Thermoforming, a plastic manufacturing process, moulds thermoplastic sheets into desired shapes using heat. Historically, its origins trace back to ancient practices of heating materials for shaping, but modern innovations have refined its applications and broadened its utility. Currently, thermoforming is essential in contemporary manufacturing thanks to its flexibility, efficiency, and cost-effectiveness.

What Is Thermoforming?

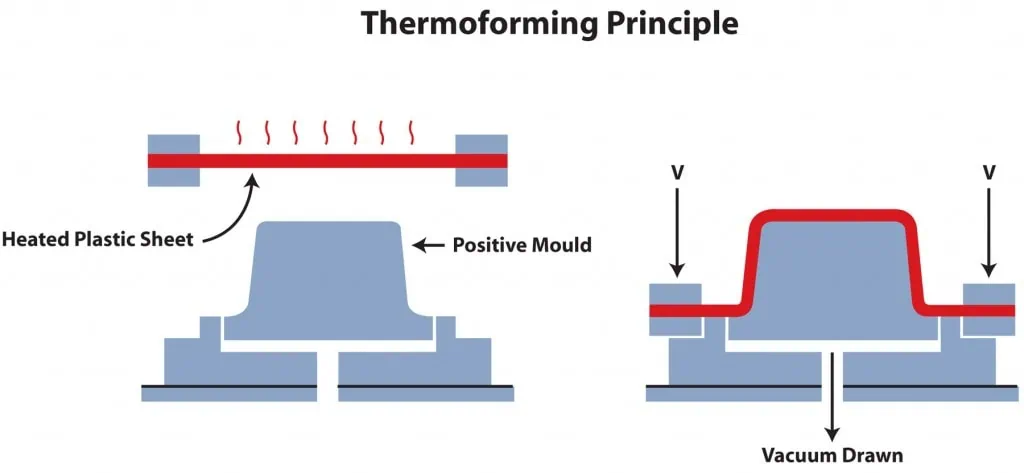

Thermoforming is a sophisticated manufacturing technique moulding thermoplastic materials into distinct 3-dimensional shapes. This foundational principle hinges on manipulating heat-sensitive plastics, making them take a desired shape. Thermoplastic materials are first exposed to a controlled heat source, making them pliable. Once sufficiently heated, these materials are stretched over a meticulously designed mould.

An external force, either vacuum or pressure, is applied to ensure the plastic conforms seamlessly to this mould. This force guarantees precision, ensuring the plastic sheet adheres tightly to every contour and detail of the mould.

The versatility of this method is truly commendable. Not only does it accommodate a wide array of thermoplastic materials, but its applications span diverse sectors. Once the thermoplastic material has achieved its final shape, subsequent steps involve precision trimming and finishing. These post-forming procedures are tailored to align with the end-user’s specific needs, further emphasising thermoforming’s adaptability.

How Does Thermoforming Work?

Step 1 – Material Selection

It’s pivotal to choose the correct type of plastic that meets the specific requirements of the end product. Various factors, including durability, flexibility, and the product’s intended use, guide this selection. Whether for thin gauge thermoforming, typically used in packaging, or thick gauge for more significant components, the choice of material is paramount.

Step 2 – Heating and Uniform Temperature Distribution

Post material selection, the plastic sheet undergoes a heating process. Achieving a uniform temperature distribution across the entire sheet is vital. Any inconsistencies can lead to faults or weaknesses in the final product. The essence of thermoforming lies in the malleability of plastics when heated. Therefore, maintaining a consistent temperature ensures the plastic remains pliable, facilitating seamless moulding.

Methods employed for heating vary, but they all aim to ensure an even temperature. Convection, radiant, and contact heating are standard practices, each with advantages. The selected technique often depends on the type of plastic and the specific gauge thermoforming employed.

Uniform heating isn’t merely about reaching the desired temperature but also ensuring that this warmth is evenly spread, preventing hotspots and consequent flaws.

Step 3 – Moulding

With a uniformly heated plastic sheet in hand, the next phase is moulding. Thermoforming moulds are pivotal in shaping the plastic into the desired 3-dimensional structure. Given the diversity of products created using thermoforming, many mould types and processes exist. Moulds are usually made from aluminium.

Two primary methods dominate the moulding process: vacuum and pressure forming. In vacuum forming, after the plastic is placed atop the mould, a vacuum draws the air out, forcing the plastic to conform to the mould’s contours. Conversely, pressure forming utilises compressed air to push the plastic against the mould, offering more detailed and textured finishes.

Step 4 – Cooling and Trimming

After the moulding process, the thermoformed product isn’t yet complete. Cooling is essential, ensuring the plastic retains its newly acquired shape. The plastic must cool uniformly to avoid deformation. Depending on the product’s size and the type of plastic, air or water might expedite the cooling process.

Once cooled, the product undergoes a trimming operation. Excess material, which doesn’t form part of the final product, is removed. Advanced trimming techniques, often automated, are employed to guarantee precision. Laser cutting or die-cutting, among others, are commonly used based on the intricacy of the product and production volume.

Thermoforming Materials

Understanding the variety of materials used in thermoforming is pivotal, as each offers unique characteristics suitable for different applications. The choice of material often hinges on the desired properties and functionality of the final product.

Most Commonly Used Materials for Thermoforming

- PVC/Acrylic: This material finds extensive use, particularly in micro-processor-based equipment housings. The inherent strength of PVC/Acrylic and its ability to meet stringent UL flammability standards adds to its appeal. Moreover, its adaptability extends to aesthetics, too; it can be crafted in many colours and textures to meet specific design demands.

- PS (Polystyrene): Polystyrene, or poly-phenylethene, is a thermoplastic polymer renowned for its electrically insulating properties. As a thermoplastic, it softens upon heating and can be reshaped, offering reusability. Its chemical resistance to acids and bases makes it a versatile material in various applications, including protective packaging and insulation.

- PET (Polyethylene Terephthalate): PET is a staple in thermoformed packaging, synthetic fibres, and bottle production. Known for its strength and durability, PET requires drying post-moulding, a crucial step to ensure stability and maintain shape. Its widespread use in food and beverage containers highlights its safety and reliability.

- PP (Polypropylene): Polypropylene (PP) is renowned for its fatigue resistance and thermal stability, making it essential in automotive parts, consumer goods, and living hinges. Its unique ability to withstand continuous bending without breaking is a key property. Additionally, its resistance to moisture, acids, and solvents makes PP ideal for containers and piping, as well as in medical and laboratory equipment.

- LDPE (Low-Density Polyethylene): LDPE, characterized by its flexibility and resilience, is a cornerstone in creating products that demand a balance of pliability and strength. Its resistance to moisture and chemicals makes it ideal for food packaging and laboratory containers. Additionally, its low-temperature resistance ensures reliable performance in applications ranging from frozen food packaging to flexible tubing and agricultural films.

- HDPE (High-Density Polyethylene): HDPE, known for its robustness, is integral in manufacturing durable goods like hard hats and corrosion-resistant piping. Its environmental resilience, coupled with a high strength-to-density ratio, makes it ideal for high-demand applications, ensuring longevity and reliability in products ranging from outdoor furniture to storage containers.

- PC (Polycarbonate): Polycarbonate (PC) stands out for its impact resistance and optical clarity, making it a prime choice for safety equipment, like bulletproof glass, and in automotive components. Its versatility extends to electronic media, like DVDs and Blu-ray discs, demonstrating its ability to maintain transparency and durability under stress.

- PMMA (Polymethyl Methacrylate): PMMA, famed for its glass-like clarity and UV resistance, is widely used in optical lenses, aquariums, and architectural features. Its excellent light transmission and weather resistance make it a preferred choice for outdoor applications, showcasing its ability to retain clarity and strength in diverse environments.

- ABS (Acrylonitrile Butadiene Styrene): ABS encompasses a broad spectrum of resins, making it versatile across numerous applications. It is robust and durable and can also be formulated to align with UL flammability standards. This adaptability makes ABS a favourite for various industries.

Comparison Table of Thermoforming Materials

| Material Name | Heat Stability | Chemical Resistance | UV Resistance | Rigidity | Cost |

| PVC | Poor | Poor | Fair | Varies | Medium |

| PS | Fair | Poor | Poor | High | Low |

| PET | Fair | Good | Poor | Varies | High |

| PP | Poor | Excellent | Poor | Varies | Low |

| LDPE | Poor | Poor | Poor | Low | Low |

| HDPE | Fair | Good | Fair | High | Low |

| PC | High | Good | Fair | Low | High |

| PMMA | Poor | Good | Fair | High | Low |

| ABS | Fair | Poor | Poor | High | Medium |

The realm of thermoforming materials is vast and varied. By aligning the material’s properties with the project’s requirements, one can harness the full potential of thermoforming, ensuring top-notch results in the final product.

Types of Thermoforming

Understanding the thermoforming processes is crucial for selecting the right method for a given application. Two primary techniques dominate: vacuum thermoforming and pressure thermoforming. Each carries its advantages, suited for specific requirements and products.

Vacuum Thermoforming

Predating many modern plastic treatments, the vacuum forming process stands out as a foundational and commonly employed method. Its influence on everyday products is profound and remains integral in shaping plastic into durable and long-lasting items.

How vacuum thermoforming works:

- A plastic sheet is initially softened through controlled heating

- This pliable heated sheet then drapes over a predetermined mould

- Employing a vacuum, the sheet gets drawn tightly against the mould, ensuring precise shape conformity

- The now-shaped sheet detaches from the mould upon cooling, retaining its new form

With advancements, contemporary vacuum forming now incorporates intricate pneumatic, hydraulic, and thermal controllers. This sophistication expedites production and refines the accuracy of the end products.

Pressure Thermoforming

A more contemporary innovation, pressure forming, is a refined approach to shape plastics. The process is distinguished from vacuum forming not by the end product but by the technique employed to achieve it.

How pressure thermoforming works:

- Vacuum and air pressure are employed simultaneously, forcing the plastic sheet into the mould

- The plastic sheet undergoes heating until it reaches an optimal pliable state

- Unlike vacuum forming, which draws out the air, pressure forming exerts air pressure. This action ensures the plastic is pushed firmly into the mould’s detailed contours

- The precise mechanism stabilising the plastic guarantees the optimal temperature, facilitating flexible yet precise mould creation

The allure of pressure thermoforming lies in its ability to produce components with enhanced detailing, sharper edges, and a superior overall finish. When a project demands intricacy and precision, pressure thermoforming emerges as the method of choice.

While both thermoforming processes are pivotal in the industry, their application depends on the product’s specific requirements. These techniques, from household items to industrial components, are instrumental in delivering quality plastic products.

Advantages of Thermoforming

Thermoforming, a key process in the plastic manufacturing domain, boasts several advantages. These benefits make it a preferred choice for manufacturers aiming for efficient, cost-effective, and flexible production. Here’s an insight into the pronounced advantages this process offers:

- Cost-effectiveness for medium production runs: Thermoforming stands out when it comes to producing large quantities. Its simplicity and streamlined nature mean fewer moving parts, reducing maintenance costs. Additionally, the moulds used are relatively less expensive than those in other processes, making it a more economical choice for low to medium-scale production.

- Speed of production: The process’s inherent simplicity ensures rapid production cycles. When contrasted with alternative methods, particularly those that require complex moulds or extended curing times, thermoforming often emerges as the quicker option.

- Flexibility in design and rapid prototyping: One of the hallmarks of thermoforming is its versatility in design. Manufacturers aren’t boxed into rigid design structures. Instead, they can swiftly adapt and modify designs as required. This flexibility extends to prototyping as well.

- Efficiency in waste and energy consumption: Thermoforming is notably efficient both in terms of material waste and energy utilisation. Excess material from the forming process can often be recycled directly back into the production cycle, reducing wastage. Furthermore, the energy required to heat the plastic sheets in thermoforming is typically lower than in many alternative methods, contributing to a reduced carbon footprint and lower operational costs.

Limitations of Thermoforming

While thermoforming offers various advantages, it comes with its set of limitations. Recognising these constraints ensures manufacturers can make informed decisions, optimising their production strategies.

- Material restrictions: Not all plastics are suitable for the thermoforming process. Certain materials lack the characteristics to be effectively formed under heat and pressure.

- Complexity of part designs: Thermoforming does have some constraints when it comes to intricate design elements. Achieving highly detailed or complicated geometries can be challenging, unlike other processes. This limitation means products requiring extremely detailed components might need supplementary processes or alternative manufacturing methods.

- Wall thickness and consistency: One of the primary challenges of thermoforming is maintaining uniform wall thickness, especially with deeper draws or more complex moulds. The nature of the process can lead to thinner walls in certain parts of the formed product. This inconsistency might affect the product’s structural integrity and overall quality.

Applications of Thermoforming

Thermoforming’s versatile nature lends itself to various industries, offering tailored solutions to meet specific demands. Its capability to mould plastics into varied forms and structures is a game-changer for numerous sectors.

Packaging Industry

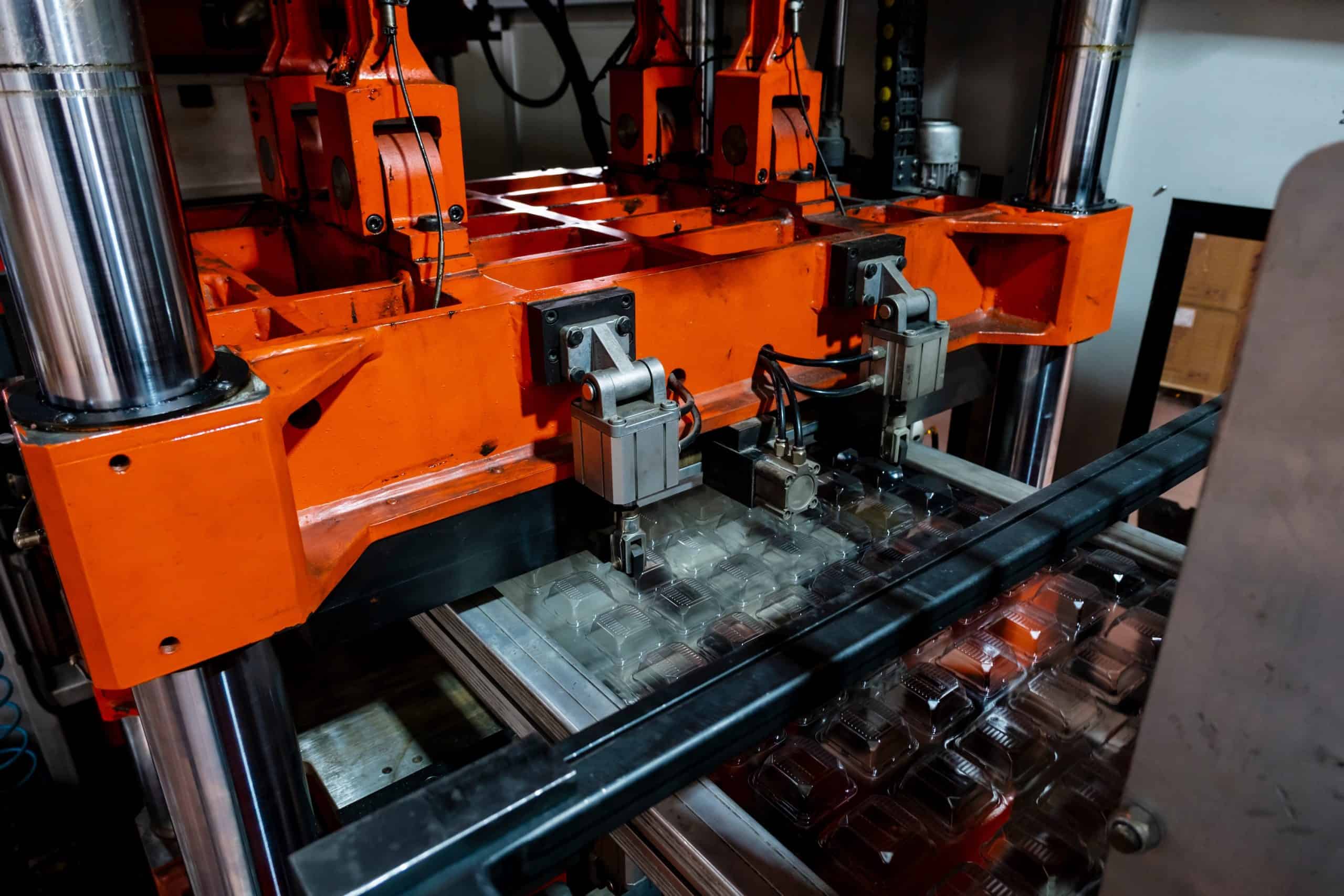

Thermoforming stands as a key process in the packaging sector. The creation of thermoformed trays ensures products are secured during transportation, minimising potential damage. Moreover, predominantly used in food packaging, and pharmaceuticals, blister packs are a testament to thermoforming’s precision, as these packs tightly encase individual items, offering protection and visibility.

Clamshells, another thermoforming product, are robust packaging solutions, especially in retail, safeguarding items from external contaminants.

Automotive Industry

The automotive industry extensively harnesses thermoforming for its myriad benefits. Components like door panels and dashboards require durability combined with a refined finish. Thermoforming facilitates the creation of these components, ensuring they’re both aesthetically pleasing and functionally robust. As vehicles continue to evolve, integrating advanced technologies, the demand for precision-moulded components increases.

Healthcare

In an industry where precision and hygiene are paramount, thermoforming plays an important role. Medical device packaging, essential for maintaining sterility, often employs thermoformed plastics. This ensures devices remain uncontaminated and ready for use when needed.

Furthermore, surgical instrument trays, moulded to hold specific tools, exemplify thermoforming’s precision. These trays organise instruments and facilitate sterilisation, underscoring the process’s significance in healthcare.

Consumer Goods

From the toys children play with to the containers used daily in households, thermoforming’s influence in the consumer goods sector is vast. The process enables the creation of durable toys, ensuring they withstand the test of time. Containers, on the other hand, benefit from thermoforming’s ability to create tight seals, keeping contents fresh. Given the diversity of consumer goods, partnering with Xometry ensures the best application of thermoforming techniques.

Thermoforming’s applications span across industries, meeting distinct challenges with tailored solutions. Its adaptability ensures it remains at the forefront of manufacturing.

Thermoforming vs. Injection Moulding

Thermoforming and injection moulding are both crucial plastic manufacturing methods. However, they differ fundamentally in approach and application.

Thermoforming involves heating a plastic sheet until it becomes pliable. This softened sheet is then moulded over a specific form. It’s a process ideal for large parts and short-to-medium runs. Its flexibility, lower tooling costs, and rapid prototype adaptability are the advantages. However, it’s typically limited to more straightforward designs and often generates more material waste.

Injection moulding, on the other hand, forces molten plastic into a mould under high pressure. This process excels in creating intricate designs and is best suited for high-volume production. The end products boast consistent quality and tight tolerances. The major downside is the higher upfront tooling cost, making it less economical for short runs.

| Injection Moulding | Thermoforming | |

| Quantity range | 50 – 1,000,000 | > 1 |

| Sample | 1 month+ | 1 month + |

| Prototyping | ✔ | ✔ |

| High-volume production | ✔ | ✘ |

| Functional | ✔ | ✔ |

| Aesthetic | ✔ | ✔ |

| Complex geometries | ✔ | ✘ |

| Coloured parts | ✔ | ✔ |

In choosing between these methods, consider the product’s complexity, production volume, and budget constraints. Both processes have their merits, but the decision often hinges on the specific requirements of the project at hand.

Make Production Orders with Thermoforming at Xometry

The thermoforming process stands as a pivotal method in the realm of manufacturing, offering versatile solutions for shaping various materials. Its adaptability across industries, including automotive, medical, and packaging, underscores its practicality.

For businesses seeking reliable solutions for low and mid-volume production, Xometry offers top-notch thermoforming services.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)