In sheet metal fabrication, thickness can be specified in two ways: as an exact measurement in millimeters or inches or using a gauge system. The gauge system, however, follows a different scale that isn’t linear. Metals gauges are standard numbers developed by measuring the thickness of sheet metal in relation to its weight per square foot.

Gauge System for Sheet Metal

Unlike standard metric measurement systems, where sheet thickness is indicated directly in mm, gauge numbers represent thickness based on historical drawing operations. This means a lower gauge number corresponds to a thicker sheet, while a higher one indicates a thinner sheet. For example, 3-gauge sheet metal is about 6.07 mm (0.2391 inches) thick, while 38-gauge sheet metal is only 0.15 mm (0.0060 inches) thick. In many regions, sheet metal over 6 mm is considered a plate rather than a sheet.

Different sheet metal gauges are recommended for specific applications. Choose wisely during the design phase. For example, a 10 ga metal sheet (3.4 mm or 0.1345 inches) would be ideal for heavy-duty applications, such as structural components.

The next section highlights gauge tables of the most commonly used sheet metal materials.

Standard Steel Gauge Chart

| Gauge | Thickness (in) | Thickness (mm) |

| 3 | .239 | 6.073 |

| 4 | .224 | 5.695 |

| 5 | .209 | 5.314 |

| 6 | .194 | 4.935 |

| 7 | .179 | 4.554 |

| 8 | .164 | 4.176 |

| 9 | .150 | 3.797 |

| 10 | .135 | 3.416 |

| 11 | .120 | 3.038 |

| 12 | .105 | 2.657 |

| 13 | .090 | 2.278 |

| 14 | .075 | 1.897 |

| 15 | .067 | 1.709 |

| 16 | .060 | 1.519 |

| 17 | .054 | 1.367 |

| 18 | .048 | 1.214 |

| 19 | .042 | 1.062 |

| 20 | .036 | 0.912 |

| 21 | .033 | 0.836 |

| 22 | .030 | 0.759 |

| 23 | .027 | 0.683 |

| 24 | .024 | 0.607 |

| 25 | .021 | 0.531 |

| 26 | .018 | 0.455 |

| 27 | .016 | 0.417 |

| 28 | .015 | 0.378 |

| 29 | .014 | 0.343 |

| 30 | .012 | 0.305 |

| 31 | .011 | 0.267 |

| 32 | .010 | 0.246 |

| 33 | .009 | 0.229 |

| 34 | .008 | 0.208 |

| 35 | .008 | 0.191 |

| 36 | .007 | 0.170 |

| 37 | .006 | 0.163 |

| 38 | .006 | 0.152 |

Galvanized Steel Gauge Chart

| Gauge | Thickness (in) | Thickness (mm) |

| 8 | .168 | 4.270 |

| 9 | .153 | 3.891 |

| 10 | .138 | 3.510 |

| 11 | .123 | 3.132 |

| 12 | .108 | 2.753 |

| 13 | .093 | 2.372 |

| 14 | .079 | 1.994 |

| 15 | .071 | 1.803 |

| 16 | .064 | 1.613 |

| 17 | .058 | 1.461 |

| 18 | .052 | 1.311 |

| 19 | .046 | 1.158 |

| 20 | .040 | 1.006 |

| 21 | .037 | 0.930 |

| 22 | .034 | 0.853 |

| 23 | .031 | 0.777 |

| 24 | .028 | 0.701 |

| 25 | .025 | 0.627 |

| 26 | .022 | 0.551 |

| 27 | .020 | 0.513 |

| 28 | .019 | 0.475 |

| 29 | .017 | 0.437 |

| 30 | .016 | 0.399 |

| 31 | .014 | 0.361 |

| 32 | .013 | 0.340 |

Stainless Steel Gauge Chart

| Gauge | Thickness (in) | Thickness (mm) |

| 00000000 | .500 | 12.700 |

| 000000 | .469 | 11.902 |

| 00000 | .438 | 11.113 |

| 0000 | .406 | 10.320 |

| 000 | .375 | 9.525 |

| 00 | .344 | 8.733 |

| 0 | .313 | 7.938 |

| 1 | .281 | 7.145 |

| 2 | .266 | 6.746 |

| 3 | .250 | 6.350 |

| 4 | .234 | 5.954 |

| 5 | .219 | 5.555 |

| 6 | .203 | 5.159 |

| 7 | .188 | 4.763 |

| 8 | .172 | 4.366 |

| 9 | .156 | 3.967 |

| 10 | .141 | 3.571 |

| 11 | .125 | 3.175 |

| 12 | .109 | 2.779 |

| 13 | .094 | 2.380 |

| 14 | .078 | 1.984 |

| 15 | .070 | 1.786 |

| 16 | .063 | 1.588 |

| 17 | .056 | 1.427 |

| 18 | .050 | 1.270 |

| 19 | .044 | 1.110 |

| 20 | .038 | 0.953 |

| 21 | .034 | 0.874 |

| 22 | .031 | 0.792 |

| 23 | .028 | 0.714 |

| 24 | .025 | 0.635 |

| 25 | .022 | 0.556 |

| 26 | .019 | 0.475 |

| 27 | .017 | 0.437 |

| 28 | .016 | 0.396 |

| 29 | .014 | 0.358 |

| 30 | .013 | 0.318 |

| 31 | .011 | 0.277 |

| 32 | .010 | 0.259 |

| 33 | .009 | 0.239 |

| 34 | .009 | 0.218 |

| 35 | .008 | 0.198 |

| 36 | .007 | 0.178 |

| 37 | .007 | 0.168 |

| 38 | .006 | 0.157 |

Carbon Steel Gauge Chart

| Gauge | Thickness (in) | Thickness (mm) |

| 3 | .239 | 6.07 |

| 4 | .224 | 5.69 |

| 5 | .209 | 5.31 |

| 6 | .194 | 4.94 |

| 7 | .179 | 4.55 |

| 8 | .164 | 4.18 |

| 9 | .149 | 3.80 |

| 10 | .134 | 3.42 |

| 11 | .120 | 3.04 |

| 12 | .105 | 2.66 |

| 13 | .090 | 2.28 |

| 14 | .075 | 1.90 |

| 15 | .067 | 1.71 |

| 16 | .060 | 1.52 |

| 17 | .054 | 1.37 |

| 18 | .048 | 1.21 |

| 19 | .042 | 1.06 |

| 20 | .036 | 0.91 |

| 21 | .033 | 0.84 |

| 22 | .030 | 0.76 |

| 23 | .027 | 0.68 |

| 24 | .024 | 0.61 |

| 25 | .021 | 0.53 |

| 26 | .018 | 0.45 |

| 27 | .016 | 0.42 |

| 28 | .015 | 0.38 |

| 29 | .013 | 0.34 |

| 30 | .012 | 0.30 |

Aluminium Sheet Gauge Chart

| Gauge | Thickness (in) | Thickness (mm) |

| 6 | .162 | 4.115 |

| 7 | .144 | 3.665 |

| 8 | .129 | 3.264 |

| 9 | .114 | 2.906 |

| 10 | .102 | 2.588 |

| 11 | .091 | 2.304 |

| 12 | .081 | 2.052 |

| 13 | .072 | 1.829 |

| 14 | .064 | 1.628 |

| 15 | .057 | 1.450 |

| 16 | .051 | 1.290 |

| 17 | .045 | 1.151 |

| 18 | .040 | 1.024 |

| 19 | .036 | 0.912 |

| 20 | .032 | 0.813 |

| 21 | .028 | 0.724 |

| 22 | .025 | 0.643 |

| 23 | .023 | 0.574 |

| 24 | .02 | 0.511 |

| 25 | .018 | 0.455 |

| 26 | .017 | 0.404 |

| 27 | .0142 | 0.361 |

| 28 | .013 | 0.320 |

| 29 | .011 | 0.287 |

| 30 | .010 | 0.254 |

Zinc Sheet Gauge Chart

| Gauge | Thickness (in) | Thickness (mm) |

| 1 | .002 | 0.051 |

| 2 | .004 | 0.102 |

| 3 | .006 | 0.152 |

| 4 | .008 | 0.203 |

| 5 | .010 | 0.254 |

| 6 | .012 | 0.305 |

| 7 | .014 | 0.356 |

| 8 | .016 | 0.406 |

| 9 | .018 | 0.457 |

| 10 | .020 | 0.508 |

| 11 | .024 | 0.610 |

| 12 | .028 | 0.711 |

| 13 | .032 | 0.813 |

| 14 | .036 | 0.914 |

| 15 | .040 | 1.016 |

| 16 | .045 | 1.143 |

| 17 | .050 | 1.270 |

| 18 | .055 | 1.397 |

| 19 | .060 | 1.524 |

| 20 | .070 | 1.778 |

| 21 | .080 | 2.032 |

| 22 | .090 | 2.286 |

| 23 | .100 | 2.540 |

| 24 | .125 | 3.175 |

| 25 | .250 | 6.350 |

| 26 | .375 | 9.525 |

| 27 | .500 | 12.700 |

| 28 | 1.000 | 25.400 |

Copper Sheet Gauge Chart

| Gauge | Thickness (in) | Thickness (mm) |

| 7 | .180 | 4.572 |

| 8 | .165 | 4.191 |

| 9 | .148 | 3.759 |

| 10 | .134 | 3.404 |

| 11 | .120 | 3.048 |

| 12 | .109 | 2.769 |

| 14 | .083 | 2.108 |

| 16 | .065 | 1.651 |

| 18 | .049 | 1.245 |

| 20 | .035 | 0.889 |

| 22 | .028 | 0.711 |

| 24 | .022 | 0.559 |

| 26 | .018 | 0.457 |

| 28 | .014 | 0.356 |

| 30 | .012 | 0.305 |

Brass Sheet Gauge Chart

| Gauge | Thickness (in) | Thickness (mm) |

| 7 | .144 | 3.665 |

| 8 | .129 | 3.264 |

| 9 | .114 | 2.906 |

| 10 | .102 | 2.588 |

| 11 | .091 | 2.305 |

| 12 | .081 | 2.053 |

| 14 | .064 | 1.628 |

| 16 | .051 | 1.291 |

| 18 | .040 | 1.024 |

| 20 | .032 | 0.812 |

| 22 | .025 | 0.644 |

| 24 | .020 | 0.511 |

| 26 | .016 | 0.405 |

| 28 | .013 | 0.321 |

| 30 | .010 | 0.255 |

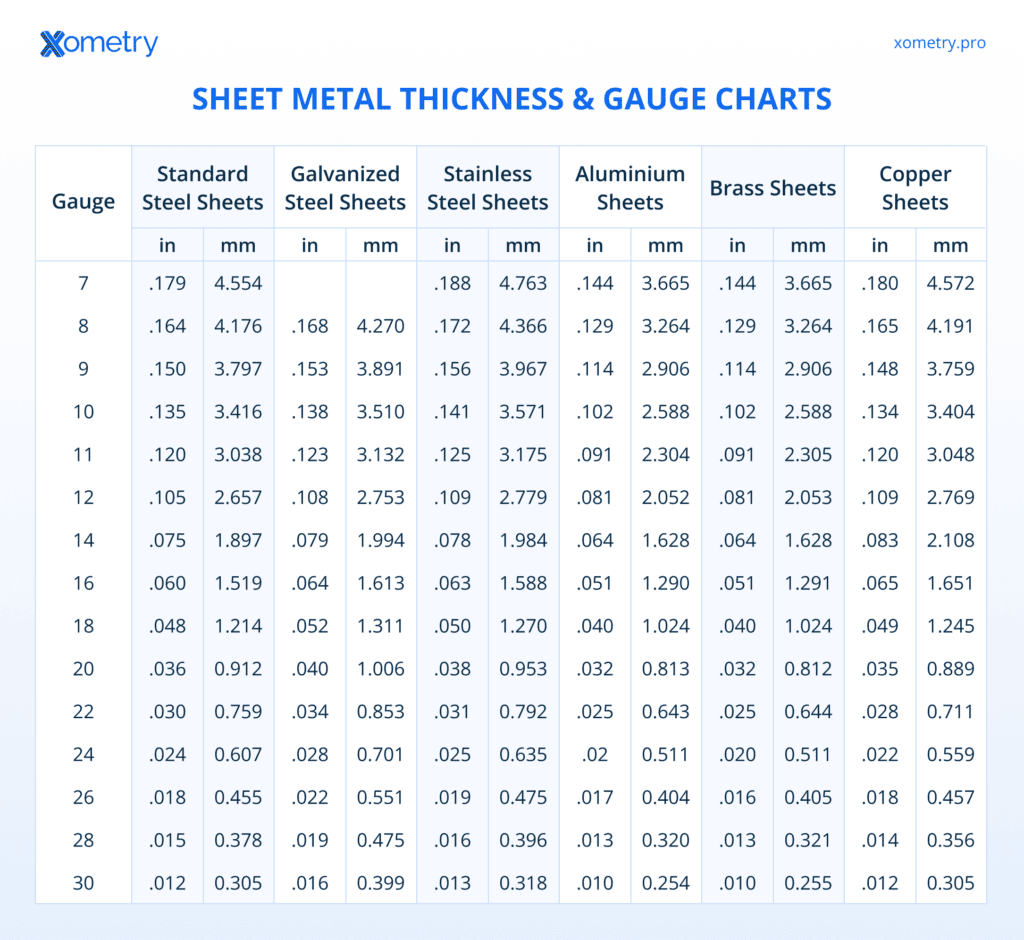

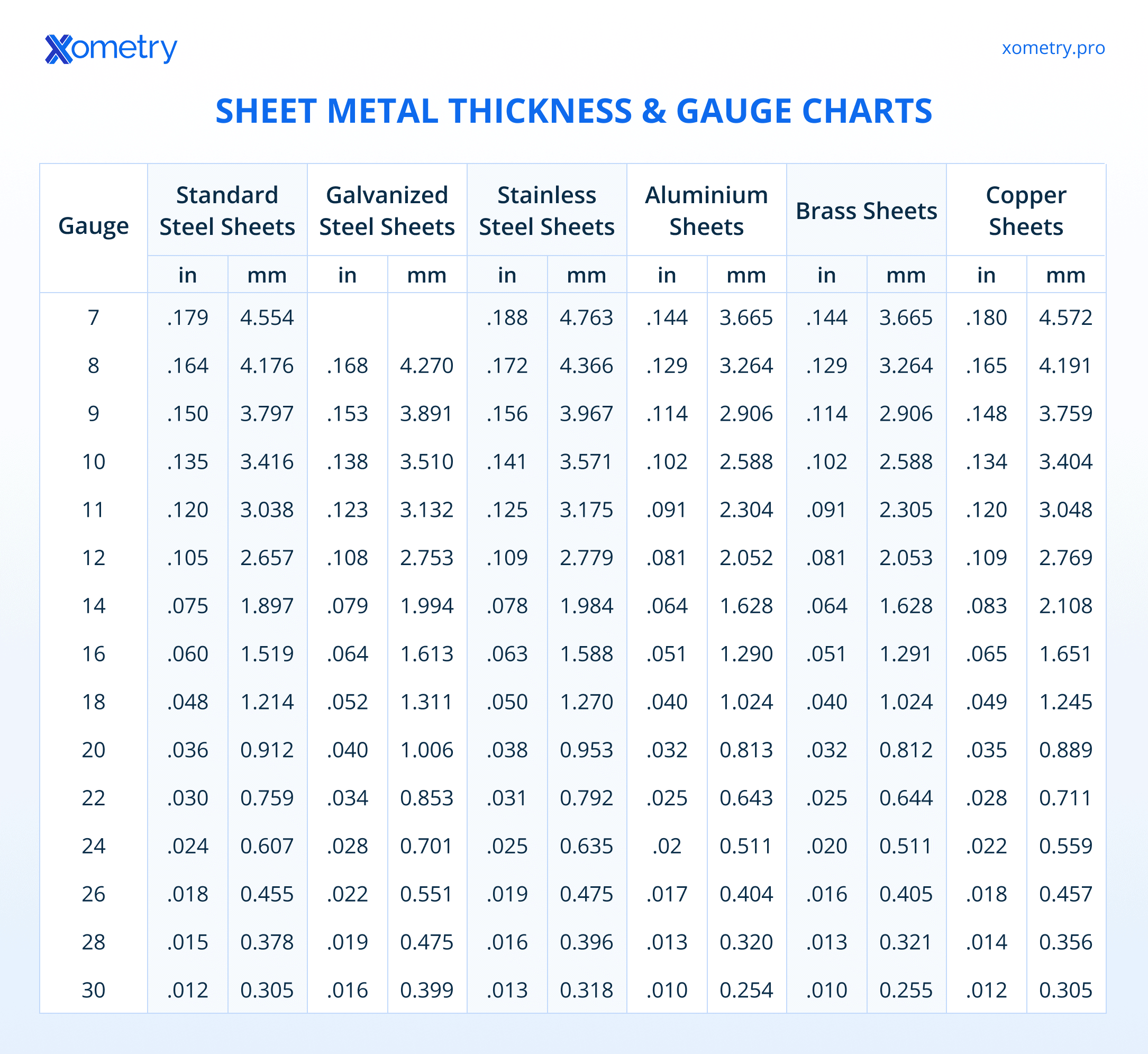

Sheet Metal Thickness & Gauges: Quick Reference Chart

To make it easier for engineers and designers, we’ve compiled all gauge conversions into a single downloadable reference chart.

Frequently Asked Questions

Are There Gauge Limitations for Specific Metal Types?

Yes. There is a limit on how thin a sheet metal can get before it becomes unusable. Most sheet metals have a lower limit of 0.5 mm and a higher limit of 6 mm, but this depends on the material type.

Does Gauge Affect Corrosion Resistance?

Yes and no. A thicker gauge does not mean the sheet metal is more corrosion-resistant. It only implies that the material will take longer to corrode, making it more durable than a thinner gauge metal.

Why Are Gauges Different for Different Metals?

Material gauge is a subject of its density. Gauge size is based on the weight of the sheet metal, which is different for each material type.

What Thickness Limit Classifies Metal as Being a Sheet?

The lower limit (the thinnest a sheet metal can be) is 0.5 mm, and the upper limit (the thickest a sheet metal can be) is 6 mm. Any metal thicker than 6 mm is no longer a sheet metal but a metal plate. However, these limits can vary from region to region.

Next Steps for Sheet Metal Fabrication Success

Making an informed decision regarding sheet metal thickness reduces waste and production costs. Before deciding on the sheet metal gauge chart to use, consider the application, material type, environmental factors, industry standards, weight, and budget. The chosen sheet metal gauge should give high performance, and the right gauge chart should be used.

Need Precision-Cut Sheet Metal Parts? If you have a sheet metal project and need high-quality cutting and bending services, Xometry offers on-demand manufacturing with a wide range of materials, thicknesses, and finishes. Get an instant quote today and bring your designs to life with expert fabrication.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)