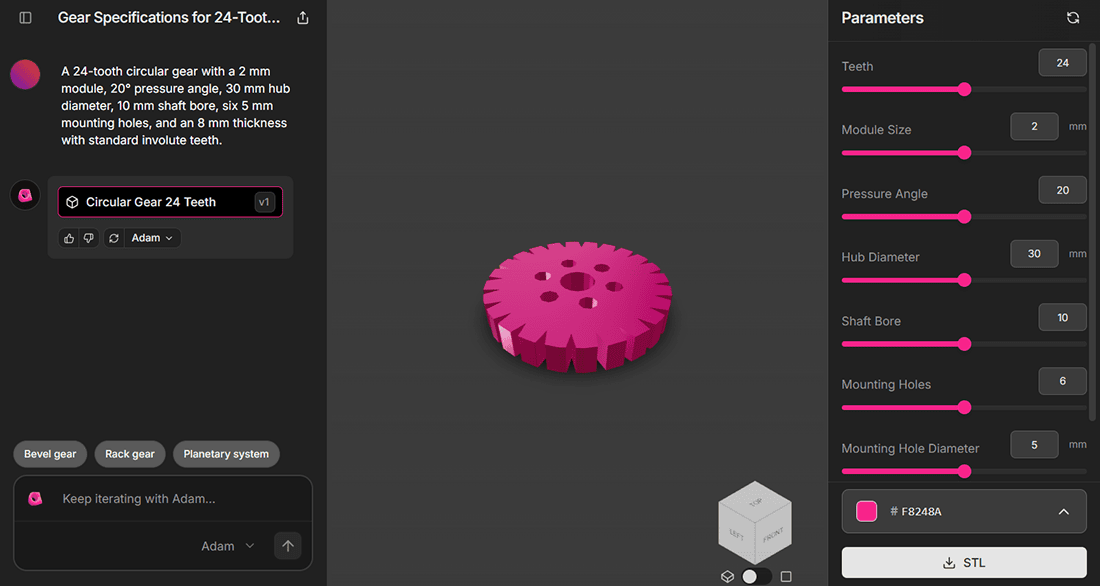

A key milestone in the Elettra 2.0 upgrade project was the development of a high-precision XYZ motion system for the Spectromicroscopy beamline. The system includes:

- Motion stages that can move with nanometer-level precision—essential for experiments requiring extreme accuracy

- Ultra-high vacuum (UHV)-compatible components made from ceramics and OFHC copper

- Vibration-isolated support feet to maintain ultra-stable positioning

Each element had to meet tight tolerances, withstand thermal and mechanical stresses, and integrate with CAD-based design workflows. Motion precision is not only a mechanical requirement—it directly affects spatial resolution, signal-to-noise ratio, and the reproducibility of nanoscale imaging and X-ray absorption measurements.

Bringing the Motion System to Life

In 2022, our team began translating detailed CAD models into physical components through Xometry’s manufacturing platform. Using digital manufacturing tools, we specified UHV-grade materials and received precision-fabricated parts within weeks.

The full XYZ assembly—including motion stages, structural elements, and supports—was built to nanometer-level tolerances, ready for integration into the beamline.

Once installed at the Spectromicroscopy end-station, the XYZ system delivered smooth, repeatable motion with nanometer precision under vacuum. All components, including ceramic and high-purity copper parts, passed vacuum cleanliness tests—guaranteeing a contamination-free environment. Meanwhile, vibration-isolation feet kept the setup stable with microscope-level steadiness. Together, these elements fulfilled the rigorous operational demands of the beamline—validating their role in the broader Elettra 2.0 platform.

A Launchpad for Further Innovation

With the XYZ system successfully implemented, Elettra is moving ahead to develop new high-frequency components for its upgraded storage ring—pushing the limits of light science even further. These parts are crafted through the same digital-to-part workflow—ensuring the same levels of precision, quality, and delivery timeliness—as the facility moves forward with its vision of a fully coherent, diffraction-limited fourth-generation light source.

What systems have you built that demand this level of precision? We’d love to hear how others approach motion, vacuum, and control in extreme environments.

Manufacturing stories & cases

Share your engineering or manufacturing story

If you want to share your story with others on xometry.pro, just fill out a short form

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)