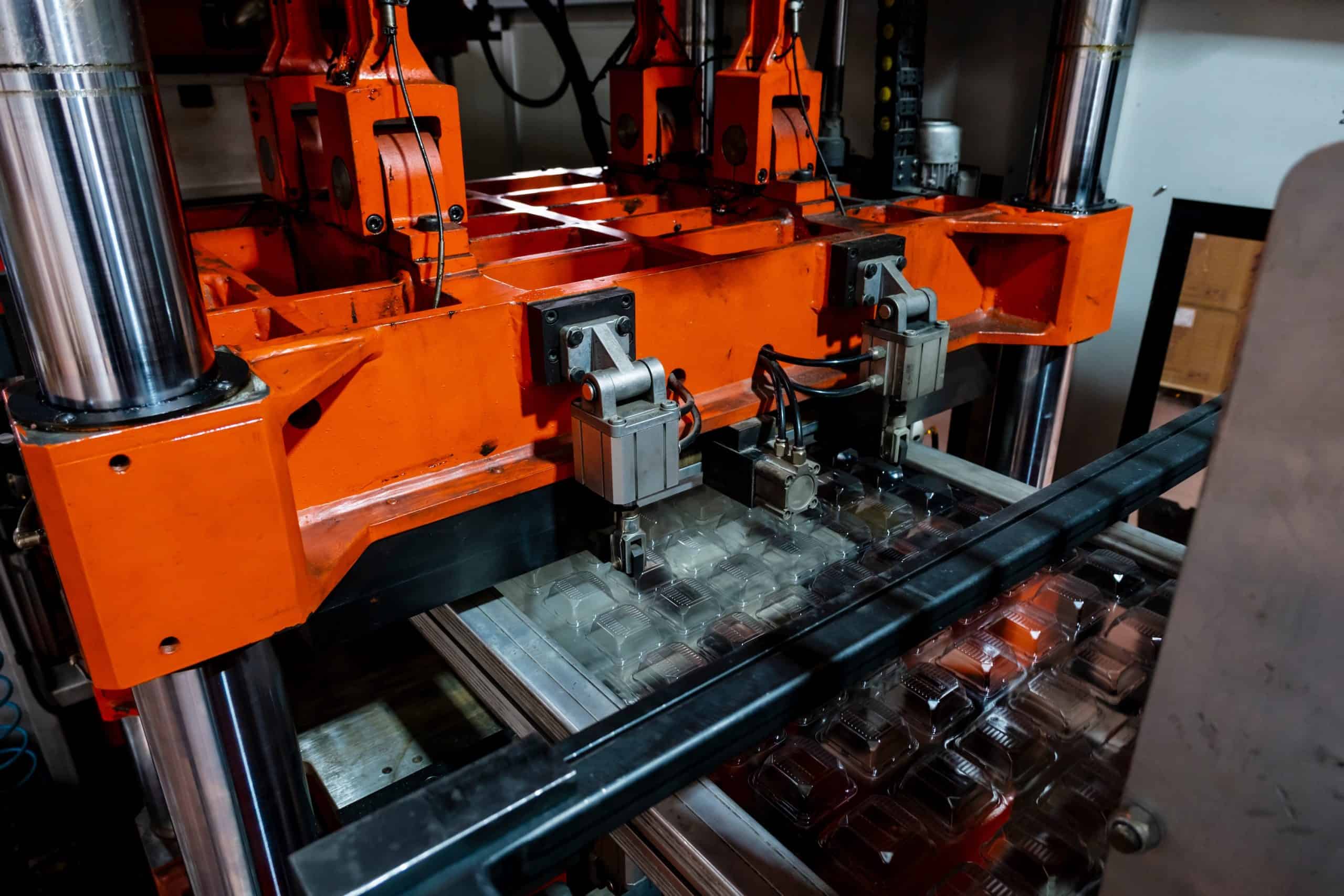

- Industry: Transport and packing technologies

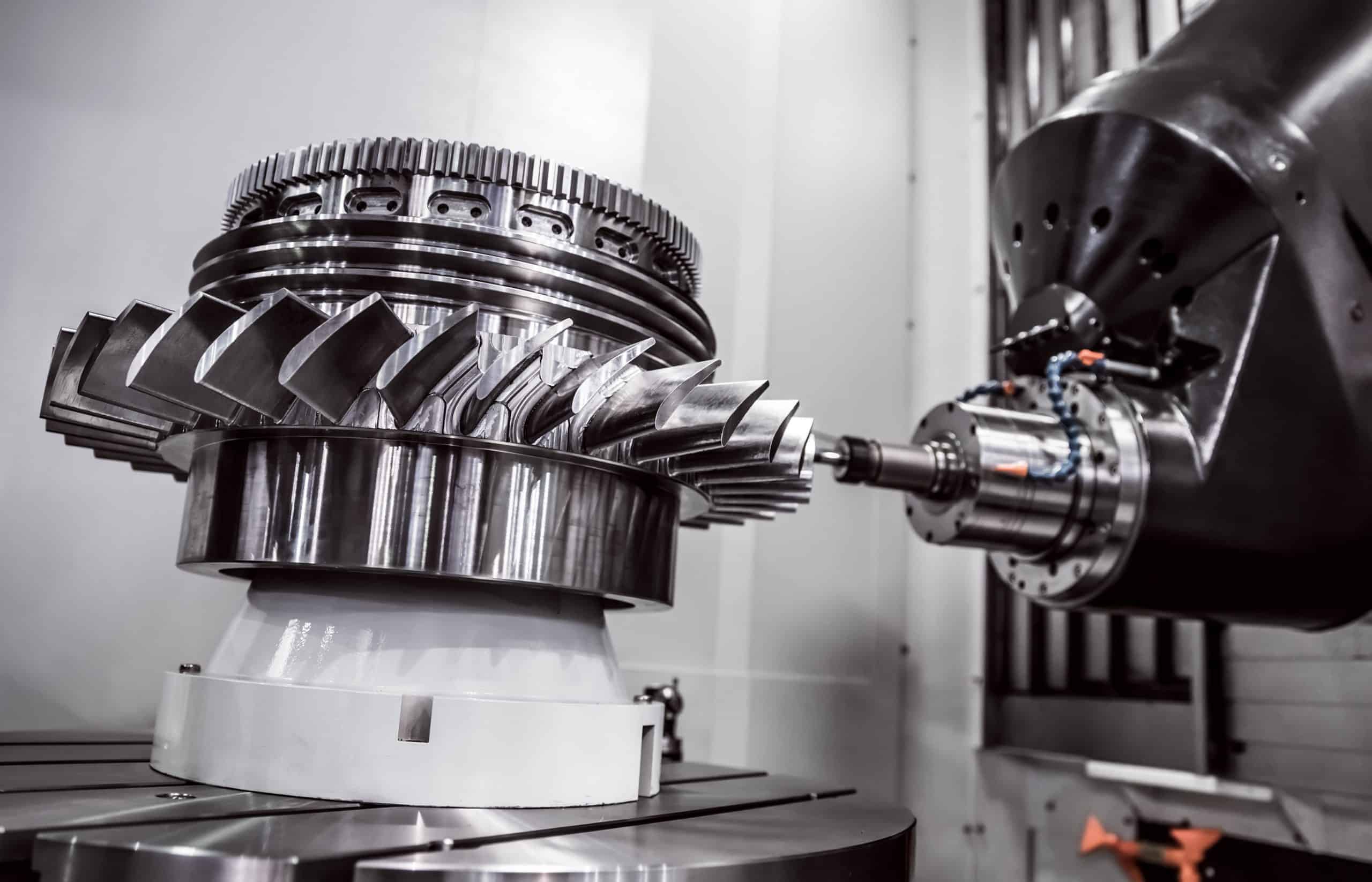

- Manufacturing processes used: CNC machining

- Challenges: Ensuring high-quality, precise components in various quantities for machine production. Meeting required supply availability despite its own capacity limits.

- Solution: Through working with Xometry, Beyer Maschinenbau was able to reliably and rapidly source high-quality components for final assembly. This smooth procurement process helped the company complete everything on schedule.

—

About Beyer Maschinenbau GmbH

Beyer Maschinenbau GmbH is a well-established family business that develops packaging and palletising systems for the food and beverage industry. With more than 150 years of experience, the company offers modern and efficient machines that are tailored to the needs of its customers. Its services include filling and packaging systems, sorting and repackaging systems as well as a comprehensive maintenance and spare parts service.

Overcoming Capacity Limits to Source Quality Components

Beyer Maschinenbau requires components in various quantities and qualities for the production of packing and palletising systems. However, due to capacity limits, not all components can be manufactured in-house, which is why the company relies on external suppliers. The aim was to find a partner who could reliably provide high-quality components and fast delivery.

Partnering with Xometry for Efficient Sourcing and Delivery

The process was seamless. It all started with Beyer Maschinenbau sharing their requirements and getting quotes. Xometry answered any questions and quickly found solutions where needed. This efficient collaboration led to Xometry being used as a reliable procurement partner.

Enhanced Production Efficiency and Seamless Assembly

Xometry now supplies highly-accurate products that are used in the final assembly of the machines. This precision enables the machines and components to be assembled quickly and smoothly, which has significantly improved the production processes at Beyer Maschinenbau.

‘Xometry is a punctual and reliable supplier that always delivers on time,’ says Roy Kuhlmann, Production Manager at Beyer Maschinenbau.

Thanks to the positive collaboration, Beyer Maschinenbau plans to continue working with Xometry for more complex projects. The combination of reliable delivery and high-quality parts makes Xometry a key strategic partner for future challenges.

Conclusion

Xometry helps Beyer Maschinenbau to source parts flexibly and efficiently, which streamlines its production processes. This collaboration gives Beyer Maschinenbau the peace of mind that it can maintain delivery capability and quality even in times of high demand.

Learn more about Beyer Maschinenbau: https://www.beyer.de/en/home

Manufacturing stories & cases

Share your engineering or manufacturing story

If you want to share your story with others on xometry.pro, just fill out a short form

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)