- Industry: Manufacturing (Safety tools)

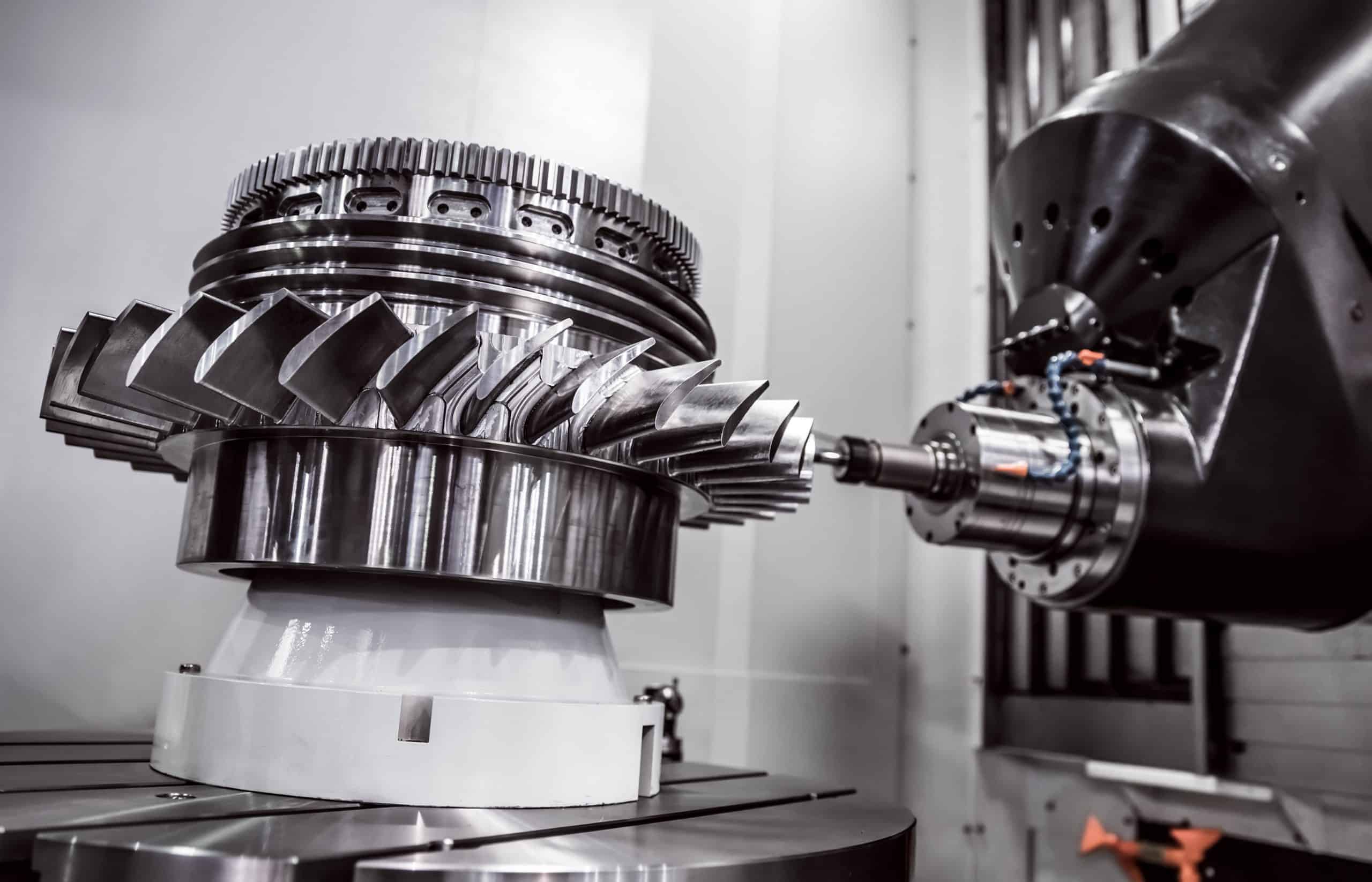

- Manufacturing processes: 3D printing, CNC machining, laser cutting and welding

- Challenge: Developing advanced safety devices for workers at height and in confined spaces while meeting strict regulatory standards.

- Solution: Genesi Protection partnered with Xometry to optimize the design and production of anchoring and fall arrest devices, leveraging performative materials and efficient manufacturing technologies.

Founded in 2023, Genesi srl emerged from the expertise of Somain Italia, a company specializing in safety solutions since 2005. The idea behind Genesi was driven by a clear mission: to enhance protection for workers at height across industrial and civil sectors.

Cutting-Edge Products and Technologies

Genesi offers a comprehensive range of fall protection systems, ensuring both safety at height and secure access to confined spaces. Its product lineup includes:

- Anchorage systems, lifelines, guardrails, and walkways

- Rails, ladders, and climbing safety systems

- Personal protective equipment (PPE) such as harnesses, connectors, retractable devices, and lanyards

- Installation, training, and maintenance services to provide complete safety solutions

Each product undergoes a rigorous development process. Designs are first created using advanced simulation software, followed by 3D-printed prototypes to test functionality and refine improvements before industrialization.

A Strategic Partnership with Xometry

A key turning point for Genesi was its partnership with Xometry. “We discovered Xometry through an online search, and it quickly proved to be the ideal partner for manufacturing our 3D-printed and CNC-machined components,” Enzo Cortinovis explains.

Xometry played a crucial role in the production of several safety-critical components, including:

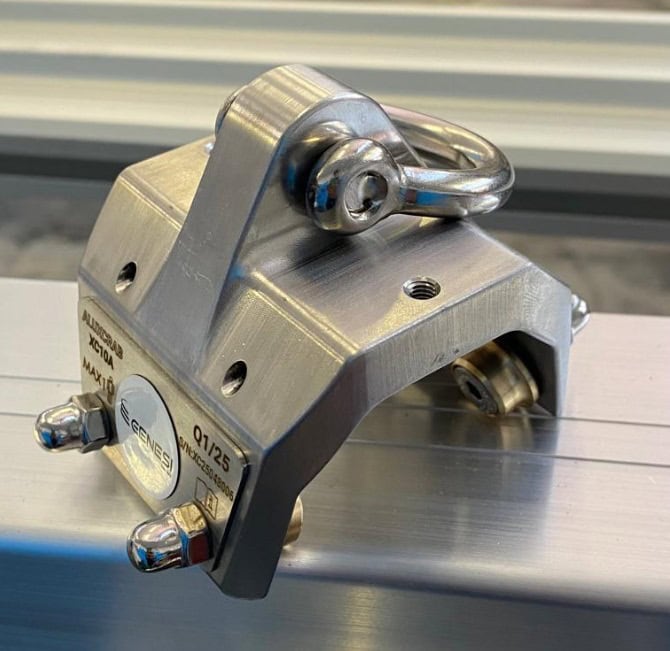

- Mobile Anchor Point XC10A – Designed for use with AluxCrab rigid anchor lines, this device meets EN 795:2012 and CEN/TS 16415:2013 standards. Xometry manufactured the outer casing from AISI316 stainless steel using CNC machining, ensuring exceptional durability and corrosion resistance.

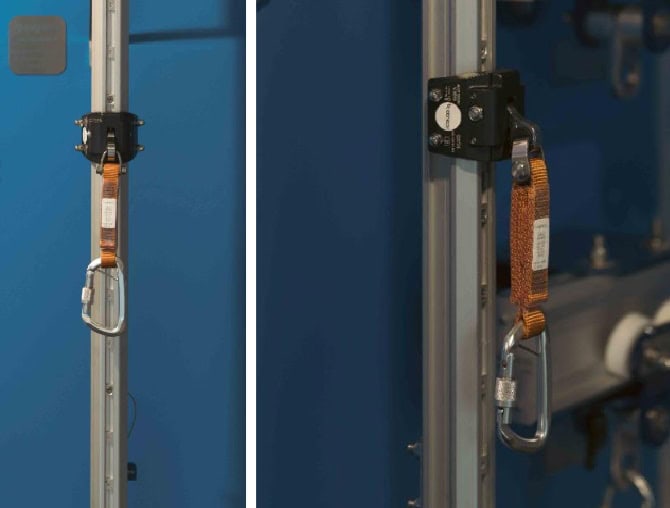

- Guided-Type Fall Arrest Device V-XC10A – Compatible with AluxCrab V and LadderCrab, this system complies with EN353-1:2014+A1:2017. Xometry produced its outer casing from anodized aluminum, ensuring an optimal balance of strength and lightweight performance.

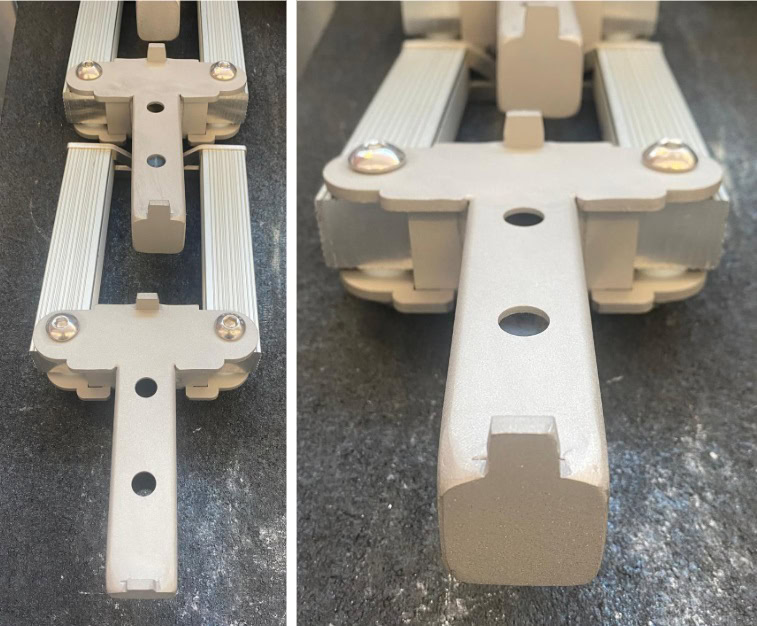

- AluxCrab V Fall Arrest System – A high-performance anchoring system meeting EN353-1:2014+A1:2017 standards. Xometry manufactured the internal aluminum profile using precision laser cutting, improving the system’s locking mechanism and overall performance.

- LadderCrab I with Reclosable Rungs – This solution enhances vertical rail climbing safety and meets EN353-1:2014+A1:2017 and EN14122-4:2016 standards. Xometry fabricated the stainless steel rungs through cutting, welding, and shot peening, ensuring maximum strength and operator safety.

The collaboration between Genesi and Xometry has received overwhelmingly positive feedback: “The Xometry team has been an invaluable partner from the early design stages. Their engineers and sales team guided us in selecting the most suitable manufacturing technologies”, shares Enzo Cortinovis.

Shaping the Future of Workplace Safety

Genesi Protection remains committed to continuous innovation, anticipating emerging industry needs and developing next-generation safety solutions.

Learn more about Genesi Protection: https://genesiprotection.com/en/

Manufacturing stories & cases

Share your engineering or manufacturing story

If you want to share your story with others on xometry.pro, just fill out a short form

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)